- Call : +91 22 67436442

- exports@petrometflange.com

Ring Joint Gasket manufacturer in India

- Home /

- Ring Joint Gasket

RTJ Gasket and Type R Ring Gaskets manufacturer in India

What is ring joint gasket?

The ring joint gasket is also known as API gasket or RTJ gasket. They are heavy duty gaskets that are used for high pressure applications, especially in large offshore and on-shore petrochemical industries. It is also used in oil-field drilling equipment, pipeworks/valve assemblies, and high-integrity pressure vessel joints.

Depending on the chemical compatibility of the media, it is very important to choose the right gasket material. The hardness of the flange should also be considered. Usually, the gasket material is around 30 brinell less than the flange material, and that ensures gasket deformation without any damages to the flange face.

The ring joint gasket can be described as a metallic ring which is suitable for various high temperature and/or high pressure applications. The ring joint gasket along with the RTJ flange helps to create a strong seal between the mating flanges.

There are three types of ring joint gasket:

- Style R gasket- These are used for applications having pressure up to 5,000 PSI. There are oval shaped and octagonal shaped gaskets in this category.

- Style RX gasket- hese are used for applications having pressure up to 50,000 PSI.

- Style BX gasket- hese are used for applications having pressure up to 20,000 PSI.

What is the difference between a full face gasket and a ring gasket?

The difference between a full face gasket and a ring gasket is that a full face gasket covers the entire flange face whereas a ring gasket inside the securing bolts. A full face gasket has the same outer diameter as that of the flange. It also comes with the necessary cuts that help in securing the bolts. On the other hand, the ring gasket sits around the bore of the pipe, which might include the raised surface if a raised face flange is used. With full face gaskets, there are no chances of dirt getting in between the two bolting surfaces. Whereas, the ring gasket is used universally as the measurement of the inner and the outer of the raised surface are required.

Can you use a ring gasket on a full face flange?

The full face flange gasket can also be used for ring gasket application, but the material present outside the face would not contribute to sealing. However, the positioning becomes easier due to the presence of bolts. But a ring type gasket cannot be used on full face flange applications as that can cause cracks and there are also chances of bending.

How does a BX Type ring joint gaskets seal?

The BX Type ring joint gaskets are bigger than the ring grooves. Thus, when the flanges or the hubs are tightened, the gasket gets slightly compressed to the ring groove so as to seal the pressure.

Can you reuse RTJ gaskets?

Reusing the RTJ gasket is not recommended except for the large grooved metal gasket. They are not to be reused as metallic gaskets basically depend on deforming and coining into the surface of the flange. This helps in effective sealing. The coining deforms yield the gasket, and hence reusing the RTJ gasket will not give you the desired sealing.

Ring Joint Gasket manufacturer in India

Rubber coated Rtj Flange Gasket and R24/ R45/ R39/ R37/ R46 Oval Ring Gasket manufacturer in India

Table of Content

- Specification of Ring Joint Gasket

- Raised face flange gasket dimensions

- Ring type joint gasket dimensions

- Price List of Ring Joint Gasket

- RTJ flange gasket chart

- Identification of RTJ Gasket

- Rtj Gasket Types

- Rtj Gasket Material

- ASME B16.20 BX SERIES Ring Joint Gaskets Dimensions

- Ring Joint Gasket Torque Chart

- Ring Joint Gasket Advantages And Disadvantages

- Can Ring Joint Gaskets Be Reused

- Tightening Torque For Ring Joint Gasket

- Ring Joint Gasket Tolerance

- Mechanical Properties Ring Joint Gaskets Materials

- How To Install Ring Joint Gasket

- R39 Ring Gasket Material and Hardness

- Applications of Bx152 Ring Gasket

- Surface Finish of Ring Joint Gasket

- Style RX Ring Joint Gaskets Dimensions

- Style BX Ring Joint Gaskets Dimensions

- How To Order Ring Joint Gasket

Specification of Ring Joint Gasket

| Material | CAF,PTFE,Metal,Graphite |

| Color | Natural |

| Thickness | 0.2 to 10 mm |

| Size | 1/2" to 16" |

| Shape | Round |

| Diameter Provided By Manufacturer | 1/2" to 16" |

| Temperature | 250 Deg C |

Leading RTJ Gasket importer, dealers, supplier, stockholders, wholesalers, exporters, stockists, distributor and Manufacturer in Mumbai.

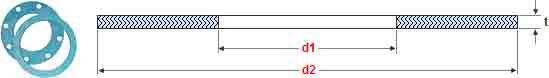

Raised face flange gasket dimensions

| NPS | d1 | d2 | ||||

| Class 150 |

Class 300 |

Class 400 |

Class 600 |

Class 900 |

||

| 1/2 | 21 | 48 | 54 | 54 | 54 | 64 |

| 3/4 | 27 | 57 | 67 | 67 | 67 | 70 |

| 1 | 33 | 67 | 73 | 73 | 73 | 79 |

| 1.1/4 | 42 | 76 | 83 | 83 | 83 | 89 |

| 1.1/2 | 48 | 86 | 95 | 95 | 95 | 98 |

| 2 | 60 | 105 | 111 | 111 | 111 | 143 |

| 2.1/2 | 73 | 124 | 130 | 130 | 130.2 | 165 |

| 3 | 89 | 137 | 149 | 149 | 149 | 168 |

| 3.1/2 | 102 | 162 | 165 | 162 | 162 | |

| 4 | 114 | 175 | 181 | 178 | 194 | 206 |

| 5 | 141 | 197 | 216 | 213 | 241 | 248 |

| 6 | 168 | 222 | 251 | 248 | 267 | 289 |

| 8 | 219 | 279 | 308 | 305 | 321 | 359 |

| 10 | 273 | 340 | 362 | 359 | 400 | 435 |

| 12 | 324 | 410 | 422 | 419 | 457 | 498 |

| 14 | 356 | 451 | 486 | 483 | 492 | 521 |

| 16 | 406 | 514 | 540 | 537 | 565 | 575 |

| 18 | 457 | 549 | 597 | 594 | 613 | 638 |

| 20 | 508 | 606 | 654 | 648 | 683 | 699 |

| 24 | 610 | 718 | 775 | 768 | 791 | 838 |

RX, BX,R Type Octagonal Rtj Gasket and Bx 155 Ring Gasket manufacturer in Mumbai in Class 150 to 2500

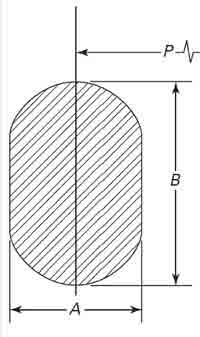

Ring type joint gasket dimensions

| R no | P-Pitch Dia | A-Width | B-Height Oval Ring |

| R-11 | 34.14 | 6.35 | 11.2 |

| R-12 | 39.7 | 7.95 | 14.2 |

| R-13 | 42.88 | 7.95 | 14.2 |

| R-14 | 44.45 | 7.95 | 14.2 |

| R-15 | 47.63 | 7.95 | 14.2 |

| R-16 | 50.8 | 7.95 | 14.2 |

| R-17 | 57.15 | 7.95 | 14.2 |

| R-18 | 60.33 | 7.95 | 14.2 |

| R-19 | 65.1 | 7.95 | 14.2 |

| R-20 | 68.28 | 7.95 | 14.2 |

| R-21 | 72.24 | 11.13 | 17.5 |

| R-22 | 82.55 | 7.95 | 14.2 |

| R-23 | 82.55 | 11.13 | 17.5 |

| R-24 | 95.25 | 11.13 | 17.5 |

| R-25 | 101.6 | 7.95 | 14.2 |

| R-26 | 101.6 | 11.13 | 17.5 |

| R-27 | 107.95 | 11.13 | 17.5 |

| R-28 | 111.13 | 12.7 | 19.1 |

| R-29 | 114.3 | 7.95 | 14.2 |

| R-30 | 117.48 | 11.13 | 17.5 |

| R-31 | 123.83 | 11.13 | 17.5 |

| R-32 | 127 | 12.7 | 19.1 |

| R-33 | 131.78 | 7.95 | 14.2 |

| R-34 | 131.78 | 11.13 | 17.5 |

| R-35 | 136.53 | 11.13 | 17.5 |

| R-36 | 149.23 | 7.95 | 14.2 |

| R-37 | 149.23 | 11.13 | 17.5 |

| R-38 | 157.18 | 15.88 | 22.4 |

| R-39 | 161.93 | 11.13 | 17.5 |

| R-40 | 171.45 | 7.95 | 14.2 |

| R-41 | 180.98 | 11.13 | 17.5 |

| R-42 | 190.5 | 19.05 | 25.4 |

| R-43 | 193.68 | 7.95 | 14.2 |

| R-44 | 193.68 | 11.13 | 17.5 |

| R-45 | 211.15 | 11.13 | 17.5 |

| R-46 | 211.15 | 12.7 | 19.1 |

| R-47 | 228.6 | 19.05 | 25.4 |

| R-48 | 247.65 | 7.95 | 14.2 |

| R-49 | 269.88 | 11.13 | 17.5 |

| R-50 | 269.88 | 15.88 | 22.4 |

| R-51 | 279.4 | 22.23 | 28.7 |

| R-52 | 304.8 | 7.95 | 14.2 |

| R-53 | 323.85 | 11.13 | 17.5 |

| R-54 | 323.85 | 15.88 | 22.4 |

| R-55 | 342.9 | 28.58 | 36.6 |

| R-56 | 381 | 7.95 | 14.2 |

| R-57 | 381 | 11.13 | 17.5 |

| R-58 | 381 | 22.23 | 28.7 |

| R-59 | 396.88 | 7.95 | 14.2 |

| R-60 | 406.4 | 31.75 | 39.6 |

| R-61 | 419.1 | 11.13 | 17.5 |

| R-62 | 419.1 | 15.88 | 22.4 |

| R-63 | 419.1 | 25.4 | 33.3 |

| R-64 | 454.03 | 7.95 | 14.2 |

| R-65 | 469.9 | 11.13 | 17.5 |

| R-66 | 469.9 | 15.88 | 22.4 |

| R-67 | 469.9 | 28.58 | 36.6 |

| R-68 | 517.53 | 7.95 | 14.2 |

| R-69 | 533.4 | 11.13 | 17.5 |

| R-70 | 533.4 | 19.05 | 25.4 |

| R-71 | 533.4 | 28.58 | 36.6 |

| R-72 | 558.8 | 7.95 | 14.2 |

| R-73 | 584.2 | 12.7 | 19.1 |

| R-74 | 584.2 | 19.05 | 25.4 |

| R-75 | 584.2 | 31.75 | 39.6 |

| R-76 | 673.1 | 7.95 | 14.2 |

| R-77 | 692.15 | 15.88 | 22.4 |

| R-78 | 692.15 | 25.4 | 33.3 |

| R-79 | 692.15 | 34.93 | 44.5 |

| R-92 | 228.6 | 11.13 | 17.5 |

Price List of Ring Joint Gasket

| Ring Joint Gasket Price Per Piece in India | RTJ Gasket Flanges Price in INR | Type R Ring Gaskets Price in UAE Dirham | Rubber coated Rtj Flange Gasket Price in USD |

| GASKET RING JOINT BX152 SS 316 Per Unit | 346 | UAE Dirham 17.10 | $4.66 |

| RING JOINT GASKET RX-49 Per Unit | 3,074 | UAE Dirham 151.91 | $41.36 |

| RING JOINT, GASKET -SPARES FOR PUMP Per PCS | 12,353 | UAE Dirham 610.48 | $166.21 |

| RING JOINT GASKET OCTAGONAL TYPE MAT:F51 Per PCS | 849 | UAE Dirham 41.96 | $11.42 |

We are leading Ring Joint Gasket manufacturer in India, Compare Price list of Type R Ring Gaskets Before Buying. We are leading R Type Octagonal Rtj Gasket Manufacturers.

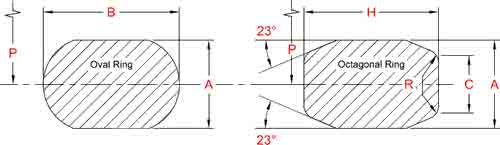

RTJ flange gasket chart

| R No |

Dia P |

Width A |

Height | Oct C |

Oct R1 |

NPS CL |

|

| Oval B |

Oct H |

||||||

| R 11 | 34.14 | 6.35 | 11.2 | 9.7 | 4.32 | 1.5 | 1/2 300 600 |

| R 12 | 39.7 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 1/2 900 1500 |

| R 13 | 42.88 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 3/4 300 600 1/2 2500 |

| R 14 | 44.45 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 3/4 900 1500 |

| R 15 | 47.63 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 1 150 |

| R 16 | 50.8 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 1 300 1500 3/4 2500 |

| R 17 | 57.15 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 1.1/4 150 |

| R 18 | 60.33 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 1.1/4 300 1500 1 2500 |

| R 19 | 65.1 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 1.1/2 150 |

| R No |

Dia P |

Width A |

Height | Oct C |

Oct R1 |

NPS CL |

|

| Oval B |

Oct H |

||||||

| R 20 | 68.28 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 1.1/2 300 1500 |

| R 21 | 72.24 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 1.1/4 2500 |

| R 22 | 82.55 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 2 150 |

| R 23 | 82.55 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 2 300 600 1.1/2 2500 |

| R 24 | 95.25 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 2 900 1500 |

| R 25 | 101.6 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 2.1/2 150 |

| R 26 | 101.6 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 2.1/2 300 600 2 2500 |

| R 27 | 107.95 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 2.1/2 900 1500 |

| R 28 | 111.13 | 12.7 | 19.1 | 17.5 | 8.66 | 1.5 | 2.1/2 2500 |

| R 29 | 114.3 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 3 150 |

| R No |

Dia P |

Width A |

Height | Oct C |

Oct R1 |

NPS CL |

|

| Oval B |

Oct H |

||||||

| R 30 * |

117.48 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 3 300 600 |

| R 31 | 123.83 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 3 300 900 |

| R 32 | 127 | 12.7 | 19.1 | 17.5 | 8.66 | 1.5 | 3 2500 |

| R 33 | 131.78 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 3.1/2 150 |

| R 34 | 131.78 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 3.1/2 300 600 |

| R 35 | 136.53 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 3 1500 |

| R 36 | 149.23 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 4 150 |

| R 37 | 149.23 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 4 300 900 |

| R 38 | 157.18 | 15.88 | 22.4 | 20.6 | 10.49 | 1.5 | 4 2500 |

| R 39 | 161.93 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 4 1500 |

| R No |

Dia P |

Width A |

Height | Oct C |

Oct R1 |

NPS CL |

|

| Oval B |

Oct H |

||||||

| R 40 | 171.45 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 5 150 |

| R 41 | 180.98 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 5 300 900 |

| R 42 | 190.5 | 19.05 | 25.4 | 23.9 | 12.32 | 1.5 | 5 2500 |

| R 43 | 193.68 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 6 150 |

| R 44 | 193.68 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 5 1500 |

| R 45 | 211.15 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 6 300 900 |

| R 46 | 211.15 | 12.7 | 19.1 | 17.5 | 8.66 | 1.5 | 6 1500 |

| R 47 | 228.6 | 19.05 | 25.4 | 23.9 | 12.32 | 1.5 | 6 2500 |

| R 48 | 247.65 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 8 150 |

| R 49 | 269.88 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 8 300 900 |

| R No |

Dia P |

Width A |

Height | Oct C |

Oct R1 |

NPS CL |

|

| Oval B |

Oct H |

||||||

| R 50 | 269.88 | 15.88 | 22.4 | 20.6 | 10.49 | 1.5 | 8 1500 |

| R 51 | 279.4 | 22.23 | 28.7 | 26.9 | 14.81 | 1.5 | 8 2500 |

| R 52 | 304.8 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 10 150 |

| R 53 | 323.85 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 10 300 900 |

| R 54 | 323.85 | 15.88 | 22.4 | 20.6 | 10.49 | 1.5 | 10 1500 |

| R 55 | 342.9 | 28.58 | 36.6 | 35.1 | 19.81 | 2.3 | 10 2500 |

| R 56 | 381 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 12 150 |

| R 57 | 381 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 12 300 900 |

| R 58 | 381 | 22.23 | 28.7 | 26.9 | 14.81 | 1.5 | 12 1500 |

| R 59 | 396.88 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 14 150 |

| R No |

Dia P |

Width A |

Height | Oct C |

Oct R1 |

NPS CL |

|

| Oval B |

Oct H |

||||||

| R 60 | 406.4 | 31.75 | 39.6 | 38.1 | 22.33 | 2.3 | 12 2500 |

| R 61 | 419.1 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 14 300 600 |

| R 62 | 419.1 | 15.88 | 22.4 | 20.6 | 10.49 | 1.5 | 14 900 |

| R 63 | 419.1 | 25.4 | 33.3 | 31.8 | 17.3 | 2.3 | 14 1500 |

| R 64 | 454.03 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 16 150 |

| R 65 | 469.9 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 16 300 600 |

| R 66 | 469.9 | 15.88 | 22.4 | 20.6 | 10.49 | 1.5 | 16 900 |

| R 67 | 469.9 | 28.58 | 36.6 | 35.1 | 19.81 | 2.3 | 16 1500 |

| R 68 | 517.53 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 18 150 |

| R 69 | 533.4 | 11.13 | 17.5 | 16 | 7.75 | 1.5 | 18 300 600 |

| R No |

Dia P |

Width A |

Height | Oct C |

Oct R1 |

NPS CL |

|

| Oval B |

Oct H |

||||||

| R 70 | 533.4 | 19.05 | 25.4 | 23.9 | 12.32 | 1.5 | 18 900 |

| R 71 | 533.4 | 28.58 | 36.6 | 35.1 | 19.81 | 2.3 | 18 1500 |

| R 72 | 558.8 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 20 150 |

| R 73 | 584.2 | 12.7 | 19.1 | 17.5 | 8.66 | 1.5 | 20 300 600 |

| R 74 | 584.2 | 19.05 | 25.4 | 23.9 | 12.32 | 1.5 | 20 900 |

| R 75 | 584.2 | 31.75 | 39.6 | 38.1 | 22.33 | 2.3 | 20 1500 |

| R 76 | 673.1 | 7.95 | 14.2 | 12.7 | 5.23 | 1.5 | 24 150 |

| R 77 | 692.15 | 15.88 | 22.4 | 20.6 | 10.49 | 1.5 | 24 300 600 |

| R 78 | 692.15 | 25.4 | 33.3 | 31.8 | 17.3 | 2.3 | 24 900 |

| R 79 | 692.15 | 34.93 | 44.5 | 41.4 | 24.82 | 2.3 | 24 1500 |

| R No |

Dia P |

Width A |

Height | Oct C |

Oct R1 |

NPS CL |

|

| Oval B |

Oct H |

||||||

Exporter of R & RX Series Oval Ring Joint Gasket and Bx 154/ 156/ 169/ 160/ 152/ 159 Ring Gasket suitable for ASME B16.47 series A flanges

Identification of RTJ Gasket

| GASKET MATERIALS | BRINELL HARDNESS NUMBER (max) | ROCKWELL B SCALE(max) | TEMPERATURE LIMIT

oC |

IDENTIFICATION |

| Soft iron | 90 | 56 | -60 to +400 | D |

| Low carbon steel | 120 | 68 | -40 to +500 | S |

| 4-6% Chrome 1/2% molybdenum | 130 | 72 | -125 to +500 | F5 |

| 410 Stainless Steel | 170 | 86 | -20 to +500 | S410 |

| 304 Stainless Steel | 160 | 83 | -250 to +650 | S304 |

| 316 Stainless Steel | 160 | 83 | -196 to +800 | S316 |

| 347 Stainless Steel | 160 | 83 | -250 to +870 | S347 |

Rtj Gasket Types

R46 Ring Gasket

Ring Joint Flange Gasket

Octagonal Gasket Rtj

Ring Joint Gasket

Rx Ring Gasket

Bx 153 Ring Gasket

Bx 159 Ring Gasket

Bx 151 Ring Gasket

Rtj Ring Gasket

R24 Ring Gasket

Bx 160 Ring Gasket

Bx 156 Ring Gasket

R37 Ring Gasket

Bx 155 Ring Gasket

Ring Gasket Bx 155

Octagonal Rtj Gasket

RTJ Gasket

Oval Ring Joint Gasket

Rtj To Rf Conversion Gasket

R39 Ring Gasket

Type R Ring Gaskets

R45 Ring Gasket

Bx152 Ring Gasket

Bx 154 Ring Gasket

Joint Gasket

Oval Ring Gasket

Rubber Ring Joints

BX Type Ring Joint Gaskets

Api Ring Gasket

Bx169 Ring Gasket

Rtj Flange Gasket

Bx Ring Gasket

API Ring Joint Gasket

Rtj Gasket Material

| RTJ GASKET MATERIAL | RING ID | ASTM GRADE | DIN GRADE | WKSTOFF NUMBER | AISI GRADE |

BS GRADE |

OTHER SPECS |

| Soft Iron | D | 1.1003 / 1.0335 | Aramco / StW24 | ||||

| LCS | S | 1.1003 / 1.0335 | Aramco / StW24 | ||||

| CS360 LT | CS360LT | A516 Gr70 | |||||

| 4140 | 4140 | UNS G41400 | 42CrMo4 | 1.7225 | 4140 | ||

| F5 | F5 | UNS K42544 | 12CrMo195 | 1.7362 | 5Cr 1/2Mo | ||

| SS304 | S304 | S30400 | X5CrNi 18 9 | 1.4301 | 304 | 304S15 | |

| SS304L | S304L | S30403 | X2CrNi 18 9 | 1.4306 | 304L | 304SS12 | |

| SS309 | S309 | S30900 | X15CrNiSi2012 | 1.4828 | 309 | 309S24 | |

| SS310 | S310 | S31008 | XX15CrNiSi2520 | 1.4841 | 310 | 310S24 | |

| SS316 | S316 | S31600 | X5CrNiMo18 10 | 1.4401 | 316 | 316S16 | |

| SS316L | S316L | S31603 | X2CrNiMo18 10 | 1.4404 | 316L | 316S11/316S12 | |

| SS316L UREA | S316UG | S31603 | X2CrNiMo 18 14 3 | 1.4435 | |||

| SS316Ti | S316Ti | S31635 | X10CrNiMoTi1810 | 1.4571 | 316Ti | 320S31/320S17 | |

| SS321 | S321 | S32100 | X10CrNiTi18 9 | 1.4541 | 321 | 321S12 | |

| SS347 | S347 | S34700 | X10CrNiNb 18 9 | 1.455 | 347 | 347S51 | |

| SS410 | S410 | S41000 | X10Cr13 | 1.4006 | 410 | 410S21 | |

| Monel 400 | Monel400 | N04400 | NiCu30Fe | 2.436 | |||

| Inconel 600 | INC600 | N06600 | NiCr15Fe | 2.4816 | |||

| Inconel 625 | INC625 | N06625 | NiCr22Mo9Nb | 2.4856 | |||

| Inconel 718 | INC718 | N07718 | |||||

| Incoloy 800 | INC800 | N08800 | X5NiCrAlTi31-20 | 1.4958 | |||

| Incoloy 800H | INC800H | N08810 | 1.4958 | ||||

| Incoloy 825 | INC825 | N08825 | NiCr21Mo | 2.4858 | |||

| 904L | 904L | N08904 | X1NiCrMoCu25-20-5 | 1.4539 | |||

| F51 | F51 | S31803 | X2CrNiMoN22-5-3 | 1.4462 | 2205 /Duplex | ||

| F53 | F53 | S32750 | X2CrNiMoN25-7-4 | 1.441 | |||

| F55 | F55 | S32760 | X2CrNiMoCuWN 25 7 4 | 1.4501 | Zeron 100 | ||

| F60 | F60 | S32205 | Duplex | ||||

| Titanium | Ti | R 50400 | 3.7035 | ||||

| 17-4PH | 17-4PH | S17400 | 1.4542 | 630 | |||

| S254 | S254 | S31254 | X1CrNiMoCuN20-18-7 | 1.4547 | F44 / 6Mo | ||

| C276 | C276 | N10276 | NiMo16Cr15W | 2.4819 | Hastelloy | ||

| Alloy 28 | Alloy28 | N08028 | X1 NiCrMoCuN 31 27 4 | 1.4563 | SANICRO 28 |

Manufacturer of API Ring Joint Gasket and Rubber Ring Joints according to API 6A, ASTM B16.20, and ASME B16.5/B16.20

ASME B16.20 BX SERIES Ring Joint Gaskets Dimensions

| RING GROOVE SIZE | FLANGE SIZE | PRESSURE RATING | LOW CARBON STEEL PART # | 316 SS PART # |

|---|---|---|---|---|

| BX-150* | 1 11/16" | 10,000/15,000 | RG801150 | RG802150 |

| BX-151 | 1 13/16" | 10,000/15,000/20,000 | RG801151 | RG802151 |

| BX-152 | 2 1/16" | 10,000/15,000/20,000 | RG801152 | RG802152 |

| BX-153 | 2 9/16" | 10,000/15,000/20,000 | RG801153 | RG802153 |

| BX-154 | 3 1/16" | 10,000/15,000/20,000 | RG801154 | RG802154 |

| BX-155 | 4 1/16" | 10,000/15,000/20,000 | RG801155 | RG802155 |

| BX-156 | 7 1/16" | 10,000/15,000/20,000 | RG801156 | RG802156 |

| BX-157 | 9" | 10,000/15,000/20,000 | RG801157 | RG802157 |

| BX-158 | 11" | 10,000/15,000/20,000 | RG801158 | RG802158 |

| BX-159 | 13 5/8" | 10,000/15,000/20,000 | RG801159 | RG802159 |

| BX-160 | 13 5/8" | 5,000 | RG801160 | RG802160 |

| BX-162 | 16 3/4" | 5,000/10,000 | RG801162 | RG802162 |

| BX-163 | 18 3/4" | 5,000 | RG801163 | RG802163 |

| BX-164 | 18 3/4" | 10,000/15,000 | RG801164 | RG802164 |

| BX-165 | 21 1/4" | 5,000 | RG801165 | RG802165 |

| BX-169** | 5 1/8" | 10,000 | RG801169 | RG802169 |

| BX-171 | 8 9/16" | 10,000/15,000 | RG801171 | RG802171 |

Ring Joint Gasket Torque Chart

| Flange NPS |

No of Bolts |

Bolt size |

Bolt Stress (MPa) |

Torque N-m μ=0.09 Copperslip |

Torque N-m μ=0.14 Chesterton Nickel |

Torque N-m μ=0.225 Unlubricated |

|---|---|---|---|---|---|---|

| ½'' | 4 | ¾ | 276 | 139 | 203 | 313 |

| ¾'' | 4 | ¾ | 276 | 139 | 203 | 313 |

| 1'' | 4 | ⅞ | 276 | 221 | 325 | 502 |

| 1¼'' | 4 | ⅞ | 276 | 221 | 325 | 502 |

| 1½'' | 4 | 1 | 276 | 330 | 485 | 748 |

| 2'' | 8 | ⅞ | 276 | 221 | 325 | 502 |

| 2½'' | 8 | 1 | 276 | 330 | 485 | 748 |

| 3'' | 8 | ⅞ | 310 | 249 | 366 | 565 |

| 4'' | 8 | 1 ⅛ | 310 | 539 | 797 | 1235 |

| 5'' | 8 | 1 ¼ | 310 | 752 | 1116 | 1736 |

| 6'' | 12 | 1 ⅛ | 310 | 539 | 797 | 1235 |

| 8'' | 12 | 1 ⅜ | 310 | 1014 | 1511 | 2356 |

| 12'' | 20 | 1 ⅜ | 310 | 1014 | 1511 | 2356 |

| 14'' | 20 | 1 ½ | 345 | 1477 | 2209 | 3453 |

| 16'' | 20 | 1 ⅝ | 345 | 1893 | 2839 | 4447 |

| 18'' | 20 | 1 ⅞ | 345 | 2951 | 4444 | 6984 |

| 20'' | 20 | 2 | 345 | 3599 | 5430 | 8545 |

| 24'' | 20 | 2 ½ | 310 | 6410 | 9728 | 15369 |

Ring Joint Gasket Advantages And Disadvantages

Advantages

- Ring type joints are utilised for high pressure sealing up to 20,000 psi.

- To meet the process application and flange grade, RTJ Gaskets can be manufactured from a range of materials.

- RTJs are exceptionally dependable and durable seals.

Disadvantages

- Because of the plastic flow of the ring joint in the flange faces to create the seal, ring-type gaskets are unsuitable for reuse.

- When compared to other types of gaskets, it is highly pricey.

- Skilled labour is necessary for successful installation.

Can Ring Joint Gaskets Be Reused

Ring joint gaskets are made with a limited amount of positive interference to guarantee that the ring type joint seats appropriately into the groove when compressed. Their re-use is not advised for two reasons:

- The gasket's initial seating will be hampered.

- Work hardening of the exterior metal surface happens when the gasket is plastically deformed. This could cause lasting damage to the groove.

Tightening Torque For Ring Joint Gasket

| Flange NPS |

No of Bolts |

Bolt size |

Bolt Stress (MPa) |

Torque N-m μ=0.09 Copperslip |

Torque N-m μ=0.14 Chesterton Nickel |

Torque N-m μ=0.225 Unlubricated |

|---|---|---|---|---|---|---|

| ½'' | 4 | ½ | 276 | 40 | 59 | 90 |

| ¾'' | 4 | ½ | 276 | 40 | 59 | 90 |

| 1'' | 4 | ½ | 276 | 40 | 59 | 90 |

| 1¼'' | 4 | ½ | 276 | 40 | 59 | 90 |

| 1½'' | 4 | ½ | 276 | 40 | 56 | 90 |

| 2'' | 4 | ⅝ | 276 | 79 | 116 | 178 |

| 2½'' | 4 | ⅝ | 276 | 79 | 116 | 178 |

| 3'' | 4 | ⅝ | 276 | 79 | 116 | 178 |

| 4'' | 8 | ⅝ | 276 | 79 | 116 | 178 |

| 5'' | 8 | ¾ | 276 | 139 | 203 | 313 |

| 6'' | 8 | ¾ | 276 | 139 | 203 | 313 |

| 8'' | 8 | ¾ | 276 | 139 | 203 | 313 |

| 10'' | 12 | ⅞ | 276 | 221 | 325 | 502 |

| 12'' | 12 | ⅞ | 276 | 221 | 325 | 502 |

| 14'' | 12 | 1 | 276 | 330 | 485 | 748 |

| 16'' | 16 | 1 | 276 | 330 | 485 | 748 |

| 18'' | 16 | 1 ⅛ | 276 | 479 | 708 | 1098 |

| 20'' | 20 | 1 ⅛ | 276 | 479 | 708 | 1098 |

| 24'' | 20 | 1 ¼ | 276 | 668 | 992 | 1543 |

Ring Joint Gasket Tolerance

- P = average pitch diameter of ring ±0.18

- A = width of ring ±0.20

- B & H = height of ring +1.3. -0.5

- Variation in height throughout the entire circumference of any given ring shall not exceed 0.5 within these tolerances

- C = width of flat on octagonal ring ±0.20

- R1 = radius in ring ±0.5

- 23 ° = angle ±0 ° 30 min

- *R-30 = for lapped joint only

Mechanical Properties Ring Joint Gaskets Materials

| Maximum Hardness of RTJ Gaskets |

|||

RTJ Gasket Material |

Brinell | HRB | ID |

Soft Iron-S |

90 | 56 | D |

Low Carbon Steel |

120 | 68 | S |

4 - 6% Chrome |

130 | 72 | F5 |

SS 304 Stainless Steel |

160 | 83 | S304 |

SS 316 Stainless Steel |

160 | 83 | S316 |

SS 347 Stainless Steel |

160 | 83 | S347 |

SS 410 Stainless Steel |

170 | 96 | S410 |

How To Install Ring Joint Gasket

The axial compressive load (from bolt tightening) acts on the Ring type joint (RTJ) gasket, causing it to distort and flow into flange groove imperfections. As a result, metal-to-metal contact has established between the gasket and the flange, forming a seal.

The ring-type joints are extremely tight and resistant to temperature and pressure changes. When installing a ring-type joint gasket, pay particular attention to the bolting up to ensure uniform load operating on the gasket. Also, ensure that the RTJ gasket and groove faces are free of flaws and debris.

R39 Ring Gasket Material and Hardness

| Material | Maximum hardness | |

| HB | HRB | |

| Soft lron | 90 | 56 |

| LowCS | 120 | 68 |

| F5 | 130 | 72 |

| SS304 | 160 | 83 |

| SS304L | 160 | 83 |

| SS309 | 160 | 83 |

| SS316 | 160 | 83 |

| SS316L | 160 | 83 |

| SS316Ti | 160 | 83 |

| SS321 | 160 | 83 |

| SS347 | 160 | 83 |

| SS410 | 140 | 86 |

| Nickel 200 | 110 | 62 |

| Monei 400 | 150 | 80 |

| Inconel 600 | 150 | 80 |

| Inconel 625 | 160 | 83 |

| Inconel 800/800H | 180 | 89 |

| Inconel 825 | 160 | 80 |

| Hastelloy C276 | 190 | 83 |

| Type 904 | 160 | 83 |

| N07718 | 190 | 91 |

| F51 | 230 | 98 |

| F53 | 230 | 98 |

| F55 | 240 | 100 |

Applications of Bx152 Ring Gasket

- Oil and gas industry

- Flange connections

- Pipe connections

- Heat exchangers

- Petrochemical industry

- Power plant technology

Surface Finish of Ring Joint Gasket

The surface finish of Style R and RX gaskets must be no rougher than 1.6m (63in.) roughness. The surface finish of Style BX gaskets must be no rougher than 0.8m (32in.) roughness.

Style RX Ring Joint Gaskets Dimensions

| RTJ GASKET RING NUMBER | 720-960 | 2900# | 3000# | 5000# | OD | HEIGHT | WIDTH | GASKET Wt. ( kg ) |

| RX20 | 1 ½ | - | 1 ½ | 1 ½ | 76.2 | 19.05 | 8.74 | 0.24 |

| RX23 | 2, 2 1/16 | - | 93.27 | 25.4 | 11.91 | 0.52 | ||

| RX24 | - | - | 2, 2 1/16 | 2, 2 1/16 | 105.97 | 25.4 | 11.91 | 0.6 |

| RX25 | - | - | - | 3 1/8 | 109.55 | 19.05 | 8.74 | 0.5 |

| RX26 | 2 ½ , 2 9/16 | - | - | - | 111.91 | 25.4 | 11.91 | 0.64 |

| RX27 | - | - | 2 ½, 2 9/16 | 2 ½, 2 9/16 | 118.26 | 25.4 | 11.91 | 0.68 |

| RX31 | 3 , 3 1/8 | - | 3, 3 1/8 | 134.54 | 25.4 | 11.91 | 0.78 | |

| RX35 | - | - | - | 3, 3 1/8 | 147.24 | 25.4 | 11.91 | 0.86 |

| RX37 | 4 , 4 1/16 | - | 4, 4 1/16 | - | 159.94 | 25.4 | 11.91 | 0.95 |

| RX39 | - | - | - | 4, 4 1/16 | 172.64 | 25.4 | 11.91 | 1.03 |

| RX41 | 5, 5 1/8 | - | 5, 5 1/8 | - | 191.69 | 25.4 | 11.91 | 1.15 |

| RX44 | - | - | - | 5, 5 1/8 | 204.39 | 25.4 | 11.91 | 1.23 |

| RX45 | 6, 7 1/16 | - | 6, 7 1/16 | - | 221.84 | 25.4 | 11.91 | 1.34 |

| RX46 | - | - | - | 6, 7 1/16 | 222.25 | 28.58 | 13.49 | 1.66 |

| RX47 | - | - | - | 8 | 245.26 | 41.28 | 19.84 | 3.88 |

| RX49 | 8, 9 | - | 8, 9 | 280.59 | 25.4 | 11.91 | 1.72 | |

| RX50 | - | - | - | 8, 9 | 283.36 | 31.75 | 16.66 | 2.43 |

| RX53 | 10, 11 | - | 10, 11 | 334.57 | 25.4 | 11.91 | 2.06 | |

| RX54 | - | - | - | 10, 11 | 337.34 | 31.75 | 16.66 | 2.92 |

| RX57 | 12, 13 5/8 | - | 12, 13 5/8 | 391.72 | 25.4 | 11.91 | 2.42 | |

| RX63 | - | - | 14 | 441.73 | 50.8 | 27 | 11.96 | |

| RX65 | 16, 16 3/4 | - | - | - | 480.62 | 25.4 | 11.91 | 3 |

| RX66 | - | - | 16, 16 3/4 | - | 457.99 | 31.75 | 16.66 | 4.25 |

| RX69 | 18 | - | 544.12 | 25.4 | 11.91 | 3.41 | ||

| RX70 | - | - | 18 | - | 550.06 | 41.28 | 19.84 | 9.12 |

| RX73 | 20, 21 1/4 | - | - | - | 596.11 | 31.75 | 13.49 | 5.27 |

| RX74 | - | - | 20, 20 3/4 | - | 600.86 | 41.28 | 19.84 | 10.01 |

| RX82 | - | 1 | - | - | 67.87 | 25.4 | 11.91 | 0.36 |

| RX84 | - | 1 ½ | - | - | 74.22 | 25.4 | 11.91 | 0.4 |

| RX85 | - | 2 | - | - | 90.09 | 25.4 | 13.49 | 0.4 |

| RX86 | - | 2 ½ | - | - | 103.58 | 28.58 | 15.09 | 0.81 |

| RX87 | - | 3 | - | - | 113.11 | 28.58 | 15.09 | 0.9 |

| RX88 | - | 4 | - | - | 139.29 | 31.75 | 17.48 | 1.46 |

| RX89 | - | 3 ½ | - | - | 129.77 | 31.75 | 18.26 | 3.09 |

| RX90 | - | 5 | - | - | 174.63 | 44.45 | 19.84 | 7.75 |

| RX91 | - | 10 | - | - | 286.94 | 45.24 | 30.18 | 1.5 |

| RX99 | 8 | - | 8 | - | 245.67 | 25.4 | 11.91 | 2.2 |

| RX201 | - | - | - | 1 3/8 | 51.46 | 11.3 | 5.74 | 0.1 |

| RX205 | - | - | - | 1 13/16 | 62.31 | 11.1 | 5.56 | 0.13 |

| RX210 | - | - | - | 2 9/16 | 97.64 | 19.05 | 9.53 | 0.35 |

| RX215 | - | - | - | 4 1/16 | 140.89 | 25.4 | 11.91 | 0.8 |

Style BX Ring Joint Gaskets Dimensions

| RTJ GASKET RING NUMBER | 2000# | 3000# | 5000# | 10000# | 15000# | 20000# | OUTSIDE DIA | HEIGHT OF THE RING |

WIDTH OF THE RING |

RTJ GASKET WEIGHT KG |

| BX 150 | - | - | - | 1 11/16 | 1 11/16 | - | 72.19 | 9.3 | 9.3 | 0.13 |

| BX 151 | - | - | - | 1 13/16 | 1 13/16 | 1 13/16 | 76.4 | 9.63 | 9.63 | 0.15 |

| BX 152 | - | - | - | 2 1/16 | 2 1/16 | 2 1/16 | 84.68 | 10.24 | 10.24 | 0.19 |

| BX 153 | - | - | - | 2 9/16 | 2 9/16 | 2 9/16 | 100.94 | 11.38 | 11.38 | 0.29 |

| BX 154 | - | - | - | 3 1/16 | 3 1/16 | 3 1/16 | 116.84 | 12.4 | 12.4 | 0.4 |

| BX 155 | - | - | - | 4 1/16 | 4 1/16 | 4 1/16 | 147.96 | 14.22 | 14.22 | 0.55 |

| BX 156 | - | - | - | 7 1/16 | 7 1/16 | 7 1/16 | 237.92 | 18.62 | 18.62 | 1.87 |

| BX 157 | - | - | - | 9 | 9 | 9 | 294.46 | 20.98 | 20.98 | 2.97 |

| BX 158 | - | - | - | 11 | 11 | 11 | 352.04 | 23.14 | 23.14 | 4.35 |

| BX 159 | - | - | - | 13 5/8 | - | - | 426.72 | 25.7 | 25.7 | 6.53 |

| BX 160 | - | - | 13 5/8 | - | - | - | 402.59 | 23.83 | 13.74 | 3.06 |

| BX 161 | - | - | 16 ¾ | - | - | - | 491.41 | 28.07 | 16.21 | 5.35 |

| BX 162 | - | - | 16 3/4 | 16 3/4 | 16 3/4 | - | 475.49 | 14.22 | 14.22 | 1.94 |

| BX 163 | - | - | 18 3/4 | - | - | - | 556.16 | 30.1 | 17.37 | 6.9 |

| BX 164 | - | - | - | 18 3/4 | 18 3/4 | - | 570.56 | 30.1 | 24.59 | 5.86 |

| BX 165 | - | - | 21 ¼ | - | - | - | 624.71 | 32.03 | 18.49 | 8.76 |

| BX 166 | - | - | - | 21 ¼ | - | - | 640.03 | 32.03 | 26.14 | 12.82 |

| BX 167 | 26 3/4 | - | - | - | - | - | 759.36 | 35.86 | 13.11 | 8.53 |

| BX 168 | - | 26 3/4 | - | - | - | - | 765.25 | 35.86 | 16.05 | 10.54 |

| BX 169 | - | - | - | 5 1/8 | - | - | 173.51 | 15.85 | 12.93 | 0.73 |

| BX 170 | - | - | - | 6 5/8 | 6 5/8 | - | 218.03 | 14.22 | 14.22 | 1.03 |

| BX 171 | - | - | - | 8 9/16 | 8 9/16 | - | 267.44 | 14.22 | 14.22 | 1.24 |

| BX 172 | - | - | - | 11 5/32 | 11 5/32 | - | 333.07 | 14.22 | 14.22 | 1.56 |

| BX 303 | 30 | 30 | - | - | - | - | 852.75 | 37.95 | 16.97 | - |

How To Order Ring Joint Gasket

| NOMINAL PIPE SIZE | PRESSURE CLASSES | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ASME B16.5 | API 6B | ASME B16.47 Series A | |||||||||||||

| 150# | 300# - 600# | 900# | 1500# | 2500# | 720# - 960# (1) | 2000# | 3000# | 5000# | 10000# | 150# | 300# - 600# | 900# | |||

| 1/2” | - | R-11 | R-12 | R-12 | R-13 | - | - | - | - | - | - | - | - | ||

| 3/4” | - | R-13 | R-14 | R-14 | R-16 | - | - | - | - | - | - | - | - | ||

| 1” | R-15 | R-16 | R-16 | R-16 | R-18 | R-16 | R-16 | R-16 | R-16 | R-82 | - | - | - | ||

| 1 1/4” | R-17 | R-18 | R-18 | R-18 | R-21 | R-18 | R-18 | R-18 | R-18 | - | - | - | - | ||

| 1 1/2” | R-19 | R-20 | R-20 | R-20 | R-23 | R-20 | R-20 | R-20 | R-20 | R-84 | - | - | - | ||

| 2” | R-22 | R-23 | R-24 | R-24 | R-26 | R-23 | R-23 | R-23 | R-24 | R-85 | - | - | - | ||

| 2 1/2” | R-25 | R-26 | R-27 | R-27 | R-28 | R-26 | R-26 | R-26 | R-27 | R-86 | - | - | - | ||

| 3” | R-29 | R-31 | R-31 | R-35 | R-32 | R-31 | R-31 | R-31 | R-35 | R-87 | - | - | - | ||

| 3 1/2” | R-33 | R-34 | - | - | - | - | - | - | R-37 | R-89 | - | - | - | ||

| 4” | R-36 | R-37 | R-37 | R-39 | R-38 | R-37 | R-37 | R-37 | R-39 | R-88 | - | - | - | ||

| 5” | R-40 | R-41 | R-41 | R-44 | R-42 | R-41 | R-41 | R-41 | R-44 | R-90 | - | - | - | ||

| 6” | R-43 | R-45 | R-45 | R-46 | R-47 | R-45 | R-45 | R-45 | R-46 | - | - | - | - | ||

| 8” | R-48 | R-49 | R-49 | R-50 | R-51 | R-49 | R-49 | R-49 | R-50 | - | - | - | - | ||

| 10” | R-52 | R-53 | R-53 | R-54 | R-55 | R-53 | R-53 | R-53 | R-54 | R-91 | - | - | - | ||

| 12” | R-56 | R-57 | R-57 | R-58 | R-60 | R-57 | R-57 | R-57 | - | - | - | R-57 | R-57 | ||

| 14” | R-59 | R-61 | R-62 | R-63 | - | R-61 | R-61 | R-61 | - | - | - | R-61 | R-62 | ||

| 16” | R-64 | R-65 | R-66 | R-67 | - | R-65 | R-65 | R-65 | - | - | - | R-65 | R-66 | ||

| 18” | R-68 | R-69 | R-70 | R-71 | - | R-69 | R-69 | R-69 | - | - | - | R-69 | R-70 | ||

| 20” | R-72 | R-73 | R-74 | R-75 | - | R-73 | R-73 | R-73 | - | - | - | R-73 | R-74 | ||

| 22” | - | - | - | - | - | - | - | - | - | - | R-80 | R-81 | - | ||

| 24” | R-76 | R-77 | R-78 | R-79 | - | - | - | - | - | - | - | R-77 | R-78 | ||

| 26” | - | - | - | - | - | - | - | - | - | - | - | R-93 | R-100 | ||

| 28” | - | - | - | - | - | - | - | - | - | - | - | R-94 | R-101 | ||

| 30” | - | - | - | - | - | - | - | - | - | - | - | R-95 | R-102 | ||

| 32” | - | - | - | - | - | - | - | - | - | - | - | R-96 | R-103 | ||

| 34” | - | - | - | - | - | - | - | - | - | - | - | R-97 | R-104 | ||

| 36” | - | - | - | - | - | - | - | - | - | - | - | R-98 | R-105 | ||

Other Products

Pipe Fittings Material

Flanges Material