- Call : +91 22 67436442

- exports@petrometflange.com

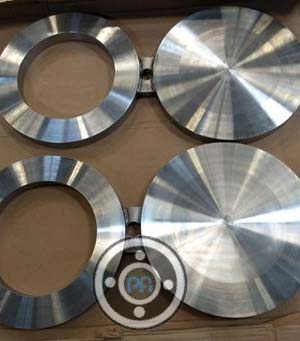

Stainless Steel 347 Flanges

- Home /

- Stainless Steel 347 Flanges

JIS 10K SA 182 Gr F347 Blind Flange & ASTM A182 F347 Weld Neck Flange manufacturer in India

What is Stainless Steel 347 Flanges?

The stainless steel 347 material can be used for a wide range of temperatures. The Stainless Steel 347 Flanges work equally well for high temperatures as well as cryogenic temperatures. They are ideal for use in applications that involve high wear and tear. The material is known for its outstanding capabilities for withstanding oxidation and wear. Due to its ability of withstanding extreme conditions and enhanced mechanical properties, the Stainless Steel 347 Flanges are widely used in heavy exhaust systems and boilers. These flanges are of the specification ASTM A182 and A240; they are forged and rolled. Also, according to the specification they are for high temperature and high pressure service applications. Stainless Steel 347 Flanges are also available under different standards, such as ASME, ANSI, EN, and DIN.

The Stainless Steel 347 Flanges are available in different types and various faces. The structure of the flange varies with the type and hence they are used for different purposes. The welding methods also change with the variation in faces, which impacts their characteristics. Their nominal diameters are within the range of ½” to 48”. They are also available with different pressure ratings, from classes 150 to 2500, and pressure number of PN6 through PN64.

The chemical composition of the Stainless Steel 347 material consists of 17% chromium, 9% nickel, carbon and several other elements in its composition. They come with a high melting point of 1454 degrees C, and that is why they can ideally be used in high temperature applications. The strength properties of the Stainless Steel 347 material is quite similar to that of the 304 grade. It possesses a minimum yield strength of 205 MPa, and minimum tensile strength of 515 MPa. Due to the unique characteristics of the material, the 347 grade is used in environments that have severe corrosive conditions, and hence they are widely used in the petroleum refining industries. Some of the common applications where SS 347 Flanges are widely used would be some chemical processes occurring in high temperature and heat exchanger tubes.

347H Stainless Steel Weld Neck Flange Vs ASTM A182 F347 Slip on Flanges

The 347H Stainless Steel Weld Neck Flange is mostly used for high temperature applications where the conditions are quite severe and critical. These flanges are capable of relocating stress to the pipes, which ensures that there is a decrease in high-stress concentration present at the bottom of the flange.

The ASTM A182 F347 Slip on Flanges are not capable of withstanding as critical situations as the 347H weld neck flanges. They are used for fluids that operate at lower pressure and they should also possess little risk of leakage. These flanges are slipped into the pipe before they are double welded from inside and outside to establish leakage proof connections.

How to weld SA 182 F347 Blind Flange?

The SA 182 F347 Blind Flange, just like any other standard flange, can be raised faced or flat faced. They are basically bolted instead of welding at the ends of the piping system or nozzle of the valve. This helps the blind flanges to easily uninstall at the time of pipe inspection or maintenance.

SS 347 Flange Vs ASTM A182 F347h Flanges

There are many differences between SS 347 Flange and ASTM A182 F347h Flanges. Firstly, they have a different chemical composition. The 347 grade contains no more than 0.08% carbon in its alloy, whereas the grade 347H contains carbon in its composition within the range of 0.04-0.10%. These materials also contain niobium, which gives them their unique characteristics. Due to the presence of higher carbon content, the 347H alloy demonstrates better high temperature and creep properties.

Stainless Steel 347 Flanges

347 Stainless Steel Plate Flange manufacturers in Mumbai offers widest selection of SA 182 Gr F347 Puddle Flanges and AISI 347 Spectacle Blind Flange in India

Table of Content

- Stainless Steel 347 Flanges Standard Specification

- ASTM A182 F347 Flange Dimensions

- Dimension of Stainless Steel 347 Blind Flange

- 347H Stainless Steel Weld Neck Flange Dimensions

- Price List of Stainless Steel 347 Flanges

- Pressure Rating of ASTM A182 F347 Flange

- 347 SS Flanges Weight

- 347 Stainless Steel Flange Forging

- ASTM A182 F347 Chemical Composition

- SS 347 Flange Mechanical Properties

- A182 F347 Equivalent

- Heat Treatment of 347 SS Flange

- Various Types of Stainless Steel 347 Flanges

- 347 Stainless Steel Flange Welding

- ASME B16.5 SS 347 Flange Application

- 347H Stainless Steel Flange Testing and Inspection

- ASTM A182 347H Flange Hs Code

- Stainless Steel 347 Flange Density

Stainless Steel 347 Flanges Standard Specification

| Size Chart | 1/2″(15 NB) to 48″ (1200NB) |

|---|---|

| DIN Pressure | 16Bar 25Bar 40Bar 6Bar 10Bar / PN25 PN64 PN10 PN16 PN6 PN40 |

| Pressure Rating Chart | 600 LBS, 150 LBS, 2500 LBS, 900 LBS, 300 LBS, 1500 LBS |

| JIS | 20 K, 16 K, 5K, 10 K, 30 K, 40 K, 63 K |

| Manufacturer of Connect Type/ Flange Face Type | RF, RTJ, FF, LJF, Small Tongue, Large Tongue & Groove |

| UNI / EN | 16Bar 6Bar 40Bar 10Bar 25Bar |

| Coating | Yellow Transparent, Zinc Plated, Anti-rust Paint, Oil Black Paint, Cold and Hot Dip Galvanized |

| Equipment | Press machine, Bending machine, Pushing Machine, Sand-blasting machine, electric bevelling machine etc |

| Common Types By Manufacturer | Threaded / Screwed / Forged / Plate |

| Origin | West Europe / Japan / Indian / USA / Korean |

| Manufacturer of | ANSI DIN, GOST, JIS, UNI, BS, AS2129, SABS, NFE, AWWA, EN etc. |

| Test | Direct-reading Spectrograph, Ultrasonic flaw detector, Magnetic particle detector, X-ray detector, Hydrostatic testing machine |

| Production technique Used By Manufacturer | Heat treated, Forged and machined |

| Standards Provided By Manufacturer | API7S-43, API605, B16.48, ISO70051, MSS S44, ANSI/ASME B16.5, B16.47 Series A & B, BS4504, BS 10, EN-1092, DIN, API7S-15, JISB2220, BS1560-3.1, ASME/ANSI B16.5/16.36/16.47A/16.47B, EN1092 |

Are you looking for Stainless Steel 347 Flanges importer, dealers, supplier, stockholders, wholesalers, exporters, stockists, distributor and Manufacturer in Mumbai.

ASTM A182 F347 Flange Dimensions

| Normal Pipe Size (NPS) Of Flanges | (I.D.) Inside Diameter | Thickness Of Raised Face (RF) (T) |

Outside Daimeter (O.D.) | Raised Face (R) |

RF (Raised Face) |

Holes Of Bolts (B) |

H | T1 | Thickness Of Flat Face (FF) (T2) |

BC (Circle Of Bolt) | Bolts Holes Numbers |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 0.88 | 0.88 | 3.75 | 1.38 | .063 | 0.62 | 1.50 | 0.50 | 0.82 | 2.62 | 4 |

| 1 | 1.36 | 1.06 | 4.88 | 2.00 | .063 | 0.75 | 2.12 | 0.63 | 1.00 | 3.50 | 4 |

| 3/4 | 1.09 | 1.00 | 4.62 | 1.69 | .063 | 0.75 | 1.88 | .056 | 0.94 | 3.25 | 4 |

| 1-1/4 | 1.70 | 1.06 | 5.25 | 2.50 | .063 | 0.75 | 2.50 | 0.69 | 1.00 | 3.88 | 4 |

| 2 | 2.44 | 1.31 | 6.50 | 3.62 | .063 | 0.75 | 3.31 | 0.82 | 1.25 | 5.00 | 8 |

| 1-1/2 | 1.95 | 1.19 | 6.12 | 2.88 | .063 | 0.88 | 2.75 | 0.75 | 1.13 | 4.50 | 4 |

| 2-1/2 | 2.94 | 1.50 | 7.50 | 4.12 | .063 | 0.88 | 3.94 | 0.94 | 1.44 | 5.88 | 8 |

| 3 | 3.57 | 1.69 | 8.25 | 5.00 | .063 | 0.88 | 4.62 | 1.06 | 1.63 | 6.62 | 8 |

| 3-1/2 | 4.07 | 1.75 | 9.00 | 5.50 | .063 | 0.88 | 5.25 | 1.13 | 1.69 | 7.25 | 8 |

| 4 | 4.57 | 1.88 | 10.00 | 6.19 | .063 | 0.88 | 5.75 | 1.19 | 1.82 | 7.88 | 8 |

| 5 | 5.66 | 2.00 | 11.00 | 7.31 | .063 | 0.88 | 7.00 | 1.32 | 1.94 | 9.25 | 8 |

| 18 | 18.18 | 3.50 | 28.00 | 21.00 | .063 | 1.38 | 21.00 | 2.32 | 3.44 | 24.75 | 24 |

| 6 | 6.72 | 2.06 | 12.50 | 8.50 | .063 | 0.88 | 8.12 | 1.38 | 2.00 | 10.62 | 12 |

| 8 | 8.72 | 2.44 | 15.00 | 10.62 | .063 | 1.00 | 10.25 | 1.56 | 2.38 | 13.00 | 12 |

| 10 | 10.88 | 2.62 | 17.50 | 12.75 | .063 | 1.12 | 12.62 | 1.82 | 2.56 | 15.25 | 16 |

| 12 | 12.88 | 2.88 | 20.50 | 15.00 | .063 | 1.25 | 14.75 | 1.94 | 2.82 | 17.75 | 16 |

| 14 | 14.14 | 3.00 | 23.00 | 16.25 | .063 | 1.25 | 16.75 | 2.06 | 2.94 | 20.25 | 20 |

| 20 | 20.20 | 3.75 | 30.50 | 23.00 | .063 | 1.38 | 23.12 | 2.44 | 3.69 | 27.00 | 24 |

| 16 | 16.16 | 3.25 | 25.50 | 18.50 | .063 | 1.38 | 19.00 | 2.19 | 3.19 | 22.50 | 20 |

| 22 | 22.22 | 4.00 | 33.00 | 25.25 | .063 | 1.63 | 25.25 | 2.57 | 3.94 | 29.25 | 24 |

| 24 | 24.25 | 4.19 | 36.00 | 27.25 | .063 | 1.62 | 27.62 | 2.69 | 4.13 | 32.00 | 24 |

Supplier of 1.4550 Stainless Steel Socket Weld Flange and SA182 F347 Lap Joint Flange for Shipyards and Chemical Process Plants

Dimension Table of Stainless Steel 347 Blind Flange

| Size in Inch | Size in mm | ISO Stud Size | RF Height | Outer Dia. | RF Dia. | Hole Size | PCD | No of Bolts | Bolt Size UNC | Flange Thickness | RF Stud Length | Weight in kg |

| D | A | C | E | B | ||||||||

| 1/2 | 15 | M20 | 7 | 135 | 34.9 | 7/8 | 88.9 | 4 | 3/4 | 30.2 | 120 | 3.2 |

| 3/4 | 20 | M20 | 7 | 140 | 42.9 | 7/8 | 95.2 | 4 | 3/4 | 31.8 | 125 | 3.7 |

| 1 | 25 | M24 | 7 | 160 | 50.8 | 1 | 108 | 4 | 7/8 | 35 | 140 | 5 |

| 1 1/4 | 32 | M27 | 7 | 185 | 63.5 | 1 1/8 | 130.2 | 4 | 1 | 38.1 | 150 | 7.8 |

| 1 1/2 | 40 | M30 | 7 | 205 | 73 | 1 1/4 | 146 | 4 | 1 1/8 | 44.5 | 170 | 10.5 |

| 2 | 50 | M27 | 7 | 235 | 92.1 | 1 1/8 | 171.4 | 8 | 1 | 50.9 | 180 | 18 |

| 2 1/2 | 65 | M30 | 7 | 265 | 104.8 | 1 1/4 | 196.8 | 8 | 1 1/8 | 57.2 | 195 | 25.5 |

| 3 | 80 | M33 | 7 | 305 | 127 | 1 3/8 | 228.6 | 8 | 1 1/4 | 66.7 | 220 | 39 |

| 4 | 100 | M39 | 7 | 355 | 157.2 | 1 5/8 | 273 | 8 | 1 1/2 | 76.2 | 255 | 61.5 |

| 5 | 125 | M45 | 7 | 420 | 185.7 | 1 7/8 | 323.8 | 8 | 1 3/4 | 92.1 | 300 | 102 |

| 6 | 150 | M52 | 7 | 485 | 215.9 | 2 1/8 | 368.3 | 8 | 2 | 108 | 345 | 157 |

| 8 | 200 | M52 | 7 | 550 | 269.9 | 2 1/8 | 438.2 | 12 | 2 | 127 | 380 | 241 |

| 10 | 250 | M64 | 7 | 675 | 323.8 | 2 5/8 | 539.8 | 12 | 2 1/2 | 165.1 | 490 | 470 |

| 12 | 300 | M72 | 7 | 760 | 381 | 2 7/8 | 619.1 | 12 | 2 3/4 | 184.2 | 540 | 575 |

347H Stainless Steel Weld Neck Flange Dimensions

| Flange NPS | H | Inside Diameter |

Flat Face Thickness (T2) |

Outside Diameter |

Raised Face (RF) |

Raised Face (R) |

H1 | Raised Face Thickness (T) |

T1 | Bolt Circle (BC) |

Bolt Hole (B) |

No. of Bolt Holes |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2" | 1.19" | 0.62" | 1.82" | 3.50" | .063" | 1.38" | 0.84" | 1.88" | .38" | 2.38" | .62" | 4 |

| 1-1/4" | 2.31" | 1.38" | 2.19" | 4.62" | .063" | 2.50" | 1.66" | 2.25" | .56" | 3.50" | .62" | 4 |

| 3/4" | 1.50" | 0.82" | 2.00" | 3.88" | .063" | 1.69" | 1.05" | 2.06" | .44" | 2.75" | .62" | 4 |

| 1-1/2" | 2.56" | 1.61" | 2.38" | 5.00" | .063" | 2.88" | 1.90" | 2.44" | .62" | 3.88" | .62" | 4 |

| 1" | 1.94" | 1.05" | 2.13" | 4.25" | .063" | 2.00" | 1.32" | 2.19" | .50" | 3.12" | .62" | 4 |

| 2" | 3.06" | 2.07" | 2.44" | 6.00" | .063" | 3.62" | 2.38" | 2.50" | .69" | 4.75" | .75" | 4 |

| 2-1/2" | 3.56" | 2.47" | 2.69" | 7.00" | .063" | 4.12" | 2.88" | 2.75" | .82" | 5.50" | .75" | 4 |

| 3" | 4.25" | 3.07" | 2.69" | 7.50" | .063" | 5.00" | 3.50" | 2.75" | .88" | 6.00" | .75" | 4 |

| 4" | 5.31" | 4.03" | 2.94" | 9.00" | .063" | 6.19" | 4.50" | 3.00" | .88" | 7.50" | .75" | 8 |

| 5" | 6.44" | 5.05" | 3.44" | 10.00" | .063" | 7.31" | 5.56" | 3.50" | .88" | 8.50" | .88" | 8 |

| 3-1/2" | 4.81" | 3.55" | 2.75" | 8.50" | .063" | 5.50" | 4.00" | 2.81" | .88" | 7.00" | .75" | 8 |

| 6" | 7.56" | 6.07" | 3.44" | 11.00" | .063" | 8.50" | 6.63" | 3.50" | .94" | 9.50" | .88" | 8 |

| 8" | 9.69" | 7.98" | 3.94" | 13.50" | .063" | 10.62" | 8.63" | 4.00" | 1.06" | 11.75" | .88" | 8 |

| 22" | 24.25" | 21.25" | 5.82" | 29.50" | .063" | 25.25" | 22.00" | 5.88" | 1.75" | 27.25" | 1.38" | 20 |

| 10" | 12.00" | 10.02" | 3.94" | 16.00" | .063" | 12.75" | 10.75" | 4.00" | 1.13" | 14.25" | 1.00" | 12 |

| 12" | 14.38" | 12.00" | 4.44" | 19.00" | .063" | 15.00" | 12.75" | 4.50" | 1.19" | 17.00" | 1.00" | 12 |

| 16" | 18.00" | 15.25" | 4.94" | 23.50" | .063" | 18.50" | 16.00" | 5.00" | 1.38" | 21.25" | 1.12" | 16 |

| 18" | 19.88" | 17.25" | 5.44" | 25.00" | .063" | 21.00" | 18.00" | 5.50" | 1.50" | 22.75" | 1.25" | 16 |

| 14" | 15.75" | 13.25" | 4.94" | 21.00" | .063" | 16.25" | 14.00" | 5.00" | 1.32" | 18.75" | 1.12" | 12 |

| 20" | 22.00" | 19.25" | 5.63" | 27.50" | .063" | 23.00" | 20.00" | 5.69" | 1.63" | 25.00" | 1.25" | 20 |

| 24" | 26.12" | 23.25" | 5.94" | 32.00" | .063" | 27.25" | 24.00" | 6.00" | 1.82" | 29.50" | 1.38" | 20 |

Price List of Stainless Steel 347 Flanges

| Stainless Steel 347 Flanges Price Per Piece in India | 347 SS Pipe Flanges Price in INR | ASTM A182 F347 Flanges Price in UAE Dirham | 347 Stainless Steel Flange Price in USD |

| STAINLESS STEEL FLANGE (347) 1.5MM X 1500 # BLRF Per Pcs | 3,422 | UAE Dirham 165.86 | $45.16 |

| FLANGE,WELD NECK - 1-2500 RTJ SCHXXS SA182 F347 Per Pcs | 12,127 | UAE Dirham 587.78 | $160.03 |

| STAINLESS STEEL FLANGE (347) 1.5MM X 2500# BLRF Per Pcs | 6,337 | UAE Dirham 307.15 | $83.62 |

| FLANGES GR.347h H SIZE 1 X 300 X SCH 40 SWRF Per Pcs | 1,368 | UAE Dirham 66.31 | $18.05 |

We are one of the most reputed SS 347 Flange Manufacturer in India. We stock and supply 150# ANSI SS 347 Plate Flange. Ask for updated price list for 347 Stainless Steel RTJ Flange while placing a order.

Pressure Rating of ASTM A182 F347 Flange

| Temperature °F | Class 150 | Class 600 | Class 1500 | Class 400 | Class 900 | Class 300 | Class 2500 |

| -20 to 100 | 275 | 1440 | 3600 | 960 | 2160 | 720 | 6000 |

| 300 | 205 | 1080 | 2700 | 720 | 1620 | 540 | 4500 |

| 200 | 230 | 1200 | 3000 | 800 | 1800 | 600 | 5000 |

| 400 | 190 | 995 | 2485 | 660 | 1490 | 495 | 4140 |

| 600 | 140 | 875 | 2185 | 580 | 1310 | 435 | 3640 |

| 650 | 125 | 860 | 2150 | 575 | 1290 | 430 | 3580 |

| 500 | 170 | 930 | 2330 | 620 | 1395 | 465 | 3880 |

| 700 | 110 | 850 | 2125 | 565 | 1275 | 425 | 3540 |

| 750 | 95 | 830 | 2075 | 555 | 1245 | 415 | 3460 |

| 850 | 65 | 790 | 1980 | 530 | 1190 | 395 | 3300 |

| 800 | 80 | 805 | 2015 | 540 | 1210 | 405 | 3360 |

| 900 | 50 | 780 | 1945 | 520 | 1165 | 390 | 3240 |

| 950 | 35 | 765 | 1910 | 510 | 1145 | 380 | 3180 |

| 1000 | 20 | 640 | 1605 | 430 | 965 | 320 | 2675 |

| 1100 | 20 | 515 | 1285 | 345 | 770 | 255 | 2145 |

| 1150 | 20 | 400 | 995 | 265 | 595 | 200 | 1655 |

| 1050 | 20 | 615 | 1545 | 410 | 925 | 310 | 2570 |

| 1200 | 20 | 310 | 770 | 205 | 465 | 155 | 1285 |

| 1250 | 20 | 225 | 565 | 150 | 340 | 115 | 945 |

| 1300 | 20 | 170 | 430 | 115 | 255 | 85 | 715 |

| 1400 | 20 | 95 | 240 | 65 | 145 | 50 | 400 |

| 1350 | 20 | 125 | 310 | 80 | 185 | 60 | 515 |

| 1450 | 15 | 70 | 170 | 45 | 105 | 35 | 285 |

| 1500 | 10 | 55 | 135 | 35 | 80 | 25 | 230 |

Bulk discount on ASME B16.5 raised and flat face AISI 347 Stainless Steel Orifice Flanges and SS DIN 1.4550 Slip On Flange material in Asia

347 SS Flanges Weight

| Slip On Flange Weights by Pressure Class and Size | ||||||||||||||||||

| Pipe Sizes | 150 # | 300 # | 600 # | 900 # | 1500 # | 2500 # | ||||||||||||

| WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | WN | SO | BLD | |

| 1/2" | 2 | 1 | 1 | 2 | 1 | 1 | 2 | 2 | 2 | SEE 1500 # WEIGHTS | 5 | 4 | 4 | 7 | 7 | 7 | ||

| 3/4" | 2 | 2 | 2 | 3 | 3 | 3 | 4 | 3 | 3 | SEE 1500 # WEIGHTS | 6 | 5 | 6 | 8 | 8 | 8 | ||

| 1" | 3 | 2 | 2 | 4 | 3 | 3 | 4 | 4 | 4 | SEE 1500 # WEIGHTS | 9 | 8 | 8 | 12 | 11 | 11 | ||

| 1 1/2" | 4 | 3 | 3 | 7 | 6 | 6 | 8 | 7 | 8 | SEE 1500 # WEIGHTS | 13 | 12 | 13 | 25 | 22 | 23 | ||

| 2" | 6 | 5 | 5 | 9 | 7 | 8 | 12 | 9 | 10 | SEE 1500 # WEIGHTS | 25 | 25 | 25 | 42 | 37 | 39 | ||

| 2 1/2" | 8 | 7 | 7 | 12 | 10 | 12 | 18 | 13 | 15 | SEE 1500 # WEIGHTS | 36 | 36 | 35 | 52 | 55 | 56 | ||

| 3" | 10 | 8 | 9 | 15 | 13 | 16 | 23 | 16 | 20 | 31 | 26 | 29 | 48 | 48 | 48 | 94 | 83 | 86 |

| 4" | 15 | 13 | 17 | 25 | 22 | 27 | 42 | 37 | 41 | 53 | 53 | 54 | 73 | 73 | 73 | 145 | 125 | 130 |

| 5" | 19 | 15 | 20 | 32 | 28 | 35 | 68 | 63 | 68 | 86 | 83 | 87 | 130 | 130 | 140 | 245 | 210 | 225 |

| 6" | 24 | 19 | 26 | 42 | 39 | 50 | 81 | 80 | 86 | 110 | 110 | 115 | 165 | 165 | 160 | 380 | 325 | 345 |

| 8" | 39 | 30 | 45 | 67 | 58 | 81 | 120 | 115 | 140 | 175 | 170 | 200 | 275 | 260 | 300 | 580 | 485 | 530 |

| 10" | 52 | 43 | 70 | 91 | 81 | 124 | 190 | 170 | 230 | 260 | 245 | 290 | 455 | 435 | 510 | 1075 | 930 | 1025 |

| 12" | 80 | 64 | 110 | 140 | 115 | 185 | 225 | 200 | 295 | 325 | 325 | 415 | 690 | 580 | 690 | 1525 | 1100 | 1300 |

| 14" | 110 | 90 | 140 | 180 | 165 | 250 | 280 | 230 | 355 | 400 | 400 | 520 | 940 | NA | 975 | NA | NA | NA |

| 16" | 140 | 98 | 180 | 250 | 190 | 295 | 390 | 330 | 495 | 495 | 425 | 600 | 1250 | NA | 1300 | NA | NA | NA |

| 18" | 150 | 130 | 220 | 320 | 250 | 395 | 475 | 400 | 630 | 680 | 600 | 850 | 1625 | NA | 1750 | NA | NA | NA |

| 20" | 180 | 165 | 285 | 400 | 315 | 505 | 590 | 510 | 810 | 830 | 730 | 1075 | 2050 | NA | 2225 | NA | NA | NA |

| 22" | 225 | 185 | 355 | 465 | 370 | 640 | 720 | 590 | 1000 | NA | NA | NA | NA | NA | NA | NA | NA | NA |

| 24" | 260 | 220 | 430 | 580 | 475 | 790 | 830 | 730 | 1250 | 1500 | 1400 | 2025 | 3325 | NA | 3625 | NA | NA | NA |

347 Stainless Steel Flange Forging

| Significant reductions (roll forging, ingot breakdown, blocking, drawing, and backward extrusion) | 2300 (1260) |

| Slight reductions (restriking, coining and end upsetting) | 2050 (1120) |

| Moderate cutbacks (upsetting and finish forging) | 2200 (1200) |

ASTM A182 F347 Chemical Composition

| Grade | Manganese | Carbon | Silicone | Phosphorus | Sulfur | Cromium | Boron carbide | Nickel | Iron |

| SS 347 | 2.0 max | 0.08 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 20.00 | 10xC – 1.10 | 9.00 - 13.00 | 62.74 min |

| SS 347H | 2.0 max | 0.04 – 0.10 | 1.0 max | 0.045 max | 0.030 max | 17.00 - 19.00 | 8xC – 1.10 | 9.0 -13.0 | 63.72 min |

Check SUS 347 Threaded Flange, ASTM A182 Gr F347 Spectacle Blinds and Werkstoff No 1.4550 Long Weld Neck Flange Price & dimensions in mm

SS 347 Flange Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

A182 F347 Equivalent

| STANDARD | WERKSTOFF NR. | UNS | JIS | GOST | EN |

| SS 347 | 1.4550 | S34700 | SUS 347 | 08Ch18N12B | X6CrNiNb18-10 |

| SS 347H | 1.4961 | S34709 | SUS 347H | - | X6CrNiNb18-12 |

Heat Treatment of 347 SS Flange

Heat treatment cannot harden 347 stainless steel Flanges; in fact, the only heat treatment operation conducted on it is annealing at roughly 1950oF (1065oC) followed by a water quench. This treatment provides the greatest corrosion resistance for type 347 forgings.

Various Types of Stainless Steel 347 Flanges

1500 LBS ASTM A182 F347 Slip On Flange

SS DIN 1.4550 Ring Joint Flange

Stainless Steel 347H SWRF Flanges

15 NB A182 F347H Reducing Flanges

ASTM A182 Gr F347 Spectacle Blind Flange

Stainless Steel 347 Socket Weld Flange

5000 NB 347 SS BLRF Flanges

SS 347 Flange

SS 347 Tongue & Groove Flange

300 LBS 347 Stainless Steel Girth Flanges

ASTM A182 F347 Flange

347 SS Flanges

SS UNS S34700 Lapped Joint Flange

600 LBS 347 Stainless Steel Screwed Flange

ASTM A182 Grade F347 Weld Neck Flanges

ASME B16.5 SS 347 Expander Flanges

150 LBS SS 347H Nipoflange Flanges

SS GOST 08Ch18N12B Long Weld Neck Flange

Stainless Steel F347 Blind Flange

ASME SA182 SS 347 Threaded Flange

900 LBS ANSI B16.5 SS 347 WNRF Flange

2500 LBS ASTM A182 Gr F347 Orifice Flanges

347H Stainless Steel Flange

ASME SA182M Stainless Steel 347 SORF Flanges

347 Stainless Steel Flange Welding

Shielded fusion and resistance welding processes can be used to fuse Type 347 Flanges. Austenitic stainless steel welds do not harden when cooled, hence the welds are robust.

Because of the likelihood of carbon pick up in the weld area, oxyacetylene welding is not suggested.

ASME B16.5 SS 347 Flange Application

- Refineries

- Nuclear Power

- Paper & Pulp

- Ship Building

- Oil And Gas Industry

- Power Plants

- Marine Applications

- Fossil Fuel Power Plants

347H Stainless Steel Flange Testing and Inspection

- Direct-reading Spectrograph

- Magnetic particle detector

- Flattening Test

- PMI Testing

- Hardness Test

- Pitting Resistance Test

- X-ray detector

- Flaring Test

- UI trasonic flaw detector

- Hydrostatic testing machine

ASTM A182 347H Flange Hs Code

| Hs Code | 73072100 |

Stainless Steel 347 Flange Density

| Density | 7.7 – 8.03 g/cm3 | 0.278 – 0.290 lb/in³ |

Flanges Material

Pipe Fittings Material

Other Products