- Call : +91 22 67436442

- exports@petrometflange.com

Spiral wound gasket manufacturer in India

- Home /

- Spiral wound gasket

ASME B16.20 Class 150 to 2500 Carbon Steel Graphite Gasket and Stainless Steel Mica Gasket supplier in Mumbai

What is a Spiral Wound Gasket?

The Spiral Wound Gasket comes with a V-shaped metal strip that can wound in spirally. It combines with a soft filler material to perform its task. The metal strip ensures recovery, while the flexible filler material guarantees proper sealing. The combination of the two makes the Spiral Wound Gasket suitable for applications in extreme conditions including fluctuating temperature and pressure. Depending on the application for which the Spiral Wound Gasket would be needed, it might have an inner and/or outer ring.

As mentioned earlier, the Spiral Wound Gasket has a winding of alternative strips consisting of metal and a filler material. Depending on the types of the metal and material, the end product can be used for a wide range of applications. Typically, the Spiral Wound Gasket is used in services that involve chemicals, oils, steam, and hydrocarbons.

The outer ring basically rests on the bolts of the flange and the gasket is centrally located on the raised face of the flange. It helps in proper sealing and prevents any kind of leakage. The ring helps in preventing any kind of sealing over-compression.

The key features of Spiral Wound Gasket would include:

- It can be used in environments up to the temperature of 1000 degrees C and pressure of 250 bar.

- They perform equally well in a wide range of media.

- It comes with easy installation primarily because of its design. It also helps in reducing damage of the gasket, but for the large diameter variants that come without any inner or outer rings, proper measures should be taken to transport and install them safely.

- The gasket can be removed easily and it is non-adhesive in nature.

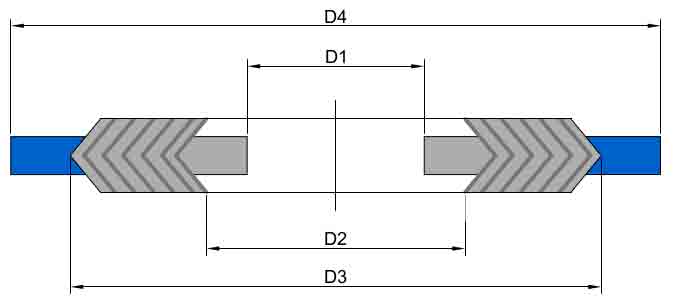

How do you identify a Spiral Wound Gasket?

A Spiral Wound Gasket can be identified easily from its structure; it consists of three elements:

- The outer ring, centering ring, or guide ring is primarily made of up carbon steel. It helps in centering the gasket while it is inserted into bolted flange joints.

- Inner ring helps to prevent windings from getting buckled inside the pipeline. It helps to avoid the common “bird nest” issues inside the pipe.

- The sealing material helps to seal the connection and prevents any kind of leakage. It consists of both windings and filler materials. Ploytetrafluroethylene is a common sealing material.

Can you use Spiral Wound Gasket with flat face flange?

A Spiral Wound Gasket can be used with both raised face flange and flat face flange, for various high temperature and pressure services, corrosive environments, or where there is a presence of any toxic media.

How much do Spiral Wound Gasket Compress?

The thickness of the Spiral Wound Gasket is 3.3 mm. There can be ± 0.13 mm based on 30,000 psi uniform bolt stress.

What Material Combinations Used in a Spiral Wound Gasket

The Material Combinations Used in a Spiral Wound Gasket would include:

- 304 Stainless Steel

- 316/L Stainless Steel

- 316 Ti Stainless Steel

- 321 Stainless Steel

- 347 Stainless Steel

- Duplex

- Nickel 200

- Monel 400

- Titanium

- Hastelloy B-2

- Hastelloy C-276

- Inconel 600

- Inconel 625

- Inconel X-750

Spiral wound gasket manufacturer in India

Looking for Spiral Wound Gasket suppliers? Manufacturer of ASME B16.20 RTJ Gasket, Mica and Graphite Gasket for high pressure and extreme temperature conditions

Table of Content

- Spiral wound gasket Specification List

- Spiral Wound Gasket Material Configurations

- Spiral Wound Gasket Price List In India

- ASME B16.20 RTJ Gasket Dimensions

- Carbon Steel Spiral Wound Gasket Torque

- Stainless Steel Spiral Wound Gasket Thickness

- ASME B16.20 Spiral Wound Gasket Pressure Rating

- Spiral Wound Gasket With Inner Ring

- Cgi Gasket Advantages

- Available Spiral Wound Gasket Shapes

- Spiral Wound Gasket Types

- Weight Of Spiral Wound Gasket

- Parts Of Spiral Wound Gasket

- Spiral Wound Gasket Compression

- What Are Spiral Wound Gaskets Used For

- Spiral Wound Gasket Filler Material

- Color Codes for Spiral Gasket Winding Materials

- Spiral Wound Gasket High Temperature

- SS 304 Spiral Wound Gasket Installation

- Spiral wound Gasket Dimensions For ASME B16.5 CLASS 150 Flanges

- Spiral wound Gasket Dimensions For ASME B16.5 CLASS 300 Flanges

- Spiral wound Gasket Dimensions For ASME B16.5 CLASS 600 Flanges

- Spiral wound Gasket Dimensions For ASME B16.5 CLASS 900 Flanges

- Spiral wound Gasket Dimensions For ASME B16.5 CLASS 1500 Flanges

- Spiral wound Gasket Dimensions For ASME B16.5 CLASS 2500 Flanges

Spiral wound gasket Specification List

| Size | 1/2 inch to 24 inch |

| Thickness | 2.5 mm. 3.5 mm , 4.5 mm, 6.5 mm |

| Material Provided By Manufacturer | SS 304, SS 306, Nickel |

| Manufacturer of Filler materials | Graphite, PTFE, Non-Asbestos fiber, CAF |

| Type | Spiral Wound Gasket |

| Shape | Round |

| Temperature (Degree Celsius) | -200 to 450 Degree C |

Well known ASME B16.20 RTJ Gasket distributor, importer, exporters, stockists, supplier, wholesalers, dealers, stockholders and Manufacturer in Mumbai.

Spiral Wound Gasket Material Configurations

| Winding / Inner / Outer Ring Material Combinations | Maximum Temperature | ASME B16.20 Colour Coding |

|---|---|---|

| Carbon Steel | 500⁰C | Silver |

| 304 Stainless Steel | 550⁰C | Yellow |

| 316/L Stainless Steel | 550⁰C | Green |

| 316 Ti Stainless Steel | 650⁰C | Light Blue |

| 321 Stainless Steel | 650⁰C | Turquoise |

| 347 Stainless Steel | 650⁰C | Blue |

| Duplex | 800⁰C | N/A |

| Nickel 200 | 600⁰C | Red |

| Monel 400 | 600⁰C | Orange |

| Titanium | 350⁰C | Purple |

| Hastelloy B-2 | 450⁰C | Brown |

| Hastelloy C-276 | 450⁰C | Beige |

| Inconel 600 | 950⁰C | Gold |

| Inconel 625 | 450⁰C | Gold |

| Inconel X-750 | 1000⁰C | Light Grey |

| Incoloy 825 | 450⁰C | White |

Spiral Wound Gasket Price List In India

| Spiral wound gasket Price Per Piece in India | Graphite Gasket Flanges Price in INR | Cgi Gasket Price in UAE Dirham | ASME B16.20 Spiral Wound Gasket Price in USD |

| BOTTOM SPIRAL WOUND GASKET Per Unit | 3,457 | UAE Dirham 170.83 | $46.51 |

| DISC SPIRAL WOUND GASKET MOC: AISI 316+GRAPHITE Per Unit | 11,914 | UAE Dirham 588.74 | $160.29 |

| DISC SPIRAL WOUND GASKET AISI316 + GRAFITE Per PCS | 4,668 | UAE Dirham 230.67 | $62.80 |

| SPIRAL WOUND GASKET (WINDING : SS316/MICA INNER & OUTER RING : SS316) SIZE: 1/2 300LB THK 4.5MM Per PCS | 155 | UAE Dirham 7.66 | $2.09 |

Petromet Flange is Spiral wound gasket manufacturer in India, Contact us to get latest price list of Gasket Spiral Wound SS316, We are leading Supplier and Exporter of Carbon Steel Spiral Wound Gasket.

ASA 150/ 600 Carbon Steel Spiral Wound Gasket and Cgi Gasket manufacturer in Mumbai, 316L/ 304/ 309/310/ 316Ti/ 321 and 347 Stainless Steel Spiral Wound Gasket available in Style SG, RIR, HTX, CRIR, & SG/IR

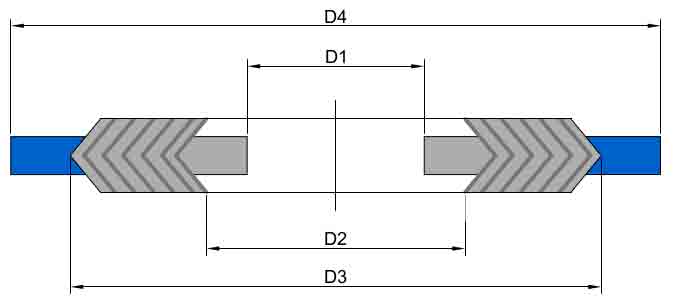

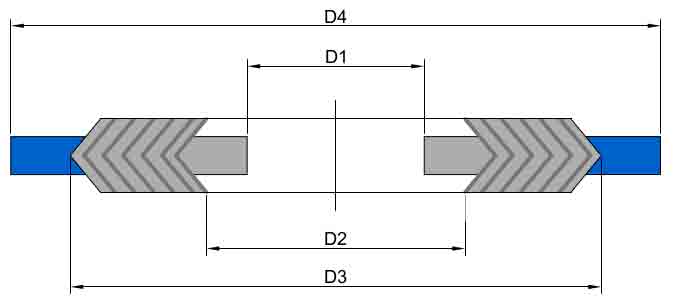

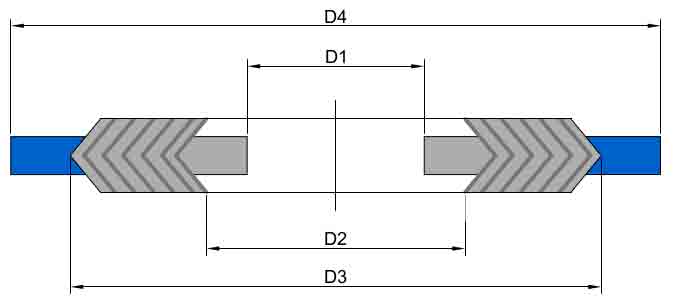

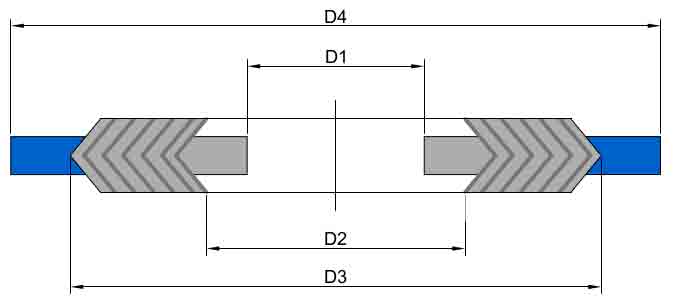

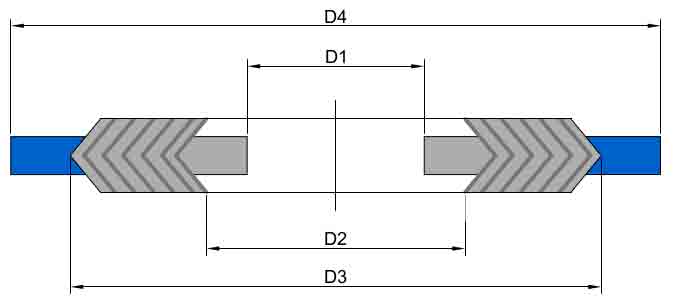

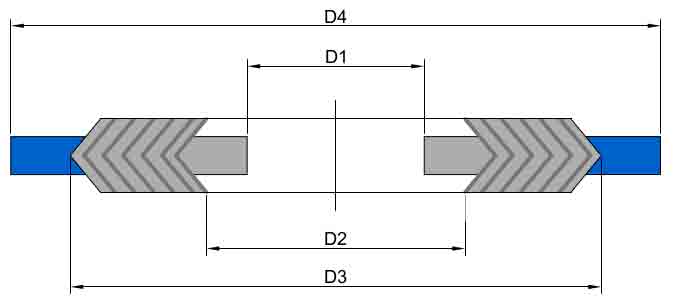

ASME B16.20 RTJ Gasket Dimensions

| NPS | Inner Ring | Sealing Element | Outer Ring | |

| d1 | d2 | d3 | d4 | |

| 1/2 | 14.2 | 19.1 | 31.8 | 47.8 |

| 3/4 | 20.6 | 25.4 | 39.6 | 57.2 |

| 1 | 26.9 | 31.8 | 47.8 | 66.8 |

| 1.1/4 | 38.1 | 47.8 | 60.5 | 76.2 |

| 1.1/2 | 44.5 | 54.1 | 69.9 | 85.9 |

| 2 | 55.6 | 69.9 | 85.9 | 104.9 |

| 2.1/2 | 66.5 | 82.6 | 98.6 | 124 |

| 3 | 81 | 101.6 | 120.7 | 136.7 |

| 4 | 106.4 | 127 | 149.4 | 174.8 |

| 5 | 131.8 | 155.7 | 177.8 | 196.9 |

| 6 | 157.2 | 182.6 | 209.6 | 222.3 |

| 8 | 215.9 | 233.4 | 263.7 | 279.4 |

| 10 | 268.2 | 287.3 | 317.5 | 339.9 |

| 12 | 317.5 | 339.9 | 374.7 | 409.7 |

| 14 | 349.3 | 371.6 | 406.4 | 450.9 |

| 16 | 400.1 | 422.4 | 463.6 | 514.4 |

| 18 | 449.3 | 474.7 | 527.1 | 549.4 |

| 20 | 500.1 | 525.5 | 577.9 | 606.6 |

| 24 | 603.3 | 628.7 | 685.8 | 717.6 |

Carbon Steel Spiral Wound Gasket Torque

| Nom.

Pipe Size |

Suggested Torque Value | ||||||

|---|---|---|---|---|---|---|---|

| Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 | |

| ½ | 47 | 47 | 47 | 65 | 65 | 65 | |

| ¾ | 60 | 70 | 70 | 93 | 93 | 93 | |

| 1 | 60 | 90 | 90 | 148 | 148 | 148 | |

| 1 ¼ | 60 | 105 | 105 | 242 | 242 | 282 | |

| 1 ½ | 60 | 170 | 170 | 351 | 351 | 385 | |

| 2 | 120 | 113 | 113 | 228 | 228 | 266 | |

| 2 ½ | 120 | 146 | 146 | 327 | 327 | 358 | |

| 3 | 120 | 200 | 200 | 318 | 449 | 496 | |

| 3 1/2 | 120 | 200 | 300 | 318 | 318 | ||

| 4 | 120 | 200 | 320 | 320 | 575 | 694 | 734 |

| 5 | 160 | 200 | 320 | 490 | 805 | 967 | 1282 |

| 6 | 200 | 200 | 320 | 490 | 661 | 867 | 1832 |

| 8 | 200 | 320 | 490 | 650 | 1003 | 1301 | 1648 |

| 10 | 320 | 490 | 710 | 875 | 915 | 2261 | 2486 |

| 12 | 320 | 710 | 1000 | 1000 | 1102 | 1941 | 3976 |

| 14 | 490 | 710 | 1000 | 1223 | 1164 | 2051 | |

| 16 | 490 | 835 | 1200 | 1335 | 1540 | 3420 | |

| 18 | 710 | 835 | 1360 | 1900 | 2971 | 4815 | |

| 20 | 710 | 1000 | 1605 | 1900 | 2800 | 5761 | |

| 24 | 1000 | 1200 | 2885 | 3000 | 4144 | 9294 | |

Stainless Steel Spiral Wound Gasket Thickness

- The nominal thickness of spiral wound gaskets is typically between 3.2 mm and 4.5 mm.

- A thickness of 4,5 mm is recommended for gaskets with diameters no greater than 1200 mm.

- For the diameter up to 1800 mm – 5,5 mm.

- Thicknesses of roughly 6.5 mm or 7 mm are more suitable for very large diameters (up to 4000 mm).

SS 304 Spiral Wound Gasket With or Without Inner Ring available in 2.5mm, 3.2 mm, 4.5 mm, 6.4 mm, 7.2 mm thicknesses For Flat Face Flange, check ASME B16.20 Gasket Spiral Wound SS316 dimensions and weight chart

ASME B16.20 Spiral Wound Gasket Pressure Rating

| Pressure Rating | 1,000-3,000 psi |

Spiral Wound Gasket With Inner Ring

The inner ring improves the gasket's axial rigidity and robustness. Its goal is to reduce turbulence in the flange area and to help avoid excessive compression owing to high seating stress in high-pressure service.

The advantages to using an inner ring include the following:

- Increases compression stop and blowout resistance.

- Prevents the accumulation of process fluid.

- Reduces erosion and turbulence

- Protects the gasket

- It prevents buckling and increases tightness.

Cgi Gasket Advantages

- Allows for a wide range of temperature variations.

- Allows for a wide variety of pressures

- Pipelines, Valves, Pumps, and Thermal Exchanges all use it.

Exporter & supplier of PN16/ PN25/ PN40 SS Spiral Wound Gasket and Type HTX Spiral Wound Gaskets for heat exchanger applications

Available Spiral Wound Gasket Shapes

| SWR | Spiral Wound Gasket without centering ring |

| SOR | Spiral Wound Gasket with centering ring. (Centering ring made of carbon steel stainless steel and other metals) |

| SIO | Spiral Wound Gasket with inner & outer rings. (Rings are made of carbon steel stainless steel and other metals) |

| SCD | Spiral Wound Gasket with centering device |

| SIOH | Spiral Wound Gasket with outer ring and inner rings supplied with bolt holes |

| SIR | Inner rings on a spiral wound gasket. (Stainless steel rings are most commonly used.) |

Spiral Wound Gasket Types

ASME B16.20 Spiral Wound Gasket

Type CR Spiral Wound Gaskets

Type R Graflex Faced Spiral Wound Gaskets

Spiral Wound Gasket Graphite Filler

PN40 SS Spiral Wound Gasket

Cgi Gasket

Spiral Wound Gasket With Inner Ring

Mica Spiral Wound Gaskets

PTFE Spiral Wound Gaskets

Spiral Wound Gasket Without Inner Ring

Gasket Spiral Wound SS 304

ASME B16.20 RTJ Gasket

graphite Spiral Wound Gaskets

Gasket Spiral Wound SS316

Spiral Wound Gasket For Flat Face Flange

Stainless Steel Spiral Wound Gasket

Carbon Steel Spiral Wound Gasket

Spiral Wound Gasket SS316 Graphite

Type R Spiral Wound Gaskets

Mica and Graphite Gasket

compressed fibre Spiral Wound Gaskets

Type RIR Spiral Wound Gaskets

SS Spiral Wound Gasket

Type CRIR Spiral Wound Gaskets

Nonas Spiral Wound Gaskets

SS 304 Spiral Wound Gasket

Type HTX Spiral Wound Gaskets

Weight Of Spiral Wound Gasket

| NPS | Weight |

|---|---|

| 1/2 | 1-1/2 oz |

| 3/4 | 2-1/2 oz |

| 1 | 2-1/2 oz |

| 1 1/4 | 3 oz |

| 1 1/2 | 4 oz |

| 2 | 4-1/2 oz |

| 2 1/2 | 6-1/2 oz |

| 3 | 7 oz |

| 4 | 9-1/2 oz |

| 5 | 12 oz |

| 6 | 1 lb |

| 8 | 1-1/2 lb |

| 10 | 1-3/4 lb |

| 12 | 2-1/4 lb |

| 14 | 3-1/2 lb |

| 16 | 4-1/4 lb |

| 18 | 5 lb |

| 20 | 6 lb |

| 22 | 6-3/4 lb |

| 24 | 7-1/2 lb |

| 30 | 10-1/2 lb |

| 36 | 12-1/2 lb |

| 42 | 14-1/2 lb |

| 48 | 16-1/2 lb |

Parts Of Spiral Wound Gasket

A spiral wound gasket consists of three elements:

- Outer ring: This outer ring, which is made of carbon steel, is also known as the centering ring or guide ring. When inserting a gasket into a bolted flange joint, it is used to centre the gasket.

- Inner ring: The inner ring is critical for the gasket because it prevents the windings inside the pipe from buckling. Parts of a gasket are pulled into the pipe when it buckles. Pieces of the gasket will normally move through the pipeline until they become entangled in something. They frequently become entangled around rotating equipment, such as a pump. The resulting mess is referred to as a "bird's nest." Inner rings assist you in avoiding this issue.

- Sealing element: The sealing element, as the name suggests, produces the seal that prevents leaks. Windings and filler material are both included in a sealing element. A flexible graphite filler material approved for high temperatures will be used in the majority of spiral wound gaskets used in oil and gas refineries.

Spiral Wound Gasket Compression

| Nom. ThicknessCompressed Thickness | |

| 2.5 mm(.098 in) | 1.9/2.1mm(.075/.085 in) |

| 3.2 mm(.125 in) | 2.4/2.6mm(.095/.105 in) |

| 4.5 mm(.175 in) | 3.2/3.45mm(.125/.135 in) |

| 6.4 mm(.250 in) | 4.6/4.8mm(.180/.190 in) |

| 7.3 mm(.285 in) | 4.7/4.9mm(.185/.195 in) |

What Are Spiral Wound Gaskets Used For

- Oil and Gas

- Offshore

- Pump and Valve

- Pharmaceutical

- Petrochemical

- Nuclear Energy

- Marine

Spiral Wound Gasket Filler Material

GRAPHITE

- To be used with hydrocarbons, oil, a variety of chemicals, and steam service.

- 450⁰C > 400 bar

PTFE

- Service of Oxygen Cleaning

- Almost all chemicals are resistant to it.

- 260⁰C > 100 bar

MICA

- Applications involving high temperatures and high pressures

- 1000⁰C >100 bar

Color Codes for Spiral Gasket Winding Materials

| Metallic Winding Material for Spiral Wound Gasket | Abbreviated Winding Material Name |

Color Code |

| Carbon steel | CRS | Silver |

| 304 SS | 304 | Yellow |

| 304 L SS | 304 L | No color |

| 309 SS | 309 | No color |

| 316 L SS | 316 L | Green |

| 347 SS | 347 | Blue |

| 321 SS | 321 | Turquoise |

| Monel 400 | MON | Orange |

| Nickel 200 | NI | Red |

| Titanium | TI | Purple |

| Hastelloy B | HAST B | Brown |

| Hastelloy C | HAST C | Beige |

Spiral Wound Gasket High Temperature

| Winding Materials | Temperature Range | Max PSI/BAR | PN Range |

| 304 Stainless Steel | min-250 max 550 °C | 650°C | 10-320 |

| 316L Stainless Steel | min - 100 max 550 °C | 800°C | 10-320 |

| 347 Stainless Steel | min -250 max 550 °C | 870°C | 10-320 |

| 321 Stainless Steel | min-250 max 550 °C | 870°C | 10-320 |

| Monel 400 | min -125 max 600 °C | 800°C | 10-320 |

| Nickel 200 | min - 250 max 600 °C | 600°C | 10-320 |

| Titanium | min - 250 max 350 °C | 450°C | 10-320 |

| Hastelloy B-2 | min - 200 max 450 °C | 500°C | 10-320 |

| Hastelloy C-276 | min -200 max 450 °C | 450°C | 10-320 |

| Inconel 600 | min - 100 max 950 °C | 1000°C | 10-320 |

| Incoloy 825 | min -100 max 450 °C | 450°C | 10-320 |

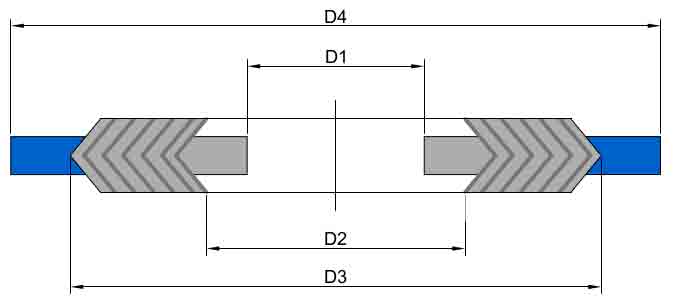

SS 304 Spiral Wound Gasket Installation

The Gasket Outer Ring fits within the Flange Bolts, putting the gasket in the centre of the raised face. The Outer Ring works as a compression stop, limiting over-compression of the sealing part and potentially causing 'blow-out.' The Inner Ring works as a shield against media attacks.

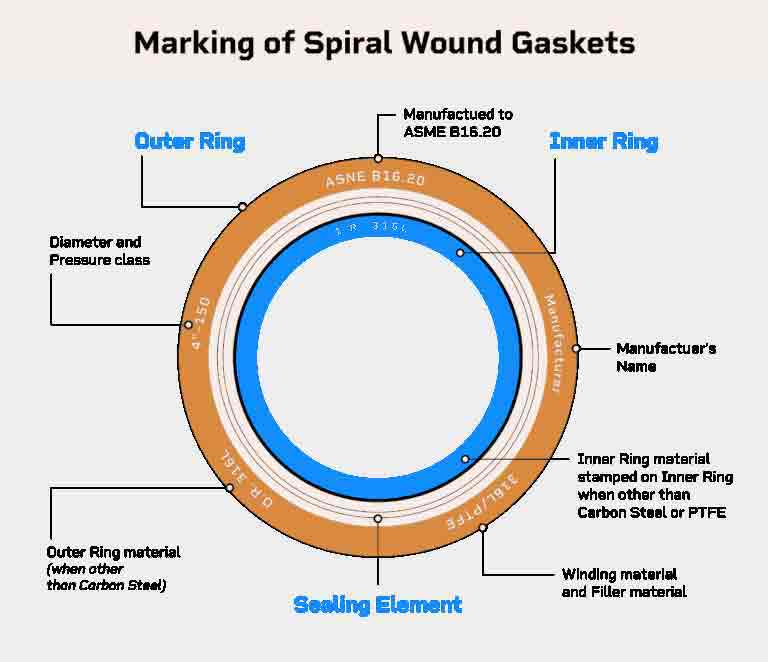

Spiral wound Gasket Dimensions For ASME B16.5 CLASS 150 Flanges

| NPS | Element | Sealing | Inner Ring | Outer Ring |

|---|---|---|---|---|

| Outside Dia (d3) | Inside Dia (d2) | Inside Dia (d1) | Outside Dia (d4) | |

| ½ | 31.8 | 19.1 | 14.2 | 47.8 |

| ¾ | 39.6 | 25.4 | 20.6 | 57.2 |

| 1 | 47.8 | 31.8 | 26.9 | 66.8 |

| 1¼ | 60.5 | 47.8 | 38.1 | 76.2 |

| 1½ | 69.9 | 54.1 | 44.5 | 85.9 |

| 2 | 85.9 | 69.9 | 55.6 | 104.9 |

| 2½ | 98.6 | 82.6 | 66.5 | 124.0 |

| 3 | 120.7 | 101.6 | 81.0 | 136.7 |

| 4 | 149.4 | 127.0 | 106.4 | 174.8 |

| 5 | 177.8 | 155.7 | 131.8 | 196.9 |

| 6 | 209.6 | 182.6 | 157.2 | 222.3 |

| 8 | 263.7 | 233.4 | 215.9 | 279.4 |

| 10 | 317.5 | 287.3 | 268.2 | 339.9 |

| 12 | 374.7 | 339.9 | 317.5 | 409.7 |

| 14 | 406.4 | 371.6 | 349.3 | 450.9 |

| 16 | 463.6 | 422.4 | 400.1 | 514.4 |

| 18 | 527.1 | 474.7 | 449.3 | 549.4 |

| 20 | 577.9 | 525.5 | 500.1 | 606.6 |

| 24 | 685.8 | 628.7 | 603.3 | 717.6 |

Spiral wound Gasket Dimensions For ASME B16.5 CLASS 300 Flanges

| NPS | Outer Ring | Sealing | Inner Ring | Element |

|---|---|---|---|---|

| Outside Dia (d4) | Inside Dia (d2) | Inside Dia (d1) | Outside Dia (d3) | |

| ½ | 54.1 | 19.1 | 14.2 | 31.8 |

| ¾ | 66.8 | 25.4 | 20.6 | 39.6 |

| 1 | 73.2 | 31.8 | 26.9 | 47.8 |

| 1 ¼ | 82.6 | 47.8 | 38.1 | 60.5 |

| 1 ½ | 95.3 | 54.1 | 44.5 | 69.9 |

| 2 | 111.3 | 69.9 | 55.6 | 85.9 |

| 2 | 130.3 | 82.6 | ½ 66.5 | 98.6 |

| 3 | 149.4 | 101.6 | 81.0 | 120.7 |

| 4 | 181.1 | 127.0 | 106.4 | 149.4 |

| 5 | 215.9 | 155.7 | 131.8 | 177.8 |

| 6 | 251.0 | 182.6 | 157.2 | 209.6 |

| 8 | 308.1 | 233.4 | 215.9 | 263.7 |

| 10 | 362.0 | 287.3 | 268.2 | 317.5 |

| 12 | 422.4 | 339.9 | 317.5 | 374.7 |

| 14 | 485.9 | 371.6 | 349.3 | 406.4 |

| 16 | 539.8 | 422.4 | 400.1 | 463.6 |

| 18 | 596.9 | 474.7 | 449.3 | 527.1 |

| 20 | 654.1 | 525.6 | 500.1 | 577.9 |

| 24 | 774.7 | 628.7 | 603.3 | 685.8 |

Spiral wound Gasket Dimensions For ASME B16.5 CLASS 600 Flanges

| NPS | Element | Sealing | Inner Ring | Outer Ring |

|---|---|---|---|---|

| Outside Dia (d3) | Inside Dia (d2) | Inside Dia (d1) | Outside Dia (d4) | |

| ½ | 31.8 | 19.1 | 14.2 | 54.1 |

| ¾ | 39.6 | 25.4 | 20.6 | 66.8 |

| 1 | 47.8 | 31.8 | 26.9 | 73.2 |

| 1 ¼ | 60.5 | 47.8 | 38.1 | 82.6 |

| 1 ½ | 69.9 | 54.1 | 44.5 | 95.3 |

| 2 | 85.9 | 69.9 | 55.6 | 111.3 |

| 2 ½ | 98.6 | 82.6 | 66.5 | 130.3 |

| 3 | 120.7 | 101.6 | 78.7 | 149.4 |

| 4 | 149.4 | 120.7 | 102.6 | 193.8 |

| 5 | 177.8 | 147.6 | 128.3 | 241.3 |

| 6 | 209.6 | 174.8 | 154.9 | 266.7 |

| 8 | 263.7 | 225.6 | 205.7 | 320.8 |

| 10 | 317.5 | 274.6 | 255.3 | 400.1 |

| 12 | 374.7 | 327.2 | 307.3 | 457.2 |

| 14 | 406.4 | 362.0 | 342.9 | 492.3 |

| 16 | 463.6 | 412.8 | 389.9 | 565.2 |

| 18 | 527.1 | 469.9 | 438.2 | 612.9 |

| 20 | 577.9 | 520.7 | 489.0 | 682.8 |

| 24 | 7 685.8 | 628. | 590.6 | 790.7 |

Spiral wound Gasket Dimensions For ASME B16.5 CLASS 900 Flanges

| NPS | Element | Outer Ring | Inner Ring | Sealing |

|---|---|---|---|---|

| Outside Dia (d3) | Outside Dia (d4) | Inside Dia (d1) | Inside Dia (d2) | |

| ½ | 31.8 | 63.5 | 14.2 | 19.1 |

| ¾ | 39.6 | 69.9 | 20.6 | 25.4 |

| 1 | 47.8 | 79.5 | 26.9 | 31.8 |

| 1¼ | 60.5 | 88.9 | 33.3 | 39.6 |

| 1½ | 69.9 | 98.6 | 41.4 | 47.8 |

| 2 | 85.9 | 143.0 | 52.3 | 58.7 |

| 2½ | 98.6 | 165.1 | 63.5 | 69.9 |

| 3 | 120.7 | 168.4 | 78.7 | 95.3 |

| 4 | 149.4 | 206.5 | 102.6 | 120.7 |

| 5 | 177.8 | 247.7 | 128.3 | 147.6 |

| 6 | 209.6 | 289.1 | 154.9 | 174.8 |

| 8 | 257.3 | 358.9 | 196.9 | 222.3 |

| 10 | 311.2 | 435.1 | 246.1 | 276.4 |

| 12 | 368.3 | 498.6 | 292.1 | 323.9 |

| 14 | 400.1 | 520.7 | 320.8 | 355.6 |

| 16 | 457.2 | 574.8 | 374.7 | 412.8 |

| 18 | 520.7 | 638.3 | 425.5 | 463.6 |

| 20 | 571.5 | 698.5 | 482.6 | 520.7 |

| 24 | 679.5 | 838.2 | 590.6 | 628.7 |

Spiral wound Gasket Dimensions For ASME B16.5 CLASS 1500 Flanges

| NPS | Element | Inner Ring | Outer Ring | Sealing |

|---|---|---|---|---|

| Outside Dia (d3) | Inside Dia (d1) | Outside Dia (d4) | Inside Dia (d2) | |

| ½ | 31.8 | 14.2 | 63.5 | 19.1 |

| ¾ | 39.6 | 20.6 | 69.9 | 25.4 |

| 1 | 47.8 | 26.9 | 79.5 | 31.8 |

| 1 ¼ | 60.5 | 33.3 | 88.9 | 39.6 |

| 1 ½ | 69.9 | 41.4 | 98.6 | 47.8 |

| 2 | 85.9 | 52.3 | 143.0 | 58.7 |

| 2 ½ | 98.6 | 63.5 | 165.1 | 69.9 |

| 3 | 120.7 | 78.7 | 174.8 | 92.2 |

| 4 | 149.4 | 97.8 | 209.6 | 117.6 |

| 5 | 177.8 | 124.5 | 254.0 | 143.0 |

| 6 | 209.6 | 147.3 | 282.7 | 171.5 |

| 8 | 257.3 | 196.9 | 352.6 | 215.9 |

| 10 | 311.2 | 246.1 | 435.1 | 266.7 |

| 12 | 368.3 | 292.1 | 520.7 | 323.9 |

| 14 | 400.1 | 320.8 | 577.9 | 362.00 |

| 16 | 457.2 | 374.7 | 641.4 | 406.4 |

| 18 | 520.7 | 425.5 | 704.9 | 463.6 |

| 20 | 571.5 | 476.3 | 755.7 | 514.4 |

| 24 | 679.5 | 577.9 | 901.7 | 616.0 |

Spiral wound Gasket Dimensions For ASME B16.5 CLASS 2500 Flanges

| NPS | Sealing | Outer Ring | Inner Ring | Element |

|---|---|---|---|---|

| Inside Dia (d2) | Outside Dia (d4) | Inside Dia (d1) | Outside Dia (d3) | |

| ½ | 19.1 | 69.9 | 14.2 | 31.8 |

| ¾ | 25.4 | 76.2 | 20.6 | 39.6 |

| 1 | 31.8 | 85.9 | 26.9 | 47.8 |

| 1 ¼ | 39.6 | 104.9 | 33.3 | 60.5 |

| 1 ½ | 47.8 | 117.6 | 41.4 | 69.9 |

| 2 | 58.7 | 146.0 | 52.3 | 85.9 |

| 2 ½ | 69.9 | 168.4 | 63.5 | 98.6 |

| 3 | 92.2 | 196.9 | 78.7 | 120.7 |

| 4 | 117.6 | 235.0 | 97.8 | 149.4 |

| 5 | 143.0 | 279.4 | 124.5 | 177.8 |

| 6 | 171.5 | 317.5 | 147.3 | 209.6 |

| 8 | 215.9 | 387.4 | 196.9 | 257.3 |

| 10 | 270.0 | 476.3 | 246.1 | 311.2 |

| 12 | 317.5 | 549.4 | 292.1 | 368.3 |

Other Products

Pipe Fittings Material

Flanges Material