- Call : +91 22 67436442

- exports@petrometflange.com

Pipe Outlet Fittings manufacturer in India

- Home /

- Pipe Outlet Fittings

ASTM A105 Welding Outlets and Carbon Steel MSS Sp 97 Elbow Outlets supplier in Mumbai

What is ASTM A105 Welding Outlets?

The ASTM A105 material grades are mainly used in pressure systems both at ambient and elevated temperatures. It is the most commonly used carbon steel material.

The Welding Outlets is a buttweld connection fitting that comes with branches attached to an outlet pipe. The ASTM A105 Welding Outlets is primarily used to minimize the stress due to concentration in the given area of the piping system. The given material grade is very subtle and can be used for manufacturing efficient piping outlets. The alloy contains carbon, chromium, and nickel in the chemical composition, making the fitting very durable. Thus, the ASTM A105 Welding Outlets has a very long service life.

The ASTM A105 Forged Welding Outlets is used in a wide range of applications that take place in various less critical environments. It is available in customized dimensions, and hence can be made according to the specific requirements. It is available in different pressure ratings and specifications. The unique properties of the ASTM A105 Welding Outlets make them perfect to be used in different applications in the construction, power, and petroleum industries.

Carbon Steel A105 Insert Outlet Vs A105N Carbon Steel Forged Welding Outlets

The Carbon Steel A105 Insert Outlet can be described as a contoured branch connection that is used in various less critical applications. It is a buttwelded connection that helps to meet specific reinforcement requirements.

The A105N Carbon Steel Forged Welding Outlets is used for creating an outlet from the run pipe to the branch pipe. In other words, they help to branched connections in the pipe length.

SA105 Welding Outlets vs Carbon Steel SA105 Socket Weld Outlets

The main difference between SA105 Welding Outlets and the Carbon Steel SA105 Socket Weld Outlets is that the Welding Outlets is a buttweld fitting whereas the Socket Weld Outlets belongs to the family of socket fittings. They are available in different pressure classes.

The Carbon Steel SA105 Socket Weld Outlets is used with smaller pipe diameters, in lower pressure applications compared to the SA105 Welding Outlets.

The Welding Outlets and the Socket Weld Outlets majorly differ in their branch connections.

What is A105 Welding Outlets welding?

The A105 Welding Outlets is a buttweld fittings that are connected to the run pipe with the help of filler welds.

What is Elbow Outlets?

The Elbow Outlets can be defined as a branch pipe fitting which is self-reinforced. They are mainly used on long -radius elbows as they help in instrument connections like thermowell. They can also be used with short radius elbows that come with 180 degree returns. They are available with threaded ends, socket weld end, and butt type end. They are also present in standard weight, extra strong, and double extra strong. Elbow Outlets is developed and is a registered trademark of the company Bonney Forge.

The Elbow Outlets is mainly used for 90 degree connections and they are available in different pressure classes, like 3000# and 6000#. .They are made from different materials, and their features depend on the chemical composition. Their standard, grade, and specification also varies accordingly. The dimensions of the Elbow Outlets can be customized according to the specific requirements.

Carbon Steel Elbow Outlets Fitting Vs Alloy Steel Elbow Outlets

The carbon steel Elbow Outlets primarily consists of carbon, iron, and other alloying elements in trace amounts. Whereas the alloy steel Elbow Outlets has a high content of various alloying elements present.

The carbon steel Elbow Outlets is hard, but it lacks ductility, weldability, and a low melting. But as the carbon content increases, the properties of the Elbow Outlets improves a bit. That is why high carbon steel Elbow Outlets are better than the low carbon steel variant.

Talking about the alloy steel Elbow Outlets, they have enhanced properties like improved hardness, ductility, weldability and resistance to corrosion, due to the chemical composition. And thus, the alloy steel Elbow Outlets can be used in more critical situations compared to the carbon steel variant.

What is Stainless Steel Elbow Outlets Standards?

The manufacturing standards of Elbow Outlets are as follows:

- ASTM A182 or ASME SA182 – This is the Standard Specification for Wrought Austenitic Stainless Steel Pipe Fittings

- ASME B16.11 – This for Forged Fittings that consist of both Socket – Weld and Threaded connections

- MSS SP-97 – This is for the Reinforced Forged Branch Elbow Outlets that consists of Buttwelding ,Socket Welding, and Threaded End

How To Buy Elbow Outlets Fitting

Before buying Elbow Outlets, it is essential to confirm:

- The quality of raw material used for making the product.

- Dimensional requirements and accuracy.

- Material specification and grade.

- Manufacturing standard.

- Delivery timeline.

- Efficiency in packaging.

- Pricing.

Confirming these points will help the clients get their hands on the best product, which they purchased to meet specific requirements.

Difference between Elbow Outlets Vs Lateral Outlets

The Elbow Outlets is primarily used with 90 degrees long radius elbows or 180 degrees short radius elbows, for instrumentation and thermowell connections.

The Lateral Outlets is a buttweld fitting that is used for 45 degrees or any other specific degrees for lateral connections. They can help to meet some specific reinforcement requirements.

Pipe Outlet Fittings manufacturer in India

Class 3000/ 6000 ASTM A105 Reducing/ Barred Welding Outlets and SA105 Steel Threaded Elbow Outlets Fitting supplier in Mumbai

Table of Content

- Standard Specification of Pipe Outlet Fittings

- ASME B31.3 Welding Outlets Dimensions

- Reducing Welding Outlets Sizes

- Threaded Welding Outlets Dimensions

- Insert Outlet Dimensions And Sizes

- Price List of Pipe Outlet Fittings

- MSS Sp 97 Elbow Outlets Dimensions

- Dimensions Reducing Socket Weld Outlets – MSS SP97

- Dimensions Reducing Threaded Outlets – MSS SP97

- Outlet Pipe Fittings Classes

- Dimensions of Nipple Outlet

- MSS SP-97 Outlets Grades and types

- Difference Between Welding Outlets and Sweep Outlet

- Pipe Outlet Fittings Types

- How To Order Outlet Fittings?

- Features of ASTM A105 Welding Outlets

- What is Lateral Welding Outlets?

- What is the difference between a Welding Outlets and a Socket Weld Outlets?

- Pipe Coupling VS Pipe Outlet Fittings

- Industrial Application of Threaded Elbow Outlets

Standard Specification of Pipe Outlet Fittings

| Type | Pipe Outlets / Pipe Welding Outlets |

|---|---|

| Pattern | Welding Outlets, Threaded Outlets, Socket Outlets, Lateral Outlets etc. |

| Specialized in | Insert Outlet |

| Pressure class | 3000/6000/9000LBS (Sch80/Xs Sch40, Sch160 Xxs) |

| size | 1/8”-4” |

| Manufacturing standards | ANSI/ASME B16.11 / MSS-SP-83 / MSS-SP-79 / MSS-SP-95 / MSS-SP-97 |

| Producing Standard | ANSI/ASME B16.11, MSS SP 97, NPT B2.1, BSPP, BSPT, JB STANDARD, BS STANDARD, DIN STANDARD, ETC |

| Corrosion Standard | NACE MR 0175, ISO-1516 |

| Nominal Pressure Provided By Manufacturer | CLASS 125, CLASS 150, CLASS 300, CLASS 400, CLASS 600, CLASS 800, CLASS 900, CLASS 1500, CLASS3000, CLASS 6000, ETC |

| Outside Diameter | 1/4" TO 48" |

| Painting Provided by Manufacturer | ANTI-RUST PAINT, OR AS PER CUSTOMER'S REQUIREMENT |

| Heat Treatment | AS PER MATERIAL STANDARD |

| Dimension Accuracy | -1%, +1% |

| APPLICATION | GAS SECTOR, OIL SECTOR, FERTILIZER SECTOR, CHEMICAL SECTOR, ETC |

Are you looking for ASTM A105 Welding Outlets importer, distributor, dealers, supplier, stockholders, stockists, wholesalers, exporters and Manufacturer in Mumbai.

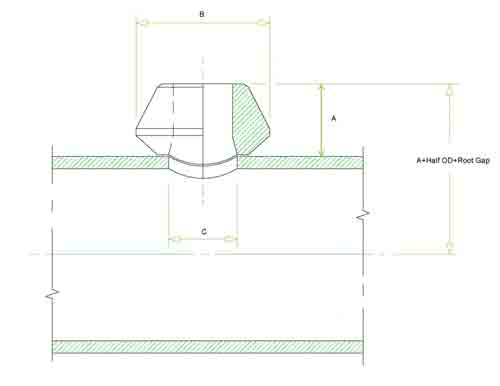

ASME B31.3 Welding Outlets Dimensions

| Size | Size in mm | Height A | OD -B | Hole Dia C | Weight in KG |

|---|---|---|---|---|---|

| 1/4 | 8 | 14.3 | 25.4 | 15.9 | 0.04 |

| 3/8 | 10 | 19.05 | 31.75 | 19.05 | 0.07 |

| 1/2 | 15 | 19.05 | 34.93 | 23.81 | 0.08 |

| 3/4 | 20 | 22.23 | 44.45 | 30.16 | 0.11 |

| 1 | 25 | 26.99 | 53.98 | 36.51 | 0.23 |

| 1 1/4 | 32 | 31.75 | 65.09 | 44.45 | 0.36 |

| 1 1/2 | 40 | 33.34 | 73.03 | 50.8 | 0.45 |

| 2 | 50 | 38.1 | 88.9 | 65.09 | 0.79 |

| 2 1/2 | 65 | 41.28 | 103.19 | 76.2 | 1.13 |

| 3 | 80 | 44.45 | 122.24 | 93.66 | 1.81 |

| 3 1/2 | 90 | 47.63 | 142.88 | 112.71 | 2.5 |

| 4 | 100 | 50.8 | 152.4 | 120.65 | 2.86 |

| 5 | 130 | 57.15 | 179.3 | 141.29 | 4.65 |

| 6 | 150 | 60.33 | 215.9 | 169.86 | 6.44 |

| 8 | 200 | 69.85 | 263.53 | 220.66 | 10.66 |

| 10 | 250 | 77.79 | 322.26 | 274.64 | 17.69 |

| 12 | 300 | 85.73 | 377.83 | 325.44 | 26.76 |

| 14 | 350 | 88.9 | 409.58 | 357.19 | 29.94 |

| 16 | 400 | 93.6 | 463.55 | 407.99 | 34.02 |

| 18 | 450 | 96.84 | 520.7 | 458.79 | 44 |

| 20 | 500 | 101.6 | 571.5 | 508 | 53.52 |

| 24 | 600 | 144.5 | 717.5 | 609.6 | 101 |

| 26 | 650 | 155.6 | 778 | 660.4 | 120 |

| 30 | 750 | 174.6 | 893.6 | 762 | 190 |

| 36 | 900 | 206.4 | 1070 | 914.4 | 310 |

| 40 | 1000 | 225.4 | 1187.6 | 1016 | 435 |

| 42 | 1050 | 235 | 1244.6 | 1066.8 | 540 |

| 48 | 1200 | 241.3 | 1404 | 1219.2 | 750 |

Reducing Welding Outlets Sizes

| NPS | A | B | C | D |

| 1/2 | 3/4 19.05 |

1.3/8 34.93 |

15/16 23.81 |

5/8 15.88 |

| 3/4 | 7/8 22.23 |

1.5/8 41.28 |

1.3/16 30.16 |

13/16 20.64 |

| 1 | 1.1/16 26.99 |

2 50.80 |

1.7/16 36.51 |

1.1/32 26.19 |

| 1.1/4 | 1.1/4 31.75 |

2.3/8 60.3 |

1.3/4 44.45 |

1.3/8 34.93 |

| 1.1/2 | 1.5/16 33.34 |

2.7/8 73 |

2 50.80 |

1.5/8 41.28 |

| 2 | 1.1/2 38.10 |

3.1/2 88.90 |

2.9/16 65.09 |

2.1/16 52.39 |

| 2.1/2 | 1.5/8 41.28 |

4.1/16 103.19 |

3 76.20 |

2.7/16 61.91 |

| 3 | 1.3/4 44.45 |

4.13/16 122.24 |

3.11/16 93.66 |

3.1/16 77.79 |

| 3.1/2 | 2 50.80 |

5.3/8 136.53 |

3.7/8 98.43 |

3.9/16 90.49 |

| 4 | 2 50.80 |

6 152.40 |

4.3/4 120.65 |

4 101.60 |

| 5 | 2.1/4 57.15 |

7.1/8 180.98 |

5.9/16 141.29 |

5.1/16 128.59 |

| 6 | 2.3/8 60.3 |

8.1/2 215.90 |

6.11/16 169.86 |

6.1/16 153.99 |

| 8 | 2.3/4 69.85 |

10.3/8 263.53 |

8.11/16 220.66 |

7.15/16 201.61 |

| 10 | 3.1/16 77.79 |

12.9/16 319.09 |

10.13/16 274.64 |

10 254.00 |

| 12 | 3.3/8 85.73 |

14.7/8 377.83 |

12.13/16 325.44 |

12 304.80 |

| 14 | 3.1/2 88.90 |

16.1/8 409.58 |

14.1/16 357.19 |

13.1/4 336.55 |

| 16 | 3.11/16 93.66 |

18¼ 463.55 |

16.1/16 407.99 |

15¼ 387.35 |

| 18 | 4.1/16 103.19 |

20.3/4 527.05 |

18.5/8 473.08 |

17¼ 438.15 |

| 20 | 4.5/8 117.48 |

23.1/16 585.79 |

20.1/16 509.59 |

19¼ 488.95 |

| 24 | 5.3/8 136.53 |

27.7/8 708.03 |

25.1/8 638.18 |

23.1/4 590.55 |

DN200 - DN65 ASTM A105 Steel Flanged Welding Outlets and SA-105 UNS K03504 Elbow Outlets Fitting manufacturer in Mumbai

Threaded Welding Outlets Dimensions

| Size in Inches | A | B | C | D | Weight in KG |

|---|---|---|---|---|---|

| 1/8 | 19.05 | 25.40 | 15.88 | 0.05 | |

| 1/4 | 19.05 | 25.40 | 15.88 | 0.05 | |

| 3/8 | 20.64 | 31.75 | 19.05 | 0.09 | |

| 1/2 | 25.40 | 35.72 | 23.81 | 0.11 | |

| 3/4 | 26.99 | 43.66 | 29.37 | 0.16 | |

| 1 | 33.34 | 50.80 | 36.51 | 0.27 | |

| 1 1/4 | 33.34 | 65.09 | 44.45 | 0.41 | |

| 1 1/2 | 34.93 | 72.23 | 50.80 | 0.45 | |

| 2 | 38.10 | 88.11 | 65.09 | 0.79 | |

| 2 1/2 | 46.04 | 103.19 | 76.20 | 1.36 | |

| 3 | 50.80 | 122.24 | 93.66 | 1.97 | |

| 3 1/2 | 53.98 | 132.56 | 101.60 | 2.61 | |

| 4 | 57.15 | 151.61 | 120.65 | 3.22 | |

| 5 | 66.68 | 185.74 | 141.29 | 5.44 | |

| 6 | 69.85 | 219.08 | 169.86 | 6.94 |

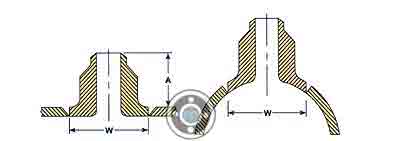

Insert Outlet Dimensions And Sizes

| Outlet Size |

A' Dimensions (Height above run pipe) |

||||||||||||||

| 1 1/2 | 2 | 2 1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | |

| Std Wt Run Pipe | 1.50 | 1.50 | 1.62 | 1.75 | 2.00 | 2.25 | 2.38 | 2.75 | 3.06 | 3.38 | 3.50 | 3.75 | 3.81 | 4 | 4.56 |

| XS Run Pipe | 1.50 | 1.50 | 1.62 | 1.75 | 2.00 | 2.25 | 3.06 | 3.87 | 3.69 | 4.06 | 3.81 | 4.19 | 4.38 | 4.69 | 5.50 |

| .500" to .750" Thick Run Pipe | - | - | - | 2.88 | 3.31 | 3.75 | 4.12 | 4.18 | 4.25 | 4.37 | 4.50 | 4.69 | 5.13 | 5.62 | 6.50 |

| .750" to 1.00" Thick Run Pipe | - | - | - | 3.22 | 3.38 | 3.75 | 4.34 | 4.62 | 4.84 | 5.10 | 5.25 | 5.88 | 6.50 | 6.75 | 7.62 |

| 1.00" to 1.25" Thick Run Pipe | - | - | - | 3.38 | 3.50 | 4.00 | 4.50 | 4.88 | 5.00 | 5.38 | 5.50 | 6.00 | 6.50 | 7.00 | 8.00 |

| 1.25" to 1.50" Thick Run Pipe | - | - | - | 3.62 | 3.87 | 4.25 | 4.69 | 5.16 | 5.31 | 5.68 | 5.81 | 6.44 | 6.50 | 7.56 | 8.72 |

| Outlet Size |

*'W' Dimensions (Max. O.D. of fitting - Max. size of hole) |

||||||||||||||

| 1 1/2 | 2 | 2 1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | |

| Std Wt Run Pipe | 3.50 | 4.25 | 4.88 | 5.69 | 7.00 | 8.06 | 9.71 | 11.71 | 14.00 | 16.32 | 17.56 | 19.75 | 22.00 | 24.00 | 29.00 |

| XS Run Pipe | 3.56 | 4.38 | 5.00 | 5.75 | 7.12 | 8.25 | 10.44 | 13.44 | 14.25 | 16.56 | 18.00 | 20.00 | 22.44 | 25.00 | 30.32 |

Price List of Pipe Outlet Fittings

| Pipe Outlet Fittings Price Per Piece in India | Outlet Fittings Price in INR | Welding Outlets Price in UAE Dirham | Pipe Outlet Fittings Price in USD |

| SW-OUTLETS 2X3/4 3000 SA/A 182 Per Kg | 9,657 | UAE Dirham 476.32 | $129.68 |

| LATERAL-OUTLETS 10X2 SCH.40 BW Per Kg | 9,299 | UAE Dirham 458.66 | $124.87 |

| BW-OUTLETS 14X2 SCH. STDX40 SA/A 182 Per Kg | 2,018 | UAE Dirham 99.53 | $27.10 |

Supplier and stockist of quality Carbon Steel MSS Sp 97 Elbow Outlets used in the Petrochemical, Gas, Pharmaceutical, Fire-Fighting and Process Industries. Leading Pipe Outlet Fittings manufacturer in India from last 20 years. Compare SA105 Steel Threaded Elbow Outlets Fitting with other manufacturers before purchasing.

CS ASTM A105 Forged Welding Outlets and ASME SA 105 Class 3000 Welding Outlets exporter in India, Check ASTM A105n Lateral Welding Outlets pressure rating & price in Mumbai

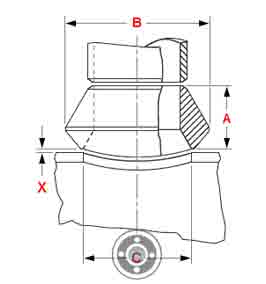

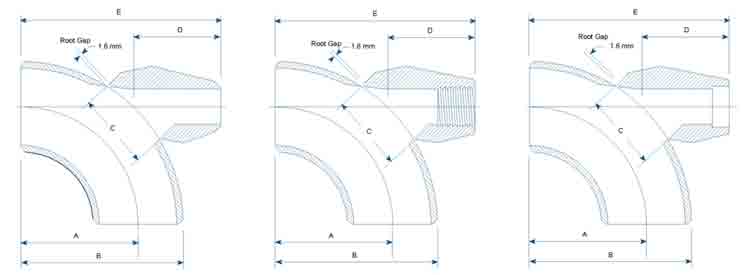

MSS Sp 97 Elbow Outlets Dimensions

| Inches | Class 3000 Threaded & Socket Weld Std. & XS Butt-Weld | ||||

|---|---|---|---|---|---|

| Size | A | B | C | D | E |

| 1/4 | Elbow Radius 1.5D (NPS) | Elbow Radius 2D (NPS) | 38.10 | 40.48 | ((Run Pipe O.D.)/2 + Root Gap) / 0.707 + D |

| 3/8 | 38.10 | 40.48 | |||

| 1/2 | 38.10 | 40.48 | |||

| 3/4 | 43.66 | 47.63 | |||

| 1 | 57.15 | 57.15 | |||

| 1 1/4 | 73.03 | 63.50 | |||

| 1 1/2 | 79.38 | 68.26 | |||

| 2 | 106.36 | 82.55 | |||

| 2 1/2 | 106.36 | 82.55 | |||

| 3 | 128.59 | 98.43 | |||

| 4 | 168.28 | 122.24 | |||

| 6 | 238.13 | 165.10 | |||

| 8 | 338.14 | 204.79 | |||

| 10 | 432.59 | 263.53 | |||

| 12 | 498.48 | 282.58 | |||

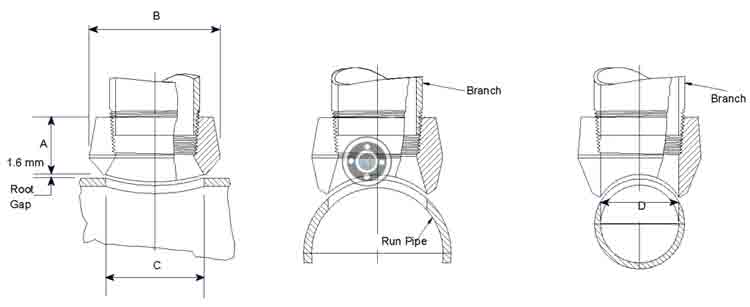

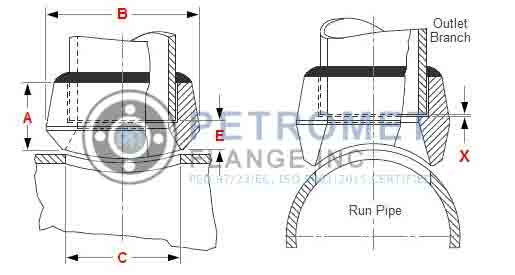

Dimensions Reducing Socket Weld Outlets – MSS SP97

| NPS | A | B | C | D | E |

| 1/2 | 1 25.40 |

1.13/32 35.71 |

29/32 23.01 |

0.622 15.80 |

9/16 14.28 |

| 3/4 | 1.1/16 26.98 |

1.23/32 43.65 |

1.5/32 29.36 |

0.824 20.93 |

9/16 14.28 |

| 1 | 1.5/16 33.33 |

2 50.8 |

1.7/16 36.51 |

1.049 26.64 |

25/32 19.84 |

| 1¼ | 1.5/16 33.33 |

2.9/16 65.08 |

1.3/4 44.45 |

1.380 35.05 |

3/4 19.05 |

| 1½ | 1.3/8 34.92 |

2.27/32 72.23 |

2 50.8 |

1.610 40.89 |

3/4 19.05 |

| 2 | 1½ 38.1 |

3.15/32 88.10 |

2.9/16 65.08 |

2.067 52.50 |

13/16 20.63 |

| 2½ | 1.9/16 39.68 |

4.1/16 103.18 |

3 76.2 |

2.469 62.71 |

3/4 19.05 |

| 3 | 1.3/4 44.45 |

4.13/16 122.23 |

3.11/16 93.66 |

3.068 77.93 |

15/16 23.81 |

| 3½ | 1.11/16 42.86 |

5.3/8 136.52 |

4.7/16 112.71 |

3.548 90.12 |

11/16 17.46 |

| 4 | 1.7/8 47.62 |

5.31/32 151.60 |

4.3/4 120.65 |

4.026 102.26 |

1.1/16 26.98 |

| 5 | 2.5/8 66.67 |

7.5/16 185.73 |

5.9/16 141.28 |

5.047 128.19 |

1.11/32 34.13 |

| 6 | 2.3/4 69.85 |

8.5/8 219.07 |

6.11/16 169.86 |

6.065 154.05 |

1.13/32 35.71 |

| X = Min. 1/16 (1.6 mm) | |||||

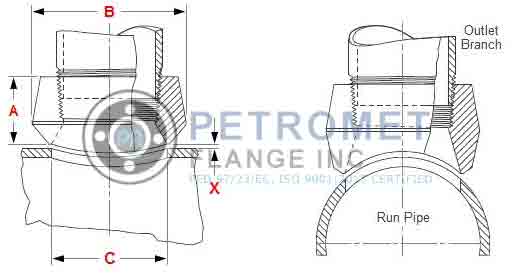

Dimensions Reducing Threaded Outlets – MSS SP97

| NPS | A | B | C |

| 1/2 | 1 25.40 |

1.13/32 35.71 |

15/16 23.81 |

| 3/4 | 1.1/16 26.98 |

1.23/32 43.65 |

1.5/32 29.36 |

| 1 | 1.5/16 33.33 |

2 50.80 |

1.7/16 36.51 |

| 1¼ | 1.5/16 33.33 |

2.9/16 65.08 |

1.3/4 44.45 |

| 1½ | 1.3/8 34.92 |

2.27/32 72.23 |

2 50.80 |

| 2 | 1½ 38.10 |

3.15/32 88.10 |

2.9/16 65.08 |

| 2½ | 1.13/16 46.03 |

4.1/16 103.18 |

3 76.20 |

| 3 | 2 50.80 |

4.13/16 122.23 |

3.11/16 93.66 |

| 3½ | 2.1/8 53.975 |

5.7/32 132.55 |

4 101.6 |

| 4 | 2¼ 57.15 |

5.31/32 151.60 |

4.3/4 120.65 |

| 5 | 2.5/8 66.67 |

7.5/16 185.73 |

5.9/16 141.28 |

| 6 | 2.3/4 69.85 |

8.5/8 219.07 |

6.11/16 169.86 |

| NPS | A | B | C |

Outlet Pipe Fittings Classes

| Pressure level, | Pressure level |

|---|---|

| 3000Lb | Sch40, Sch80, STD, XS |

| 6000Lb | Sch160 XXS |

Manufacturer of ASTM A105 Carbon Steel Welding Outlets Pipe Fittings and SA 105 Hot Tap Welding Outlets, Check metric A105 UNS K03504 Extra Strong Welding Outlets and Alloy Steel En 13480 Welding Outlets maximum size and dimensions

Dimensions of Nipple Outlet

| Outlet Size (NPS) | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | |

|---|---|---|---|---|---|---|---|

| XS | A | 3 1/2 | 3 1/2 | 3 1/2 | 3 1/2 | 3 1/2 | 3 1/2 |

| C | 15/16 | 1 3/16 | 1 7/16 | 1 3/4 | 2 | 2 9/16 | |

| XXS | A | 3 1/2 | 3 1/2 | 3 1/2 | 3 1/2 | 3 1/2 | 3 1/2 |

| C | 9/16 | 3/4 | 1 | 1 5/16 | 1 1/2 | 1 11/16 | |

MSS SP-97 Outlets Grades and types

| Material | Types | Grades |

|---|---|---|

| Stainless Steel |

|

ASTM A182 F304, F304L, F304H, F309, F310, F316, F316L, F317L, F321, F347, F904L. DIN 1.4301, 1.4306, 1.4401, 1.4571 JIS SUS304,SUS304, SUS304L, SUS316, SUS316 |

| Alloy Steel | ASTM A182 F11/ F22/ F91/ F1/ F5/ F9 | |

| Carbon Steel | ASTM A105/ SA 105N, A694 Grade F42/ F46/ F52/ F60/ F65/ F56/ F70. | |

| Low Temperature Carbon Steel | ASTM A350 LF3/A350 LF2 | |

| Nickel Alloy | ASTM / ASME SB 564 / SB 160 / SB 472 UNS 6600 (INCONEL 600, UNS 6601 (INCONEL 601, UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C276), UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8825 (INCOLOY 825), UNS 8020 (ALLOY 20) | |

| Duplex & Super Duplex | ASTM / ASME A/SA 182 F44, F45, F51, F53, F55, F60, F61 (UNS S31803, S32205, S32750, S32760) |

|

| Titanium | Titanium Grade 2/ 5 | |

| Copper Nickel | ASTM / ASME SB 61 / 62 / 151 / 152 – C70600 (Cupro Nickel CUNI-90/10 ), C71500 (Copper Nickel CUNI-70/30 ) |

Difference Between Welding Outlets and Sweep Outlet

Because the weld metal thickness of the Welding Outletss is always bigger than that of the Sweep Outlet, welding may require some extra time to allow cooling off on the heat input to prevent banana-warping the pipe.

Sweep Outlet are less common. Without specific Sweep Outlet experience, prepping and beveling the pipe for it may be more difficult/time-consuming than with Welding Outletss. Because the Sweep Outlet form is extremely definite, the Sweep Outlet may be set down on the pipe and the contour can be drawn, and because the Sweep Outlet is much larger than the Welding Outlets, more material must be removed.

Pipe Outlet Fittings Types

Welding Outlets

Welding Outlets Fitting

Reducing Welding Outlets

Threaded Welding Outlets

Weld O Let Fitting

Welding Outlets Pipe Fittings

Carbon Steel MSS Sp 97 Elbow Outlets

45 Degree Welding Outlets

90 Degree Welding Outlets

MSS Sp 97 Welding Outlets

ASME B31.3 Welding Outlets

ASME B16 9 Welding Outlets

ASTM A105 Welding Outlets

Class 3000 Welding Outlets

Extra Strong Welding Outlets

SA105 Steel Threaded Elbow Outlets

En 13480 Welding Outlets

SA-105 UNS K03504 Braze Outlet

ASTM A182 F5 Forged Welding Outlets

ASTM A 105 N Flexo Outlet Butt Weld

ASME SA 105 Nipple Outlet

A105 Carbon Steel Lateral Outlets

CS ASTM A105 Flexo Outlet Socket Weld

ASTM A105n Outlets

A105n Carbon Steel Flanged Welding Outlets

ASTM A105 Steel Flexo Outlet Threaded

ASTM A182 F11 Long Welding Outlets

A105 Metal Barred Welding Outlets

A105n Steel Socket weld Elbow Outlets

ASTM A105 Carbon Steel Coupling Outlet

ASTM A105 UNS K03504 Insert Outlet

SA 105 Socket Weld Outlets

UNS K03504 Sweep Outlet

ASTM A182 F12 Welding Outlets Sch 80

ASTM A182 F9 Lateral Welding Outlets

A105 Steel Threaded Outlets

ASTM A182 F91 Welding Outlets 6000 Lb

A105 ASTM Elbow Outlets

ASTM A182 F22 Hot Tap Welding Outlets

How To Order Outlet Fittings?

- Size of the header run pipe (which is generally expressed as a range of possible sizes, example 36-22)

- Size of branch pipe (the NPS of the connecting pipe to the run pipe, example 6 inches)

- For buttweld connections, use a branch pipe schedule (which can be STD, XS, 160, or XXS) (rating shall be provided for socket weld and NPT threaded Outlets)

- Branch fitting design (Welding Outlets, Threaded Outlets, Nipple Outlet, Socket Weld Outlets, etc)

- Grade of Material (example A105, A350 LF2, A182 F304)

Features of ASTM A105 Welding Outlets

- Abrasion resistance

- Corrosion resistance

- Durability

- Low Maintenance

- Long Service Life

- Dimensional accuracy

- High performance

What is Lateral Welding Outlets?

Lateral Welding Outlets is used for taking branch which is not at 90 degrees to run pipe. Its comes in a 45° or any other special degree as required by the customer. End connections of a Lateral Welding Outlets can be socket welded, butt welded or threaded.

What is the difference between a Welding Outlets and a Socket Weld Outlets?

Socket Weld Outlets are "socket fittings" and come in classes 3000#, 6000#, and 9000#, whereas Welding Outletss are buttweld fittings. Socket Weld Outlets, as opposed to Welding Outletss, are utilised for lower pressure applications and smaller pipe sizes.

Pipe Coupling VS Pipe Outlet Fittings

Outlet Fittings are used to open the Outlets on the main pipe wall; the connection form with the main pipe is welding, and the connection mode with the Outlets can be butt welding, socket welding, or thread; the main pipe and the Outlets are connected by the Outlets table in a vertical or oblique Cross relationship.

The pipeline Coupling is used to connect two pipes at the pipe junction; the two pipes' connection mode to the pipe Coupling is socket welding or thread; the two pipes connected by the pipe Coupling have the same axial direction.

Industrial Application of Threaded Elbow Outlets

- Oil and Gas Industry

- Aerospace Industry

- Petrochemical Industry

- Food Processing Industry

- Chemical Industry

- Pulp & Paper Indusry

- Pharmaceuticals Industry

- Energy Industry

Forged Fittings

Other Products

Pipe Fittings Material

Flanges Material