- Call : +91 22 67436442

- exports@petrometflange.com

Titanium Flanges Manufacturer In India

- Home /

- Titanium Flanges

Ti Gr 5 Blind Flange & ASTM B381 Gr F2 Slip On Flange exporter in Mumbai

What is Titanium Flanges?

Titanium flanges and fittings have become quite popular in recent years across several industries. They are built under the ASTM or ASME B381 material specification, and their dimensions can be fully customized according to the requirements specified.The titanium flanges can be a great choice when strength to weight ratio is an issue. Titanium is known for its strength and the flanges made with it also possess high strength.

Titanium grade 2 flanges are the most commonly requested pipe across different industries. Apart from having a high strength, they are also known for their corrosion resistance. They are widely used in marine equipment due to their oxidation resistance, and one of the best things about this material is that they retain their properties even at elevated temperatures. Titanium grade 12 material is known for its high weldability and malleability. Titanium flanges are one of the most popular choices for high temperature and high pressure services, but they come at a reduced weight. These flanges are used in the military equipment and aerospace industry. The flanges show good corrosion resistance in marine and chloride environments, and that is why they are popularly used as an assembly for heat exchangers or a component of offshore oil drilling machineries.

The titanium material also comes with high formability and enhanced workability. They can be both hot and cold formed, and during these procedures, they will be able to retain their mechanical properties.Titanium weighs almost 40-45% less than your regular stainless steel flanges, which helps them be easier to handle during the welding or installation period. Thus, using the titanium flanges once can expect to get better performances with convenience.

The highlights of the titanium flanges are as follows:

- Their physical properties like low density and improved strength, helps in enhancing the mechanism load along with decreasing both the structural weight and the string stress. They show good resistance at high temperature and for fractures. These flanges are mostly non-magnetic.

- They show good resistance to corrosion in a wide range of media, including organic chemicals, acids, alkaline, chloride, sulfur dioxide, nitric acids, and many more. They are able to retain their structural quality and hence they are ideal for prolonged usage. Due to these properties, they are popularly used for a wide range of applications.

- Due to their high durability and prolonged usable years, the titanium flanges are considered as a very economical choice. They do not need frequent replacements or any other additional material to improve the structural strength. It has a good longevity which is preferred by most of the industries.

Titanium Grade 2 Flanges Vs Titanium Grade 5 Flanges

The titanium grade 2 flanges is made of the grade 2 titanium which is a commercial pure alpha alloy. It has great corrosion resisting properties especially in a wide range of aggressive media. The grade 2 material might be preferred over grade 5 material where aqueous corrosion is an issue. The grade 2 titanium also comes with high formability compared to grade 5.

The titanium grade 5 material can be described as an alpha beta alloy, which can be heat treated to give medium to high strength. It has a limited hardenability and that is why any section which is above 25mm thick might not develop the desired properties. They come with good weldability and hot formability. However, when it comes to hot forming, their degree is limited.

Ti Grade 2 Slip on Flange Vs Titanium Gr 5 RTJ Flanges

The Ti grade 2 slip on flanges are metallic rings that are slipped over to the ends of the pipe. They are then joined to the piping system through double welds, both from inside and outside. This helps to make the piping system leak-proof. The grade 2 flanges are mostly used in corrosive environments, as they can resist it effectively. However, they are capable of tackling low-pressure flows where there is a less leakage risk.

The Titanium Gr 5 RTJ Flanges have high strength and hence they are used for applications that involve high temperature and pressure. The ring type joint flange is a machined metallic ring that has deep cuts and grooves in its face. They help in giving leak-proof connections by establishing a strong seal.

Does Ti Grade 5 Flange rust or corrode?

The Ti Grade 5 Flange has corrosion resisting properties but the grade 2 titanium material offers better performances in such conditions.

Titanium Flanges Manufacturer In India

Nace Certified Titanium Flanges manufacturers in Mumbai offers wide selection of ASME B16.5 ASTM B381 Grade F2 Weld Neck Flange Collar and Titanium Grade 2 Grooved Flange in India

Table of Content

- Titanium Flanges Specification List

- Titanium Grade 2 Flanges Size Chart

- Titanium Blind Flange Dimensions

- Titanium Flanges Price List

- UNS R50400 Slip on Flange Annealing Temperature

- Machinability Of DIN 3.7035 Weld Neck Flange

- Titanium Grade 2 Flange Casting

- Titanium Pipe Flange Chemical Composition

- Titanium Exhaust Flanges Mechanical Properties

- Titanium Conflat Flanges Equivalent Grade

- Gr 2 Ti Blind Flange Thermal Expansion Coefficient

- Titanium Grade 2 Flanges Hardness

- Titanium Gr. 2 Flanges Temperature Limits

- Ti Alloy Grade 2 Flange Corrosion Resistance

- Ti Grade 2 Flange Thermal Properties

- Types of Titanium Flanges

- Heat Treatment Of Cp Titanium Grade 2 Flanges

- Value Added Services for Titanium Gr. 2 Flanges

- Titanium Flange Pressure Temperature Rating

- Titanium Flange Weight

- Manufacturing Facilities of Titanium Gr 2 Flanges

- Difference Between Titanium Grade 2 And 5 Flange

- Surface Treatment of Cp Grade 5 Titanium Flanges

- Titanium Gr 5 Flanges Applications

Titanium Flanges Specification List

| Size Range | 1/2″ to 48″ |

|---|---|

| JIS | 40 K, 16 K, 5K, 10 K, 30 K, 20 K, 63 K |

| Chart of Pressure Rating | 300 LBS, 2500 LBS, 1500 LBS, 900 LBS, 150 LBS, 600 LBS |

| Production technique Used By Manufacturer | Heat treated, Forged and machined |

| Origin | Japan / West Europe / Indian / USA / Korean |

| DIN Pressure Calculation | 25Bar 40Bar 16Bar 6Bar 10Bar / PN64 PN10 PN25 PN16 PN6 PN40 |

| Manufacturer of Connect / Flange Face Type | LJF, RF, RTJ, FF, Small Tongue, Large Tongue & Groove |

| Test | Magnetic particle detector, X-ray detector, Ultrasonic flaw detector, Direct-reading Spectrograph, Hydrostatic testing machine |

| Standards Provided By Manufacturer | ISO70051, MSS S44, BS1560-3.1, API7S-43, B16.48, ANSI/ASME B16.5, B16.47 Series A & B, BS4504, JISB2220, ASME/ANSI B16.5/16.36/16.47A/16.47B, API605, BS 10, EN-1092, DIN, API7S-15, EN1092 |

| UNI / EN | 16Bar 6Bar 40Bar 10Bar 25Bar |

| Coating | Zinc Plated, Anti-rust Paint, Yellow Transparent, Oil Black Paint, Cold and Hot Dip Galvanized |

| Manufacturer of | GOST, JIS, ANSI, DIN, UNI, BS, AWWA, AS2129, SABS, NFE, EN etc. |

| Common Types By Manufacturer | Threaded / Screwed / Forged / Plate |

| Equipment | Pushing Machine, Press machine, Sand-blasting machine, Bending machine, electric bevelling machine etc |

We are Well known Titanium Pipe Flange stockholders, stockists, distributor, importer, dealers, supplier, wholesalers, exporters and Manufacturer in Mumbai.

Titanium Grade 2 Flanges Size Chart

| Nominal Pipe Size (inch) |

Dia. of Flange (inch) |

No. of Bolts |

Dia. of Bolts (inch) |

Dia. of Bolt Holes (inch) |

Bolt Circle (inch) |

|---|---|---|---|---|---|

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 3/4 | 3-7/8 | 4 | 1/2 | 0.62 | 2-3/4 |

| 1 | 4-1/4 | 4 | 1/2 | 0.62 | 3-1/8 |

| 1/2 | 3-1/2 | 4 | 1/2 | 0.62 | 2-3/8 |

| 1-1/4 | 4-5/8 | 4 | 1/2 | 0.62 | 3-1/2 |

| 2 | 6 | 4 | 5/8 | 0.75 | 4-3/4 |

| 2-1/2 | 7 | 4 | 5/8 | 0.75 | 5-1/2 |

| 1-1/2 | 5 | 4 | 1/2 | 0.62 | 3-7/8 |

| 3 | 7-1/2 | 4 | 5/8 | 0.75 | 6 |

| 3-1/2 | 8-1/2 | 8 | 5/8 | 0.75 | 7 |

| 4 | 9 | 8 | 5/8 | 0.75 | 7-1/2 |

| 20 | 27-1/2 | 20 | 1-1/8 | 1.25 | 25 |

| 6 | 11 | 8 | 3/4 | 0.88 | 9-1/2 |

| 8 | 13-1/2 | 8 | 3/4 | 0.88 | 11-3/4 |

| 5 | 10 | 8 | 3/4 | 0.88 | 8-1/2 |

| 10 | 16 | 12 | 7/8 | 1 | 14-1/4 |

| 14 | 21 | 12 | 1 | 1.12 | 18-3/4 |

| 16 | 23-1/2 | 16 | 1 | 1.12 | 21-1/4 |

| 12 | 19 | 12 | 7/8 | 1 | 17 |

| 18 | 25 | 16 | 1-1/8 | 1.25 | 22-3/4 |

| 24 | 32 | 20 | 1-1/4 | 1.38 | 29-1/2 |

Supplier of ASTM B381 Gr F2 Socket Weld Flange and Titanium Grade 5 Orifice Flanges offers pressure test with each delivery

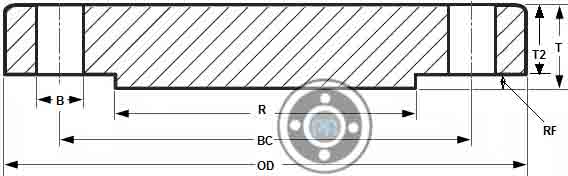

Titanium Blind Flange Dimensions

| FLANGE NPS |

Outside Diameter |

Raised Face (RF) | Bolt Hole (B) | Bolt Circle (BC) | Raised Face (R) | Flat Face Thickness (T2) |

Raised Face Thickness (T) |

No. of Bolt Holes |

|---|---|---|---|---|---|---|---|---|

| 3/4" | 3.88" | .063" | .62" | 2.75" | 1.69" | .44" | .50" | 4 |

| 1" | 4.25" | .063" | .62" | 3.12" | 2.00" | .50" | .56" | 4 |

| 1/2" | 3.50" | .063" | .62" | 2.38" | 1.38" | .38" | .44" | 4 |

| 1-1/4" | 4.62" | .063" | .62" | 3.50" | 2.50" | .56" | .62" | 4 |

| 1-1/2" | 5.00" | .063" | .62" | 3.88" | 2.88" | .62" | .68" | 4 |

| 2" | 6.00" | .063" | .75" | 4.75" | 3.62" | .69" | .75" | 4 |

| 3" | 7.50" | .063" | .75" | 6.00" | 5.00" | .88" | .94" | 4 |

| 3-1/2" | 8.50" | .063" | .75" | 7.00" | 5.50" | .88" | .94" | 8 |

| 22" | 29.50" | .063" | 1.38" | 27.25" | 25.25" | 1.75" | 1.81" | 20 |

| 4" | 9.00" | .063" | .75" | 7.50" | 6.19" | .88" | .94" | 8 |

| 2-1/2" | 7.00" | .063" | .75" | 5.50" | 4.12" | .82" | .88" | 4 |

| 5" | 10.00" | .063" | .88" | 8.50" | 7.31" | .88" | .94" | 8 |

| 6" | 11.00" | .063" | .88" | 9.50" | 8.50" | .94" | 1.00" | 8 |

| 8" | 13.50" | .063" | .88" | 11.75" | 10.62" | 1.06" | 1.12" | 8 |

| 10" | 16.00" | .063" | 1.00" | 14.25" | 12.75" | 1.13" | 1.19" | 12 |

| 14" | 21.00" | .063" | 1.12" | 18.75" | 16.25" | 1.32" | 1.38" | 12 |

| 16" | 23.50" | .063" | 1.12" | 21.25" | 18.50" | 1.38" | 1.44" | 16 |

| 12" | 19.00" | .063" | 1.00" | 17.00" | 15.00" | 1.19" | 1.25" | 12 |

| 18" | 25.00" | .063" | 1.25" | 22.75" | 21.00" | 1.50" | 1.56" | 16 |

| 20" | 27.50" | .063" | 1.25" | 25.00" | 23.00" | 1.63" | 1.69" | 20 |

| 24" | 32.00" | .063" | 1.38" | 29.50" | 27.25" | 1.82" | 1.88" | 20 |

Titanium Flanges Price List

| Titanium Flange Price Per Piece in India | Ti Alloy Flange Price in INR | Titanium Pipe Flange Price in UAE Dirham | Ti Flange Price in USD |

| TITANIUM FORGED FLANGE PT3B - DIA 300 X 80MM Per Kg | 1,856 | UAE Dirham 91.28 | $24.85 |

| TITANIUM FLANGE SORF SB381GRF2 25 NB X 150# Per Kg | 4,048 | UAE Dirham 199.09 | $54.20 |

| TITANIUM GR2 CIRCULAR FLANGE 737 MM ODX511MM ID X 6MM Per Kg | 1,320 | UAE Dirham 64.96 | $17.68 |

| ASTM B381 GR2 TITANIUM FLANGES Per Kg | 2,176 | UAE Dirham 107.08 | $29.15 |

If you buy directly from Titanium Flanges manufacturer in India you can save 8-10% cost. We are most reliable and trusted Titanium Flanges Suppliers in Mumbai. Call or Mail us to get latest Price list of Titanium Header Flanges.

UNS R50400 Slip on Flange Annealing Temperature

| Annealing Temperature | 1200°F to 1400°F for 6 minutes to 2 hours |

Machinability Of DIN 3.7035 Weld Neck Flange

| Material | Hardness | Machinability | SAE | DIN |

|---|---|---|---|---|

| Ti-99.5 (Grade 1) | 100 HRB | 46% | Grade 1 B381F4 | Ti-99.5 |

| Ti-99.6 (Grade 2) | 90 HRB | 40% | Grade 2 B381F3 | Ti-99.6 |

| Ti-99.7 (Grade 3) | 80 HRB | 35% | Grade 3 B381F2 | Ti-99.7 |

| Ti-99.8 (grade 4) | 70 HRB | 28% | Grade 4 B381F1 | Ti-99.8 |

Titanium Grade 2 Flange Casting

Grade C-2 titanium Flanges is a casting-grade titanium alloy. The attributes listed are for the as-fabricated (no tempering or treatment) condition. Among the cast titaniums in the database, it has a reasonably low embodied energy.

Titanium Pipe Flange Chemical Composition

| Grade | Ti | C | Fe | H | N | O | Al | V |

| Ti Grade2 | 99.2 min | 0.1 max | 0.3 max | 0.015 max | 0.03 max | 0.25 max | - | - |

| Ti Grade5 | 90 min | - | 0.25 max | - | - | 0.2 max | 6 min | 4 min |

Titanium Exhaust Flanges Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Titanium Gr. 2 | 4.5 g/cm3 | 1665 °C (3030 °F) | Psi – 49900 , MPa – 344 | Psi – 39900 , MPa – 275 | 20 % |

| Titanium Gr. 5 | 4.43 g/cm3 | 1632 °C (2970 °F) | Psi – 138000 , MPa – 950 | Psi – 128000 , MPa – 880 | 14 % |

Titanium Conflat Flanges Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS |

| Titanium Gr. 2 | 3.7035 | R50400 |

| Titanium Gr. 5 | 3.7165 | N56400 |

Bulk discount on RF, TF, FF, GF, RTJ Titanium Lap Joint Flange and ASME SB 381 Gr F2 Spectacle Blind Flange in Maharashtra

Gr 2 Ti Blind Flange Thermal Expansion Coefficient

| Heat of Fusion | 325 J/g | 140 BTU/lb |

| CTE, linear 20°C | 8.6 µm/m-°C | 4.78 µin/in-°F |

| CTE, linear 250°C | 9.2 µm/m-°C | 5.11 µin/in-°F |

| CTE, linear 500°C | 9.7 µm/m-°C | 5.39 µin/in-°F |

| Specific Heat Capacity | 0.523 J/g-°C | 0.125 BTU/lb-°F |

| Thermal Conductivity | 16.4 W/m-K | 114 BTU-in/hr-ft²-°F |

| Melting Point | Max 1665 °C | Max 3030 °F |

| Liquidus | 1665 °C | 3030 °F |

| Beta Transus | 913 °C | 1680 °F |

Titanium Grade 2 Flanges Hardness

| Hardness, Knoop | 170 | 170 |

| Hardness, Rockwell B | 80 | 80 |

| Hardness, Vickers | 145 | 145 |

Titanium Gr. 2 Flanges Temperature Limits

| Service temperature | -210°C – 400°C for reliable structural integrity | Depends on environments e.g. up to 316°C for steam and seawater |

Ti Alloy Grade 2 Flange Corrosion Resistance

Titanium grade 2 Flange corrosion resistance is due to the formation of a strongly adhering, stable, protective oxide film in the presence of oxygen. This film protects commercially pure titanium grades against most oxidising, neutral, and inhibited reducing conditions, as well as slightly reducing situations. Ti Grade 2 Flange is highly resistant to seawater and marine atmospheric corrosion. Corrosion resistance is similar among the four C.P. grades, however mechanical qualities differ due to differences in oxygen and iron concentration.

Ti Grade 2 Flange Thermal Properties

| Properties | Metric | Imperial |

|---|---|---|

| Thermal expansion co-efficient (@0.000-100°C/32-212°F) | 8.60 µm/m°C | 4.78 µin/in°F |

| Thermal conductivity | 21.97 W/mK | 152.5 BTU in/hr.ft².°F |

Check Titanium Threaded/ Forged Flange and ASTM B381 Grade F2 Plate Flange equivalent specification & price in Mumbai

Types of Titanium Flanges

Titanium Grade 7 Reducing Flanges

Cp Grade 5 Titanium SORF Flanges

Gr 2 Ti Socket Weld Flange

2500 LBS Ti gr 5 Weld Neck Flanges

Titanium Gr. 2 Spectacle Blind Flange

ASTM B381 Titanium Grade 2 WNRF Flange

15 NB Titanium Grade 1 Tongue & Groove Flange

Ti Alloy Gr 5 Slip On Flange

Titanium Exhaust Flanges

300 LBS Titanium NCF Gr 2 BLRF Flanges

3.7035 Titanium Grade 2 Expander Flanges

Titanium Pipe Flange

Titanium Grade 2 Nipoflange

Titanium Blind Flange

UNS R56400 Ring Joint Flange

150 LBS Ti Alloy Screwed Flange

Titanium Gr 2 Flanges

1500 LBS WERKSTOFF NR. 3.7165 SWRF Flanges

Titanium Gr 5 Flanges

600 LBS Titanium Grade 5 Long Weld Neck Flange

900 LBS ASME B16.5 Titanium grade 5 Orifice Flanges

Titanium Gr 2 Threaded Flange

Titanium Conflat Flanges

Titanium Grade 2 Flanges

Titanium Header Flanges

UNS R50400 Lapped Joint Flange

5000 NB DIN 3.7035 Girth Flanges

Heat Treatment Of Cp Titanium Grade 2 Flanges

- Anneal

- Hold at 1103° to 1400F (595° to 760°C) for two hours

- Air cool

- Stress relive by holding at 1004° to 1103°F (540° to 595°C) for 15 to 30 minutes

- Air cool

- Intermediate and final annealing in inert gas or vacuum

- Perform final heat treatments in vacuum

Value Added Services for Titanium Gr. 2 Flanges

- Eddy Current Testing

- Flaring Test

- Macro Test

- Flattening Test

- Dye Penetrant Test (DP Test)

- Radiography Test

- Hardness Test

- Ultra Sonic Test (UT)

- Pitting Resistance Test

- Micro Test

- Intergranular Corrosion (IGC) Test

Titanium Flange Pressure Temperature Rating

| Temperature °F | Class 150 | Class 600 | Class 1500 | Class 400 | Class 900 | Class 300 | Class 2500 |

| -20 to 100 | 275 | 1440 | 3600 | 960 | 2160 | 720 | 6000 |

| 300 | 205 | 1080 | 2700 | 720 | 1620 | 540 | 4500 |

| 200 | 230 | 1200 | 3000 | 800 | 1800 | 600 | 5000 |

| 400 | 190 | 995 | 2485 | 660 | 1490 | 495 | 4140 |

| 600 | 140 | 875 | 2185 | 580 | 1310 | 435 | 3640 |

| 650 | 125 | 860 | 2150 | 575 | 1290 | 430 | 3580 |

| 500 | 170 | 930 | 2330 | 620 | 1395 | 465 | 3880 |

| 700 | 110 | 850 | 2125 | 565 | 1275 | 425 | 3540 |

| 750 | 95 | 830 | 2075 | 555 | 1245 | 415 | 3460 |

| 850 | 65 | 790 | 1980 | 530 | 1190 | 395 | 3300 |

| 800 | 80 | 805 | 2015 | 540 | 1210 | 405 | 3360 |

| 900 | 50 | 780 | 1945 | 520 | 1165 | 390 | 3240 |

| 950 | 35 | 765 | 1910 | 510 | 1145 | 380 | 3180 |

| 1000 | 20 | 640 | 1605 | 430 | 965 | 320 | 2675 |

| 1100 | 20 | 515 | 1285 | 345 | 770 | 255 | 2145 |

| 1150 | 20 | 400 | 995 | 265 | 595 | 200 | 1655 |

| 1050 | 20 | 615 | 1545 | 410 | 925 | 310 | 2570 |

| 1200 | 20 | 310 | 770 | 205 | 465 | 155 | 1285 |

| 1250 | 20 | 225 | 565 | 150 | 340 | 115 | 945 |

| 1300 | 20 | 170 | 430 | 115 | 255 | 85 | 715 |

| 1400 | 20 | 95 | 240 | 65 | 145 | 50 | 400 |

| 1350 | 20 | 125 | 310 | 80 | 185 | 60 | 515 |

| 1450 | 15 | 70 | 170 | 45 | 105 | 35 | 285 |

| 1500 | 10 | 55 | 135 | 35 | 80 | 25 | 230 |

Titanium Flange Weight

| NPS (Nominal Pipe Size) | NPT (Threaded) | WRNR (Weld Neck) | SWRF (Socket Weld) | Loose (Lap Joint) | SORF (Slip On) | BLRF (Blind) |

|---|---|---|---|---|---|---|

| ½ | 1 | 2 | 2 | 1 | 1 | 2 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 |

| 1 | 2 | 3 | 2 | 2 | 2 | 2 |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 |

| 1½ | 3 | 4 | 3 | 3 | 3 | 4 |

| 2 | 5 | 6 | 5 | 5 | 5 | 5 |

| 2½ | 8 | 10 | 8 | 8 | 8 | 7 |

| 3 | 9 | 11.5 | 9 | 9 | 9 | 9 |

| 3½ | 12 | 12 | 11 | 11 | 11 | 13 |

| 4 | 13 | 16.5 | 13 | 13 | 13 | 17 |

| 5 | 15 | 21 | 15 | 15 | 15 | 20 |

| 6 | 19 | 26 | 19 | 19 | 19 | 27 |

| 8 | 30 | 42 | 30 | 30 | 30 | 47 |

| 10 | 43 | 54 | 43 | 43 | 43 | 70 |

| 12 | 64 | 88 | 64 | 64 | 64 | 123 |

| 14 | 90 | 114 | 90 | 105 | 90 | 140 |

| 16 | 98 | 140 | 98 | 140 | 106 | 180 |

| 18 | 130 | 165 | 130 | 160 | 130 | 220 |

| 20 | 165 | 197 | 165 | 195 | 165 | 285 |

| 22 | 185 | 225 | 185 | 245 | 185 | 355 |

| 24 | 220 | 268 | 220 | 275 | 220 | 430 |

Manufacturing Facilities of Titanium Gr 2 Flanges

- Bolt Hole drilling: High speed CNC Vertical Machining Center

- Raw material cutting: band saw

- Open / Close Die Forging & Rolling: Hammer /Press / Ring Rolling

- Heat treatment: Solution Annealing (batch annealing furnaces)

- Machining: SPM lathes/ CNC lathes

Difference Between Titanium Grade 2 And 5 Flange

| PROPERTIES | TI 6AL-4V (UNS R56400) | TITANIUM GRADE 2 (UNS R50400) |

|---|---|---|

| METALLURGY | 895 MPa | 345 MPa |

| ULTIMATE TENSILE STRENGTH | 827 MPa | 276 MPa |

| 0.2% OFFSET YIELD STRENGTH | 827 MPa | 276 MPa |

| % ELONGATION (DUCTILITY) | 10 | 20 |

| CORROSION RESISTANCE | Very good | Outstanding |

| CREEP AND STRESS-RUPTURE | High | NA |

| FATIGUE | High | NA |

Surface Treatment of Cp Grade 5 Titanium Flanges

- Oil Black Paint

- Yellow Transparent

- Cold and Hot Dip Galvanized

- Anti-rust Paint

- Zinc Plated

Titanium Gr 5 Flanges Applications

- Sea Water Equipment

- Power Generation

- Pulp and Paper Industry

- Gas Processing

- Specialty Chemicals

- Pharmaceutical Equipment

- Chemical Equipment

- Petrochemicals

- Off-Shore Oil Drilling Companies

Flanges Material

Pipe Fittings Material

Other Products