- Call : +91 22 67436442

- exports@petrometflange.com

ASTM A105 Flange manufacturer in India

- Home /

- ASTM A105 Flange

Nace certified ASME SA 105 Slip On Flange and A105n Blind Flange supplier in Mumbai

The ASTM A105 can be defined as a specification for the flanges. It can include various grades of the stainless steel material that makes up the flanges. The ASTM A105 Flange is mostly of the forged carbon steel and they are usually used in high-temperature services. The ASTM A105 material consists of different elements in its chemical composition; it has chromium and molybdenum in its alloy which increases the hardenability of the flanges. Different types of flanges are available in this specification and each of them have separate applications according to its structure. For example, the ASTM A105 Blind Flange is used for closing a pipeline. These flanges are also known for their high strength. The minimum yield strength of the ASTM A105 Flange is 250 MPa and its minimum tensile strength is 485 MPa. The material has a Brinell hardness score of 187.

The ASTM A105 Flanges are available in different pressure classes, such as class 150, 300, and it goes up to 2500, and from PN6 to PN64. Any ASTM A105 Flange below class 300 do not need heat treatment, while the flanges with higher pressure classes might choose to undergo heat treatment. These flanges can be forged and they possess high weldability. These flanges are also available in the bolted and screwed forms, which are applied to the threaded pipes for making a connection.

The ASTM A105 Flange offers several benefits like they are resistant to corrosion, and has advantages in oxidizing media like nitric acid solution. It is because the ASTM A105 material has low content of molybdenum. They have a smooth and simple sealing surface which makes it very easy to machine them.

ASTM A105 Sorf Flange Vs ASME SA105 Blind Flange

The ASTM A105 Sorf Flange or Slip-on Raised Face Flange are mostly used for various fabricated applications. They are basically attached to the pipe with the help of a filler welding that is present at the hub and also at the pipe end, on the inner side of the flange. The ASTM A105 Sorf Flange is available in various sizes and they can be used for various applications. It is mostly used for low temperature and low pressure applications. These slip-on flanges are preferred by engineers of industries such as oil and gas, due to its affordability.

The ASME SA105 Blind Flange does not have a hub or a center with a bore. They basically have the face thickness of a flange with a matching face type and there is also a similar bolting pattern. It is mostly used for sealing the nozzle opening of a pressure vessel, or the end of the pipe to stop the connection. They are used on that nozzle of a vessel or part of the pipe that is not under any use, as it completely blocks off the operation.

Is A105 Carbon Steel Class 150 Flange low temp?

The A105 Carbon Steel Flange is capable of withstanding different pressure at different temperatures. Generally, with the increase in the temperature, the pressure rating of the flange decreases. For example, the A105 Carbon Steel Class 150 Flange is rated at around 270 PSIG at ambient conditions whereas it is approximately 180 PSIG at 204 degrees C. Thus as the pressure goes down, the temperature increases, and vice-versa. Thus, generally it can be said that the A105 Carbon Steel Class 150 Flange is low temperature.

ASTM A105 Flange manufacturer in India

Produce SA 105 material and ASTM A105 forged steel flanges through bar blanks for high strength, A105 Carbon Steel Flat Flange and Puddle Flanges manufacturer in Mumbai according to ANSI/ ASME B16.5 standard

ASTM A105n Flange Vs SA 105 Flange

There is no difference between the chemical composition of the ASTM A105n Flange and the SA 105 Flange. However, the difference lies in its standard and mechanical properties. Basically, when there is an auxiliary requirement for heat treatment for the ASTM A105 material in normalized condition, it is known as the ASTM A105n material. The SA 105 Flange does not have any heat treatment requirements. Thus, it can be said that the ASTM A105n Flange possesses better mechanical properties compared to the ASTM A105 Flange as the former have increased strength and give better performance at low temperature services. Thus, it can be concluded that even though the ASTM A105n Flange and the SA 105 Flange have the same chemical composition, the ASTM A105n Flange has enhanced mechanical properties and that is why they are used for critical applications.

Table of Content

- ASTM A105 Flange Specification

- SA 105 material Price in India

- ASTM A105 Forged Steel Flanges surface finish

- Sizes of ASTM A105 Carbon Steel Flanges

- Testing and Inspection Plan for SA-105 UNS K03504 material

- SA 105 Flange Weight Chart

- A105 Forging Temperature

- ASTM A105 Flange Dimensions

- ASTM A105 Yield Strength

- ASTM A105 Temperature Range

- ASTM A105 Class 300 Flange Dimensions

- ASTM A105 Heat Treatment

- A105 Flange pressure rating

- A105 Hardness

- ASTM A105 Flange Types

- ASTM A105n Chemical Properties

- ASTM A 105 N Mechanical Properties

- ASTM A105 Chemical Composition

- A105 Mechanical Properties

- ASTM A105 UNS K03504 Forged Flange Physical Properties

- UNS K03504 Equivalent

- Packaging of A105n Carbon Steel Flange

- ASTM A105 slip on flange dimensions

- A105 forged steel flange Protection coating

- A105 Blind Flange Dimensions

- ASTM A105 weld neck flange dimensions

- ASTM A105 vs IS 2062 material

- Documentation We Provide for A105N Normalized Flange

- Max service temperature of ASTM A105 SORF Flange

- SA 105 Pipe Flange Facing Finish Imperfections

- Production Process of SA105 Steel Forged Flange

- SA A105 Killed Carbon Steel Flange Applications

- ASTM A105 Steel Flange Thickness

ASTM A105 Flange Specification

| Size Range | 1/2″ to 48″ |

|---|---|

| Chart of Pressure Rating | 300 LBS, 2500 LBS, 1500 LBS, 900 LBS, 150 LBS, 600 LBS |

| JIS | 40 K, 16 K, 5K, 10 K, 30 K, 20 K, 63 K |

| DIN Pressure Calculation | 25Bar 40Bar 16Bar 6Bar 10Bar / PN64 PN10 PN25 PN16 PN6 PN40 |

| Manufacturer of Connect / Flange Face Type | LJF, RF, RTJ, FF, Small Tongue, Large Tongue & Groove |

| Test | Magnetic particle detector, X-ray detector, Ultrasonic flaw detector, Direct-reading Spectrograph, Hydrostatic testing machine |

| Production technique Used By Manufacturer | Heat treated, Forged and machined |

| Origin | Japan / West Europe / Indian / USA / Korean |

| Standards Provided By Manufacturer | ISO70051, MSS S44, BS1560-3.1, API7S-43, B16.48, ANSI/ASME B16.5, B16.47 Series A & B, BS4504, JISB2220, ASME/ANSI B16.5/16.36/16.47A/16.47B, API605, BS 10, EN-1092, DIN, API7S-15, EN1092 |

| UNI / EN | 16Bar 6Bar 40Bar 10Bar 25Bar |

| Common Types By Manufacturer | Threaded / Screwed / Forged / Plate |

| Equipment | Pushing Machine, Press machine, Sand-blasting machine, Bending machine, electric bevelling machine etc |

| Coating | Zinc Plated, Anti-rust Paint, Yellow Transparent, Oil Black Paint, Cold and Hot Dip Galvanized |

| Manufacturer of | GOST, JIS, ANSI, DIN, UNI, BS, AWWA, AS2129, SABS, NFE, EN etc. |

Well know ASTM A105 Steel Flange distributor, importer, stockists, wholesalers, stockholders, dealers, supplier, exporters and Manufacturer in Mumbai.

BS4504 PN16 SA105 Steel Forged Flanges and ASME B16.47 ASTM A105 Blind Flange manufacturer in India offers 100% Radiography Test Report

SA 105 material Price in India

| Killed Carbon Steel A105 Flange Price Per Piece in India | Price Applicable for jan 2022 to june 2022 | Price Applicable for July 2022 to December 2022 |

| LOOSE FLANGE A105 150# B16.5, 2 (ASTM A105 AS PER ASME B16.5) Per Kg | US $2.67 | US $4.67 |

| FLANGE SW RF A105 3/4 105# Per Kg | US $3.03 | US $5.03 |

| REDUCING WNRT J FLANGE 2X1 SCH160 300#A105N MOC:ASTM A105N ASME B16.5 Per Unit | US $34.84 | US $36.84 |

| FLANGE 5 IN ANSI 150 LB SLIP ON RAISED FACE ASTM A105 Per Kg | US $8.09 | US $10.09 |

Why to buy from stockist? Buy directly through A105 Flange manufacturers and save cost. A leading industrial Killed Carbon Steel Astm A105 Flange Manufacturer in India, we offer a wide range of cost effective A105n Steel Flange

ASTM A105 Forged Steel Flanges surface finish

- Stock Flange Finish

- Spiral Serrated Finish

- Concentric Serrated Finish

- Smooth Finish

- Cold Water Finish

Sizes of ASTM A105 Carbon Steel Flanges

| Nominal Pipe Size (inch) | Dia. of Flange (inch) | No. of Bolts | Dia. of Bolts (inch) | Dia. of Bolt Holes (inch) | Bolt Circle (inch) |

|---|---|---|---|---|---|

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 3/4 | 3-7/8 | 4 | 1/2 | 0.62 | 2-3/4 |

| 1 | 4-1/4 | 4 | 1/2 | 0.62 | 3-1/8 |

| 1/2 | 3-1/2 | 4 | 1/2 | 0.62 | 2-3/8 |

| 1-1/4 | 4-5/8 | 4 | 1/2 | 0.62 | 3-1/2 |

| 2 | 6 | 4 | 5/8 | 0.75 | 4-3/4 |

| 2-1/2 | 7 | 4 | 5/8 | 0.75 | 5-1/2 |

| 1-1/2 | 5 | 4 | 1/2 | 0.62 | 3-7/8 |

| 3 | 7-1/2 | 4 | 5/8 | 0.75 | 6 |

| 3-1/2 | 8-1/2 | 8 | 5/8 | 0.75 | 7 |

| 4 | 9 | 8 | 5/8 | 0.75 | 7-1/2 |

| 20 | 27-1/2 | 20 | 1-1/8 | 1.25 | 25 |

| 6 | 11 | 8 | 3/4 | 0.88 | 9-1/2 |

| 8 | 13-1/2 | 8 | 3/4 | 0.88 | 11-3/4 |

| 5 | 10 | 8 | 3/4 | 0.88 | 8-1/2 |

| 10 | 16 | 12 | 7/8 | 1 | 14-1/4 |

| 14 | 21 | 12 | 1 | 1.12 | 18-3/4 |

| 16 | 23-1/2 | 16 | 1 | 1.12 | 21-1/4 |

| 12 | 19 | 12 | 7/8 | 1 | 17 |

| 18 | 25 | 16 | 1-1/8 | 1.25 | 22-3/4 |

| 24 | 32 | 20 | 1-1/4 | 1.38 | 29-1/2 |

Testing and Inspection Plan for SA-105 UNS K03504 material

- Positive Material Identification – PMI Testing

- Pitting Resistance Test

- Hardness Test

- Flaring Test

- Mechanical Testing Such as Tensile of Area

- Chemical Analysis – Spectro Analysis

- Flattening Test

- Micro and Macro Test

- Intergranular Corrosion (IGC) Test

Choose A105 Flange manufacturers in India for lowest price and ready stock, we produce large diameter A105n Steel Socket Weld Flange and ASTM A105n Threaded Flange as per customer's dimensions

SA 105 Flange Weight Chart

| NPS (Nominal Pipe Size) | Loose (Lap Joint) | NPT (Threaded) | SORF (Slip On) | BLRF (Blind) | SWRF (Socket Weld) | WRNR (Weld Neck) |

|---|---|---|---|---|---|---|

| ½ | 1 | 1 | 1 | 2 | 2 | 2 |

| 1 | 2 | 2 | 2 | 2 | 2 | 3 |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 |

| 1½ | 3 | 3 | 3 | 4 | 3 | 4 |

| 2½ | 8 | 8 | 8 | 7 | 8 | 10 |

| 2 | 5 | 5 | 5 | 5 | 5 | 6 |

| 3 | 9 | 9 | 9 | 9 | 9 | 11.5 |

| 4 | 13 | 13 | 13 | 17 | 13 | 16.5 |

| 3½ | 11 | 12 | 11 | 13 | 11 | 12 |

| 5 | 15 | 15 | 15 | 20 | 15 | 21 |

| 8 | 30 | 30 | 30 | 47 | 30 | 42 |

| 6 | 19 | 19 | 19 | 27 | 19 | 26 |

| 10 | 43 | 43 | 43 | 70 | 43 | 54 |

| 24 | 275 | 220 | 220 | 430 | 220 | 268 |

| 14 | 105 | 90 | 90 | 140 | 90 | 114 |

| 12 | 64 | 64 | 64 | 123 | 64 | 88 |

| 16 | 140 | 98 | 106 | 180 | 98 | 140 |

| 20 | 195 | 165 | 165 | 285 | 165 | 197 |

| 18 | 160 | 130 | 130 | 220 | 130 | 165 |

| 22 | 245 | 185 | 185 | 355 | 185 | 225 |

A105 Forging Temperature

| Forging Temperature | Between 1,700 degrees F and 2,200 degrees F |

Looking for Class 150/ 300 A105 Steel Lap Joint Flange for petrochemical plants? Manufacturer of Carbon Steel UNS K03504 ASTM A105 Long Weld Neck Flange and A105n Spectacle Blinds in India, buy ASTM A105 Material for industrial application

ASTM A105 Flange Dimensions

| Size in Inch | RF Dia. | Size in mm | Machine Bolt Length | Flange Thickness | ISO Stud Size | PCD | No of Bolts | Bolt Size UNC | Outer Dia. | RF Height | RF Stud Length | Hole Size | Weight in kg |

| C | B | E | A | D | |||||||||

| 1/2 | 34.9 | 15 | 50 | 9.6 | M14 | 60.3 | 4 | 1/2 | 90 | 2 | 55 | 5/8 | 0.9 |

| 1 | 50.8 | 25 | 55 | 12.7 | M14 | 79.4 | 4 | 1/2 | 110 | 2 | 65 | 5/8 | 0.9 |

| 1 1/4 | 63.5 | 32 | 55 | 14.3 | M14 | 88.9 | 4 | 1/2 | 115 | 2 | 70 | 5/8 | 1.4 |

| 3/4 | 42.9 | 20 | 50 | 11.2 | M14 | 69.9 | 4 | 1/2 | 100 | 2 | 65 | 5/8 | 0.9 |

| 1 1/2 | 73 | 40 | 65 | 15.9 | M14 | 98.4 | 4 | 1/2 | 125 | 2 | 70 | 5/8 | 1.8 |

| 2 | 92.1 | 50 | 70 | 17.5 | M16 | 120.7 | 4 | 5/8 | 150 | 2 | 85 | 3/4 | 2.3 |

| 3 | 127 | 80 | 75 | 22.3 | M16 | 152.4 | 4 | 5/8 | 190 | 2 | 90 | 3/4 | 4.1 |

| 3 1/2 | 139.7 | 90 | 75 | 22.3 | M16 | 177.8 | 8 | 5/8 | 215 | 2 | 90 | 3/4 | 5.9 |

| 4 | 157.2 | 100 | 75 | 22.3 | M16 | 190.5 | 8 | 5/8 | 230 | 2 | 90 | 3/4 | 7.7 |

| 5 | 185.7 | 125 | 85 | 22.3 | M20 | 215.9 | 8 | 3/4 | 255 | 2 | 95 | 7/8 | 9.1 |

| 2 1/2 | 104.8 | 65 | 75 | 20.7 | M16 | 139.7 | 4 | 5/8 | 180 | 2 | 90 | 3/4 | 3.2 |

| 6 | 215.9 | 150 | 85 | 23.9 | M20 | 241.3 | 8 | 3/4 | 280 | 2 | 100 | 7/8 | 11.8 |

| 8 | 269.9 | 200 | 90 | 27 | M20 | 298.5 | 8 | 3/4 | 345 | 2 | 110 | 7/8 | 20.5 |

| 10 | 323.8 | 250 | 100 | 28.6 | M24 | 362 | 12 | 7/8 | 405 | 2 | 115 | 1 | 32 |

| 12 | 381 | 300 | 100 | 30.2 | M24 | 431.8 | 12 | 7/8 | 485 | 2 | 120 | 1 | 50 |

| 14 | 412.8 | 350 | 115 | 33.4 | M27 | 476.3 | 12 | 1 | 535 | 2 | 135 | 1 1/8 | 64 |

| 16 | 469.9 | 400 | 115 | 35 | M27 | 539.8 | 16 | 1 | 595 | 2 | 135 | 1 1/8 | 82 |

| 18 | 533.4 | 450 | 125 | 38.1 | M30 | 577.9 | 16 | 1 1/8 | 635 | 2 | 145 | 1 1/4 | 100 |

| 20 | 584.2 | 500 | 140 | 41.3 | M30 | 635 | 20 | 1 1/8 | 700 | 2 | 160 | 1 1/4 | 130 |

| 24 | 692.2 | 600 | 150 | 46.1 | M33 | 749.3 | 20 | 1 1/4 | 815 | 2 | 170 | 1 3/8 | 196 |

ASTM A105 Yield Strength

| Yield Strength | 36,000 psi |

ASTM A105 Temperature Range

| Temp. | -20~100 | 150 | 200 | 300 | 400 |

| S | 20.0 | 20.0 | 20.0 | 20.0 | 20.0 |

| Temp. | 500 | 600 | 650 | 700 | 750 |

| S | 19.6 | 18.4 | 17.8 | 17.2 | 14.8 |

| Temp. | 800 | 850 | 900 | 950 | 1000 |

| S | 12.0 | 9.3 | 6.7 | 4.0 | 2.5 |

ASTM A105 Class 300 Flange Dimensions

| Nominal Pipe Size (inches) | Class 300 | ||||

|---|---|---|---|---|---|

| Dia of Flange (inches) | No. of Bolts | Dia of Bolts (inches) | Dia of Bolt Holes (inches) | Bolt Circle (inches) | |

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 1/2 | 3-3/4 | 4 | 1/2 | 0.62 | 2-5/8 |

| 3/4 | 4-5/8 | 4 | 5/8 | 0.75 | 3-1/4 |

| 1 | 4-7/8 | 4 | 5/8 | 0.75 | 3-1/2 |

| 1-1/4 | 5-1/4 | 4 | 5/8 | 0.75 | 3-7/8 |

| 1-1/2 | 6-1/8 | 4 | 3/4 | 0.88 | 4-1/2 |

| 2 | 6-1/2 | 8 | 5/8 | 0.75 | 5 |

| 2-1/2 | 7-1/2 | 8 | 3/4 | 0.88 | 5-7/8 |

| 3 | 8-1/4 | 8 | 3/4 | 0.88 | 6-5/8 |

| 3-1/2 | 9 | 8 | 3/4 | 0.88 | 7-1/4 |

| 4 | 10 | 8 | 3/4 | 0.88 | 7-7/8 |

| 5 | 11 | 8 | 3/4 | 0.88 | 9-1/4 |

| 6 | 12-1/2 | 12 | 3/4 | 0.88 | 10-5/8 |

| 8 | 15 | 12 | 7/8 | 1 | 13 |

| 10 | 17-1/2 | 16 | 1 | 1.12 | 15-1/4 |

| 12 | 20-1/2 | 16 | 1-1/8 | 1.25 | 17-3/4 |

| 14 | 23 | 20 | 1-1/8 | 1.25 | 20-1/4 |

| 16 | 25-1/2 | 20 | 1-1/4 | 1.38 | 22-1/2 |

| 18 | 28 | 24 | 1-1/4 | 1.38 | 24-3/4 |

| 20 | 30-1/2 | 24 | 1-1/4 | 1.38 | 27 |

| 24 | 36 | 24 | 1-1/2 | 1.62 | 32 |

ASTM A105 Heat Treatment

- Annealing-During annealing, the material is uniformly reheated to a temperature above the transformation range and then slowly cooled to a temperature below the transformation range after holding at this temperature for a suitable time.

- Normalizing-The material is uniformly warmed to a temperature above the transformation range and then cooled in room temperature air.

- Normalizing and tempering

- Quenching and tempering-In this procedure, the material is thoroughly austenitized before being instantly quenched in an appropriate liquid medium. The quenched fittings were then warmed to a minimum temperature of 590°C (1100°F) and chilled in still air.

A105 Flange pressure rating

| Temperature °F | Class 150 | Class 600 | Class 1500 | Class 400 | Class 900 | Class 300 | Class 2500 |

| -20 to 100 | 275 | 1440 | 3600 | 960 | 2160 | 720 | 6000 |

| 300 | 205 | 1080 | 2700 | 720 | 1620 | 540 | 4500 |

| 200 | 230 | 1200 | 3000 | 800 | 1800 | 600 | 5000 |

| 400 | 190 | 995 | 2485 | 660 | 1490 | 495 | 4140 |

| 600 | 140 | 875 | 2185 | 580 | 1310 | 435 | 3640 |

| 650 | 125 | 860 | 2150 | 575 | 1290 | 430 | 3580 |

| 500 | 170 | 930 | 2330 | 620 | 1395 | 465 | 3880 |

| 700 | 110 | 850 | 2125 | 565 | 1275 | 425 | 3540 |

| 750 | 95 | 830 | 2075 | 555 | 1245 | 415 | 3460 |

| 850 | 65 | 790 | 1980 | 530 | 1190 | 395 | 3300 |

| 800 | 80 | 805 | 2015 | 540 | 1210 | 405 | 3360 |

| 900 | 50 | 780 | 1945 | 520 | 1165 | 390 | 3240 |

| 950 | 35 | 765 | 1910 | 510 | 1145 | 380 | 3180 |

| 1000 | 20 | 640 | 1605 | 430 | 965 | 320 | 2675 |

| 1100 | 20 | 515 | 1285 | 345 | 770 | 255 | 2145 |

| 1150 | 20 | 400 | 995 | 265 | 595 | 200 | 1655 |

| 1050 | 20 | 615 | 1545 | 410 | 925 | 310 | 2570 |

| 1200 | 20 | 310 | 770 | 205 | 465 | 155 | 1285 |

| 1250 | 20 | 225 | 565 | 150 | 340 | 115 | 945 |

| 1300 | 20 | 170 | 430 | 115 | 255 | 85 | 715 |

| 1400 | 20 | 95 | 240 | 65 | 145 | 50 | 400 |

| 1350 | 20 | 125 | 310 | 80 | 185 | 60 | 515 |

| 1450 | 15 | 70 | 170 | 45 | 105 | 35 | 285 |

| 1500 | 10 | 55 | 135 | 35 | 80 | 25 | 230 |

A105 Hardness

| Hardness | 137 to 187 HB |

ASTM A105 Flange Types

ASTM A105 Flange

A105N Nace certified Flanges

SA 105 material

SA 105 Pipe Flange

SA105 Steel Forged Flanges

ASTM A105 forged steel flanges

A105 forged steel flanges

ASTM A105 Blind Flange

ASTM A105n Ring Joint Flange

A105n Material

ASTM A105 Material

A105 Flange

SA 105 Flange

ASTM A105n Material

A105n Flange

A105 Steel Flange

A105 Normalized Flanges

A105N Normalized Flange

A105 Forging

ASME SA105 Material

ASTM A105 SORF Flange

ASTM A105 Slip On Flange

CS ASTM A105 Weld Neck Flanges

600 LBS ASME SA 105 WNRF Flange

ASTM A105 Carbon Steel Socket Weld Flange

300 LBS A105n Carbon Steel SWRF Flanges

SA105 Steel BLRF Flanges

900 LBS A105 Carbon Steel Lapped Joint Flange

ASTM A 105 N Orifice Flanges

15 NB A105n Steel Spectacle Blind Flange

A105 Metal Tongue & Groove Flange

2500 LBS SA-105 UNS K03504 Nipoflange

ASTM A105 UNS K03504 Long Weld Neck Flange

5000 NB A105 Steel Reducing Flange

A105 ASTM Girth Flange

1500 LBS CS A105 Expander Flange

UNS K03504 Screwed Flange

150 LBS ASTM A105 Steel Threaded Flange

A105 Carbon Steel Flange

ASTM A105n Chemical Properties

| Element | ASTM A105N |

| C% | 0.35 max |

| Si% | 0.10-0.35 |

| Mn% | 0.60-1.05 |

| P% | 0.035 max |

| S% | 0.040 max |

| Cu% | 0.40 max |

| Ni% | 0.40 max |

| Cr% | 0.30 max |

| Mo% | 0.12 max |

| V% | 0.08 max |

| Nb% | 0.02 max |

ASTM A 105 N Mechanical Properties

| Element | ASTM A105N |

| Tensile Strength, min: | 70,000 psi (485 MPa] |

| Min. Yield Point: | 36,000 psi [250 MPa] |

| Reduction of area, min: | 30% min |

| Hardness, HB, max | 187 |

ASTM A105 Chemical Composition

| ELEMENT | COMPOSITION, % |

| Carbon | 0.35 max |

| Manganese | 0.60-1.05 |

| Nickel | 0.40 max (1) |

| Silicon | 0.10-0.35 |

| Copper | 0.40 max (1) |

| Molybdenum | 0.12 max (1-2) |

| Vanadium | 0.08 max |

| Chromium | 0.30 max (1-2) |

| Phosphorus | 0.035 max |

| Sulfur | 0.040 max |

A105 Mechanical Properties

| Mechanical Properties | Requirements |

|---|---|

| Yield strength,min,psi [MPa] | 36000 [250] |

| Tensile strength,min,psi [MPa] | 70000 [485] |

| Elongation, min, % | 30 |

| Hardness,HB,max | 187 |

| Reductionofarea,min,% | 30 |

ASTM A105 UNS K03504 Forged Flange Physical Properties

| Density (lb / cu. in.) | 0.284 |

| Specific Heat (Btu/lb/Deg F – [32-212 Deg F]) | 0.107 |

| Melting Point (Deg F) | 2740 |

| Thermal Conductivity | 360 |

| Specific Gravity | 7.9 |

| Mean Coeff Thermal Expansion | 6.7 |

| Modulus of Elasticity Torsion | 11 |

| Modulus of Elasticity Tension | 30 |

UNS K03504 Equivalent

| Standard | Astm A105 |

| AFNOR | - |

| GOST | - |

| BS | - |

| UNS | K03504 |

| WERKSTOFF NR. | 1.0460 |

| JIS | - |

| EN | - |

Packaging of A105n Carbon Steel Flange

ASTM A105 Carbon Steel Flange is wrapped in plastic cloth and packed in a wooden box, a wooden pallet, and a fumigated wooden carrate. Our packaging is fully transportable and waterproof, with proper strips on a wooden box with a lifting point.

ASTM A105 slip on flange dimensions

| Size in Inch | Size in mm | No of Bolts | Outer Dia. | Hub OD | ISO Stud Size | Flange Length | RF Height | Flange Thick. | RF Dia. | PCD | Hole Size | Socket Bore | Weight in kg |

| A | C | D | F | B | E | G | H | ||||||

| 1/2 | 15 | 4 | 90 | 30 | M14 | 14 | 2 | 9.6 | 34.9 | 60.3 | 5/8 | 22.2 | 0.8 |

| 1 | 25 | 4 | 110 | 49 | M14 | 16 | 2 | 12.7 | 50.8 | 79.4 | 5/8 | 34.5 | 0.9 |

| 3/4 | 20 | 4 | 100 | 38 | M14 | 14 | 2 | 11.2 | 42.9 | 69.9 | 5/8 | 27.7 | 0.9 |

| 1 1/4 | 32 | 4 | 115 | 59 | M14 | 19 | 2 | 14.3 | 63.5 | 88.9 | 5/8 | 43.2 | 1.4 |

| 2 | 50 | 4 | 150 | 78 | M16 | 24 | 2 | 17.5 | 92.1 | 120.7 | 3/4 | 61.9 | 2.3 |

| 1 1/2 | 40 | 4 | 125 | 65 | M14 | 21 | 2 | 15.9 | 73 | 98.4 | 5/8 | 49.5 | 1.4 |

| 2 1/2 | 65 | 4 | 180 | 90 | M16 | 27 | 2 | 20.7 | 104.8 | 139.7 | 3/4 | 74.6 | 3.2 |

| 3 | 80 | 4 | 190 | 108 | M16 | 29 | 2 | 22.3 | 127 | 152.4 | 3/4 | 90.7 | 3.7 |

| 4 | 100 | 8 | 230 | 135 | M16 | 32 | 2 | 22.3 | 157.2 | 190.5 | 3/4 | 116.1 | 5.9 |

| 3 1/2 | 90 | 8 | 215 | 122 | M16 | 30 | 2 | 22.3 | 139.7 | 177.8 | 3/4 | 103.4 | 5 |

| 5 | 125 | 8 | 255 | 164 | M20 | 35 | 2 | 22.3 | 185.7 | 215.9 | 7/8 | 143.8 | 6.8 |

| 8 | 200 | 8 | 345 | 246 | M20 | 43 | 2 | 27 | 269.9 | 298.5 | 7/8 | 221.5 | 13.7 |

| 10 | 250 | 12 | 405 | 305 | M24 | 48 | 2 | 28.6 | 323.8 | 362 | 1 | 276.2 | 19.5 |

| 6 | 150 | 8 | 280 | 192 | M20 | 38 | 2 | 23.9 | 215.9 | 241.3 | 7/8 | 170.7 | 8.6 |

| 12 | 300 | 12 | 485 | 365 | M24 | 54 | 2 | 30.2 | 381 | 431.8 | 1 | 327 | 29 |

| 24 | 600 | 20 | 815 | 663 | M33 | 81 | 2 | 46.1 | 692.2 | 749.3 | 1 3/8 | 616 | 100 |

| 16 | 400 | 16 | 595 | 457 | M27 | 62 | 2 | 35 | 469.9 | 539.8 | 1 1/8 | 410.5 | 54 |

| 18 | 450 | 16 | 635 | 505 | M30 | 67 | 2 | 38.1 | 533.4 | 577.9 | 1 1/4 | 461.8 | 59 |

| 14 | 350 | 12 | 535 | 400 | M27 | 56 | 2 | 33.4 | 412.8 | 476.3 | 1 1/8 | 359.2 | 41 |

| 20 | 500 | 20 | 700 | 559 | M30 | 71 | 2 | 41.3 | 584.2 | 635 | 1 1/4 | 513.1 | 75 |

A105 forged steel flange Protection coating

- Yellow Transparent

- Anti-rust Paint

- Zinc Plated

- Cold and Hot Dip Galvanized

- Oil Black Paint

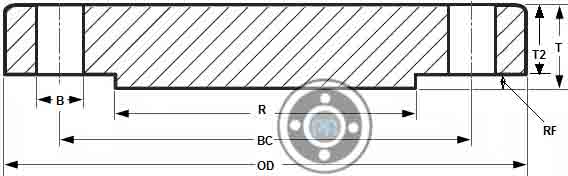

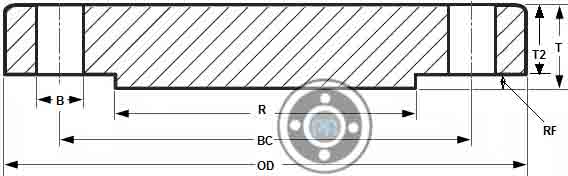

A105 Blind Flange Dimensions

Class 150 A105 Blind Flange

| FLANGE NPS | Outside Diameter | Raised Face (RF) | Bolt Hole (B) | Bolt Circle (BC) | Raised Face (R) | Flat Face Thickness (T2) | Raised Face Thickness (T) | No. of Bolt Holes |

|---|---|---|---|---|---|---|---|---|

| 3/4" | 3.88" | .063" | .62" | 2.75" | 1.69" | .44" | .50" | 4 |

| 1" | 4.25" | .063" | .62" | 3.12" | 2.00" | .50" | .56" | 4 |

| 1/2" | 3.50" | .063" | .62" | 2.38" | 1.38" | .38" | .44" | 4 |

| 1-1/4" | 4.62" | .063" | .62" | 3.50" | 2.50" | .56" | .62" | 4 |

| 1-1/2" | 5.00" | .063" | .62" | 3.88" | 2.88" | .62" | .68" | 4 |

| 2" | 6.00" | .063" | .75" | 4.75" | 3.62" | .69" | .75" | 4 |

| 3" | 7.50" | .063" | .75" | 6.00" | 5.00" | .88" | .94" | 4 |

| 3-1/2" | 8.50" | .063" | .75" | 7.00" | 5.50" | .88" | .94" | 8 |

| 22" | 29.50" | .063" | 1.38" | 27.25" | 25.25" | 1.75" | 1.81" | 20 |

| 4" | 9.00" | .063" | .75" | 7.50" | 6.19" | .88" | .94" | 8 |

| 2-1/2" | 7.00" | .063" | .75" | 5.50" | 4.12" | .82" | .88" | 4 |

| 5" | 10.00" | .063" | .88" | 8.50" | 7.31" | .88" | .94" | 8 |

| 6" | 11.00" | .063" | .88" | 9.50" | 8.50" | .94" | 1.00" | 8 |

| 8" | 13.50" | .063" | .88" | 11.75" | 10.62" | 1.06" | 1.12" | 8 |

| 10" | 16.00" | .063" | 1.00" | 14.25" | 12.75" | 1.13" | 1.19" | 12 |

| 14" | 21.00" | .063" | 1.12" | 18.75" | 16.25" | 1.32" | 1.38" | 12 |

| 16" | 23.50" | .063" | 1.12" | 21.25" | 18.50" | 1.38" | 1.44" | 16 |

| 12" | 19.00" | .063" | 1.00" | 17.00" | 15.00" | 1.19" | 1.25" | 12 |

| 18" | 25.00" | .063" | 1.25" | 22.75" | 21.00" | 1.50" | 1.56" | 16 |

| 20" | 27.50" | .063" | 1.25" | 25.00" | 23.00" | 1.63" | 1.69" | 20 |

| 24" | 32.00" | .063" | 1.38" | 29.50" | 27.25" | 1.82" | 1.88" | 20 |

Class 300 A105 Blind Flange

| FLANGE NPS | Raised Face (R) | Bolt Circle (BC) | Bolt Hole (B) | Raised Face (RF) | Flat Face Thickness (T2) | Raised Face Thickness (T) | Outside Diameter | No. of Bolt Holes |

|---|---|---|---|---|---|---|---|---|

| 1/2" | 1.38" | 2.62" | 0.62" | .063" | 0.50" | 0.56" | 3.75" | 4 |

| 3/4" | 1.69" | 3.25" | 0.75" | .063" | .056" | 0.62" | 4.62" | 4 |

| 1" | 2.00" | 3.50" | 0.75" | .063" | 0.63" | 0.69" | 4.88" | 4 |

| 1-1/4" | 2.50" | 3.88" | 0.75" | .063" | 0.69" | 0.75" | 5.25" | 4 |

| 1-1/2" | 2.88" | 4.50" | 0.88" | .063" | 0.75" | 0.81" | 6.12" | 4 |

| 2" | 3.62" | 5.00" | 0.75" | .063" | 0.82" | 0.88" | 6.50" | 8 |

| 2-1/2" | 4.12" | 5.88" | 0.88" | .063" | 0.94" | 1.00" | 7.50" | 8 |

| 3" | 5.00" | 6.62" | 0.88" | .063" | 1.06" | 1.12" | 8.25" | 8 |

| 3-1/2" | 5.50" | 7.25" | 0.88" | .063" | 1.13" | 1.19" | 9.00" | 8 |

| 4" | 6.19" | 7.88" | 0.88" | .063" | 1.19" | 1.25" | 10.00" | 8 |

| 5" | 7.31" | 9.25" | 0.88" | .063" | 1.32" | 1.38" | 11.00" | 8 |

| 6" | 8.50" | 10.62" | 0.88" | .063" | 1.38" | 1.44" | 12.50" | 12 |

| 8" | 10.62" | 13.00" | 1.00" | .063" | 1.56" | 1.62" | 15.00" | 12 |

| 10" | 12.75" | 15.25" | 1.12" | .063" | 1.82" | 1.88" | 17.50" | 16 |

| 12" | 15.00" | 17.75" | 1.25" | .063" | 1.94" | 2.00" | 20.50" | 16 |

| 14" | 16.25" | 20.25" | 1.25" | .063" | 2.06" | 2.12" | 23.00" | 20 |

| 16" | 18.50" | 22.50" | 1.38" | .063" | 2.19" | 2.25" | 25.50" | 20 |

| 18" | 21.00" | 24.75" | 1.38" | .063" | 2.32" | 2.38" | 28.00" | 24 |

| 20" | 23.00" | 27.00" | 1.38" | .063" | 2.44" | 2.50" | 30.50" | 24 |

| 22" | 25.25" | 29.25" | 1.63" | .063" | 2.57" | 2.63" | 33.00" | 24 |

| 24" | 27.25" | 32.00" | 1.62" | .063" | 2.69" | 2.75" | 36.00" | 24 |

Class 600 A105 Blind Flange

| Size in Inch | Size in mm | PCD | Outer Dia. | ISO Stud Size | RF Dia. | No of Bolts | RF Height | Bolt Size UNC | RF Stud Length | Hole Size | Flange Thick. | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| E | A | C | D | B | ||||||||

| 1/2 | 15 | 66.7 | 95 | M14 | 34.9 | 4 | 7 | 1/2 | 75 | 5/8 | 14.3 | 1.4 |

| 3/4 | 20 | 82.6 | 115 | M16 | 42.9 | 4 | 7 | 5/8 | 90 | 3/4 | 15.9 | 1.4 |

| 1 | 25 | 88.9 | 125 | M16 | 50.8 | 4 | 7 | 5/8 | 90 | 3/4 | 17.5 | 1.8 |

| 1 1/4 | 32 | 98.4 | 135 | M16 | 63.5 | 4 | 7 | 5/8 | 95 | 3/4 | 20.7 | 2.3 |

| 1 1/2 | 40 | 114.3 | 155 | M20 | 73 | 4 | 7 | 3/4 | 110 | 7/8 | 22.3 | 3.7 |

| 2 | 50 | 127 | 165 | M16 | 92.1 | 8 | 7 | 5/8 | 110 | 3/4 | 25.4 | 4.6 |

| 2 1/2 | 65 | 149.2 | 190 | M20 | 104.8 | 8 | 7 | 3/4 | 120 | 7/8 | 28.6 | 6.8 |

| 3 | 80 | 168.3 | 210 | M20 | 127 | 8 | 7 | 3/4 | 125 | 7/8 | 31.8 | 9.1 |

| 3 1/2 | 90 | 184.2 | 230 | M24 | N/A | 8 | 7 | 7/8 | 140 | 1 | 35 | 13.2 |

| 4 | 100 | 215.9 | 275 | M24 | 157.2 | 8 | 7 | 7/8 | 145 | 1 | 38.1 | 18.7 |

| 5 | 125 | 266.7 | 330 | M27 | 185.7 | 8 | 7 | 1 | 165 | 1 1/8 | 44.5 | 31 |

| 6 | 150 | 292.1 | 355 | M27 | 215.9 | 12 | 7 | 1 | 170 | 1 1/8 | 47.7 | 39 |

| 8 | 200 | 349.2 | 420 | M30 | 269.9 | 12 | 7 | 1 1/8 | 190 | 1 1/4 | 55.6 | 64 |

| 10 | 250 | 431.8 | 510 | M33 | 323.8 | 16 | 7 | 1 1/4 | 215 | 1 3/8 | 63.5 | 105 |

| 12 | 300 | 489 | 560 | M33 | 381 | 20 | 7 | 1 1/4 | 220 | 1 3/8 | 66.7 | 134 |

| 14 | 350 | 527 | 605 | M36 | 412.8 | 20 | 7 | 1 3/8 | 235 | 1 1/2 | 69.9 | 161 |

| 16 | 400 | 603.2 | 685 | M39 | 469.9 | 20 | 7 | 1 1/2 | 255 | 1 5/8 | 76.2 | 225 |

| 18 | 450 | 654 | 745 | M42 | 533.4 | 20 | 7 | 1 5/8 | 275 | 1 3/4 | 82.6 | 286 |

| 20 | 500 | 723.9 | 815 | M42 | 584.2 | 24 | 7 | 1 5/8 | 285 | 1 3/4 | 88.9 | 368 |

| 24 | 600 | 838.2 | 940 | M48 | 692.2 | 24 | 7 | 1 7/8 | 330 | 2 | 101.6 | 568 |

Class 900 A105 Blind Flange

| Size in Inch | ISO Stud Size | Size in mm | Flange Thick. | Bolt Size UNC | RF Height | No of Bolts | RF Dia. | RF Stud Length | PCD | Hole Size | Outer Dia. | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B | D | C | E | A | ||||||||

| 1/2 | M20 | 15 | 22.3 | 3/4 | 7 | 4 | 34.9 | 110 | 82.6 | 7/8 | 120 | 1.8 |

| 3/4 | M20 | 20 | 25.4 | 3/4 | 7 | 4 | 42.9 | 115 | 88.9 | 7/8 | 130 | 2.7 |

| 1 | M24 | 25 | 28.6 | 7/8 | 7 | 4 | 50.8 | 125 | 101.6 | 1 | 150 | 3.6 |

| 1 1/4 | M24 | 32 | 28.6 | 7/8 | 7 | 4 | 63.5 | 125 | 111.1 | 1 | 160 | 4.1 |

| 1 1/2 | M27 | 40 | 31.8 | 1 | 7 | 4 | 73 | 140 | 123.8 | 1 1/8 | 180 | 5.9 |

| 2 | M24 | 50 | 38.1 | 7/8 | 7 | 8 | 92.1 | 145 | 165.1 | 1 | 215 | 10.1 |

| 2 1/2 | M27 | 65 | 41.3 | 1 | 7 | 8 | 104.8 | 160 | 190.5 | 1 1/8 | 245 | 16 |

| 3 | M24 | 80 | 38.1 | 7/8 | 7 | 8 | 127 | 145 | 190.5 | 1 | 240 | 13 |

| 4 | M30 | 100 | 44.5 | 1 1/8 | 7 | 8 | 157.2 | 170 | 235 | 1 1/4 | 290 | 24.5 |

| 5 | M33 | 125 | 50.8 | 1 1/4 | 7 | 8 | 185.7 | 190 | 279.4 | 1 3/8 | 350 | 39.5 |

| 6 | M30 | 150 | 55.6 | 1 1/8 | 7 | 12 | 215.9 | 190 | 317.5 | 1 1/4 | 380 | 53 |

| 8 | M36 | 200 | 63.5 | 1 3/8 | 7 | 12 | 269.9 | 220 | 393.7 | 1 1/2 | 470 | 91 |

| 10 | M36 | 250 | 69.9 | 1 3/8 | 7 | 16 | 323.8 | 235 | 469.9 | 1 1/2 | 545 | 132 |

| 12 | M36 | 300 | 79.4 | 1 3/8 | 7 | 20 | 381 | 255 | 533.4 | 1 1/2 | 610 | 189 |

| 14 | M39 | 350 | 85.8 | 1 1/2 | 7 | 20 | 412.8 | 275 | 558.8 | 1 5/8 | 640 | 237 |

| 16 | M42 | 400 | 88.9 | 1 5/8 | 7 | 20 | 469.9 | 285 | 616 | 1 3/4 | 705 | 273 |

| 18 | M48 | 450 | 101.6 | 1 7/8 | 7 | 20 | 533.4 | 325 | 685.8 | 2 | 785 | 367 |

| 20 | M52 | 500 | 108 | 2 | 7 | 20 | 584.2 | 350 | 749.3 | 2 1/8 | 855 | 463 |

| 24 | M64 | 600 | 139.7 | 2 1/2 | 7 | 20 | 692.2 | 440 | 901.7 | 2 5/8 | 1040 | 875 |

Class 1500 A105 Blind Flange

| Size in Inch | RF Height | Size in mm | Outer Dia. | PCD | No of Bolts | Bolt Size UNC | Flange Thick. | RF Stud Length | Weight in kg | Hole Size | RF Dia. | ISO Stud Size |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D | A | E | B | C | ||||||||

| 1/2 | 7 | 15 | 120 | 82.6 | 4 | 3/4 | 22.3 | 110 | 1.8 | 7/8 | 34.9 | M20 |

| 3/4 | 7 | 20 | 130 | 88.9 | 4 | 3/4 | 25.4 | 115 | 2.7 | 7/8 | 42.9 | M20 |

| 1 | 7 | 25 | 150 | 101.6 | 4 | 7/8 | 28.6 | 125 | 3.7 | 1 | 50.8 | M24 |

| 1 1/4 | 7 | 32 | 160 | 111.1 | 4 | 7/8 | 28.6 | 125 | 4.1 | 1 | 63.5 | M24 |

| 1 1/2 | 7 | 40 | 180 | 123.8 | 4 | 1 | 31.8 | 140 | 5.9 | 1 1/8 | 73 | M27 |

| 2 | 7 | 50 | 215 | 165.1 | 8 | 7/8 | 38.1 | 145 | 10.1 | 1 | 92.1 | M24 |

| 2 1/2 | 7 | 65 | 245 | 190.5 | 8 | 1 | 41.3 | 160 | 15.9 | 1 1/8 | 104.8 | M27 |

| 3 | 7 | 80 | 265 | 203.2 | 8 | 1 1/8 | 47.7 | 180 | 21.8 | 1 1/4 | 127 | M30 |

| 4 | 7 | 100 | 310 | 241.3 | 8 | 1 1/4 | 54 | 195 | 33 | 1 3/8 | 157.2 | M33 |

| 5 | 7 | 125 | 375 | 292.1 | 8 | 1 1/2 | 73.1 | 250 | 64 | 1 5/8 | 185.7 | M39 |

| 6 | 7 | 150 | 395 | 317.5 | 12 | 1 3/8 | 82.6 | 260 | 75 | 1 1/2 | 215.9 | M36 |

| 8 | 7 | 200 | 485 | 393.7 | 12 | 1 5/8 | 92.1 | 290 | 136 | 1 3/4 | 269.9 | M42 |

| 10 | 7 | 250 | 585 | 482.6 | 12 | 1 7/8 | 108 | 335 | 232 | 2 | 323.8 | M48 |

| 12 | 7 | 300 | 675 | 571.5 | 16 | 2 | 123.9 | 375 | 314 | 2 1/8 | 381 | M52 |

| 14 | 7 | 350 | 750 | 635 | 16 | 2 1/4 | 133.4 | 405 | 443 | 2 3/8 | 412.8 | M56 |

| 16 | 7 | 400 | 825 | 704.8 | 16 | 2 1/2 | 146.1 | 445 | 591 | 2 5/8 | 469.9 | M64 |

| 18 | 7 | 450 | 915 | 774.7 | 16 | 2 3/4 | 162 | 495 | 795 | 2 7/8 | 533.4 | M72 |

| 20 | 7 | 500 | 985 | 831.8 | 16 | 3 | 177.8 | 540 | 1022 | 3 1/8 | 584.2 | M76 |

| 24 | 7 | 600 | 1170 | 990.6 | 16 | 3 1/2 | 203.2 | 615 | 1648 | 3 5/8 | 692.2 | M90 |

Manufacturer of JIS B2220 ASTM A105 Plate flange, JIS 10K SA 105 Weld Neck Flange and EN 1092-2 CS SA 105 Orifice Flanges in RTJ/ RJ/ Flat/ Raised face suitable for petroleum, power plant generation,oil and gas industry

ASTM A105 weld neck flange dimensions

| Flange NPS | H | Inside Diameter | Flat Face Thickness (T2) | Outside Diameter | Raised Face (RF) | Raised Face (R) | H1 | Raised Face Thickness (T) | T1 | Bolt Circle (BC) | Bolt Hole (B) | No. of Bolt Holes |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2" | 1.19" | 0.62" | 1.82" | 3.50" | .063" | 1.38" | 0.84" | 1.88" | .38" | 2.38" | .62" | 4 |

| 1-1/4" | 2.31" | 1.38" | 2.19" | 4.62" | .063" | 2.50" | 1.66" | 2.25" | .56" | 3.50" | .62" | 4 |

| 3/4" | 1.50" | 0.82" | 2.00" | 3.88" | .063" | 1.69" | 1.05" | 2.06" | .44" | 2.75" | .62" | 4 |

| 1-1/2" | 2.56" | 1.61" | 2.38" | 5.00" | .063" | 2.88" | 1.90" | 2.44" | .62" | 3.88" | .62" | 4 |

| 1" | 1.94" | 1.05" | 2.13" | 4.25" | .063" | 2.00" | 1.32" | 2.19" | .50" | 3.12" | .62" | 4 |

| 2" | 3.06" | 2.07" | 2.44" | 6.00" | .063" | 3.62" | 2.38" | 2.50" | .69" | 4.75" | .75" | 4 |

| 2-1/2" | 3.56" | 2.47" | 2.69" | 7.00" | .063" | 4.12" | 2.88" | 2.75" | .82" | 5.50" | .75" | 4 |

| 3" | 4.25" | 3.07" | 2.69" | 7.50" | .063" | 5.00" | 3.50" | 2.75" | .88" | 6.00" | .75" | 4 |

| 4" | 5.31" | 4.03" | 2.94" | 9.00" | .063" | 6.19" | 4.50" | 3.00" | .88" | 7.50" | .75" | 8 |

| 5" | 6.44" | 5.05" | 3.44" | 10.00" | .063" | 7.31" | 5.56" | 3.50" | .88" | 8.50" | .88" | 8 |

| 3-1/2" | 4.81" | 3.55" | 2.75" | 8.50" | .063" | 5.50" | 4.00" | 2.81" | .88" | 7.00" | .75" | 8 |

| 6" | 7.56" | 6.07" | 3.44" | 11.00" | .063" | 8.50" | 6.63" | 3.50" | .94" | 9.50" | .88" | 8 |

| 8" | 9.69" | 7.98" | 3.94" | 13.50" | .063" | 10.62" | 8.63" | 4.00" | 1.06" | 11.75" | .88" | 8 |

| 22" | 24.25" | 21.25" | 5.82" | 29.50" | .063" | 25.25" | 22.00" | 5.88" | 1.75" | 27.25" | 1.38" | 20 |

| 10" | 12.00" | 10.02" | 3.94" | 16.00" | .063" | 12.75" | 10.75" | 4.00" | 1.13" | 14.25" | 1.00" | 12 |

| 12" | 14.38" | 12.00" | 4.44" | 19.00" | .063" | 15.00" | 12.75" | 4.50" | 1.19" | 17.00" | 1.00" | 12 |

| 16" | 18.00" | 15.25" | 4.94" | 23.50" | .063" | 18.50" | 16.00" | 5.00" | 1.38" | 21.25" | 1.12" | 16 |

| 18" | 19.88" | 17.25" | 5.44" | 25.00" | .063" | 21.00" | 18.00" | 5.50" | 1.50" | 22.75" | 1.25" | 16 |

| 14" | 15.75" | 13.25" | 4.94" | 21.00" | .063" | 16.25" | 14.00" | 5.00" | 1.32" | 18.75" | 1.12" | 12 |

| 20" | 22.00" | 19.25" | 5.63" | 27.50" | .063" | 23.00" | 20.00" | 5.69" | 1.63" | 25.00" | 1.25" | 20 |

| 24" | 26.12" | 23.25" | 5.94" | 32.00" | .063" | 27.25" | 24.00" | 6.00" | 1.82" | 29.50" | 1.38" | 20 |

ASTM A105 vs IS 2062 material

ASTM A105 is the most generally used carbon steel material grade for forging piping components such as flange and forged fittings of small diameter piping, whereas IS 2062 is a steel product standard of the Bureau of Indian Standards. It establishes requirements for Hot Rolled Medium and High Tensile Structural Steel. These steels are utilised in structural applications.

Documentation We Provide for A105N Normalized Flange

- Material Test Certificates (MTC)

- Heat Treatment Charts

- Guarantee Letter

- Commercial Invoice including HS Code

- Material Traceability Records

- Quality Assurance Plan (QAP)

- NABL approved Laboratory Test Reports

- Packing List including Complete Details

- Certificate of Origin legalized

Max service temperature of ASTM A105 SORF Flange

| Max service temperature | 500 °C |

SA 105 Pipe Flange Facing Finish Imperfections

| NPS | A | B |

|---|---|---|

| 1/2 | 3.0 | 1.5 |

| 3/4 | 3.0 | 1.5 |

| 1 | 3.0 | 1.5 |

| 1-1/4 | 3.0 | 1.5 |

| 1-1/2 | 3.0 | 1.5 |

| 2 | 3.0 | 1.5 |

| 2-1/2 | 3.0 | 1.5 |

| 3 | 4.5 | 1.5 |

| 3-1/2 | 6.0 | 3.0 |

| 4 | 6.0 | 3.0 |

| 5 | 6.0 | 3.0 |

| 6 | 6.0 | 3.0 |

| 8 | 8.0 | 4.5 |

| 10 | 8.0 | 4.5 |

| 12 | 8.0 | 4.5 |

| 14 | 8.0 | 4.5 |

| 16 | 10.0 | 4.5 |

| 18 | 12.0 | 6.0 |

| 20 | 12.0 | 6.0 |

| 22 | 12.0 | 6.0 |

| 24 | 12.0 | 6.0 |

Production Process of SA105 Steel Forged Flange

SA A105 Killed Carbon Steel Flange Applications

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Power Generation

- Pulp and Paper Industry

- Off-Shore Oil Drilling Companies

ASTM A105 Steel Flange Thickness

| Nominal Size | Outside Diameter (OD) | Bore Diameter (B) | No. of Bolt Holes | Bolt Hole Diam. | Bolt Circle (BC) | Thickness (T) | Hub Length (L) | Hub Diam. (H) | Lap Radius ( R ) | Approx. Weight (lbs) |

| 1 | 4.25 | 1.38 | 4 | 0.625 | 3.13 | 0.563 | 0.688 | 1.938 | 0.13 | 2 |

| 1 1/4 | 4.68 | 1.72 | 4 | 0.625 | 3.50 | 0.625 | 0.813 | 2.312 | 0.19 | 3 |

| 1 1/2 | 5.00 | 1.97 | 4 | 0.625 | 3.88 | 0.688 | 0.875 | 2.563 | 0.25 | 3 |

| 2 | 6.00 | 2.46 | 4 | 0.750 | 4.75 | 0.750 | 1.000 | 3.063 | 0.31 | 5 |

| 2 1/2 | 7.00 | 2.97 | 4 | 0.750 | 5.50 | 0.875 | 1.125 | 3.563 | 0.31 | 7 |

| 3 | 7.50 | 3.60 | 4 | 0.750 | 6.00 | 0.938 | 1.188 | 4.250 | 0.38 | 8 |

| 3 1/2 | 8.50 | 4.10 | 8 | 0.750 | 7.00 | 0.938 | 1.250 | 4.812 | 0.38 | 11 |

| 4 | 9.00 | 4.60 | 8 | 0.750 | 7.50 | 0.938 | 1.312 | 5.312 | 0.44 | 13 |

| 5 | 10.00 | 5.69 | 8 | 0.875 | 8.50 | 0.938 | 1.438 | 6.438 | 0.44 | 15 |

| 6 | 11.00 | 6.75 | 8 | 0.875 | 9.50 | 1.000 | 1.562 | 7.562 | 0.50 | 18 |

| 8 | 13.50 | 8.75 | 8 | 0.875 | 11.75 | 1.125 | 1.750 | 9.688 | 0.50 | 30 |

| 10 | 16.00 | 10.92 | 12 | 1.000 | 14.25 | 1.188 | 1.938 | 12.000 | 0.50 | 42 |

| 12 | 19.00 | 12.92 | 12 | 1.000 | 17.00 | 1.250 | 2.188 | 14.375 | 0.50 | 64 |

| 14 | 21.00 | 14.19 | 12 | 1.125 | 18.75 | 1.375 | 2.250 | 15.750 | 0.50 | 90 |

| 16 | 23.50 | 16.19 | 16 | 1.125 | 21.25 | 1.438 | 2.500 | 18.000 | 0.50 | 98 |

| 18 | 25.00 | 18.20 | 16 | 1.250 | 22.75 | 1.562 | 2.688 | 19.875 | 0.50 | 125 |

| 20 | 27.50 | 20.25 | 20 | 1.250 | 25.00 | 1.688 | 2.875 | 22.000 | 0.50 | 160 |

| 24 | 32.00 | 24.25 | 20 | 1.375 | 29.50 | 1.875 | 3.250 | 26.125 | 0.50 | 212 |

| 30** | 38.75 | 30.25 | 28 | 1.375 | 36.00 | 2.125 | 3.500 | 32.750 | 0.50 | 305 |

| 36** | 46.00 | 36.25 | 32 | 1.625 | 42.75 | 2.375 | 3.750 | 39.250 | 0.50 | 440 |

Flanges Material

Pipe Fittings Material

Other Products