- Call : +91 22 67436442

- exports@petrometflange.com

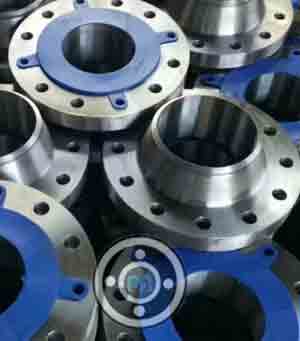

Inconel 625 Flanges

- Home /

- Inconel 625 Flanges

Alloy 625 Slip On Flanges & ASTM B564 UNS N06625 material manufacturer in India

What is Inconel 625 Flange?

The Inconel 625 is an abundantly used alloy material used in a wide range of industries. They are capable of handling mixed acids in both oxidizing and reducing environments. The Inconel 625 Flanges can withstand severely corrosive environments- they are resistant to general corrosion, pitting, and crevice corrosion. The material is prone to work-hardening, and hence it is essential that low cutting speeds are used on the material and also, the cutting tool should be kept engaged all the time.

Different types of Inconel 625 Flanges are available in the market. They are used for different purposes according to their structures. For example, the Inconel 625 Blind Flanges are used for blocking the flow whereas the Inconel 625 Slip-On Flanges are used in piping connection with low pressure and lesser risk of leakage.

The Inconel 625 Flanges are basically made of a chromium-nickel alloy that can resist corrosion. It consists of several other elements in the alloy which enhances its mechanical and physical properties. The flanges possess a very high tensile strength of 930 MPa, and 517 MPa is its minimum yield strength. It comes with a melting point of 1350 degrees C. Thus, it can be said that the flanges are used for high-temperature and stressful applications. The flanges are made following international standards like ANSI, ASME B16.5, B16.47 and others.

The Inconel 625 Flanges comes with various pressure classes that range from 150 to 2500, and the pressure number is between PN6 through PN64, and so on. Depending on the type of flange in use, they can be used in critical industries like pharmaceuticals, speciality chemicals, power generation, off-shore oil drilling, gas processing, etc.The 625 alloy shows excellent corrosion resistance properties in various medias, including environments that are highly acidic or in water. This is why the Inconel 625 Flanges are popularly used in the nuclear and marine industries.

The benefits of the Inconel 625 Flanges would include:

- Corrosion resistance

- Excellent mechanical properties at elevated temperatures.

- Gives great performances even in different acidic environments.

- Excellent stress corrosion cracking resistance capabilities.

ASTM B564 UNS N06625 Weld Neck Flanges v.s Alloy 625 Ring Type Joint Flange

The ASTM B564 UNS N06625 material is a nickel-molybdenum alloy that is known for its high strength and excellent corrosion resisting properties. The ASTM B564 UNS N06625 Weld Neck Flanges are high hub flanges that are mostly used for relocating the stress to the pipes. It also ensures to decrease a high stress of the concentration at the bottom of the pipe. The ASTM B564 UNS N06625 Weld Neck Flanges are mostly used in all types of severe and critical applications.

The Alloy 625 Ring Type Joint Flange is made of the same alloy and hence they oo are used in similar high pressure and high temperature environments. They are basically used when a metal-to-metal seal is required by the two mating flanges.

Nickel 625 Blind Flange v.s the ASME B16.5 Inconel 625 Slip on Flange

Both the Nickel 625 Blind Flange and the ASME B16.5 Inconel 625 Slip on Flange are made of the same alloy material and hence they are used in similar environments and also across similar industries. However, due to the difference in their structural configuration, their functions are quite different.

The blind flanges have no bore and they are used at the end of a pipe, pressure vessel or valve opening. They help in obstructing a segment of the pipe or nozzle that is not under use.

The slip on flange looks like a ring placed over the end of a pipe. It is then double welded, from both inside and outside to join with the pipe. They are used for not so critical applications for different fluid pipelines.

Why is DIN 2.4856 Flanges so hard to machine?

The Inconel 625 material has a very high tensile strength and high yield strength at high temperatures, which is much higher than normal stainless steel grades. This is why the DIN 2.4856 Flanges are so hard to machine.

Inconel 625 Flanges

KOC approved Inconel Flanges manufacturers in India offers wide selection of Nickel Alloy 625 Blind Flange and SB 564 UNS N06625 Weld Neck Flange in Mumbai

Table of Content

- Inconel 625 Flanges Standard Specification

- Alloy 625 Flange Dimensions

- Weight Of Nickel 625 Flanges

- Inconel Alloy 625 Weld Neck Flange Dimensions Table

- ASTM B564 UNS N06625 Blind Flange Dimensions

- Inconel 625 Slip On Flange Dimensions

- Inconel 625 Flanges Price List

- Corrosion Resistance of Nickel Alloy 625 Blind Flanges

- Ni Alloy 625 Flanges Crevice corrosion temperature

- Inconel 625 Flanges Pressure Rating

- Alloy 625 Flanges Chemical Composition

- Astm B564 UNS N06625 Flanges Mechanical Properties

- Inconel 625 BLRF Flanges Equivalent Grade

- Nickel 625 Flange Physical Properties

- Different Types of Inconel 625 Flanges

- Maximum Allowable Stress of DIN 2.4856 Flanges

- Heat Treatment of Inconel 2.4856 Flanges

- Thermal Expansion Coefficients for Alloy 625 Flanges

- Inconel UNS N06625 Flange Tests and Inspection

- Incoloy 625 Pipe Flanges Applications

Inconel 625 Flanges Standard Specification

| Size Range | 1/2″ to 48″ |

|---|---|

| Chart of Pressure Rating | 300 LBS, 2500 LBS, 1500 LBS, 900 LBS, 150 LBS, 600 LBS |

| Manufacturer of | GOST, JIS, ANSI, DIN, UNI, BS, AWWA, AS2129, SABS, NFE, EN etc. |

| JIS | 40 K, 16 K, 5K, 10 K, 30 K, 20 K, 63 K |

| Manufacturer of Connect / Flange Face Type | LJF, RF, RTJ, FF, Small Tongue, Large Tongue & Groove |

| DIN Pressure Calculation | 25Bar 40Bar 16Bar 6Bar 10Bar / PN64 PN10 PN25 PN16 PN6 PN40 |

| Equipment | Pushing Machine, Press machine, Sand-blasting machine, Bending machine, electric bevelling machine etc |

| Origin | Japan / West Europe / Indian / USA / Korean |

| Common Types By Manufacturer | Threaded / Screwed / Forged / Plate |

| UNI / EN | 16Bar 6Bar 40Bar 10Bar 25Bar |

| Test | Magnetic particle detector, X-ray detector, Ultrasonic flaw detector, Direct-reading Spectrograph, Hydrostatic testing machine |

| Coating | Zinc Plated, Anti-rust Paint, Yellow Transparent, Oil Black Paint, Cold and Hot Dip Galvanized |

| Standards Provided By Manufacturer | ISO70051, MSS S44, BS1560-3.1, API7S-43, B16.48, ANSI/ASME B16.5, B16.47 Series A & B, BS4504, JISB2220, ASME/ANSI B16.5/16.36/16.47A/16.47B, API605, BS 10, EN-1092, DIN, API7S-15, EN1092 |

| Production technique Used By Manufacturer | Heat treated, Forged and machined |

Leading Nickel Alloy 625 Flanges supplier, distributor, stockholders, importer, stockists, dealers, wholesalers, exporters and Manufacturer in Mumbai

Alloy 625 Flange Dimensions

| Size in Inch | RF Dia. | Size in mm | Machine Bolt Length | Flange Thickness | ISO Stud Size | PCD | No of Bolts | Bolt Size UNC | Outer Dia. | RF Height | RF Stud Length | Hole Size | Weight in kg |

| C | B | E | A | D | |||||||||

| 1/2 | 34.9 | 15 | 50 | 9.6 | M14 | 60.3 | 4 | 1/2 | 90 | 2 | 55 | 5/8 | 0.9 |

| 1 | 50.8 | 25 | 55 | 12.7 | M14 | 79.4 | 4 | 1/2 | 110 | 2 | 65 | 5/8 | 0.9 |

| 1 1/4 | 63.5 | 32 | 55 | 14.3 | M14 | 88.9 | 4 | 1/2 | 115 | 2 | 70 | 5/8 | 1.4 |

| 3/4 | 42.9 | 20 | 50 | 11.2 | M14 | 69.9 | 4 | 1/2 | 100 | 2 | 65 | 5/8 | 0.9 |

| 1 1/2 | 73 | 40 | 65 | 15.9 | M14 | 98.4 | 4 | 1/2 | 125 | 2 | 70 | 5/8 | 1.8 |

| 2 | 92.1 | 50 | 70 | 17.5 | M16 | 120.7 | 4 | 5/8 | 150 | 2 | 85 | 3/4 | 2.3 |

| 3 | 127 | 80 | 75 | 22.3 | M16 | 152.4 | 4 | 5/8 | 190 | 2 | 90 | 3/4 | 4.1 |

| 3 1/2 | 139.7 | 90 | 75 | 22.3 | M16 | 177.8 | 8 | 5/8 | 215 | 2 | 90 | 3/4 | 5.9 |

| 4 | 157.2 | 100 | 75 | 22.3 | M16 | 190.5 | 8 | 5/8 | 230 | 2 | 90 | 3/4 | 7.7 |

| 5 | 185.7 | 125 | 85 | 22.3 | M20 | 215.9 | 8 | 3/4 | 255 | 2 | 95 | 7/8 | 9.1 |

| 2 1/2 | 104.8 | 65 | 75 | 20.7 | M16 | 139.7 | 4 | 5/8 | 180 | 2 | 90 | 3/4 | 3.2 |

| 6 | 215.9 | 150 | 85 | 23.9 | M20 | 241.3 | 8 | 3/4 | 280 | 2 | 100 | 7/8 | 11.8 |

| 8 | 269.9 | 200 | 90 | 27 | M20 | 298.5 | 8 | 3/4 | 345 | 2 | 110 | 7/8 | 20.5 |

| 10 | 323.8 | 250 | 100 | 28.6 | M24 | 362 | 12 | 7/8 | 405 | 2 | 115 | 1 | 32 |

| 12 | 381 | 300 | 100 | 30.2 | M24 | 431.8 | 12 | 7/8 | 485 | 2 | 120 | 1 | 50 |

| 14 | 412.8 | 350 | 115 | 33.4 | M27 | 476.3 | 12 | 1 | 535 | 2 | 135 | 1 1/8 | 64 |

| 16 | 469.9 | 400 | 115 | 35 | M27 | 539.8 | 16 | 1 | 595 | 2 | 135 | 1 1/8 | 82 |

| 18 | 533.4 | 450 | 125 | 38.1 | M30 | 577.9 | 16 | 1 1/8 | 635 | 2 | 145 | 1 1/4 | 100 |

| 20 | 584.2 | 500 | 140 | 41.3 | M30 | 635 | 20 | 1 1/8 | 700 | 2 | 160 | 1 1/4 | 130 |

| 24 | 692.2 | 600 | 150 | 46.1 | M33 | 749.3 | 20 | 1 1/4 | 815 | 2 | 170 | 1 3/8 | 196 |

Weight Of Nickel 625 Flanges

| NPS (Nominal Pipe Size) | NPT (Threaded) | WRNR (Weld Neck) | SWRF (Socket Weld) | Loose (Lap Joint) | SORF (Slip On) | BLRF (Blind) |

|---|---|---|---|---|---|---|

| ½ | 1 | 2 | 2 | 1 | 1 | 2 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 |

| 1 | 2 | 3 | 2 | 2 | 2 | 2 |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 |

| 1½ | 3 | 4 | 3 | 3 | 3 | 4 |

| 2 | 5 | 6 | 5 | 5 | 5 | 5 |

| 2½ | 8 | 10 | 8 | 8 | 8 | 7 |

| 3 | 9 | 11.5 | 9 | 9 | 9 | 9 |

| 3½ | 12 | 12 | 11 | 11 | 11 | 13 |

| 4 | 13 | 16.5 | 13 | 13 | 13 | 17 |

| 5 | 15 | 21 | 15 | 15 | 15 | 20 |

| 6 | 19 | 26 | 19 | 19 | 19 | 27 |

| 8 | 30 | 42 | 30 | 30 | 30 | 47 |

| 10 | 43 | 54 | 43 | 43 | 43 | 70 |

| 12 | 64 | 88 | 64 | 64 | 64 | 123 |

| 14 | 90 | 114 | 90 | 105 | 90 | 140 |

| 16 | 98 | 140 | 98 | 140 | 106 | 180 |

| 18 | 130 | 165 | 130 | 160 | 130 | 220 |

| 20 | 165 | 197 | 165 | 195 | 165 | 285 |

| 22 | 185 | 225 | 185 | 245 | 185 | 355 |

| 24 | 220 | 268 | 220 | 275 | 220 | 430 |

Supply ASME B16.5 625 Inconel Socket Weld Flange and Class 150/ 300/ 600 DIN 2.4856 Forged Flange with Isolation and Hydrostatic Weld Testing

Inconel Alloy 625 Weld Neck Flange Dimensions Table

| Flange NPS | H | Inside Diameter |

Flat Face Thickness (T2) |

Outside Diameter |

Raised Face (RF) |

Raised Face (R) |

H1 | Raised Face Thickness (T) |

T1 | Bolt Circle (BC) |

Bolt Hole (B) |

No. of Bolt Holes |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2" | 1.19" | 0.62" | 1.82" | 3.50" | .063" | 1.38" | 0.84" | 1.88" | .38" | 2.38" | .62" | 4 |

| 1-1/4" | 2.31" | 1.38" | 2.19" | 4.62" | .063" | 2.50" | 1.66" | 2.25" | .56" | 3.50" | .62" | 4 |

| 3/4" | 1.50" | 0.82" | 2.00" | 3.88" | .063" | 1.69" | 1.05" | 2.06" | .44" | 2.75" | .62" | 4 |

| 1-1/2" | 2.56" | 1.61" | 2.38" | 5.00" | .063" | 2.88" | 1.90" | 2.44" | .62" | 3.88" | .62" | 4 |

| 1" | 1.94" | 1.05" | 2.13" | 4.25" | .063" | 2.00" | 1.32" | 2.19" | .50" | 3.12" | .62" | 4 |

| 2" | 3.06" | 2.07" | 2.44" | 6.00" | .063" | 3.62" | 2.38" | 2.50" | .69" | 4.75" | .75" | 4 |

| 2-1/2" | 3.56" | 2.47" | 2.69" | 7.00" | .063" | 4.12" | 2.88" | 2.75" | .82" | 5.50" | .75" | 4 |

| 3" | 4.25" | 3.07" | 2.69" | 7.50" | .063" | 5.00" | 3.50" | 2.75" | .88" | 6.00" | .75" | 4 |

| 4" | 5.31" | 4.03" | 2.94" | 9.00" | .063" | 6.19" | 4.50" | 3.00" | .88" | 7.50" | .75" | 8 |

| 5" | 6.44" | 5.05" | 3.44" | 10.00" | .063" | 7.31" | 5.56" | 3.50" | .88" | 8.50" | .88" | 8 |

| 3-1/2" | 4.81" | 3.55" | 2.75" | 8.50" | .063" | 5.50" | 4.00" | 2.81" | .88" | 7.00" | .75" | 8 |

| 6" | 7.56" | 6.07" | 3.44" | 11.00" | .063" | 8.50" | 6.63" | 3.50" | .94" | 9.50" | .88" | 8 |

| 8" | 9.69" | 7.98" | 3.94" | 13.50" | .063" | 10.62" | 8.63" | 4.00" | 1.06" | 11.75" | .88" | 8 |

| 22" | 24.25" | 21.25" | 5.82" | 29.50" | .063" | 25.25" | 22.00" | 5.88" | 1.75" | 27.25" | 1.38" | 20 |

| 10" | 12.00" | 10.02" | 3.94" | 16.00" | .063" | 12.75" | 10.75" | 4.00" | 1.13" | 14.25" | 1.00" | 12 |

| 12" | 14.38" | 12.00" | 4.44" | 19.00" | .063" | 15.00" | 12.75" | 4.50" | 1.19" | 17.00" | 1.00" | 12 |

| 16" | 18.00" | 15.25" | 4.94" | 23.50" | .063" | 18.50" | 16.00" | 5.00" | 1.38" | 21.25" | 1.12" | 16 |

| 18" | 19.88" | 17.25" | 5.44" | 25.00" | .063" | 21.00" | 18.00" | 5.50" | 1.50" | 22.75" | 1.25" | 16 |

| 14" | 15.75" | 13.25" | 4.94" | 21.00" | .063" | 16.25" | 14.00" | 5.00" | 1.32" | 18.75" | 1.12" | 12 |

| 20" | 22.00" | 19.25" | 5.63" | 27.50" | .063" | 23.00" | 20.00" | 5.69" | 1.63" | 25.00" | 1.25" | 20 |

| 24" | 26.12" | 23.25" | 5.94" | 32.00" | .063" | 27.25" | 24.00" | 6.00" | 1.82" | 29.50" | 1.38" | 20 |

ASTM B564 UNS N06625 Blind Flange Dimensions

| Size in Inch | Size in mm | ISO Stud Size | RF Height | Outer Dia. | RF Dia. | Hole Size | PCD | No of Bolts | Bolt Size UNC | Flange Thickness | RF Stud Length | Weight in kg |

| D | A | C | E | B | ||||||||

| 1/2 | 15 | M20 | 7 | 135 | 34.9 | 7/8 | 88.9 | 4 | 3/4 | 30.2 | 120 | 3.2 |

| 3/4 | 20 | M20 | 7 | 140 | 42.9 | 7/8 | 95.2 | 4 | 3/4 | 31.8 | 125 | 3.7 |

| 1 | 25 | M24 | 7 | 160 | 50.8 | 1 | 108 | 4 | 7/8 | 35 | 140 | 5 |

| 1 1/4 | 32 | M27 | 7 | 185 | 63.5 | 1 1/8 | 130.2 | 4 | 1 | 38.1 | 150 | 7.8 |

| 1 1/2 | 40 | M30 | 7 | 205 | 73 | 1 1/4 | 146 | 4 | 1 1/8 | 44.5 | 170 | 10.5 |

| 2 | 50 | M27 | 7 | 235 | 92.1 | 1 1/8 | 171.4 | 8 | 1 | 50.9 | 180 | 18 |

| 2 1/2 | 65 | M30 | 7 | 265 | 104.8 | 1 1/4 | 196.8 | 8 | 1 1/8 | 57.2 | 195 | 25.5 |

| 3 | 80 | M33 | 7 | 305 | 127 | 1 3/8 | 228.6 | 8 | 1 1/4 | 66.7 | 220 | 39 |

| 4 | 100 | M39 | 7 | 355 | 157.2 | 1 5/8 | 273 | 8 | 1 1/2 | 76.2 | 255 | 61.5 |

| 5 | 125 | M45 | 7 | 420 | 185.7 | 1 7/8 | 323.8 | 8 | 1 3/4 | 92.1 | 300 | 102 |

| 6 | 150 | M52 | 7 | 485 | 215.9 | 2 1/8 | 368.3 | 8 | 2 | 108 | 345 | 157 |

| 8 | 200 | M52 | 7 | 550 | 269.9 | 2 1/8 | 438.2 | 12 | 2 | 127 | 380 | 241 |

| 10 | 250 | M64 | 7 | 675 | 323.8 | 2 5/8 | 539.8 | 12 | 2 1/2 | 165.1 | 490 | 470 |

| 12 | 300 | M72 | 7 | 760 | 381 | 2 7/8 | 619.1 | 12 | 2 3/4 | 184.2 | 540 | 575 |

Bulk discount on flat/ raised face Gost 12815 Inconel 625 UNS N06625 Orifice Flanges and Alloy 625 Lap Joint Flange in Asia

Inconel 625 Slip On Flange Dimensions

| Size in Inch | Size in mm | No of Bolts | Outer Dia. | Hub OD | ISO Stud Size | Flange Length | RF Height | Flange Thick. | RF Dia. | PCD | Hole Size | Socket Bore | Weight in kg |

| A | C | D | F | B | E | G | H | ||||||

| 1/2 | 15 | 4 | 90 | 30 | M14 | 14 | 2 | 9.6 | 34.9 | 60.3 | 5/8 | 22.2 | 0.8 |

| 1 | 25 | 4 | 110 | 49 | M14 | 16 | 2 | 12.7 | 50.8 | 79.4 | 5/8 | 34.5 | 0.9 |

| 3/4 | 20 | 4 | 100 | 38 | M14 | 14 | 2 | 11.2 | 42.9 | 69.9 | 5/8 | 27.7 | 0.9 |

| 1 1/4 | 32 | 4 | 115 | 59 | M14 | 19 | 2 | 14.3 | 63.5 | 88.9 | 5/8 | 43.2 | 1.4 |

| 2 | 50 | 4 | 150 | 78 | M16 | 24 | 2 | 17.5 | 92.1 | 120.7 | 3/4 | 61.9 | 2.3 |

| 1 1/2 | 40 | 4 | 125 | 65 | M14 | 21 | 2 | 15.9 | 73 | 98.4 | 5/8 | 49.5 | 1.4 |

| 2 1/2 | 65 | 4 | 180 | 90 | M16 | 27 | 2 | 20.7 | 104.8 | 139.7 | 3/4 | 74.6 | 3.2 |

| 3 | 80 | 4 | 190 | 108 | M16 | 29 | 2 | 22.3 | 127 | 152.4 | 3/4 | 90.7 | 3.7 |

| 4 | 100 | 8 | 230 | 135 | M16 | 32 | 2 | 22.3 | 157.2 | 190.5 | 3/4 | 116.1 | 5.9 |

| 3 1/2 | 90 | 8 | 215 | 122 | M16 | 30 | 2 | 22.3 | 139.7 | 177.8 | 3/4 | 103.4 | 5 |

| 5 | 125 | 8 | 255 | 164 | M20 | 35 | 2 | 22.3 | 185.7 | 215.9 | 7/8 | 143.8 | 6.8 |

| 8 | 200 | 8 | 345 | 246 | M20 | 43 | 2 | 27 | 269.9 | 298.5 | 7/8 | 221.5 | 13.7 |

| 10 | 250 | 12 | 405 | 305 | M24 | 48 | 2 | 28.6 | 323.8 | 362 | 1 | 276.2 | 19.5 |

| 6 | 150 | 8 | 280 | 192 | M20 | 38 | 2 | 23.9 | 215.9 | 241.3 | 7/8 | 170.7 | 8.6 |

| 12 | 300 | 12 | 485 | 365 | M24 | 54 | 2 | 30.2 | 381 | 431.8 | 1 | 327 | 29 |

| 24 | 600 | 20 | 815 | 663 | M33 | 81 | 2 | 46.1 | 692.2 | 749.3 | 1 3/8 | 616 | 100 |

| 16 | 400 | 16 | 595 | 457 | M27 | 62 | 2 | 35 | 469.9 | 539.8 | 1 1/8 | 410.5 | 54 |

| 18 | 450 | 16 | 635 | 505 | M30 | 67 | 2 | 38.1 | 533.4 | 577.9 | 1 1/4 | 461.8 | 59 |

| 14 | 350 | 12 | 535 | 400 | M27 | 56 | 2 | 33.4 | 412.8 | 476.3 | 1 1/8 | 359.2 | 41 |

| 20 | 500 | 20 | 700 | 559 | M30 | 71 | 2 | 41.3 | 584.2 | 635 | 1 1/4 | 513.1 | 75 |

Inconel 625 Flanges Price List

| Inconel 625 Flanges Price Per Piece in India | Inconel 625 Flanges Price in INR | Inconel 625 Pipe Flanges Price in UAE Dirham | Inconel 625 Flange Price in USD |

| Inconel 625 Flange, Size: 10 X 300 Lb Rtj Per Kg | 3,219 | UAE Dirham 156.95 | $42.73 |

| Inconel 625 Flanges 2 Bl 2500 Pound Per Piece | 49,824 | UAE Dirham 2429.33 | $661.42 |

| Inconel 625 Blind Flanges 2 Class 300 Per Piece | 19,599 | UAE Dirham 955.61 | $260.18 |

| Inconel 625 Flanges 16api 10000 # Rtj Per Piece | 44,659 | UAE Dirham 2177.49 | $592.85 |

Petromet Flange Inc is of Inconel 625 Pipe Flanges Manufacturer in India as per ASME B16.5 Standards. ASTM B564 UNS N06625 Flanges Offer are used for various industries applications. This is an approximate Price of Inconel 625 Flanges in India.

Corrosion Resistance of Nickel Alloy 625 Blind Flanges

Alloy |

Quiet | Flowing, 2 ft/sec | ||||

| Weight Loss, g | Range of Pit Depth, mils | Weight Loss, g | Range of Pit Depth, mils | |||

| Panel | Crevice Area | Panel | Crevice Area | |||

625 |

Nil | Nil | Nil | 0.25 | Nil | Nil |

Ni Alloy 625 Flanges Crevice corrosion temperature

| Alloy | UNS No. | Molybdenum Content | °C | °F | Pitting Resistance Equivalent, (PRE)N |

| 625 | N06625 | 9.0 | 45 | 113 | 51 |

Inconel 625 Flanges Pressure Rating

| Temperature °F | Class 150 | Class 600 | Class 1500 | Class 400 | Class 900 | Class 300 | Class 2500 |

| -20 to 100 | 275 | 1440 | 3600 | 960 | 2160 | 720 | 6000 |

| 300 | 205 | 1080 | 2700 | 720 | 1620 | 540 | 4500 |

| 200 | 230 | 1200 | 3000 | 800 | 1800 | 600 | 5000 |

| 400 | 190 | 995 | 2485 | 660 | 1490 | 495 | 4140 |

| 600 | 140 | 875 | 2185 | 580 | 1310 | 435 | 3640 |

| 650 | 125 | 860 | 2150 | 575 | 1290 | 430 | 3580 |

| 500 | 170 | 930 | 2330 | 620 | 1395 | 465 | 3880 |

| 700 | 110 | 850 | 2125 | 565 | 1275 | 425 | 3540 |

| 750 | 95 | 830 | 2075 | 555 | 1245 | 415 | 3460 |

| 850 | 65 | 790 | 1980 | 530 | 1190 | 395 | 3300 |

| 800 | 80 | 805 | 2015 | 540 | 1210 | 405 | 3360 |

| 900 | 50 | 780 | 1945 | 520 | 1165 | 390 | 3240 |

| 950 | 35 | 765 | 1910 | 510 | 1145 | 380 | 3180 |

| 1000 | 20 | 640 | 1605 | 430 | 965 | 320 | 2675 |

| 1100 | 20 | 515 | 1285 | 345 | 770 | 255 | 2145 |

| 1150 | 20 | 400 | 995 | 265 | 595 | 200 | 1655 |

| 1050 | 20 | 615 | 1545 | 410 | 925 | 310 | 2570 |

| 1200 | 20 | 310 | 770 | 205 | 465 | 155 | 1285 |

| 1250 | 20 | 225 | 565 | 150 | 340 | 115 | 945 |

| 1300 | 20 | 170 | 430 | 115 | 255 | 85 | 715 |

| 1400 | 20 | 95 | 240 | 65 | 145 | 50 | 400 |

| 1350 | 20 | 125 | 310 | 80 | 185 | 60 | 515 |

| 1450 | 15 | 70 | 170 | 45 | 105 | 35 | 285 |

| 1500 | 10 | 55 | 135 | 35 | 80 | 25 | 230 |

Alloy 625 Flanges Chemical Composition

| Grade | C | Mn | Si | Fe | S | Cr2 | Al-Ti | Ni | |

| 625 | min. | – | – | – | – | – | 20.0 | – | 58.0 |

| max. | 0.10 | 0.50 | 0.50 | 5.0 | 0.015 | 23.0 | 0.40 | – | |

Astm B564 UNS N06625 Flanges Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 625 | Psi – 1,35,000 , MPa -930 | Psi – 75,000 , MPa – 517 | 42.5 | – | – |

Inconel 625 BLRF Flanges Equivalent Grade

| Grade | UNS No | Old British | Euronorm | GOST | Japanese JIS | ||

| BS | En | No | AFNOR | ||||

| Inconel 625 | N06625 | NA 21 | NiCr22Mo9Nb | 2.4856 | NC22DNB4M | ХН75МБТЮ | NCF 625 |

Nickel 625 Flange Physical Properties

| Density | Melting Range | Specific Heat | Permeability at 200 Oersted | Curie Temperature | |||

|---|---|---|---|---|---|---|---|

| lb/cu in | gram/cc | °F | °C | Btu/lb°F (J/kg°C) 70°F(21°C) |

15.9 kA/m | °F | °C |

| 0.305 | 8.44 | 2350-2460 | 1290-1350 | 0.098(410) | 1.0006 | <-320 | -196 |

Check EN 1092-2 PN10 SB 564 UNS N06625 Spectacle Blind, Alloy 625 Long Weld Neck Flange, Inconel 625 Threaded Flange and DIN 2.4856 Plate Flange torque specs & price in Mumbai

Different Types of Inconel 625 Flanges

Alloy 625 Flanges

ASTM B564 UNS N06625 Weld Neck Flanges

Inconel Alloy 625 Socket Weld Flange

150 LBS Inconel 625 Uns N06625 Long Weld Neck Flange

JIS NCF 625 SORF Flanges

900 LBS Inconel UNS N06625 WNRF Flange

UNS N06625 Screwed Flange

15 NB DIN 2.4856 Lapped Joint Flange

625 Inconel Girth Flanges

300 LBS Nickel Inconel 625 BLRF Flanges

Alloy 625 Reducing Flanges

1500 LBS Ni alloy 625 Threaded Flange

ASTM B564 UNS N06625 Slip On Flange

Nickel 625 Tongue & Groove Flange

Inconel 625 Uns N06625 Nipoflange

600 LBS ASME B16.5 Inconel 625 Blind Flange

Inconel 2.4856 Weld Neck Flanges

2500 LBS Nickel Alloy 625 Orifice Flanges

Werkstoff Nr. 2.4856 Expander Flanges

5000 NB Inconel Alloy 625 Uns N06625 Ring Joint Flange

Inconel 625 SWRF Flanges

ASTM B564 UNS N06625 Spectacle Blind Flange

JIS NCF 625 RTJ Flange

Nickel Alloy 625 Slip on Raised Face Flange

Maximum Allowable Stress of DIN 2.4856 Flanges

| *Temp. | *MAS | *Temp. | *MAS |

|---|---|---|---|

| -20~100 | 26.7 | 1000 | 19.6 |

| 200 | 24.6 | 1050 | 19.5 |

| 300 | 23.4 | 1100 | 19.4 |

| 400 | 22.4 | 1150 | 19.3 |

| 500 | 21.7 | 1200 | 19.3 |

| 600 | 21.0 | 1250 | 15.0 |

| 650 | 20.8 | 1300 | 11.6 |

| 700 | 20.5 | 1350 | 8.5 |

| 750 | 20.3 | 1400 | 6.7 |

| 800 | 20.1 | 1450 | 4.9 |

| 850 | 20.0 | 1500 | 3.8 |

| 900 | 19.8 | 1550 | 2.6 |

| 950 | 19.7 | 1600 | 1.9 |

Heat Treatment of Inconel 2.4856 Flanges

- High Solution Anneal - 2000/2200°F (1093/1204°C), air quench or faster.

- Low Solution Anneal - 1700/1900°F (927/1038°C), air quench or faster.

- Stress Relieve - 1650°F (899°C), air quench.

Thermal Expansion Coefficients for Alloy 625 Flanges

| Temp. | Coefficient A | Coefficient B | Coefficient C |

|---|---|---|---|

| 70 | 6.7 | 6.7 | 0 |

| 100 | 6.9 | 6.8 | 0.2 |

| 150 | 7.2 | 7.0 | 0.7 |

| 200 | 7.4 | 7.1 | 1.1 |

| 250 | 7.4 | 7.2 | 1.6 |

| 300 | 7.5 | 7.2 | 2.0 |

| 350 | 7.5 | 7.3 | 2.4 |

| 400 | 7.5 | 7.3 | 2.9 |

| 450 | 7.5 | 7.3 | 3.3 |

| 500 | 7.5 | 7.4 | 3.8 |

Inconel UNS N06625 Flange Tests and Inspection

- Magnetic particle detector

- Direct-reading Spectrograph

- Hardness Test

- X-ray detector

- Hydrostatic testing machine

- Flaring Test

- Pitting Resistance Test

- Flattening Test

- PMI Testing

- UI trasonic flaw detector

Incoloy 625 Pipe Flanges Applications

- Oil And Gas Industry

- Fossil Fuel Power Plants

- Nuclear Power

- Paper & Pulp

- Ship Building

- Marine Applications

- Refineries

- Power Plants

Flanges Material

Pipe Fittings Material

Other Products