- Call : +91 22 67436442

- exports@petrometflange.com

Duplex Flanges manufacturer in India

- Home /

- Duplex Flanges

EN 1092-2 Alloy 2205 SORF Flange & Duplex Stainless Steel Blind Flange manufacturer in India

What is Duplex Flanges?

The Duplex steel is a variant of austenitic-ferritic stainless steel that offers much higher resistance to stress corrosion cracking compared to the austenitic stainless steel of 304 and 316 grades. However, the duplex steel possesses lower impact strength and toughness. The duplex steel material is included in the category of 2205, F53, and F60 grades. The Duplex Flanges are used across several industries and their popularity have increased due to the unique chemical and mechanical properties. They offer enhanced features compared to the basic stainless steel. Also, due to the increased availability of the Duplex Flanges, they have become cost-effective in recent years.

The ferritic-austenitic hybrid granular structure of duplex steel comes with an enhanced strength to weight ratio when compared to the 304 or 316 grades of stainless steel. It has good weldability, and mechanical toughness in applications with a colder ambient temperature. Due to all these features, the Duplex Flanges are widely used in off-shore drilling and marine applications. It is known for its excellent corrosion-resistant properties. One can also find the Duplex Flanges pressure vessel and desalination equipment.

However, it is to be noted that the duplex material comes with low formidability. This grade of stainless steel is used for making flanges that help establish simple connections. The Duplex Flanges are not preferred in case of complex metallic shapes. However, the formidability becomes less of an issue for structural steel as more preferences are given to simple mild steel for various types of non-corrosive applications.

There are several benefits getting the Duplex Flanges, like:

- They possess improved strength- they are almost twice as much stronger as the austenitic and ferritic grades of stainless steel.

- Toughness and durability- It is more formable in high pressure conditions compared to other stainless steel types. Their unique chemical composition also gives the flanges high toughness and durability.

- Corrosion resistance- They offer comparable and sometimes better corrosion resistance compared to the austenitic grades of stainless steel.

- Cost-effectiveness- The duplex steel comes with all the above properties but they have low amounts of nickel and molybdenum in its chemical composition, which makes the flanges very cost-effective.

Duplex 2205 RTJ Flanges Vs Duplex F51 Weld Neck Flange

The Duplex 2205 stainless steel material is widely used for services that need corrosion resistance and high strength- they are ideal for high pressure applications. The Duplex 2205 RTJ Flanges are machined metallic rings that have cuts and deep grooves in its face. It helps to give a leak-proof highly sealed piping connection.

The F51 grade of duplex stainless steel comes with improved stress corrosion cracking resistance, and they also resist crevice corrosion pitting, and possess high strength. The Duplex F51 Weld Neck Flange is ideal for chloride and sulphide environments, where the conditions are severe and critical. The weld neck flange comes with a tapered hub that is capable of relocating the stress of the pipe and ensures to decrease the high stress concentration present at the flange’s bottom.

UNS S31803 Slip On Flange Vs ASTM A182 Duplex Steel Blind Flange

The UNS S31803 can be defined as a ferritic-austenitic duplex grade stainless steel that possesses high strength and good corrosion resistance properties. The UNS S31803 slip-on flanges are used for considerably low pressure applications that have little leakage risks, in chloride or sulfide environments. It is a popular grade for flange that is used across several industries.

The ASTM A182 Duplex Steel Blind Flange looks like a steel plate with bored holes surrounding it and without a central hole. They are used for blocking the piping connections or to seal the nozzles of a valve. It is mainly used where the pipe is not under frequent use or for those pipes that need frequent inspection, maintenance, modifications.

What is properties of Duplex Stainless Steel Flanges?

Due to the chemical composition, the properties of Duplex Stainless Steel Flanges include:

- They are resistant to general and stress corrosion.

- It has high stress and thus the duplex flanges are hard to fracture, neither by stress corrosion, nor by fatigue.

- They are magnetic in nature.

- They have high tensile strength.

- High mechanical strength.

- Twice the elastic limit compared to other types of austenitic steel.

- Higher tenacity compared to ferritic steel.

- Lower thermal expansion.

- Constant hardness which remains unaffected by heat treatment.

- Possesses high weldability and workability.

All these properties help to make the duplex steel a very adaptable material. It means they can be transformed in several ways to meet some specific needs. All these properties makes it one of the most demanded materials in the world.

Save 8-10% if you buy directly from duplex flanges manufacturers in India, we at Petromet Flange offer lowest price in Asia.

Duplex Flanges

European Directive 2014/68/eu certified Duplex Flanges manufacturer in India offers widest range of ASTM A182 F51 Weld Neck Flange, Spades, Spectacle Blinds, Ring Spacers and UNS S31803 Lap Joint Flange in Mumbai

Table of Content

- Specification list of Duplex Flanges

- Duplex 2205 Flanges PCD Chart

- Duplex Flange Pressure Rating

- Duplex Blind Flange Dimensions

- UNS S31803 Slip On Flange Dimensions

- SS 2205 Duplex Weld Neck Flange Dimensions Table

- Price List of Duplex Flanges

- WNR 1.4462 Flange Torque Chart

- Dimensions Tolerances Of F51 Duplex Flange

- 2205 Duplex Flanges Chemical Composition

- Duplex Stainless Steel Flanges Mechanical Properties

- Duplex Steel Flanges Equivalent Grade

- Physical Properties of ASTM A182 Gr F51 Flange

- Various Types of Duplex Flanges

- Duplex F51 Flange Weight Chart

- ASTM A182 Duplex Steel Flanges HS Code

- Hardness of Alloy 2205 Stainless Steel Flange

- Inspection and Testing of ASTM A182 F51 Flange

- ASTM A182 F60 Flange Applications

- Duplex Steel Slip on Flange Features & Benefits

- 2205 Duplex Steel Flange Wall Thickness

- Thermal Conductivity Of Duplex Stainless Steel Flanges

- Heat Resistance of Duplex 2205 RTJ Flanges

- Avesta 2205 Flanges Machinability

- Class 150 Alloy 2205 Lap Joint Flange Dimensions

- 300 LBS F51 Duplex Flange Dimensions

- Dimension Table of 400# 2205 Duplex Steel Flanges

- Dimension Chart of CL 600 ASTM A182 Duplex Steel Flanges

- Class 900 SAF 2205 Flange Dimension

- 1500# Alloy 2205 Flange Dimension Table

- Dimension Chart of Class 2500 2205 Duplex Flanges

- SS 2205 Duplex Flange Alignment Procedure

- Manufacturing Standards of ASTM A182 Grade F60 Flanges

- Duplex Steel Flange Leakage Checking by Pressure Equivalent Method

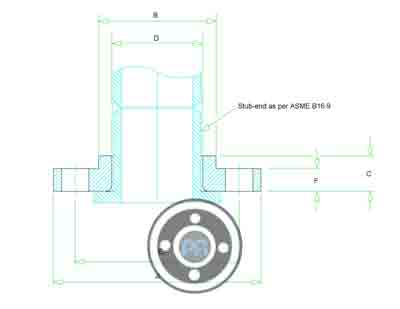

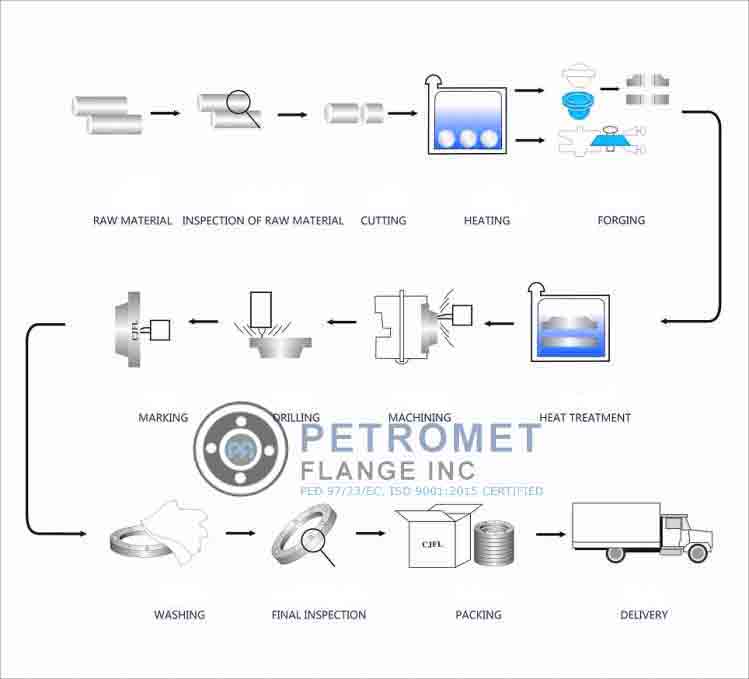

- Duplex 2205 Flange Manufacturing Process

- What is the difference between duplex and super duplex Flanges

Specification list of Duplex Flanges

| Size Range | 1/2″(15 NB) to 48″ (1200NB) |

|---|---|

| Pressure Rating Chart ANSI | 150 LBS, 300 LBS, 2500 LBS, 900 LBS, 600 LBS, 1500 LBS |

| JIS | 16 K, 5K, 10 K, 20 K, 30 K, 40 K, 63 K |

| Manufacturer of Connect Type/ Flange Face Type | RF, Small Tongue, RTJ, FF, LJF, Large Tongue & Groove |

| Coating | Zinc Plated, Anti-rust Paint, Yellow Transparent, Oil Black Paint, Cold and Hot Dip Galvanized |

| Manufacturer of | GOST, JIS, ANSI, DIN, UNI, BS, AWWA, AS2129, SABS, NFE, EN etc. |

| DIN Pressure Calculation | 25Bar 40Bar 16Bar 6Bar 10Bar / PN64 PN10 PN25 PN16 PN6 PN40 |

| Equipment | Pushing Machine, Press machine, Sand-blasting machine, Bending machine, electric bevelling machine etc |

| Origin | Japan / West Europe / Indian / USA / Korean |

| UNI / EN | 16Bar 6Bar 40Bar 10Bar 25Bar |

| Test | X-ray detector, Direct-reading Spectrograph, Magnetic particle detector, Ultrasonic flaw detector, Hydrostatic testing machine |

| Standards Provided By Manufacturer | ISO70051, MSS S44, API7S-43, API605, B16.48, ANSI/ASME B16.5, B16.47 Series A & B, BS4504, JISB2220, BS1560-3.1, ASME/ANSI B16.5/16.36/16.47A/16.47B, BS 10, EN-1092, DIN, API7S-15, EN1092 |

| Common Types By Manufacturer | Threaded / Screwed / Forged / Plate |

| Production technique Used By Manufacturer | Heat treated, Forged and machined |

Well known S31803 Duplex Stainless Steel Flange wholesalers, supplier, exporters, dealers, stockholders, importer, stockists, distributor and Manufacturer in Mumbai

Duplex 2205 Flanges PCD Chart

| Pipe NB | Bolt PCD | No. of Bolts | Bolt Size | Flange OD |

| 1/2" | 2 3/8" | 4 | 1/2" | 3 1/2" |

| 1" | 3 1/8" | 4 | 1/2" | 4 1/4" |

| 2" | 4 3/4" | 4 | 5/8" | 6" |

| 4" | 7 1/2" | 8 | 5/8" | 9" |

| 6" | 9 1/2" | 8 | 3/4" | 11" |

| 8" | 11 3/4" | 8 | 3/4" | 13 1/2" |

| 10" | 14 1/4" | 12 | 7/8" | 16" |

| 12" | 17 " | 12 | 7/8" | 19" |

| 14" | 18 3/4" | 12 | 1" | 21" |

Duplex Flange Pressure Rating

| Temperature °F | Class 150 | Class 600 | Class 1500 | Class 400 | Class 900 | Class 300 | Class 2500 |

| -20 to 100 | 275 | 1440 | 3600 | 960 | 2160 | 720 | 6000 |

| 300 | 205 | 1080 | 2700 | 720 | 1620 | 540 | 4500 |

| 200 | 230 | 1200 | 3000 | 800 | 1800 | 600 | 5000 |

| 400 | 190 | 995 | 2485 | 660 | 1490 | 495 | 4140 |

| 600 | 140 | 875 | 2185 | 580 | 1310 | 435 | 3640 |

| 650 | 125 | 860 | 2150 | 575 | 1290 | 430 | 3580 |

| 500 | 170 | 930 | 2330 | 620 | 1395 | 465 | 3880 |

| 700 | 110 | 850 | 2125 | 565 | 1275 | 425 | 3540 |

| 750 | 95 | 830 | 2075 | 555 | 1245 | 415 | 3460 |

| 850 | 65 | 790 | 1980 | 530 | 1190 | 395 | 3300 |

| 800 | 80 | 805 | 2015 | 540 | 1210 | 405 | 3360 |

| 900 | 50 | 780 | 1945 | 520 | 1165 | 390 | 3240 |

| 950 | 35 | 765 | 1910 | 510 | 1145 | 380 | 3180 |

| 1000 | 20 | 640 | 1605 | 430 | 965 | 320 | 2675 |

| 1100 | 20 | 515 | 1285 | 345 | 770 | 255 | 2145 |

| 1150 | 20 | 400 | 995 | 265 | 595 | 200 | 1655 |

| 1050 | 20 | 615 | 1545 | 410 | 925 | 310 | 2570 |

| 1200 | 20 | 310 | 770 | 205 | 465 | 155 | 1285 |

| 1250 | 20 | 225 | 565 | 150 | 340 | 115 | 945 |

| 1300 | 20 | 170 | 430 | 115 | 255 | 85 | 715 |

| 1400 | 20 | 95 | 240 | 65 | 145 | 50 | 400 |

| 1350 | 20 | 125 | 310 | 80 | 185 | 60 | 515 |

| 1450 | 15 | 70 | 170 | 45 | 105 | 35 | 285 |

| 1500 | 10 | 55 | 135 | 35 | 80 | 25 | 230 |

Duplex Blind Flange Dimensions

| Size in Inch | Size in mm | ISO Stud Size | RF Height | Outer Dia. | RF Dia. | Hole Size | PCD | No of Bolts | Bolt Size UNC | Flange Thickness | RF Stud Length | Weight in kg |

| D | A | C | E | B | ||||||||

| 1/2 | 15 | M20 | 7 | 135 | 34.9 | 7/8 | 88.9 | 4 | 3/4 | 30.2 | 120 | 3.2 |

| 3/4 | 20 | M20 | 7 | 140 | 42.9 | 7/8 | 95.2 | 4 | 3/4 | 31.8 | 125 | 3.7 |

| 1 | 25 | M24 | 7 | 160 | 50.8 | 1 | 108 | 4 | 7/8 | 35 | 140 | 5 |

| 1 1/4 | 32 | M27 | 7 | 185 | 63.5 | 1 1/8 | 130.2 | 4 | 1 | 38.1 | 150 | 7.8 |

| 1 1/2 | 40 | M30 | 7 | 205 | 73 | 1 1/4 | 146 | 4 | 1 1/8 | 44.5 | 170 | 10.5 |

| 2 | 50 | M27 | 7 | 235 | 92.1 | 1 1/8 | 171.4 | 8 | 1 | 50.9 | 180 | 18 |

| 2 1/2 | 65 | M30 | 7 | 265 | 104.8 | 1 1/4 | 196.8 | 8 | 1 1/8 | 57.2 | 195 | 25.5 |

| 3 | 80 | M33 | 7 | 305 | 127 | 1 3/8 | 228.6 | 8 | 1 1/4 | 66.7 | 220 | 39 |

| 4 | 100 | M39 | 7 | 355 | 157.2 | 1 5/8 | 273 | 8 | 1 1/2 | 76.2 | 255 | 61.5 |

| 5 | 125 | M45 | 7 | 420 | 185.7 | 1 7/8 | 323.8 | 8 | 1 3/4 | 92.1 | 300 | 102 |

| 6 | 150 | M52 | 7 | 485 | 215.9 | 2 1/8 | 368.3 | 8 | 2 | 108 | 345 | 157 |

| 8 | 200 | M52 | 7 | 550 | 269.9 | 2 1/8 | 438.2 | 12 | 2 | 127 | 380 | 241 |

| 10 | 250 | M64 | 7 | 675 | 323.8 | 2 5/8 | 539.8 | 12 | 2 1/2 | 165.1 | 490 | 470 |

| 12 | 300 | M72 | 7 | 760 | 381 | 2 7/8 | 619.1 | 12 | 2 3/4 | 184.2 | 540 | 575 |

Supplier of ASTM A182 Gr F51 Threaded Flange, UNS S32205 Slip On Flange and Duplex 2205 Forged Flange offers Hydrotest and Pneumatic Test to confirm the integrity of weldments

UNS S31803 Slip On Flange Dimensions

| Size in Inch | Size in mm | No of Bolts | Outer Dia. | Hub OD | ISO Stud Size | Flange Length | RF Height | Flange Thick. | RF Dia. | PCD | Hole Size | Socket Bore | Weight in kg |

| A | C | D | F | B | E | G | H | ||||||

| 1/2 | 15 | 4 | 90 | 30 | M14 | 14 | 2 | 9.6 | 34.9 | 60.3 | 5/8 | 22.2 | 0.8 |

| 1 | 25 | 4 | 110 | 49 | M14 | 16 | 2 | 12.7 | 50.8 | 79.4 | 5/8 | 34.5 | 0.9 |

| 3/4 | 20 | 4 | 100 | 38 | M14 | 14 | 2 | 11.2 | 42.9 | 69.9 | 5/8 | 27.7 | 0.9 |

| 1 1/4 | 32 | 4 | 115 | 59 | M14 | 19 | 2 | 14.3 | 63.5 | 88.9 | 5/8 | 43.2 | 1.4 |

| 2 | 50 | 4 | 150 | 78 | M16 | 24 | 2 | 17.5 | 92.1 | 120.7 | 3/4 | 61.9 | 2.3 |

| 1 1/2 | 40 | 4 | 125 | 65 | M14 | 21 | 2 | 15.9 | 73 | 98.4 | 5/8 | 49.5 | 1.4 |

| 2 1/2 | 65 | 4 | 180 | 90 | M16 | 27 | 2 | 20.7 | 104.8 | 139.7 | 3/4 | 74.6 | 3.2 |

| 3 | 80 | 4 | 190 | 108 | M16 | 29 | 2 | 22.3 | 127 | 152.4 | 3/4 | 90.7 | 3.7 |

| 4 | 100 | 8 | 230 | 135 | M16 | 32 | 2 | 22.3 | 157.2 | 190.5 | 3/4 | 116.1 | 5.9 |

| 3 1/2 | 90 | 8 | 215 | 122 | M16 | 30 | 2 | 22.3 | 139.7 | 177.8 | 3/4 | 103.4 | 5 |

| 5 | 125 | 8 | 255 | 164 | M20 | 35 | 2 | 22.3 | 185.7 | 215.9 | 7/8 | 143.8 | 6.8 |

| 8 | 200 | 8 | 345 | 246 | M20 | 43 | 2 | 27 | 269.9 | 298.5 | 7/8 | 221.5 | 13.7 |

| 10 | 250 | 12 | 405 | 305 | M24 | 48 | 2 | 28.6 | 323.8 | 362 | 1 | 276.2 | 19.5 |

| 6 | 150 | 8 | 280 | 192 | M20 | 38 | 2 | 23.9 | 215.9 | 241.3 | 7/8 | 170.7 | 8.6 |

| 12 | 300 | 12 | 485 | 365 | M24 | 54 | 2 | 30.2 | 381 | 431.8 | 1 | 327 | 29 |

| 24 | 600 | 20 | 815 | 663 | M33 | 81 | 2 | 46.1 | 692.2 | 749.3 | 1 3/8 | 616 | 100 |

| 16 | 400 | 16 | 595 | 457 | M27 | 62 | 2 | 35 | 469.9 | 539.8 | 1 1/8 | 410.5 | 54 |

| 18 | 450 | 16 | 635 | 505 | M30 | 67 | 2 | 38.1 | 533.4 | 577.9 | 1 1/4 | 461.8 | 59 |

| 14 | 350 | 12 | 535 | 400 | M27 | 56 | 2 | 33.4 | 412.8 | 476.3 | 1 1/8 | 359.2 | 41 |

| 20 | 500 | 20 | 700 | 559 | M30 | 71 | 2 | 41.3 | 584.2 | 635 | 1 1/4 | 513.1 | 75 |

SS 2205 Duplex Weld Neck Flange Dimensions Table

| Flange NPS | H | Inside Diameter | Flat Face Thickness (T2) | Outside Diameter | Raised Face (RF) | Raised Face (R) | H1 | Raised Face Thickness (T) | T1 | Bolt Circle (BC) | Bolt Hole (B) | No. of Bolt Holes |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2" | 1.19" | 0.62" | 1.82" | 3.50" | .063" | 1.38" | 0.84" | 1.88" | .38" | 2.38" | .62" | 4 |

| 1-1/4" | 2.31" | 1.38" | 2.19" | 4.62" | .063" | 2.50" | 1.66" | 2.25" | .56" | 3.50" | .62" | 4 |

| 3/4" | 1.50" | 0.82" | 2.00" | 3.88" | .063" | 1.69" | 1.05" | 2.06" | .44" | 2.75" | .62" | 4 |

| 1-1/2" | 2.56" | 1.61" | 2.38" | 5.00" | .063" | 2.88" | 1.90" | 2.44" | .62" | 3.88" | .62" | 4 |

| 1" | 1.94" | 1.05" | 2.13" | 4.25" | .063" | 2.00" | 1.32" | 2.19" | .50" | 3.12" | .62" | 4 |

| 2" | 3.06" | 2.07" | 2.44" | 6.00" | .063" | 3.62" | 2.38" | 2.50" | .69" | 4.75" | .75" | 4 |

| 2-1/2" | 3.56" | 2.47" | 2.69" | 7.00" | .063" | 4.12" | 2.88" | 2.75" | .82" | 5.50" | .75" | 4 |

| 3" | 4.25" | 3.07" | 2.69" | 7.50" | .063" | 5.00" | 3.50" | 2.75" | .88" | 6.00" | .75" | 4 |

| 4" | 5.31" | 4.03" | 2.94" | 9.00" | .063" | 6.19" | 4.50" | 3.00" | .88" | 7.50" | .75" | 8 |

| 5" | 6.44" | 5.05" | 3.44" | 10.00" | .063" | 7.31" | 5.56" | 3.50" | .88" | 8.50" | .88" | 8 |

| 3-1/2" | 4.81" | 3.55" | 2.75" | 8.50" | .063" | 5.50" | 4.00" | 2.81" | .88" | 7.00" | .75" | 8 |

| 6" | 7.56" | 6.07" | 3.44" | 11.00" | .063" | 8.50" | 6.63" | 3.50" | .94" | 9.50" | .88" | 8 |

| 8" | 9.69" | 7.98" | 3.94" | 13.50" | .063" | 10.62" | 8.63" | 4.00" | 1.06" | 11.75" | .88" | 8 |

| 22" | 24.25" | 21.25" | 5.82" | 29.50" | .063" | 25.25" | 22.00" | 5.88" | 1.75" | 27.25" | 1.38" | 20 |

| 10" | 12.00" | 10.02" | 3.94" | 16.00" | .063" | 12.75" | 10.75" | 4.00" | 1.13" | 14.25" | 1.00" | 12 |

| 12" | 14.38" | 12.00" | 4.44" | 19.00" | .063" | 15.00" | 12.75" | 4.50" | 1.19" | 17.00" | 1.00" | 12 |

| 16" | 18.00" | 15.25" | 4.94" | 23.50" | .063" | 18.50" | 16.00" | 5.00" | 1.38" | 21.25" | 1.12" | 16 |

| 18" | 19.88" | 17.25" | 5.44" | 25.00" | .063" | 21.00" | 18.00" | 5.50" | 1.50" | 22.75" | 1.25" | 16 |

| 14" | 15.75" | 13.25" | 4.94" | 21.00" | .063" | 16.25" | 14.00" | 5.00" | 1.32" | 18.75" | 1.12" | 12 |

| 20" | 22.00" | 19.25" | 5.63" | 27.50" | .063" | 23.00" | 20.00" | 5.69" | 1.63" | 25.00" | 1.25" | 20 |

| 24" | 26.12" | 23.25" | 5.94" | 32.00" | .063" | 27.25" | 24.00" | 6.00" | 1.82" | 29.50" | 1.38" | 20 |

Bulk discount on raised and flat face UNS S32205 Duplex Steel Flanges and DIN 1.4462 Plate Flange in Maharashtra

Price List of Duplex Flanges

| Duplex Flanges Price Per Piece in India | Price Applicable for jan 2022 to june 2022 | Price Applicable for July 2022 to December 2022 |

| DUPLEX SS FLANGE LWNRF SA182 GR. F51 (UNSS31803) NPS 2 (DN 50) X 19.5 MM THK X CLASS 600 ASME B16.5 Per Piece | US $236.31 | US $238.31 |

| DUPLEX SS FLANGE LWNRF SA182 GR. F51 Per Piece | US $253.89 | US $255.89 |

| 300# BLRF DUPLEX -FLANGE Per Piece | US $60.73 | US $62.73 |

| 1" A182 F61 B16.5 Duplex Blind Pipe Flange Per Kg | US $2.98 | US $4.98 |

We are Duplex Flanges Manufacturer in India in Various forms Such as Slip on, Blind, Weld Neck and Socket Weld Flange. This is an approximate Cost of ASME B16.5 Duplex 2205 Flanges in India. Compare our price with other A182 F51 Duplex Stainless Steel Flanges manufacturer in India.

WNR 1.4462 Flange Torque Chart

| Sizes in Inch | Imperfections Max. Radial Projection | |

|---|---|---|

| No deeper than the serrations bottom, mm | Serrations Deeper Than the Serrations Bottom, mm | |

| 1/2 | 3.0 | 1.5 |

| 1 1/2 | 3.0 | 1.5 |

| 1 | 3.0 | 1.5 |

| 1 1/4 | 3.0 | 1.5 |

| 2 | 3.0 | 1.5 |

| 3/4 | 3.0 | 1.5 |

| 3 | 4.5 | 1.5 |

| 3 1/2 | 6.0 | 3.0 |

| 4 | 6.0 | 3.0 |

| 2 1/2 | 3.0 | 1.5 |

| 5 | 6.0 | 3.0 |

| 8 | 8.0 | 4.5 |

| 10 | 8.0 | 4.5 |

| 6 | 6.0 | 3.0 |

| 12 | 8.0 | 4.5 |

| 18 | 12.0 | 6.0 |

| 14 | 8.0 | 4.5 |

| 20 | 12.0 | 6.0 |

| 16 | 10.0 | 4.5 |

| 24 | 12.0 | 6.0 |

Dimensions Tolerances Of F51 Duplex Flange

| Flange | Tolerance Table | |

|---|---|---|

| D | Inside Diameter (I.D.) |

|

| K | Length of hub |

|

| B | Diameter of contact face |

|

| A | O.D. (Outside Diameter) |

|

| J | Diameter of hub at base |

|

| P | Drilling |

|

| Eccentricity of bolt circle with respect to facing |

| |

| H | Diameter of hub at point of welding |

|

| C | Thickness |

|

2205 Duplex Flanges Chemical Composition

| Grade | Phosphorus | Carbon | Silicon | Sulfur | Chromium | Molybdenum | Nickel | Nitrogen | Iron | Manganese |

| S31803 / S32205 | 0.030 Maximum | 0.030 Maximum | 1.00 Maximum | 0.020 Maximum | 22.0 To 23.0 | 3.0 To 3.5 | 4.50 To 6.50 | 0.14 To 0.20 | 63.72 Minimum | 2.00 Maximum |

Duplex Stainless Steel Flanges Mechanical Properties

| Grades | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| S31803 / S32205 | 7.805 | 0.285 | 1420 – 1465 | 2588 – 2669 |

Duplex Steel Flanges Equivalent Grade

| STANDARD | UNS | WNR |

| 2205 | S31803 / S32205 | 1.4462 |

Check Duplex 2205 Flanges, ASTM A182 gr F51 Orifice Flanges and SA 182 F51 Duplex Steel Socket Weld Flange pressure ratings & price list

Physical Properties of ASTM A182 Gr F51 Flange

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Co-eff of Thermal Expansion (μm/m/°C) | Thermal Conductivity (W/m.K) | Specific Heat 0-100°C ( J/kg.K) | Electrical Resistivity (nΩ.m) | |||

| 0-100°C | 0-315°C | 0-538°C | at 100°C | at 500°C | |||||

| 2205 | 782 | 190 | 13.7 | 14.2 | - | 19 | - | 418 | 850 |

Various Types of Duplex Flanges

A182 Gr F60 Forged Flanges

SS 2205 Socket Weld Flange

Alloy 2205 SWRF Flanges

Sa182 F51 Weld Neck Flanges

2205 Duplex Steel Spectacle Blind Flange

5000 NB SA182 F60 Blind Flange

ASTM A182 Grade F60 Blind Raised Face Flange

SS 2205 Duplex Raised Face Flange

DIN 1.4462 Slip On Flange

A182 Gr F51 Puddle Flange

600 LBS F51 Duplex Long Weld Neck Flange

SA 182 F60 Flat Face Flange

A182 F51 Nipoflange

UNS S32205 SORF Flanges

150 LBS SA 182 F51 Threaded Flange

WNR 1.4462 Girth Flanges

ASTM A182 F60 Spades ring spacers flanges

A182 F51 Uns S31803 Expander Flanges

Duplex 2205 Weld neck Raised Face Flanges

SA-182 F60 S32205 Reducing Flanges

2500 LBS SAF 2205 Duplex Lapped Joint Flange

SS S32205 Tongue & Groove Flange

1500 LBS ASTM A182 Duplex Steel BLRF Flanges

ASTM A 182 F51 Plate Flange

15 NB ASTM A 182 Gr F51 WNRF Flange

900 LBS ASTM A182 Gr F51 Ring Joint Flange

A182 F51 Duplex Stainless Steel Slip on RF Flanges

UNS S31803 Screwed Flange

300 LBS SS 2205 Duplex Steel Orifice Flanges

Duplex 2205 Flanges

Duplex Blind Flange

Duplex F51 Flange

2205 Duplex Flanges

Duplex Stainless Steel Flanges

Duplex Steel Flanges

Avesta 2205 Flanges

2205 Duplex Steel Flanges

Alloy 2205 Stainless Steel Flange

SAF 2205 Spectacle Blind Flanges

ASTM A182 F61 Flange

ASTM A182 F51 Flange

ASTM A182 F60 Flange

Duplex F51 Flange Weight Chart

| NPS (Nominal Pipe Size) | NPT (Threaded) | WRNR (Weld Neck) | SWRF (Socket Weld) | Loose (Lap Joint) | SORF (Slip On) | BLRF (Blind) |

|---|---|---|---|---|---|---|

| ½ | 1 | 2 | 2 | 1 | 1 | 2 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 |

| 1 | 2 | 3 | 2 | 2 | 2 | 2 |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 |

| 1½ | 3 | 4 | 3 | 3 | 3 | 4 |

| 2 | 5 | 6 | 5 | 5 | 5 | 5 |

| 2½ | 8 | 10 | 8 | 8 | 8 | 7 |

| 3 | 9 | 11.5 | 9 | 9 | 9 | 9 |

| 3½ | 12 | 12 | 11 | 11 | 11 | 13 |

| 4 | 13 | 16.5 | 13 | 13 | 13 | 17 |

| 5 | 15 | 21 | 15 | 15 | 15 | 20 |

| 6 | 19 | 26 | 19 | 19 | 19 | 27 |

| 8 | 30 | 42 | 30 | 30 | 30 | 47 |

| 10 | 43 | 54 | 43 | 43 | 43 | 70 |

| 12 | 64 | 88 | 64 | 64 | 64 | 123 |

| 14 | 90 | 114 | 90 | 105 | 90 | 140 |

| 16 | 98 | 140 | 98 | 140 | 106 | 180 |

| 18 | 130 | 165 | 130 | 160 | 130 | 220 |

| 20 | 165 | 197 | 165 | 195 | 165 | 285 |

| 22 | 185 | 225 | 185 | 245 | 185 | 355 |

| 24 | 220 | 268 | 220 | 275 | 220 | 430 |

ASTM A182 Duplex Steel Flanges HS Code

| HS Code | 73072100 | Duplex SS Flange |

Hardness of Alloy 2205 Stainless Steel Flange

| Hardness | 217 MPa |

Inspection and Testing of ASTM A182 F51 Flange

- Direct-reading Spectrograph

- X-ray detector

- Magnetic particle detector

- Flattening Test

- PMI Testing

- UI trasonic flaw detector

- Hydrostatic testing machine

- Flaring Test

- Hardness Test

- Pitting Resistance Test

ASTM A182 F60 Flange Applications

- Ship Building

- Paper & Pulp

- Oil And Gas Industry

- Nuclear Power

- Marine Applications

- Power Plants

- Fossil Fuel Power Plants

- Refineries

Duplex Steel Slip on Flange Features & Benefits

- Although typically less expensive than a weld-neck flange, welding costs can be higher.

- It's easy to install because there's less need to trim the pipe length precisely.

- For easy bolt alignment, the slide on flange is free to spin on the pipe.

2205 Duplex Steel Flange Wall Thickness

| Nom Pipe Size | OD | Sch 80 | Sch 10 | Sch 140 | Sch 30 | Sch 40 | Sch 60 | EXT Hvy | STD Wall | Sch 20 | Sch 100 | Sch 160 | Sch 120 | XX Hvy |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ½ | 0.84 | 0.147 | 0.083 | 0.109 | 0.147 | 0.109 | 0.188 | 0.294 | ||||||

| ¾ | 1.05 | 0.154 | 0.083 | 0.113 | 0.154 | 0.113 | 0.219 | 0.308 | ||||||

| 1 | 1.315 | 0.179 | 0.109 | 0.133 | 0.179 | 0.133 | 0.25 | 0.358 | ||||||

| 1 ¼ | 1.66 | 0.191 | 0.109 | 0.14 | 0.191 | 0.14 | 0.25 | 0.382 | ||||||

| 1 ½ | 1.9 | 0.2 | 0.109 | 0.145 | 0.2 | 0.145 | 0.281 | 0.4 | ||||||

| 2 | 2.375 | 0.218 | 0.109 | 0.154 | 0.218 | 0.154 | 0.344 | 0.436 | ||||||

| 2 ½ | 2.875 | 0.276 | 0.12 | 0.203 | 0.276 | 0.203 | 0.375 | 0.552 | ||||||

| 3 | 3.5 | 0.3 | 0.12 | 0.216 | 0.3 | 0.216 | 0.438 | 0.6 | ||||||

| 3 ½ | 4 | 0.318 | 0.12 | 0.226 | 0.318 | 0.226 | 0.636 | |||||||

| 4 | 4.5 | 0.337 | 0.12 | 0.237 | 0.337 | 0.237 | 0.531 | 0.438 | 0.674 | |||||

| 5 | 5.563 | 0.375 | 0.134 | 0.258 | 0.375 | 0.258 | 0.625 | 0.5 | 0.75 | |||||

| 6 | 6.625 | 0.432 | 0.134 | 0.28 | 0.432 | 0.28 | 0.719 | 0.562 | 0.864 | |||||

| 8 | 8.625 | 0.5 | 0.148 | 0.812 | 0.277 | 0.322 | 0.406 | 0.5 | 0.322 | 0.25 | 0.594 | 0.906 | 0.719 | 0.875 |

| 10 | 10.75 | 0.594 | 0.165 | 1 | 0.307 | 0.365 | 0.5 | 0.5 | 0.365 | 0.25 | 0.719 | 1.125 | 0.844 | 1 |

| 12 | 12.75 | 0.688 | 0.18 | 1.125 | 0.33 | 0.406 | 0.562 | 0.5 | 0.375 | 0.25 | 0.844 | 1.312 | 1 | 1 |

| 14 | 14 | 0.75 | 0.25 | 1.25 | 0.375 | 0.438 | 0.594 | 0.5 | 0.375 | 0.312 | 0.938 | 1.406 | 1.094 | |

| 16 | 16 | 0.844 | 0.25 | 1.438 | 0.375 | 0.5 | 0.656 | 0.5 | 0.375 | 0.312 | 1.031 | 1.594 | 1.219 | |

| 18 | 18 | 0.938 | 0.25 | 1.562 | 0.438 | 0.562 | 0.75 | 0.5 | 0.375 | 0.312 | 1.156 | 1.781 | 1.375 | |

| 20 | 20 | 1.031 | 0.25 | 1.75 | 0.5 | 0.594 | 0.812 | 0.5 | 0.375 | 0.375 | 1.281 | 1.969 | 1.5 | |

| 22 | 22 | 0.25 | 0.5 | 0.375 | ||||||||||

| 24 | 24 | 1.219 | 0.25 | 2.062 | 0.562 | 0.688 | 0.969 | 0.5 | 0.375 | 0.375 | 1.531 | 2.344 | 1.812 | |

| 26 | 26 | 0.5 | 0.375 | |||||||||||

| 30 | 30 | 0.312 | 0.625 | 0.5 | 0.375 | 0.5 | ||||||||

| 36 | 36 | 0.312 | 0.625 | 0.75 | 0.5 | 0.375 | 0.5 | |||||||

| 40 | 40 | 0.5 | 0.375 | |||||||||||

| 42 | 42 | 0.5 | 0.375 | |||||||||||

| 48 | 48 | 0.5 | 0.375 |

Thermal Conductivity Of Duplex Stainless Steel Flanges

| Thermal Conductivity | 13 - 30 W/(m·K) |

Heat Resistance of Duplex 2205 RTJ Flanges

Duplex stainless steels flanges high chromium content, which protects against corrosion, produces embrittlement at temperatures above 300°C.

Duplex flanges are more ductile than ferritic and martensitic grades at low temperatures. Duplex 2205 Flanges may withstand temperatures as low as -50°C.

Avesta 2205 Flanges Machinability

Due to their high strength, duplex stainless steels flanges are difficult to process. Cutting 2205 Alloy Flanges, for example, is about 20% slower than machining 304.

The following guidelines will assist you in improving your machining:

- The cutting edges must remain razor-sharp. Excessive work hardening is caused by dull edges.

- Light cuts should be made, but they should be deep enough to prevent work hardening by riding on the material's surface.

- Chip breakers should be used to help keep swarf out of the way of the job.

Class 150 Alloy 2205 Lap Joint Flange Dimensions

| Size in Inch | Size in mm | Flange Thick. | Bolt Size UNC | Lapped Thick. | Lapped ID | ISO Stud Size | Lapped Radius | No of Bolts | Lapped Thick. | Outer Diameter | Machine Bolt Length | RF Stud Length | Hole Size | PCD | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B | C | D | G | A | E | ||||||||||

| 1/2 | 15 | 30 | 1/2 | 16 | 22.9 | M14 | 3 | 4 | 11.2 | 90 | 50 | 55 | 5/8 | 60.3 | 0.8 |

| 3/4 | 20 | 38 | 1/2 | 16 | 28.2 | M14 | 3 | 4 | 12.7 | 100 | 50 | 65 | 5/8 | 69.9 | 0.9 |

| 1 | 25 | 49 | 1/2 | 17 | 34.9 | M14 | 3 | 4 | 14.3 | 110 | 55 | 65 | 5/8 | 79.4 | 0.9 |

| 1 1/4 | 32 | 59 | 1/2 | 21 | 43.7 | M14 | 5 | 4 | 15.9 | 115 | 55 | 70 | 5/8 | 88.9 | 1.4 |

| 1 1/2 | 40 | 65 | 1/2 | 22 | 50 | M14 | 6 | 4 | 17.5 | 125 | 65 | 70 | 5/8 | 98.4 | 1.4 |

| 2 | 50 | 78 | 5/8 | 25 | 62.5 | M16 | 8 | 4 | 19.1 | 150 | 70 | 85 | 3/4 | 120.7 | 2.3 |

| 2 1/2 | 65 | 90 | 5/8 | 29 | 75.4 | M16 | 8 | 4 | 22.3 | 180 | 75 | 90 | 3/4 | 139.7 | 3.2 |

| 3 | 80 | 108 | 5/8 | 30 | 91.4 | M16 | 10 | 4 | 23.9 | 190 | 75 | 90 | 3/4 | 152.4 | 3.7 |

| 3 1/2 | 90 | 122 | 5/8 | 32 | 104.1 | M16 | 11 | 8 | 23.9 | 215 | 75 | 90 | 3/4 | 177.8 | 5 |

| 4 | 100 | 135 | 5/8 | 33 | 116.8 | M16 | 11 | 8 | 23.9 | 230 | 75 | 90 | 3/4 | 190.5 | 5.9 |

| 5 | 125 | 164 | 3/4 | 36 | 144.4 | M20 | 11 | 8 | 23.9 | 255 | 85 | 95 | 7/8 | 215.9 | 6.8 |

| 6 | 150 | 192 | 3/4 | 40 | 171.4 | M20 | 13 | 8 | 25.4 | 280 | 85 | 100 | 7/8 | 241.3 | 8.6 |

| 8 | 200 | 246 | 3/4 | 44 | 222.2 | M20 | 13 | 8 | 28.6 | 345 | 90 | 110 | 7/8 | 298.5 | 13.7 |

| 10 | 250 | 305 | 7/8 | 49 | 277.4 | M24 | 13 | 12 | 30.2 | 405 | 100 | 115 | 1 | 362 | 19.5 |

| 12 | 300 | 365 | 7/8 | 56 | 328.2 | M24 | 13 | 12 | 31.8 | 485 | 100 | 120 | 1 | 431.8 | 29 |

| 14 | 350 | 400 | 1 | 79 | 360.2 | M27 | 13 | 12 | 35 | 535 | 115 | 135 | 1 1/8 | 476.3 | 41 |

| 16 | 400 | 457 | 1 | 87 | 411.2 | M27 | 13 | 16 | 36.6 | 595 | 115 | 135 | 1 1/8 | 539.8 | 54 |

| 18 | 450 | 505 | 1 1/8 | 97 | 462.3 | M30 | 13 | 16 | 39.7 | 635 | 125 | 145 | 1 1/4 | 577.9 | 59 |

| 20 | 500 | 559 | 1 1/8 | 103 | 514.4 | M30 | 13 | 20 | 42.9 | 700 | 140 | 160 | 1 1/4 | 635 | 75 |

| 24 | 600 | 663 | 1 1/4 | 111 | 616 | M33 | 13 | 20 | 47.9 | 815 | 150 | 170 | 1 3/8 | 749.3 | 100 |

300 LBS F51 Duplex Flange Dimensions

| Nominal Pipe Size (inches) | Class 300 | ||||

|---|---|---|---|---|---|

| Dia of Flanges (inches) | No. of Bolts | Dia of Bolts (inches) | Dia of Bolt Holes (inches) | Bolt Circle (inches) | |

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 1/2 | 3-3/4 | 4 | 1/2 | 0.62 | 2-5/8 |

| 3/4 | 4-5/8 | 4 | 5/8 | 0.75 | 3-1/4 |

| 1 | 4-7/8 | 4 | 5/8 | 0.75 | 3-1/2 |

| 1-1/4 | 5-1/4 | 4 | 5/8 | 0.75 | 3-7/8 |

| 1-1/2 | 6-1/8 | 4 | 3/4 | 0.88 | 4-1/2 |

| 2 | 6-1/2 | 8 | 5/8 | 0.75 | 5 |

| 2-1/2 | 7-1/2 | 8 | 3/4 | 0.88 | 5-7/8 |

| 3 | 8-1/4 | 8 | 3/4 | 0.88 | 6-5/8 |

| 3-1/2 | 9 | 8 | 3/4 | 0.88 | 7-1/4 |

| 4 | 10 | 8 | 3/4 | 0.88 | 7-7/8 |

| 5 | 11 | 8 | 3/4 | 0.88 | 9-1/4 |

| 6 | 12-1/2 | 12 | 3/4 | 0.88 | 10-5/8 |

| 8 | 15 | 12 | 7/8 | 1 | 13 |

| 10 | 17-1/2 | 16 | 1 | 1.12 | 15-1/4 |

| 12 | 20-1/2 | 16 | 1-1/8 | 1.25 | 17-3/4 |

| 14 | 23 | 20 | 1-1/8 | 1.25 | 20-1/4 |

| 16 | 25-1/2 | 20 | 1-1/4 | 1.38 | 22-1/2 |

| 18 | 28 | 24 | 1-1/4 | 1.38 | 24-3/4 |

| 20 | 30-1/2 | 24 | 1-1/4 | 1.38 | 27 |

| 24 | 36 | 24 | 1-1/2 | 1.62 | 32 |

Dimension Table of 400# 2205 Duplex Steel Flanges

| Nominal Pipe Size NPS (in) | Class 600 | ||||

|---|---|---|---|---|---|

| Dia of Flange (in) | No. of Bolts | Dia of Bolts (in) | Dia of Bolt Holes (in) | Bolt Circle (in) | |

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 1/2 | 3-3/4 | 4 | 1/2 | 0.62 | 2-5/8 |

| 3/4 | 4-5/8 | 4 | 5/8 | 0.75 | 3-1/4 |

| 1 | 4-7/8 | 4 | 5/8 | 0.75 | 3-1/2 |

| 1-1/4 | 5-1/4 | 4 | 5/8 | 0.75 | 3-7/8 |

| 1-1/2 | 6-1/8 | 4 | 3/4 | 0.88 | 4-1/2 |

| 2 | 6-1/2 | 8 | 5/8 | 0.75 | 5 |

| 2-1/2 | 7-1/2 | 8 | 3/4 | 0.88 | 5-7/8 |

| 3 | 8-1/4 | 8 | 3/4 | 0.88 | 6-5/8 |

| 3-1/2 | 9 | 8 | 7/8 | 1 | 7-1/4 |

| 4 | 10-3/4 | 8 | 7/8 | 1 | 8-1/2 |

| 5 | 13 | 8 | 1 | 1.12 | 10-1/2 |

| 6 | 14 | 12 | 1 | 1.12 | 11-1/2 |

| 8 | 16-1/2 | 12 | 1-1/8 | 1.25 | 13-3/4 |

| 10 | 20 | 16 | 1-1/4 | 1.38 | 17 |

| 12 | 22 | 20 | 1-1/4 | 1.38 | 19-1/4 |

| 14 | 23-3/4 | 20 | 1-3/8 | 1.5 | 20-3/4 |

| 16 | 27 | 20 | 1-1/2 | 1.62 | 23-3/4 |

| 18 | 29-1/4 | 20 | 1-5/8 | 1.75 | 25-3/4 |

| 20 | 32 | 24 | 1-5/8 | 1.75 | 28-1/2 |

| 24 | 37 | 24 | 1-7/8 | 2 | 33 |

Dimension Chart of CL 600 ASTM A182 Duplex Steel Flanges

| Nominal Pipe Size NPS (in) | Class 600 | ||||

|---|---|---|---|---|---|

| Dia of Flange (in) | No. of Bolts | Dia of Bolts (in) | Dia of Bolt Holes (in) | Bolt Circle (in) | |

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 1/2 | 3-3/4 | 4 | 1/2 | 0.62 | 2-5/8 |

| 3/4 | 4-5/8 | 4 | 5/8 | 0.75 | 3-1/4 |

| 1 | 4-7/8 | 4 | 5/8 | 0.75 | 3-1/2 |

| 1-1/4 | 5-1/4 | 4 | 5/8 | 0.75 | 3-7/8 |

| 1-1/2 | 6-1/8 | 4 | 3/4 | 0.88 | 4-1/2 |

| 2 | 6-1/2 | 8 | 5/8 | 0.75 | 5 |

| 2-1/2 | 7-1/2 | 8 | 3/4 | 0.88 | 5-7/8 |

| 3 | 8-1/4 | 8 | 3/4 | 0.88 | 6-5/8 |

| 3-1/2 | 9 | 8 | 7/8 | 1 | 7-1/4 |

| 4 | 10-3/4 | 8 | 7/8 | 1 | 8-1/2 |

| 5 | 13 | 8 | 1 | 1.12 | 10-1/2 |

| 6 | 14 | 12 | 1 | 1.12 | 11-1/2 |

| 8 | 16-1/2 | 12 | 1-1/8 | 1.25 | 13-3/4 |

| 10 | 20 | 16 | 1-1/4 | 1.38 | 17 |

| 12 | 22 | 20 | 1-1/4 | 1.38 | 19-1/4 |

| 14 | 23-3/4 | 20 | 1-3/8 | 1.5 | 20-3/4 |

| 16 | 27 | 20 | 1-1/2 | 1.62 | 23-3/4 |

| 18 | 29-1/4 | 20 | 1-5/8 | 1.75 | 25-3/4 |

| 20 | 32 | 24 | 1-5/8 | 1.75 | 28-1/2 |

| 24 | 37 | 24 | 1-7/8 | 2 | 33 |

Class 900 SAF 2205 Flange Dimension

| Nominal Pipe Size NPS (in) | Class 900 | ||||

|---|---|---|---|---|---|

| Dia of Flange (in) | No. of Bolts | Dia of Bolts (in) | Dia of Bolt Holes (in) | Bolt Circle (in) | |

| 1/2 | 4-3/4 | 4 | 3/4 | 0.88 | 3-1/4 |

| 3/4 | 5-1/8 | 4 | 3/4 | 0.88 | 3-1/2 |

| 1 | 5-7/8 | 4 | 7/8 | 1 | 4 |

| 1-1/4 | 6-1/4 | 4 | 7/8 | 1 | 4-3/8 |

| 1-1/2 | 7 | 4 | 1 | 1.12 | 4-7/8 |

| 2 | 8-1/2 | 8 | 7/8 | 1 | 6-1/2 |

| 2-1/2 | 9-5/8 | 8 | 1 | 1.12 | 7-1/2 |

| 3 | 9-1/2 | 8 | 7/8 | 1 | 7-1/2 |

| 4 | 11-1/2 | 8 | 1-1/8 | 1.25 | 9-1/4 |

| 5 | 13-3/4 | 8 | 1-1/4 | 1.38 | 11 |

| 6 | 15 | 12 | 1-1/8 | 1.25 | 12-1/2 |

| 8 | 18-1/2 | 12 | 1-3/8 | 1.5 | 15-1/2 |

| 10 | 21-1/2 | 16 | 1-3/8 | 1.5 | 18-1/2 |

| 12 | 24 | 20 | 1-3/8 | 1.5 | 21 |

| 14 | 25-1/4 | 20 | 1-1/2 | 1.62 | 22 |

| 16 | 27-3/4 | 20 | 1-5/8 | 1.75 | 24-1/2 |

| 18 | 31 | 20 | 1-7/8 | 2 | 27 |

| 20 | 33-3/4 | 20 | 2 | 2.12 | 29-1/2 |

| 24 | 41 | 20 | 2-1/2 | 2.62 | 35-1/2 |

1500# Alloy 2205 Flange Dimension Table

| Nominal Pipe Size (in) | Class 1500 | ||||

|---|---|---|---|---|---|

| Dia of Flange (in) | No. of Bolts | Dia of Bolts (in) | Dia of Bolt Holes (in) | Bolt Circle (in) | |

| 1/2 | 4-3/4 | 4 | 3/4 | 0.88 | 3-1/4 |

| 3/4 | 5-1/8 | 4 | 3/4 | 0.88 | 3-1/2 |

| 1 | 5-7/8 | 4 | 7/8 | 1 | 4 |

| 1-1/4 | 6-1/4 | 4 | 7/8 | 1 | 4-3/8 |

| 1-1/2 | 7 | 4 | 1 | 1.12 | 4-7/8 |

| 2 | 8-1/2 | 8 | 7/8 | 1 | 6-1/2 |

| 2-1/2 | 9-5/8 | 8 | 1 | 1.12 | 7-1/2 |

| 3 | 10-1/2 | 8 | 1-1/8 | 1.25 | 8 |

| 4 | 12-1/4 | 8 | 1-1/4 | 1.38 | 9-1/2 |

| 5 | 14-3/4 | 8 | 1-1/2 | 1.62 | 11-1/2 |

| 6 | 15-1/2 | 12 | 1-3/8 | 1.5 | 12-1/2 |

| 8 | 19 | 12 | 1-5/8 | 1.75 | 15-1/2 |

| 10 | 23 | 12 | 1-7/8 | 2 | 19 |

| 12 | 26-1/2 | 16 | 2 | 2.12 | 22-1/2 |

| 14 | 29-1/2 | 16 | 2-1/4 | 2.38 | 25 |

| 16 | 32-1/2 | 16 | 2-1/2 | 2.62 | 27-3/4 |

| 18 | 36 | 16 | 2-3/4 | 2.88 | 30-1/2 |

| 20 | 38-3/4 | 16 | 3 | 3.12 | 32-3/4 |

| 24 | 46 | 16 | 3-1/2 | 3.62 | 39 |

Dimension Chart of Class 2500 2205 Duplex Flanges

| Nominal Pipe Size (in) | Class 2500 | ||||

|---|---|---|---|---|---|

| Dia of Flange (in) | No. of Bolts | Dia of Bolts (in) | Dia of Bolt Holes (in) | Bolt Circle (in) | |

| 1/2 | 5-1/4 | 4 | 3/4 | 0.88 | 3-1/2 |

| 3/4 | 5-1/2 | 4 | 3/4 | 0.88 | 3-3/4 |

| 1 | 6-1/4 | 4 | 7/8 | 1 | 4-1/4 |

| 1-1/4 | 7-1/4 | 4 | 1 | 1.12 | 5-1/8 |

| 1-1/2 | 8 | 4 | 1-1/8 | 1.25 | 5-3/4 |

| 2 | 9-1/4 | 8 | 1 | 1.12 | 6-3/4 |

| 2-1/2 | 10-1/2 | 8 | 1-1/8 | 1.25 | 7-3/4 |

| 3 | 12 | 8 | 1-1/4 | 1.38 | 9 |

| 4 | 14 | 8 | 1-1/2 | 1.62 | 10-3/4 |

| 5 | 16-1/2 | 8 | 1-3/4 | 1.88 | 12-3/4 |

| 6 | 19 | 8 | 2 | 2.12 | 14-1/2 |

| 8 | 21-3/4 | 12 | 2 | 2.12 | 17-1/4 |

| 10 | 26-1/2 | 12 | 2-1/2 | 2.62 | 21-1/4 |

| 12 | 30 | 12 | 2-3/4 | 2.88 | 24-3/8 |

SS 2205 Duplex Flange Alignment Procedure

If the gasket for the Alloy 2205 flanges isn't already known or provided by the piping provider, choose one. Align the SS 2205 flanges as needed. If you're going to utilize gaskets, be sure they're in the right place. Duplex Flanges and gaskets should be brought together. Check the ASTM A182 Duplex Steel flange alignment once more. Place the bolts in place. Ensure that the DIN 1.4462 flange bolts are securely fastened. Check that the 2205 Duplex Steel flanges are centered and that the mating surfaces of the Duplex flanges are aligned. Check to see if the Stainless Steel Type 2205 flange bolts are overtorqued.

Manufacturing Standards of ASTM A182 Grade F60 Flanges

- ASME B16.5

- ASME B16.47

- BS EN 1092-1

- API 6A (wellhead equipment)

- ASME B16.36 (orifice flanges)

Duplex Steel Flange Leakage Checking by Pressure Equivalent Method

The following equations are used to translate the axial force (F) and bending moment (M) on the Duplex flange into equivalent pressure (Pe).

- Equivalent Pressure for Axial force, Pe1=4F/ΠG2

- Equivalent Pressure for bending moment, Pe2=16M/ΠG3

- Here G=diameter at location of gasket load reaction =(Gasket OD+ID)/2 when bo<=6 mm =(Gasket OD-2b) when bo>6 mm. Here bo=basic gasket seating width as given in table 2-5.2 of ASME sec VIII

Duplex 2205 Flange Manufacturing Process

What is the difference between duplex and super duplex Flanges

Duplex Flanges have a 22 percent chromium content, whereas super duplex Flanges have a 25 percent chromium content. The level of pitting corrosion resistance is raised by increasing the chromium concentration. However, in order to maintain a favorable balance between austenitic and ferritic microstructures, the concentration of nickel and other elements must be increased, which raises the cost.

Flanges Material

Pipe Fittings Material

Other Products