- Call : +91 22 67436442

- exports@petrometflange.com

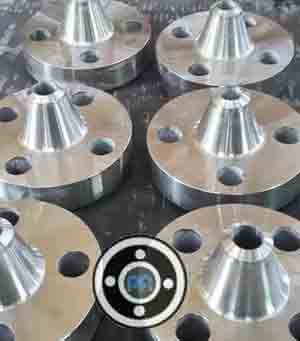

Nickel 200 Flanges

- Home /

- Nickel 200 Flanges

Alloy 200 Weld Neck Flange manufacturer in India according to ASTM B564 UNS N02200 specification

Nickel 200 Flange Properties

The Nickel 200 Flange has some excellent properties and that is why they are used in a wide range of industries. They are durable, offer dimensional stability, and come with a fine surface finish. These are also resistant to corrosion in oxidizing as well as neutral environments. Because of these properties, they are used in equipment that deals with food handling. The flanges of the given grade are produced in different shapes, sizes, and they can be customized according to specific requirements. They are available in different types of face and various pressure classes which makes them suitable for different equipment.

What is ASTM B564 UNS N02200 Weld Neck flange

The ASTM B564 UNS N02200 weld neck flanges are easily recognizable from their tapered hub. Due to their structure, they can easily be used in high pressure services, including applications at sub-zero and elevated temperatures. These flanges are customized in such a way that the bore matches the inside diameter of the mating pipe, this helps to improve the overall product flow. The structure also helps to reduce turbulence and they are resistant to erosion too. Due to the tapered hub, these flanges can distribute the stress properly. Any kind of flaw in the ASTM B564 UNS N02200 weld neck flanges can easily be detected by radiographs.

Alloy 200 Blind flange corrosion resistance and tempreature range

The Alloy 200 is capable of resisting corrosion excellently in both neutral, as well as oxidizing media. However, ensure that the oxidizing media allows passive oxide film formation. This film helps the alloy to resist corrosion excellently, even in caustic environments.

The Alloy 200 are exposed for a long time within the temperature range of 427-649 degrees C. This can cause carbon phase precipitation and also there will be a loss of ductility. Thus, this alloy is perfect to be used for services above the temperature of 316 degrees C. For temperatures below that, the Alloy 201 material should be considered.

Table of Content

- Nickel 200 Flanges Specification List

- Alloy 200 Flanges Dimensions

- Nickel alloy 200 Flange Weight Chart

- Pressure Rating of ASTM B564 Alloy 200 Flanges

- Nickel 200 Flanges Price List

- Alloy 200 Flanges Chemical Composition

- ASTM B564 UNS N02200 Flanges Mechanical Properties

- Nickel Alloy 200 Flanges Equivalent Grade

- Physical Properties of ASTM B564 Nickel 200 Flanges

- NW 2200 Flanges Thermal Properties

- Various Types of Nickel 200 Flanges

- DIN 2.4066 Flanges Testing and Inspection

Nickel 200 Flanges Specification List

| Size Range | 1/2″ to 48″ |

|---|---|

| DIN Pressure Calculation | 25Bar 40Bar 16Bar 6Bar 10Bar / PN64 PN10 PN25 PN16 PN6 PN40 |

| JIS | 40 K, 16 K, 5K, 10 K, 30 K, 20 K, 63 K |

| Chart of Pressure Rating | 300 LBS, 2500 LBS, 1500 LBS, 900 LBS, 150 LBS, 600 LBS |

| Production technique Used By Manufacturer | Heat treated, Forged and machined |

| Manufacturer of Connect / Flange Face Type | LJF, RF, RTJ, FF, Small Tongue, Large Tongue & Groove |

| Standards Provided By Manufacturer | ISO70051, MSS S44, BS1560-3.1, API7S-43, B16.48, ANSI/ASME B16.5, B16.47 Series A & B, BS4504, JISB2220, ASME/ANSI B16.5/16.36/16.47A/16.47B, API605, BS 10, EN-1092, DIN, API7S-15, EN1092 |

| Test | Magnetic particle detector, X-ray detector, Ultrasonic flaw detector, Direct-reading Spectrograph, Hydrostatic testing machine |

| UNI / EN | 16Bar 6Bar 40Bar 10Bar 25Bar |

| Coating | Zinc Plated, Anti-rust Paint, Yellow Transparent, Oil Black Paint, Cold and Hot Dip Galvanized |

| Origin | Japan / West Europe / Indian / USA / Korean |

| Equipment | Pushing Machine, Press machine, Sand-blasting machine, Bending machine, electric bevelling machine etc |

| Manufacturer of | GOST, JIS, ANSI, DIN, UNI, BS, AWWA, AS2129, SABS, NFE, EN etc. |

| Common Types By Manufacturer | Threaded / Screwed / Forged / Plate |

Exporter & supplier of Ni 200 Slip-on Flange and Din 2.4066 Blind Flanges in Mumbai, check dimensions and price list

Alloy 200 Flanges Dimensions

| Normal Pipe Size (NPS) Of Flanges | (I.D.) Inside Diameter | Thickness Of Raised Face (RF) (T) |

Outside Daimeter (O.D.) | Raised Face (R) |

RF (Raised Face) |

Holes Of Bolts (B) |

H | T1 | Thickness Of Flat Face (FF) (T2) |

BC (Circle Of Bolt) | Bolts Holes Numbers |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 0.88 | 0.88 | 3.75 | 1.38 | .063 | 0.62 | 1.50 | 0.50 | 0.82 | 2.62 | 4 |

| 1 | 1.36 | 1.06 | 4.88 | 2.00 | .063 | 0.75 | 2.12 | 0.63 | 1.00 | 3.50 | 4 |

| 3/4 | 1.09 | 1.00 | 4.62 | 1.69 | .063 | 0.75 | 1.88 | .056 | 0.94 | 3.25 | 4 |

| 1-1/4 | 1.70 | 1.06 | 5.25 | 2.50 | .063 | 0.75 | 2.50 | 0.69 | 1.00 | 3.88 | 4 |

| 2 | 2.44 | 1.31 | 6.50 | 3.62 | .063 | 0.75 | 3.31 | 0.82 | 1.25 | 5.00 | 8 |

| 1-1/2 | 1.95 | 1.19 | 6.12 | 2.88 | .063 | 0.88 | 2.75 | 0.75 | 1.13 | 4.50 | 4 |

| 2-1/2 | 2.94 | 1.50 | 7.50 | 4.12 | .063 | 0.88 | 3.94 | 0.94 | 1.44 | 5.88 | 8 |

| 3 | 3.57 | 1.69 | 8.25 | 5.00 | .063 | 0.88 | 4.62 | 1.06 | 1.63 | 6.62 | 8 |

| 3-1/2 | 4.07 | 1.75 | 9.00 | 5.50 | .063 | 0.88 | 5.25 | 1.13 | 1.69 | 7.25 | 8 |

| 4 | 4.57 | 1.88 | 10.00 | 6.19 | .063 | 0.88 | 5.75 | 1.19 | 1.82 | 7.88 | 8 |

| 5 | 5.66 | 2.00 | 11.00 | 7.31 | .063 | 0.88 | 7.00 | 1.32 | 1.94 | 9.25 | 8 |

| 18 | 18.18 | 3.50 | 28.00 | 21.00 | .063 | 1.38 | 21.00 | 2.32 | 3.44 | 24.75 | 24 |

| 6 | 6.72 | 2.06 | 12.50 | 8.50 | .063 | 0.88 | 8.12 | 1.38 | 2.00 | 10.62 | 12 |

| 8 | 8.72 | 2.44 | 15.00 | 10.62 | .063 | 1.00 | 10.25 | 1.56 | 2.38 | 13.00 | 12 |

| 10 | 10.88 | 2.62 | 17.50 | 12.75 | .063 | 1.12 | 12.62 | 1.82 | 2.56 | 15.25 | 16 |

| 12 | 12.88 | 2.88 | 20.50 | 15.00 | .063 | 1.25 | 14.75 | 1.94 | 2.82 | 17.75 | 16 |

| 14 | 14.14 | 3.00 | 23.00 | 16.25 | .063 | 1.25 | 16.75 | 2.06 | 2.94 | 20.25 | 20 |

| 20 | 20.20 | 3.75 | 30.50 | 23.00 | .063 | 1.38 | 23.12 | 2.44 | 3.69 | 27.00 | 24 |

| 16 | 16.16 | 3.25 | 25.50 | 18.50 | .063 | 1.38 | 19.00 | 2.19 | 3.19 | 22.50 | 20 |

| 22 | 22.22 | 4.00 | 33.00 | 25.25 | .063 | 1.63 | 25.25 | 2.57 | 3.94 | 29.25 | 24 |

| 24 | 24.25 | 4.19 | 36.00 | 27.25 | .063 | 1.62 | 27.62 | 2.69 | 4.13 | 32.00 | 24 |

Nickel alloy 200 Flange Weight Chart

| NPS (Nominal Pipe Size) | Loose (Lap Joint) | NPT (Threaded) | SORF (Slip On) | BLRF (Blind) | SWRF (Socket Weld) | WRNR (Weld Neck) |

|---|---|---|---|---|---|---|

| ½ | 1 | 1 | 1 | 2 | 2 | 2 |

| 1 | 2 | 2 | 2 | 2 | 2 | 3 |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 |

| 1½ | 3 | 3 | 3 | 4 | 3 | 4 |

| 2½ | 8 | 8 | 8 | 7 | 8 | 10 |

| 2 | 5 | 5 | 5 | 5 | 5 | 6 |

| 3 | 9 | 9 | 9 | 9 | 9 | 11.5 |

| 4 | 13 | 13 | 13 | 17 | 13 | 16.5 |

| 3½ | 11 | 12 | 11 | 13 | 11 | 12 |

| 5 | 15 | 15 | 15 | 20 | 15 | 21 |

| 8 | 30 | 30 | 30 | 47 | 30 | 42 |

| 6 | 19 | 19 | 19 | 27 | 19 | 26 |

| 10 | 43 | 43 | 43 | 70 | 43 | 54 |

| 24 | 275 | 220 | 220 | 430 | 220 | 268 |

| 14 | 105 | 90 | 90 | 140 | 90 | 114 |

| 12 | 64 | 64 | 64 | 123 | 64 | 88 |

| 16 | 140 | 98 | 106 | 180 | 98 | 140 |

| 20 | 195 | 165 | 165 | 285 | 165 | 197 |

| 18 | 160 | 130 | 130 | 220 | 130 | 165 |

| 22 | 245 | 185 | 185 | 355 | 185 | 225 |

Manufacturer of Nickel Alloy 200 Orifice Flange and Ni 2.4066 Forged Flanges in class 150 to 2500, call now for a free sample!

Pressure Rating of ASTM B564 Alloy 200 Flanges

| Temperature °F | Class 150 | Class 600 | Class 1500 | Class 400 | Class 900 | Class 300 | Class 2500 |

| -20 to 100 | 275 | 1440 | 3600 | 960 | 2160 | 720 | 6000 |

| 300 | 205 | 1080 | 2700 | 720 | 1620 | 540 | 4500 |

| 200 | 230 | 1200 | 3000 | 800 | 1800 | 600 | 5000 |

| 400 | 190 | 995 | 2485 | 660 | 1490 | 495 | 4140 |

| 600 | 140 | 875 | 2185 | 580 | 1310 | 435 | 3640 |

| 650 | 125 | 860 | 2150 | 575 | 1290 | 430 | 3580 |

| 500 | 170 | 930 | 2330 | 620 | 1395 | 465 | 3880 |

| 700 | 110 | 850 | 2125 | 565 | 1275 | 425 | 3540 |

| 750 | 95 | 830 | 2075 | 555 | 1245 | 415 | 3460 |

| 850 | 65 | 790 | 1980 | 530 | 1190 | 395 | 3300 |

| 800 | 80 | 805 | 2015 | 540 | 1210 | 405 | 3360 |

| 900 | 50 | 780 | 1945 | 520 | 1165 | 390 | 3240 |

| 950 | 35 | 765 | 1910 | 510 | 1145 | 380 | 3180 |

| 1000 | 20 | 640 | 1605 | 430 | 965 | 320 | 2675 |

| 1100 | 20 | 515 | 1285 | 345 | 770 | 255 | 2145 |

| 1150 | 20 | 400 | 995 | 265 | 595 | 200 | 1655 |

| 1050 | 20 | 615 | 1545 | 410 | 925 | 310 | 2570 |

| 1200 | 20 | 310 | 770 | 205 | 465 | 155 | 1285 |

| 1250 | 20 | 225 | 565 | 150 | 340 | 115 | 945 |

| 1300 | 20 | 170 | 430 | 115 | 255 | 85 | 715 |

| 1400 | 20 | 95 | 240 | 65 | 145 | 50 | 400 |

| 1350 | 20 | 125 | 310 | 80 | 185 | 60 | 515 |

| 1450 | 15 | 70 | 170 | 45 | 105 | 35 | 285 |

| 1500 | 10 | 55 | 135 | 35 | 80 | 25 | 230 |

Nickel 200 Flanges Price List

| Nickel 200 Flanges Price Per Piece in India | ASTM B564 UNS N02200 Flanges Price in INR | Nickel Alloy 200 Flanges Price in UAE Dirham | Alloy 200 Flanges Price in USD |

| Nickel 200 forged 6" 1500# WN flange Per Kg | 7,237 | UAE Dirham 356.26 | $96.98 |

| Nickel alloy 200 RF 3000# female threaded flange Per Kg | 6855 | UAE Dirham 332.16 | $91.88 |

Manufacturer of ASME SB564 UNS No 2200 Long Weld Neck Flange in raised/ flat face, buy Alloy 200 Reducing Flanges at factory price in India

Alloy 200 Flanges Chemical Composition

| Grade | C | Si | Fe | S | Cu | Mn | Ni |

| Nickel 200 | 0.15 max | 0.35 max | 0.40 max | 0.01 max | 0.25 max | 0.35 max | 99.0 min |

ASTM B564 UNS N02200 Flanges Mechanical Properties

| Element | Density | Yield Strength (0.2%Offset) | Tensile Strength | Melting Point | Elongation |

| Nickel 200 | 8.9 g/cm3 | Psi – 21500 , MPa – 148 | Psi – 67000 , MPa – 462 | 1446 °C (2635 °F) | 45 % |

Nickel Alloy 200 Flanges Equivalent Grade

| STANDARD | UNS | AFNOR | JIS | BS | GOST | WERKSTOFF NR. | EN |

| Nickel 200 | N02200 | N-100M | NW 2200 | NA 11 | НП-2 | 2.4066 | Ni 99.2 |

Physical Properties of ASTM B564 Nickel 200 Flanges

| Properties | Metric | Imperial |

|---|---|---|

| Density | 8.89 g/cm3 | 0.321 lb/in3 |

| Melting point | 1435-1446°C | 2615-2635°F |

Manufacturer of Nickel 200 Flanges according to ANSI/ ASME B16.5, specialized in large diameter Alloy 200 Spectacle Blind flange in India, view pressure rating and properties

NW 2200 Flanges Thermal Properties

| Properties | Metric | Imperial |

|---|---|---|

| Thermal expansion co-efficient (@20-100°C/68-212°F) | 13.3 µm/m°C | 7.39 µin/in°F |

| Thermal conductivity | 70.2 W/mK | 487 BTU.in/hrft².°F |

Various Types of Nickel 200 Flanges

Nickel 200 Raised Face Flange

UNS N02200 Weld Neck Flanges

Nickel 200 Reducing Flanges

Alloy 200 Blind Flange

DIN 2.4066 Long Weld Neck Flange

ASTM B564 UNS N02200 SORF Flanges

Nickel Alloy 200 Spectacle Blind Flange

Nickel Alloy 200 BLRF Flanges

UNS N02200 Ring Joint Flange

ASTM B564 Nickel 200 Girth Flanges

Alloy 200 Tongue & Groove Flange

UNS N02200 Nipoflange

Nickel Alloy 200 Screwed Flange

ASTM B564 UNS N02200 WNRF Flange

Alloy 200 Lapped Joint Flange

Alloy 200 Threaded Flange

Nickel 200 Socket Weld Flange

ASTM B564 Nickel 200 Orifice Flanges

DIN 2.4066 Slip On Flange

Nickel 200 SWRF Flanges

ASTM B564 Nickel 200 Expander Flanges

DIN 2.4066 Flanges Testing and Inspection

- PMI Testing

- Micro and Macro Test

- Intergranular Corrosion (IGC) Test

- Pitting Resistance Test

- Chemical Analysis – Spectro Analysis

- Flattening Test

- Hardness Test

- Flaring Test

- Mechanical Testing

Flanges Material

Pipe Fittings Material

Other Products