- Call : +91 22 67436442

- exports@petrometflange.com

Copper Nickel Flange manufacturer in India

- Home /

- Copper Nickel Flanges

ASTM B171 UNS C70600 Blind Flange and 90/10 Copper Nickel Slip On Flange supplier in Mumbai

What is Copper Nickel Flanges?

The copper nickel flanges are made of cupro-nickel material that shows high resistance to saltwater corrosion. They are also resistant to biofouling, pitting, crevice corrosion and stress corrosion cracking in the chloride environments. The material is able to retain its properties even at an elevated temperature. The copper nickel flanges have high ductility and they show good thermal conductivity, even in cryogenic temperatures. With the addition of nickel content to the alloys, the flow rates and strength of the flanges can be increased. Due to all these useful properties, the copper nickel flanges are widely used in different types of applications like marine, shipbuilding and repair, offshore oil drilling, power generation, etc. They are also used in different condensers and heat exchangers. Thus, the copper nickel flanges show great performance in both marine and non-marine environments.

There are different types of flanges available in the market, and each have their unique usage:

- Weld neck flange- These are used in applications that involve severe and critical conditions.

- Slip-on flange- They are suitable for low pressure applications.

- Blind flange- They help to seal the ends of a piping system or pressure vessel opening.

- Lap joint flange- These are a type of slip-on flange that comes with stub-end fittings. They are great for piping systems that need regular inspection and maintenance, as they can be disassembled easily.

- Socket weld flange- These are used in small and high pressure pipes.

- Threaded flange- They are used in pipes with threaded ends.

- Orifice flange- They are used for accessing the line that helps to meter liquids or gases.

- Ring-type joint flange- They are mostly used for high temperature and pressure applications. They help reduce the risk of leakages.

- Reducing flange- These help in connecting one pipe to the other.

- Forged flange- They help in creating pipework web for valves, pipes, and similar other devices.

Choosing the right type of flange is essential for proper execution of operations, as not all flanges are capable of withstanding all types of environments.

How can you Join Cupro Nickel Flange to Cuni Pipe?

A flange can be described as the way of joining pipes, valves, and other similar equipment, through welding or screwing. The copper nickel flanges are resistant to corrosion, and are also known for their high ductility. They also possess good fabricability and are biofouling resistant. Depending on the type of flange that is needed to be attached to the pipe, it is decided whether welding or screwing is needed to attach the flange with the pipe. For example, the slip-on flanges must be slid into the pipe before it is welded. This flange would also need double welding. On the other hand, the threaded flange does not need welding; it is joined by screwing the flanges to the pipe. It does not need any seam welding.

Copper Nickel 70/30 Flanges vs 90/10 Copper Nickel Flanges

The basic difference between the Copper Nickel 70/30 Flanges and the 90/10 Copper Nickel Flanges, is in its chemical composition. The 70/30 flanges consist of 70% copper and 30% nickel, with trace amounts of other elements. Similarly, the 90/10 flanges have 90% copper with 10% nickel, along with trace amounts of other elements. Due to this difference in the chemical composition, they have some difference in their physical properties too. The 70/30 CuNi flanges are resistant to seawater due to the manganese and iron elements present in it. The 90/10 CuNi flanges offer high strength corrosion resistance, with enhanced ductility and toughness. They are widely used in industrial and architectural applications.

The strength of 70/30 CuNi flanges are slightly more compared to the 90/10 CuNi flanges, and that is why the former is used for more demanding applications. The 90/10 CuNi can be described as a cost-effective substitute of 70/30 CuNi flanges. Both of them are superior in resisting corrosion, but 90/10 CuNi flanges offer a slightly better performance compared to the 70/30 CuNi flanges.

What should you Consider when Buying Copper Nickel Slip On Flanges?

The CuNi slip-on flanges are suitable for low pressure applications. They come with easy installation and can be welded into different pipes. It is essential to check the quality of the raw material and also the flanges should go through all the required tests before they are delivered for real-life applications. Primarily, these flanges are used in saltwater environments, heat exchangers, desalination plants, etc.

Are there Special Surface Finish for Copper Nickel Pipe Flanges?

There are several types of surface finishes available for CuNi flanges, like:

- Stock Finish- here, the gasket formation takes place through a continuous spiral group. It is generated with the help of round-nose tools.

- Smooth Finish- It comes without a visible tool marking; this surface finish looks very smooth.

- Spiral serrated- It is quite similar to stock finish, except the fact that it comes with a “V” geometry.

- Concentric Serrated- This one comes with concentric grooves, and there are even serration spaces present throughout the face.

- Coldwater Finish- This one gives the flanges a finish that has a mirror-like appearance. This one is perfect to be used in metal to metal surface contacting, without the presence of any gasket.

Copper Nickel Flanges

Manufacturer of UNS C71500 Weld Neck Flange and Copper Nickel Blind Flange as per ASME B16.5

Table of Content

- Copper Nickel Flanges Specification

- Copper Nickel Flange Weight

- Pressure Rating of Copper Nickel Pipe Flanges

- Copper Nickel Flange Dimensions

- Standard Table of Cupro Nickel Flanges

- DIN Standard Cu Ni Flanges

- EEMUA 145 Standard Copper Nickel 70/30 Flanges

- Copper Nickel Flanges Price List

- DIN 86037 Flange Dimensions

- Dimension Table of Copper Nickel Slip On Flange

- Copper Nickel Blind Flange Dimensions

- Copper Nickel Threaded Flange Dimension Chart

- Dimension table of Class 150 70/30 Copper Nickel Flanges

- CL 300 Copper Nickel Composite Flanges Dimension

- 400 LBS Cupro Nickel 70-30 Flanges Dimension Table

- Dimension Chart of 600# Cupro Nickel 90/10 Flanges

- Class 900 UNS C70600 Flange Dimension

- Dimension Table of 1500 LBS UNS C71500 Flange

- CL 2500 70/30 Copper Nickel Flanges Dimension

- Types of Copper Nickel Flanges

- Cupro Nickel Flanges Chemical Composition

- Copper Nickel Composite Flange Mechanical Properties

- Cuni Flange Physical Properties

- Cupro Nickel Flanges Equivalent

- Working Temperature of Cupro nickel 70/30 Flanges?

- How can you Test the Quality of ASTM B171 UNS C70600 Flanges?

- How can you Measure Cuni Flanges?

- Can you Weld 90/10 Cu-Ni Flanges?

- Difference Between Cupronickel Slip-on VS Lap Joint Flanges

- What is Pitch Circle Diameter (PCD) on 70/30 Copper Nickel Flanges?

- How to Buy 90/10 Cu-Ni Flanges?

- Standard Specifications of Copper nickel 90/10 Flanges

- Applications of Cupro nickel 70/30 flanges

- Benefits of Copper Nickel 70/30 Flanges

- Classification of Copper Nickel Flange Forging

- Manufacturing Process Of Copper Nickel Forged Flanges

- Difference between ANSI and DIN Copper Nickel Flanges?

Copper Nickel Flanges Specification

| Size Chart | 1/2″(15 NB) to 48″ (1200NB) |

|---|---|

| Pressure Rating Chart ANSI | 150 LBS, 300 LBS, 2500 LBS, 900 LBS, 600 LBS, 1500 LBS |

| UNI / EN | 16Bar 6Bar 40Bar 10Bar 25Bar |

| DIN Pressure Calculation | 25Bar 40Bar 16Bar 6Bar 10Bar / PN64 PN10 PN25 PN16 PN6 PN40 |

| JIS | 16 K, 5K, 10 K, 20 K, 30 K, 40 K, 63 K |

| Manufacturer of Connect Type/ Flanges Face Type | RF, RTJ, FF, LJF, Small Tongue, Large Tongue & Groove |

| Coating | Yellow Transparent, Zinc Plated, Anti-rust Paint, Oil Black Paint, Cold and Hot Dip Galvanized |

| Common Types By Manufacturer | Threaded / Screwed / Forged / Plate |

| Origin | West Europe / Japan / Indian / USA / Korean |

| Manufacturer of | ANSI DIN, GOST, JIS, UNI, BS, AS2129, SABS, NFE, AWWA, EN etc. |

| Standards Provided By Manufacturer | API7S-43, API605, B16.48, ISO70051, MSS S44, ANSI/ASME B16.5, B16.47 Series A & B, BS4504, BS 10, EN-1092, DIN, API7S-15, JISB2220, BS1560-3.1, ASME/ANSI B16.5/16.36/16.47A/16.47B, EN1092 |

| Test | Direct-reading Spectrograph, Ultrasonic flaw detector, Magnetic particle detector, X-ray detector, Hydrostatic testing machine |

| Equipment | Press machine, Bending machine, Pushing Machine, Sand-blasting machine, electric bevelling machine etc |

| Production technique Used By Manufacturer | Heat treated, Forged and machined |

Well know Copper Nickel Weld Neck Flange distributor, importer, stockists, wholesalers, stockholders, dealers, supplier, exporters and Manufacturer in Mumbai.

Copper Nickel Flange Weight

| Size (in) | Number of Bolt Holes | Flange Diameter (in) | Bolt Circle Diameter (in) | Flange Thickness (in) | Bolt Hole Diameter (in) | Approx Weight (lbs) | Bore |

|---|---|---|---|---|---|---|---|

| 1/2 | 4 | 3.5 | 2.38 | 0.44 | 0.63 | 1.2 | Sch 40 (Std) |

| 3/4 | 4 | 3.88 | 2.75 | 0.5 | 0.63 | 1.7 | Sch 40 (Std) |

| 1 | 4 | 4.25 | 3.13 | 0.56 | 0.63 | 2.2 | Sch 40 (Std) |

| 1-1/4 | 4 | 4.63 | 3.5 | 0.63 | 0.63 | 2.9 | Sch 40 (Std) |

| 1-1/2 | 4 | 5 | 3.88 | 0.69 | 0.63 | 3.7 | Sch 40 (Std) |

| 2 | 4 | 6 | 4.75 | 0.75 | 0.75 | 5.7 | Sch 40 (Std) |

| 2-1/2 | 4 | 7 | 5.5 | 0.88 | 0.75 | 9 | Sch 40 (Std) |

| 3 | 4 | 7.5 | 6 | 0.94 | 0.75 | 10.5 | Sch 40 (Std) |

| 3-1/2 | 8 | 8.5 | 7 | 0.94 | 0.75 | 13 | Sch 40 (Std) |

| 4 | 8 | 9 | 7.5 | 0.94 | 0.75 | 14.2 | Sch 40 (Std) |

| 5 | 8 | 10 | 8.5 | 0.94 | 0.88 | 16 | Sch 40 (Std) |

| 6 | 8 | 11 | 9.5 | 1 | 0.88 | 19.4 | Sch 40 (Std) |

| 8 | 8 | 13.5 | 11.75 | 1.13 | 0.88 | 31.3 | Sch 40 (Std) |

| 10 | 12 | 16 | 14.25 | 1.19 | 1 | 42.3 | Sch 40 (Std) |

| 12 | 12 | 19 | 17 | 12.88 | 1 | 69.6 | Sch 40 (Std) |

Pressure Rating of Copper Nickel Pipe Flanges

| Temperature °F | Class 150 | Class 600 | Class 1500 | Class 400 | Class 900 | Class 300 | Class 2500 |

| -20 to 100 | 275 | 1440 | 3600 | 960 | 2160 | 720 | 6000 |

| 300 | 205 | 1080 | 2700 | 720 | 1620 | 540 | 4500 |

| 200 | 230 | 1200 | 3000 | 800 | 1800 | 600 | 5000 |

| 400 | 190 | 995 | 2485 | 660 | 1490 | 495 | 4140 |

| 600 | 140 | 875 | 2185 | 580 | 1310 | 435 | 3640 |

| 650 | 125 | 860 | 2150 | 575 | 1290 | 430 | 3580 |

| 500 | 170 | 930 | 2330 | 620 | 1395 | 465 | 3880 |

| 700 | 110 | 850 | 2125 | 565 | 1275 | 425 | 3540 |

| 750 | 95 | 830 | 2075 | 555 | 1245 | 415 | 3460 |

| 850 | 65 | 790 | 1980 | 530 | 1190 | 395 | 3300 |

| 800 | 80 | 805 | 2015 | 540 | 1210 | 405 | 3360 |

| 900 | 50 | 780 | 1945 | 520 | 1165 | 390 | 3240 |

| 950 | 35 | 765 | 1910 | 510 | 1145 | 380 | 3180 |

| 1000 | 20 | 640 | 1605 | 430 | 965 | 320 | 2675 |

| 1100 | 20 | 515 | 1285 | 345 | 770 | 255 | 2145 |

| 1150 | 20 | 400 | 995 | 265 | 595 | 200 | 1655 |

| 1050 | 20 | 615 | 1545 | 410 | 925 | 310 | 2570 |

| 1200 | 20 | 310 | 770 | 205 | 465 | 155 | 1285 |

| 1250 | 20 | 225 | 565 | 150 | 340 | 115 | 945 |

| 1300 | 20 | 170 | 430 | 115 | 255 | 85 | 715 |

| 1400 | 20 | 95 | 240 | 65 | 145 | 50 | 400 |

| 1350 | 20 | 125 | 310 | 80 | 185 | 60 | 515 |

| 1450 | 15 | 70 | 170 | 45 | 105 | 35 | 285 |

| 1500 | 10 | 55 | 135 | 35 | 80 | 25 | 230 |

90/10 Copper Nickel Flanges are available in class 150 to 2500, view 7060x Composite and Cuni 90/10 Threaded Flange dimensions

Copper Nickel Flange Dimensions

| Size in Inch | RF Dia. | Size in mm | Machine Bolt Length | Flange Thickness | ISO Stud Size | PCD | No of Bolts | Bolt Size UNC | Outer Dia. | RF Height | RF Stud Length | Hole Size | Weight in kg |

| C | B | E | A | D | |||||||||

| 1/2 | 34.9 | 15 | 50 | 9.6 | M14 | 60.3 | 4 | 1/2 | 90 | 2 | 55 | 5/8 | 0.9 |

| 1 | 50.8 | 25 | 55 | 12.7 | M14 | 79.4 | 4 | 1/2 | 110 | 2 | 65 | 5/8 | 0.9 |

| 1 1/4 | 63.5 | 32 | 55 | 14.3 | M14 | 88.9 | 4 | 1/2 | 115 | 2 | 70 | 5/8 | 1.4 |

| 3/4 | 42.9 | 20 | 50 | 11.2 | M14 | 69.9 | 4 | 1/2 | 100 | 2 | 65 | 5/8 | 0.9 |

| 1 1/2 | 73 | 40 | 65 | 15.9 | M14 | 98.4 | 4 | 1/2 | 125 | 2 | 70 | 5/8 | 1.8 |

| 2 | 92.1 | 50 | 70 | 17.5 | M16 | 120.7 | 4 | 5/8 | 150 | 2 | 85 | 3/4 | 2.3 |

| 3 | 127 | 80 | 75 | 22.3 | M16 | 152.4 | 4 | 5/8 | 190 | 2 | 90 | 3/4 | 4.1 |

| 3 1/2 | 139.7 | 90 | 75 | 22.3 | M16 | 177.8 | 8 | 5/8 | 215 | 2 | 90 | 3/4 | 5.9 |

| 4 | 157.2 | 100 | 75 | 22.3 | M16 | 190.5 | 8 | 5/8 | 230 | 2 | 90 | 3/4 | 7.7 |

| 5 | 185.7 | 125 | 85 | 22.3 | M20 | 215.9 | 8 | 3/4 | 255 | 2 | 95 | 7/8 | 9.1 |

| 2 1/2 | 104.8 | 65 | 75 | 20.7 | M16 | 139.7 | 4 | 5/8 | 180 | 2 | 90 | 3/4 | 3.2 |

| 6 | 215.9 | 150 | 85 | 23.9 | M20 | 241.3 | 8 | 3/4 | 280 | 2 | 100 | 7/8 | 11.8 |

| 8 | 269.9 | 200 | 90 | 27 | M20 | 298.5 | 8 | 3/4 | 345 | 2 | 110 | 7/8 | 20.5 |

| 10 | 323.8 | 250 | 100 | 28.6 | M24 | 362 | 12 | 7/8 | 405 | 2 | 115 | 1 | 32 |

| 12 | 381 | 300 | 100 | 30.2 | M24 | 431.8 | 12 | 7/8 | 485 | 2 | 120 | 1 | 50 |

| 14 | 412.8 | 350 | 115 | 33.4 | M27 | 476.3 | 12 | 1 | 535 | 2 | 135 | 1 1/8 | 64 |

| 16 | 469.9 | 400 | 115 | 35 | M27 | 539.8 | 16 | 1 | 595 | 2 | 135 | 1 1/8 | 82 |

| 18 | 533.4 | 450 | 125 | 38.1 | M30 | 577.9 | 16 | 1 1/8 | 635 | 2 | 145 | 1 1/4 | 100 |

| 20 | 584.2 | 500 | 140 | 41.3 | M30 | 635 | 20 | 1 1/8 | 700 | 2 | 160 | 1 1/4 | 130 |

| 24 | 692.2 | 600 | 150 | 46.1 | M33 | 749.3 | 20 | 1 1/4 | 815 | 2 | 170 | 1 3/8 | 196 |

Standard Table of Cupro Nickel Flanges

| COPPER NICKEL FLANGES | MATERIAL | DIN | EEMUA | ANSI |

| COMPOSITE WELD NECK INNER FLANGES | CuNi | DIN 86037 | 145 | |

| SOLID SOCKET WELDING | CuNi | B 16-5 | ||

| COMPOSITE WELD NECK BACKING FLANGES | Carbon steel | DIN 86037 | 145 | |

| SOLID WELD NECK | CuNi | DIN 2632/2633 | 145 | B 16-5 |

| SOLID SLIP ON | CuNi | DIN 86033 | 145 | B 16-5 |

| COMPOSITE SLIP ON BACKING FLANGES | Carbon steel | DIN 86036 | 145 | |

| SOLID BLIND | CuNi | B 16-5 | ||

| COMPOSITE SLIP ON INNER FLANGES | CuNi | DIN 86036 | 145 | |

| THREADED WELDING | CuNi | B 16-5 |

DIN Standard Cu Ni Flanges

- DIN 86037 Composite WNRF Flanges

- DIN 86033 Copper Nickel SORF Flanges

- DIN 86036 Composite SORF Flanges

- DIN 2632/2633 Copper Nickel Weld Neck Flanges

EEMUA 145 Standard Copper Nickel 70/30 Flanges

EEMUA 145 Standard copper-nickel flanges are commonly used on maritime and offshore structures.

Material: it can be named as UNS 7060X

Copper Nickel Flanges Price List

| Copper Nickel Pipe Flanges Price Per Piece in India | Price Applicable for jan 2022 to june 2022 | Price Applicable for July 2022 to December 2022 |

| DN100 X DIN86037 CUNI COMPOSITE W.N. FLANGE Per Kg | US $22.69 | US $24.69 |

| COPPER-NICKEL 90/10 SOLID W/N FLANGE FF ASME B16.5 UNS C70600 4 X WT 3.0mm Per Piece | US $215.46 | US $217.46 |

| COPPER-NICKEL 90/10 BLIND FLANGE RF ASME B16.5 Per Kg | US $11.57 | US $14.57 |

| COPPER NICKEL FLANGES WN INNER 108,0X2,5 Per Kg | US $22.79 | US $23.79 |

| 90/10 COPPER NICKEL WELD NECK INNER FLANGES 1 1/2 Per Kg | US $40.36 | US $42.36 |

Are you looking for Copper Nickel Flange manufacturer in India, Contact us to get latest price list of Cu Ni Flanges. We are leading Copper Nickel Flange supplier and exporter in various countries.

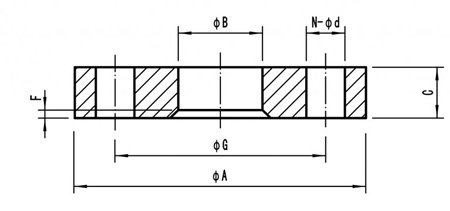

DIN 86037 Flange Dimensions

| Outside diameter of pipe | DIN86037 | ||||||||

| PN10 | |||||||||

| ØD | Drilling | Theo. | |||||||

| ØA | C | ØB | F | ØG | N | Ød | weight | ||

| nominal | actual | mm | mm | mm | mm | mm | mm | mm | Kg/piece |

| inch | mm | ||||||||

| 0.5 | 16 | – | – | – | – | – | – | – | – |

| 0.75 | 25 | 105 | 14 | 28 | 3 | 75 | 4 | 14 | 0.8 |

| 1 | 30 | 115 | 16 | 33 | 4 | 85 | 4 | 14 | 1.1 |

| 1.25 | 38 | 140 | 16 | 42 | 4 | 100 | 4 | 18 | 1.65 |

| 1.5 | 44.5 | 150 | 16 | 50 | 4 | 110 | 4 | 18 | 1.85 |

| 2 | 57 | 165 | 16 | 62 | 5 | 125 | 4 | 18 | 2.2 |

| 2.5 | 76.1 | 185 | 16 | 81 | 5 | 145 | 4 | 18 | 2.65 |

| 3 | 88.9 | 200 | 18 | 94 | 5 | 160 | 8 | 18 | 3.3 |

| 4 | 108 | 220 | 18 | 113 | 5 | 180 | 8 | 18 | 3.65 |

| 5 | 133 | 250 | 18 | 138 | 5 | 210 | 8 | 18 | 4.55 |

| 6 | 159 | 285 | 18 | 164 | 5 | 240 | 8 | 22 | 5.6 |

| 7 | 193.7 | 315 | 22 | 200 | 5 | 270 | 8 | 22 | 7.5 |

| 8 | 219.1 | 340 | 20 | 225 | 5 | 295 | 8 | 22 | 7.45 |

| 10 | 267 | 395 | 22 | 273 | 5 | 350 | 12 | 22 | 10.3 |

| 12 | 323.9 | 445 | 24 | 331 | 7 | 400 | 12 | 22 | 12 |

| 14 | 368 | 505 | 24 | 375 | 7 | 460 | 16 | 22 | 16 |

| 16 | 419.1 | 565 | 26 | 426 | 7 | 515 | 16 | 26 | 20 |

| 18 | 457.2 | 615 | 28 | 465 | 7 | 565 | 20 | 26 | 25 |

| 20 | 508 | 670 | 30 | 517 | 7 | 620 | 20 | 26 | 31 |

| 24 | 610 | 780 | 32 | 618 | 9 | 725 | 20 | 30 | 40 |

A wide selection of Cuni Flange in all standard sizes, faces and pressure ratings, ready stock of Copper Nickel 90/10 Socket Weld, Orifice and in Composite Flange in UAE and India

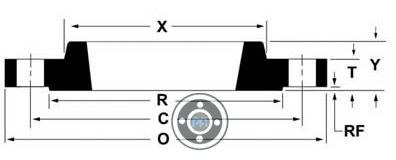

Dimension Table of Copper Nickel Slip On Flange

| Size in Inch | Size in mm | No of Bolts | Outer Dia. | Hub OD | ISO Stud Size | Flange Length | RF Height | Flange Thick. | RF Dia. | PCD | Hole Size | Socket Bore | Weight in kg |

| A | C | D | F | B | E | G | H | ||||||

| 1/2 | 15 | 4 | 90 | 30 | M14 | 14 | 2 | 9.6 | 34.9 | 60.3 | 5/8 | 22.2 | 0.8 |

| 1 | 25 | 4 | 110 | 49 | M14 | 16 | 2 | 12.7 | 50.8 | 79.4 | 5/8 | 34.5 | 0.9 |

| 3/4 | 20 | 4 | 100 | 38 | M14 | 14 | 2 | 11.2 | 42.9 | 69.9 | 5/8 | 27.7 | 0.9 |

| 1 1/4 | 32 | 4 | 115 | 59 | M14 | 19 | 2 | 14.3 | 63.5 | 88.9 | 5/8 | 43.2 | 1.4 |

| 2 | 50 | 4 | 150 | 78 | M16 | 24 | 2 | 17.5 | 92.1 | 120.7 | 3/4 | 61.9 | 2.3 |

| 1 1/2 | 40 | 4 | 125 | 65 | M14 | 21 | 2 | 15.9 | 73 | 98.4 | 5/8 | 49.5 | 1.4 |

| 2 1/2 | 65 | 4 | 180 | 90 | M16 | 27 | 2 | 20.7 | 104.8 | 139.7 | 3/4 | 74.6 | 3.2 |

| 3 | 80 | 4 | 190 | 108 | M16 | 29 | 2 | 22.3 | 127 | 152.4 | 3/4 | 90.7 | 3.7 |

| 4 | 100 | 8 | 230 | 135 | M16 | 32 | 2 | 22.3 | 157.2 | 190.5 | 3/4 | 116.1 | 5.9 |

| 3 1/2 | 90 | 8 | 215 | 122 | M16 | 30 | 2 | 22.3 | 139.7 | 177.8 | 3/4 | 103.4 | 5 |

| 5 | 125 | 8 | 255 | 164 | M20 | 35 | 2 | 22.3 | 185.7 | 215.9 | 7/8 | 143.8 | 6.8 |

| 8 | 200 | 8 | 345 | 246 | M20 | 43 | 2 | 27 | 269.9 | 298.5 | 7/8 | 221.5 | 13.7 |

| 10 | 250 | 12 | 405 | 305 | M24 | 48 | 2 | 28.6 | 323.8 | 362 | 1 | 276.2 | 19.5 |

| 6 | 150 | 8 | 280 | 192 | M20 | 38 | 2 | 23.9 | 215.9 | 241.3 | 7/8 | 170.7 | 8.6 |

| 12 | 300 | 12 | 485 | 365 | M24 | 54 | 2 | 30.2 | 381 | 431.8 | 1 | 327 | 29 |

| 24 | 600 | 20 | 815 | 663 | M33 | 81 | 2 | 46.1 | 692.2 | 749.3 | 1 3/8 | 616 | 100 |

| 16 | 400 | 16 | 595 | 457 | M27 | 62 | 2 | 35 | 469.9 | 539.8 | 1 1/8 | 410.5 | 54 |

| 18 | 450 | 16 | 635 | 505 | M30 | 67 | 2 | 38.1 | 533.4 | 577.9 | 1 1/4 | 461.8 | 59 |

| 14 | 350 | 12 | 535 | 400 | M27 | 56 | 2 | 33.4 | 412.8 | 476.3 | 1 1/8 | 359.2 | 41 |

| 20 | 500 | 20 | 700 | 559 | M30 | 71 | 2 | 41.3 | 584.2 | 635 | 1 1/4 | 513.1 | 75 |

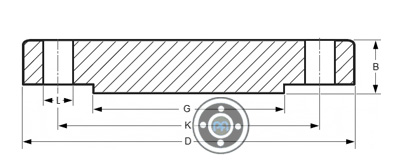

Copper Nickel Blind Flange Dimensions

| Nominal Pipe Size | OD of Flange (D) | Dia of Bolt Circle (K) | No of Bolt Holes | Dia of Bolt Holes (L) | Thickness of Flange (B) | Dia of Bolt (inches) | Dia of Raised Face (G) | Approx Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| 1/2 | 88.9 | 60.5 | 4 | 15.7 | 11.2 | 1/2 | 35.1 | 0.5 |

| 3/4 | 98.6 | 69.9 | 4 | 15.7 | 12.7 | 1/2 | 42.9 | 1 |

| 1 | 108 | 79.2 | 4 | 15.7 | 14.2 | 1/2 | 50.8 | 1 |

| 1-1/4 | 117.3 | 88.9 | 4 | 15.7 | 15.7 | 1/2 | 63.5 | 1 |

| 1-1/2 | 127 | 98.6 | 4 | 15.7 | 17.5 | 1/2 | 73.2 | 2 |

| 2 | 152.4 | 120.7 | 4 | 19.1 | 19.1 | 5/8 | 91.9 | 2 |

| 2-1/2 | 177.8 | 139.7 | 4 | 19.1 | 22.4 | 5/8 | 104.6 | 3 |

| 3 | 190.5 | 152.4 | 4 | 19.1 | 23.9 | 5/8 | 127 | 4 |

| 3-1/2 | 215.9 | 177.8 | 8 | 19.1 | 23.9 | 5/8 | 139.7 | 6 |

| 4 | 228.6 | 190.5 | 8 | 19.1 | 23.9 | 5/8 | 157.2 | 8 |

| 5 | 254 | 215.9 | 8 | 22.4 | 23.9 | 3/4 | 185.7 | 9 |

| 6 | 279.4 | 241.3 | 8 | 22.4 | 25.4 | 3/4 | 215.9 | 12 |

| 8 | 342.9 | 298.5 | 8 | 22.4 | 28.4 | 3/4 | 269.7 | 20 |

| 10 | 406.4 | 362 | 12 | 25.4 | 30.2 | 7/8 | 323.9 | 32 |

| 12 | 482.6 | 431.8 | 12 | 25.4 | 31.8 | 7/8 | 381 | 50 |

| 14 | 533.4 | 476.3 | 12 | 28.4 | 35.1 | 1 | 412.8 | 64 |

| 16 | 596.9 | 539.8 | 16 | 28.4 | 36.6 | 1 | 469.9 | 82 |

| 18 | 635 | 577.9 | 16 | 31.8 | 39.6 | 1-1/8 | 533.4 | 100 |

| 20 | 698.5 | 635 | 20 | 31.8 | 42.9 | 1-1/8 | 584.2 | 129 |

| 24 | 812.8 | 749.3 | 20 | 35.1 | 47.8 | 1-1/4 | 692.2 | 195 |

Copper Nickel Threaded Flange Dimension Chart

| Pipe Size (NPS) | Thickness of Flange C | Diameter of Raised Face B | Minimum Thread Length N | Diameter of Hub at Base J | Length of Hub L | Number of Bolt Holes | Outside Diameter of Flange A | Approx. Weight (Lbs.) |

|---|---|---|---|---|---|---|---|---|

| 1/2 | 7/16 | 1 3/8 | 5/8 | 1 3/16 | 5/8 | 4 | 3 1/2 | 2 |

| 3/4 | 1/2 | 1 11/16 | 5/8 | 1 1/2 | 5/8 | 4 | 3 7/8 | 2 |

| 1 | 9/16 | 2 | 11/16 | 1 15/16 | 11/16 | 4 | 4 1/4 | 2 |

| 1 1/4 | 5/8 | 2 1/2 | 13/16 | 2 5/16 | 13/16 | 4 | 4 5/8 | 3 |

| 1 1/2 | 11/16 | 2 7/8 | 7/8 | 2 9/16 | 7/8 | 4 | 5 | 3 |

| 2 | 3/4 | 3 5/8 | 1 | 3 7/16 | 1 | 4 | 6 | 5 |

| 2 1/2 | 7/8 | 4 1/8 | 1 1/8 | 3 9/16 | 1 1/8 | 4 | 7 | 7 |

| 3 | 15/16 | 5 | 1 3/16 | 4 1/4 | 1 3/16 | 4 | 7 1/2 | 8 |

| 3 1/2 | 15/16 | 5 1/2 | 1 1/4 | 4 13/16 | 1 1/4 | 8 | 8 1/2 | 11 |

| 4 | 15/16 | 6 3/16 | 1 5/16 | 5 5/16 | 1 5/16 | 8 | 9 | 13 |

| 5 | 15/16 | 7 5/16 | 1 7/16 | 6 7/16 | 1 7/16 | 8 | 10 | 15 |

| 6 | 1 | 8 1/2 | 1 9/16 | 7 9/16 | 1 9/16 | 8 | 11 | 19 |

| 8 | 1 1/8 | 10 5/8 | 1 3/4 | 9 11/16 | 1 3/4 | 8 | 13 1/2 | 30 |

| 10 | 1 3/16 | 12 3/4 | 1 15/16 | 12 | 1 15/16 | 12 | 16 | 43 |

| 12 | 1 1/4 | 15 | 2 3/16 | 14 3/8 | 2 3/16 | 12 | 19 | 64 |

| 14 | 1 3/8 | 16 1/4 | 2 1/4 | 15 3/4 | 2 1/4 | 12 | 21 | 85 |

| 16 | 1 7/16 | 18 1/2 | 2 1/2 | 18 | 2 1/2 | 16 | 23 1/2 | 93 |

| 18 | 1 9/16 | 21 | 2 11/16 | 19 7/8 | 2 11/16 | 16 | 25 | 120 |

| 20 | 1 11/16 | 23 | 2 7/8 | 22 | 2 7/8 | 20 | 27 1/2 | 155 |

| 22 | 1 13/16 | 25 1/4 | 3 1/8 | 24 | 3 1/8 | 20 | 29 1/2 | 159 |

| 24 | 1 7/8 | 27 1/4 | 3 1/4 | 26 1/8 | 3 1/4 | 20 | 32 | 210 |

Dimension table of Class 150 70/30 Copper Nickel Flanges

| Nominal Pipe Size (in) | Class 150 | ||||

|---|---|---|---|---|---|

| Diameter of Flange (in) | No. of Bolts | Dia of Bolts (in) | Dia of Bolt Holes (in) | Bolt Circle (in) | |

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 1/2 | 3-1/2 | 4 | 1/2 | 0.62 | 2-3/8 |

| 3/4 | 3-7/8 | 4 | 1/2 | 0.62 | 2-3/4 |

| 1 | 4-1/4 | 4 | 1/2 | 0.62 | 3-1/8 |

| 1-1/4 | 4-5/8 | 4 | 1/2 | 0.62 | 3-1/2 |

| 1-1/2 | 5 | 4 | 1/2 | 0.62 | 3-7/8 |

| 2 | 6 | 4 | 5/8 | 0.75 | 4-3/4 |

| 2-1/2 | 7 | 4 | 5/8 | 0.75 | 5-1/2 |

| 3 | 7-1/2 | 4 | 5/8 | 0.75 | 6 |

| 3-1/2 | 8-1/2 | 8 | 5/8 | 0.75 | 7 |

| 4 | 9 | 8 | 5/8 | 0.75 | 7-1/2 |

| 5 | 10 | 8 | 3/4 | 0.88 | 8-1/2 |

| 6 | 11 | 8 | 3/4 | 0.88 | 9-1/2 |

| 8 | 13-1/2 | 8 | 3/4 | 0.88 | 11-3/4 |

| 10 | 16 | 12 | 7/8 | 1 | 14-1/4 |

| 12 | 19 | 12 | 7/8 | 1 | 17 |

| 14 | 21 | 12 | 1 | 1.12 | 18-3/4 |

| 16 | 23-1/2 | 16 | 1 | 1.12 | 21-1/4 |

| 18 | 25 | 16 | 1-1/8 | 1.25 | 22-3/4 |

| 20 | 27-1/2 | 20 | 1-1/8 | 1.25 | 25 |

| 24 | 32 | 20 | 1-1/4 | 1.38 | 29-1/2 |

CL 300 Copper Nickel Composite Flanges Dimension

| Nominal Pipe Size (inches) | Class 300 | ||||

|---|---|---|---|---|---|

| Dia of Flanges (inches) | No. of Bolts | Dia of Bolts (inches) | Dia of Bolt Holes (inches) | Bolt Circle (inches) | |

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 1/2 | 3-3/4 | 4 | 1/2 | 0.62 | 2-5/8 |

| 3/4 | 4-5/8 | 4 | 5/8 | 0.75 | 3-1/4 |

| 1 | 4-7/8 | 4 | 5/8 | 0.75 | 3-1/2 |

| 1-1/4 | 5-1/4 | 4 | 5/8 | 0.75 | 3-7/8 |

| 1-1/2 | 6-1/8 | 4 | 3/4 | 0.88 | 4-1/2 |

| 2 | 6-1/2 | 8 | 5/8 | 0.75 | 5 |

| 2-1/2 | 7-1/2 | 8 | 3/4 | 0.88 | 5-7/8 |

| 3 | 8-1/4 | 8 | 3/4 | 0.88 | 6-5/8 |

| 3-1/2 | 9 | 8 | 3/4 | 0.88 | 7-1/4 |

| 4 | 10 | 8 | 3/4 | 0.88 | 7-7/8 |

| 5 | 11 | 8 | 3/4 | 0.88 | 9-1/4 |

| 6 | 12-1/2 | 12 | 3/4 | 0.88 | 10-5/8 |

| 8 | 15 | 12 | 7/8 | 1 | 13 |

| 10 | 17-1/2 | 16 | 1 | 1.12 | 15-1/4 |

| 12 | 20-1/2 | 16 | 1-1/8 | 1.25 | 17-3/4 |

| 14 | 23 | 20 | 1-1/8 | 1.25 | 20-1/4 |

| 16 | 25-1/2 | 20 | 1-1/4 | 1.38 | 22-1/2 |

| 18 | 28 | 24 | 1-1/4 | 1.38 | 24-3/4 |

| 20 | 30-1/2 | 24 | 1-1/4 | 1.38 | 27 |

| 24 | 36 | 24 | 1-1/2 | 1.62 | 32 |

400 LBS Cupro Nickel 70-30 Flanges Dimension Table

| Nominal Pipe Size (inches) | Class 400 | ||||

|---|---|---|---|---|---|

| Dia of Flange (inches) | No. of Bolts | Dia of Bolts (inches) | Dia of Bolt Holes (inches) | Bolt Circle (inches) | |

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 1/2 | 3-3/4 | 4 | 1/2 | 0.62 | 2-5/8 |

| 3/4 | 4-5/8 | 4 | 5/8 | 0.75 | 3-1/4 |

| 1 | 4-7/8 | 4 | 5/8 | 0.75 | 3-1/2 |

| 1-1/4 | 5-1/4 | 4 | 5/8 | 0.75 | 3-7/8 |

| 1-1/2 | 6-1/8 | 4 | 3/4 | 0.88 | 4-1/2 |

| 2 | 6-1/2 | 8 | 5/8 | 0.75 | 5 |

| 2-1/2 | 7-1/2 | 8 | 3/4 | 0.88 | 5-7/8 |

| 3 | 8-1/4 | 8 | 3/4 | 0.88 | 6-5/8 |

| 3-1/2 | 9 | 8 | 7/8 | 1 | 7-1/4 |

| 4 | 10 | 8 | 7/8 | 1 | 7-7/8 |

| 5 | 11 | 8 | 7/8 | 1 | 9-1/4 |

| 6 | 12-1/2 | 12 | 7/8 | 1 | 10-5/8 |

| 8 | 15 | 12 | 1 | 1.12 | 13 |

| 10 | 17-1/2 | 16 | 1-1/8 | 1.25 | 15-1/4 |

| 12 | 20-1/2 | 16 | 1-1/4 | 1.38 | 17-3/4 |

| 14 | 23 | 20 | 1-1/4 | 1.38 | 20-1/4 |

| 16 | 25-1/2 | 20 | 1-3/8 | 1.5 | 22-1/2 |

| 18 | 28 | 24 | 1-3/8 | 1.5 | 24-3/4 |

| 20 | 30-1/2 | 24 | 1-1/2 | 1.62 | 27 |

| 24 | 36 | 24 | 1-3/4 | 1.88 | 32 |

Dimension Chart of 600# Cupro Nickel 90/10 Flanges

| Nominal Pipe Size NPS (in) | Class 600 | ||||

|---|---|---|---|---|---|

| Dia of Flange (in) | No. of Bolts | Dia of Bolts (in) | Dia of Bolt Holes (in) | Bolt Circle (in) | |

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 1/2 | 3-3/4 | 4 | 1/2 | 0.62 | 2-5/8 |

| 3/4 | 4-5/8 | 4 | 5/8 | 0.75 | 3-1/4 |

| 1 | 4-7/8 | 4 | 5/8 | 0.75 | 3-1/2 |

| 1-1/4 | 5-1/4 | 4 | 5/8 | 0.75 | 3-7/8 |

| 1-1/2 | 6-1/8 | 4 | 3/4 | 0.88 | 4-1/2 |

| 2 | 6-1/2 | 8 | 5/8 | 0.75 | 5 |

| 2-1/2 | 7-1/2 | 8 | 3/4 | 0.88 | 5-7/8 |

| 3 | 8-1/4 | 8 | 3/4 | 0.88 | 6-5/8 |

| 3-1/2 | 9 | 8 | 7/8 | 1 | 7-1/4 |

| 4 | 10-3/4 | 8 | 7/8 | 1 | 8-1/2 |

| 5 | 13 | 8 | 1 | 1.12 | 10-1/2 |

| 6 | 14 | 12 | 1 | 1.12 | 11-1/2 |

| 8 | 16-1/2 | 12 | 1-1/8 | 1.25 | 13-3/4 |

| 10 | 20 | 16 | 1-1/4 | 1.38 | 17 |

| 12 | 22 | 20 | 1-1/4 | 1.38 | 19-1/4 |

| 14 | 23-3/4 | 20 | 1-3/8 | 1.5 | 20-3/4 |

| 16 | 27 | 20 | 1-1/2 | 1.62 | 23-3/4 |

| 18 | 29-1/4 | 20 | 1-5/8 | 1.75 | 25-3/4 |

| 20 | 32 | 24 | 1-5/8 | 1.75 | 28-1/2 |

| 24 | 37 | 24 | 1-7/8 | 2 | 33 |

Class 900 UNS C70600 Flange Dimension

| Nominal Pipe Size NPS (in) |

Class 900 | ||||

|---|---|---|---|---|---|

| Dia of Flange (in) |

No. of Bolts |

Dia of Bolts (in) |

Dia of Bolt Holes (in) |

Bolt Circle (in) |

|

| 1/2 | 4-3/4 | 4 | 3/4 | 0.88 | 3-1/4 |

| 3/4 | 5-1/8 | 4 | 3/4 | 0.88 | 3-1/2 |

| 1 | 5-7/8 | 4 | 7/8 | 1 | 4 |

| 1-1/4 | 6-1/4 | 4 | 7/8 | 1 | 4-3/8 |

| 1-1/2 | 7 | 4 | 1 | 1.12 | 4-7/8 |

| 2 | 8-1/2 | 8 | 7/8 | 1 | 6-1/2 |

| 2-1/2 | 9-5/8 | 8 | 1 | 1.12 | 7-1/2 |

| 3 | 9-1/2 | 8 | 7/8 | 1 | 7-1/2 |

| 4 | 11-1/2 | 8 | 1-1/8 | 1.25 | 9-1/4 |

| 5 | 13-3/4 | 8 | 1-1/4 | 1.38 | 11 |

| 6 | 15 | 12 | 1-1/8 | 1.25 | 12-1/2 |

| 8 | 18-1/2 | 12 | 1-3/8 | 1.5 | 15-1/2 |

| 10 | 21-1/2 | 16 | 1-3/8 | 1.5 | 18-1/2 |

| 12 | 24 | 20 | 1-3/8 | 1.5 | 21 |

| 14 | 25-1/4 | 20 | 1-1/2 | 1.62 | 22 |

| 16 | 27-3/4 | 20 | 1-5/8 | 1.75 | 24-1/2 |

| 18 | 31 | 20 | 1-7/8 | 2 | 27 |

| 20 | 33-3/4 | 20 | 2 | 2.12 | 29-1/2 |

| 24 | 41 | 20 | 2-1/2 | 2.62 | 35-1/2 |

Dimension Table of 1500 LBS UNS C71500 Flange

| Nominal Pipe Size (in) |

Class 1500 | ||||

|---|---|---|---|---|---|

| Dia of Flange (in) |

No. of Bolts |

Dia of Bolts (in) |

Dia of Bolt Holes (in) |

Bolt Circle (in) |

|

| 1/2 | 4-3/4 | 4 | 3/4 | 0.88 | 3-1/4 |

| 3/4 | 5-1/8 | 4 | 3/4 | 0.88 | 3-1/2 |

| 1 | 5-7/8 | 4 | 7/8 | 1 | 4 |

| 1-1/4 | 6-1/4 | 4 | 7/8 | 1 | 4-3/8 |

| 1-1/2 | 7 | 4 | 1 | 1.12 | 4-7/8 |

| 2 | 8-1/2 | 8 | 7/8 | 1 | 6-1/2 |

| 2-1/2 | 9-5/8 | 8 | 1 | 1.12 | 7-1/2 |

| 3 | 10-1/2 | 8 | 1-1/8 | 1.25 | 8 |

| 4 | 12-1/4 | 8 | 1-1/4 | 1.38 | 9-1/2 |

| 5 | 14-3/4 | 8 | 1-1/2 | 1.62 | 11-1/2 |

| 6 | 15-1/2 | 12 | 1-3/8 | 1.5 | 12-1/2 |

| 8 | 19 | 12 | 1-5/8 | 1.75 | 15-1/2 |

| 10 | 23 | 12 | 1-7/8 | 2 | 19 |

| 12 | 26-1/2 | 16 | 2 | 2.12 | 22-1/2 |

| 14 | 29-1/2 | 16 | 2-1/4 | 2.38 | 25 |

| 16 | 32-1/2 | 16 | 2-1/2 | 2.62 | 27-3/4 |

| 18 | 36 | 16 | 2-3/4 | 2.88 | 30-1/2 |

| 20 | 38-3/4 | 16 | 3 | 3.12 | 32-3/4 |

| 24 | 46 | 16 | 3-1/2 | 3.62 | 39 |

CL 2500 70/30 Copper Nickel Flanges Dimension

| Nominal Pipe Size (in) |

Class 2500 | ||||

|---|---|---|---|---|---|

| Dia of Flange (in) |

No. of Bolts |

Dia of Bolts (in) |

Dia of Bolt Holes (in) |

Bolt Circle (in) |

|

| 1/2 | 5-1/4 | 4 | 3/4 | 0.88 | 3-1/2 |

| 3/4 | 5-1/2 | 4 | 3/4 | 0.88 | 3-3/4 |

| 1 | 6-1/4 | 4 | 7/8 | 1 | 4-1/4 |

| 1-1/4 | 7-1/4 | 4 | 1 | 1.12 | 5-1/8 |

| 1-1/2 | 8 | 4 | 1-1/8 | 1.25 | 5-3/4 |

| 2 | 9-1/4 | 8 | 1 | 1.12 | 6-3/4 |

| 2-1/2 | 10-1/2 | 8 | 1-1/8 | 1.25 | 7-3/4 |

| 3 | 12 | 8 | 1-1/4 | 1.38 | 9 |

| 4 | 14 | 8 | 1-1/2 | 1.62 | 10-3/4 |

| 5 | 16-1/2 | 8 | 1-3/4 | 1.88 | 12-3/4 |

| 6 | 19 | 8 | 2 | 2.12 | 14-1/2 |

| 8 | 21-3/4 | 12 | 2 | 2.12 | 17-1/4 |

| 10 | 26-1/2 | 12 | 2-1/2 | 2.62 | 21-1/4 |

| 12 | 30 | 12 | 2-3/4 | 2.88 | 24-3/8 |

Buy directly from Copper Nickel Flange manufacturer and save cost, we produce C70600 Flange in Forged and Plate as per customer drawing

Types of Copper Nickel Flanges

2500 LBS Copper Nickel 90/10 Girth Flanges

70/30 Copper Nickel Orifice Flanges

Copper Nickel Backing Rings

ASME B16.5 Cuni 70/30 Nipoflange Flanges

300 LBS Cupro nickel 70/30 Lapped Joint Flange

Cu-Ni 70/30 Spectacle Blind Flange

C71500 Flange

70/30 Copper Nickel Flanges

ASTM A151 Cuni C70600 BLRF Flanges

Cupro Nickel 90/10 Flanges

Cupro Nickel Flanges

Cupro Nickel 90/10 Slip On Flange

DIN 86037 Flange

C70600 Flange

Cupro Nickel 70/30 Flanges

90/10 Cu-Ni Ring Joint Flange

5000 NB DIN 2.0882 SORF Flanges

Cu-Ni 70/30 Reducing Flanges

70/30 Cu-Ni Socket Weld Flange

150 LBS 90/10 Cupro Nickel Screwed Flange

15 NB cu ni 70/30 Expander Flanges

Copper Nickel 70/30 Flanges

EEMUA 234 Flange

Cuni Flange

1500 LBS Cu-Ni 90/10 Long Weld Neck Flange

Collar DIN 86037

UNS C70600 Weld Neck Flanges

Copper nickel 70/30 Tongue & Groove Flange

Inner Flange DIN 86037

Copper Nickel Composite Flange

EEMUA 145 Flange

7060x Flange

900 LBS ASTM B171 UNS C70600 Threaded Flange

90/10 Copper Nickel SWRF Flanges

Copper Nickel Alloy 90/10 WNRF Flange

Copper nickel 90/10 Flanges

90/10 Copper Nickel Flanges

600 LBS 70/30 Cupro Nickel Blind Flange

Cupro Nickel Flange

Cupro Nickel Flanges Chemical Composition

| Grade | Fe | Cu | Pb | Ni | Mn | Zn |

| Cu-Ni 70-30 | 0.4-1.0 | 65.0 min | .05 max | 29-33 | 1 max | 1 max |

| Cu-Ni 90-10 | 1.8 max | 88.6 min | .05 max | 9-11 max | 1.0 max | 1 max |

Copper Nickel Composite Flange Mechanical Properties

| Typical Values | Units | CuNi 70/30 | CuNi 90/10 |

| Proof Stress (YS 0,2), (Rp 0,2) | MPa | > 130 | > 110 |

| ksi | > 19 | > 16 | |

| Tensile Strength (UTS),(Rm) | MPa | > 350 | > 310 |

| ksi | > 51 | > 44 | |

| Hardness (HB10 D2 ) | > 80 | > 70 | |

| Elongation (E 5,65 VS) | % | > 30 | > 35 |

Cuni Flange Physical Properties

| Values | Units | CuNi 70/30 | CuNi 90/10 |

| Density (20°C) | kg/m3 | 8900 | 8900 |

| Magnetic Permeability (20°C annealed) | < 1.05 | 1.08 – 1.80 | |

| Thermal Conductivity (20°C to 200°C) | W/m.°K | 30 | 50 |

| Modulus of Elasticity (20°C annealed) | Mpa | 126 000 | 126 000 |

| Electrical Resistivity (20°C annealed) | μΩ.cm | 34 | 19 |

| Annealing Temperature | °C | 760 820 | 760 – 800 |

| Coefficient of Expansion (20°C to 200°C) | C x 10-6 | 16 | 17 |

| Melting Interval | °C | 1180 1240 | 1100 – 1150 |

Cupro Nickel Flanges Equivalent

| STANDARD | WERKSTOFF NR. | UNS |

| Cupro Nickel 90/10 | 2.0872 | C70600 |

| Cupro Nickel 70/30 | 2.0882 | C71500 |

Working Temperature of Cupro nickel 70/30 Flanges?

| Working Temperature | up to 300 Degree C |

How can you Test the Quality of ASTM B171 UNS C70600 Flanges?

- Magnetic particle inspection test

- Tensile test

- Proof test

- Visual test

- Ultrasonic testing

- Flattening Test

- PMI Testing

- Flaring Test

How can you Measure Cuni Flanges?

Measuring Process Includes:

- Using a level surface to place the cupronickel flange.

- Choosing two bolt holes on the cupronickel flange that are opposite one other.

- Measure the distance between the centers of one bolt hole and the center of the other bolt hole on your cupronickel flange with a tape measure.

Can you Weld 90/10 Cu-Ni Flanges?

Welding copper-nickel alloys flanges is simple. Welders of simple metallic structures do not need to pre-heat surfaces or apply any post-welding treatments because of the alloys. The sole criterion is that all surfaces that will be welded are free of impurities.

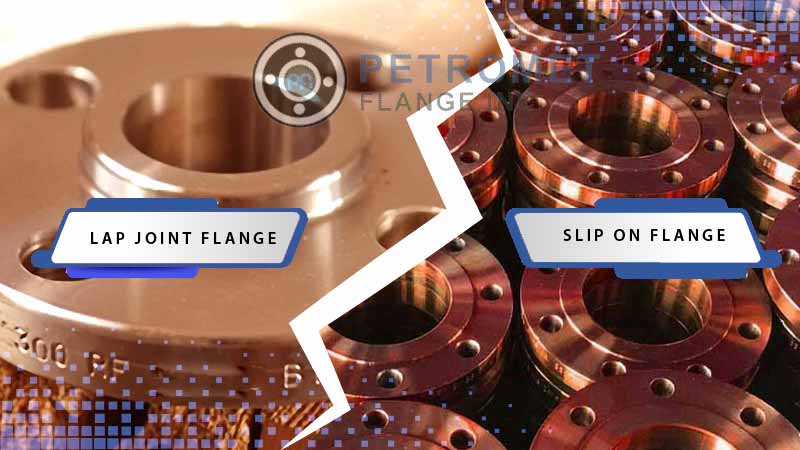

Difference Between Cupronickel Slip-on VS Lap Joint Flanges

They're very similar to one other, and they're common in applications that necessitate frequent disassembly for inspection. A lap joint copper nickel flange, on the other hand, is designed with a curved radius on the bore and face to accommodate the stub end of a lap joint.

What is Pitch Circle Diameter (PCD) on 70/30 Copper Nickel Flanges?

The diameter of a circle that passes through each of the bolt holes is known as PCD (Pitch Circle Diameter). The Pitch Circle Diameter (PCD), which can indicate if the flange bolt holes will match, is one of the most significant metrics. From one side of the interior opening to the other, take a measurement across the center.

How to Buy 90/10 Cu-Ni Flanges?

- Copper Nickel Flange Type : Flanges are used for a variety of purposes, including connecting piping systems, redirecting, and dividing fluid flow.

- Standard Specifications : should adhere to the appropriate quality performance standards

- Material Grades : Copper Nickel 90-10 and Cuni 70-30 are two common material grades.

- Size of the Flange: For a secure connection, the size of your cupronickel flange should match the size of your piping system.

- Pressure and Temperature Rating : should be able to handle the pipe system's pressure and temperature

Standard Specifications of Copper nickel 90/10 Flanges

- ASME/ANSI B16.9

- DIN Standard

- EEMUA 146/EEMUA 234

Applications of Cupro nickel 70/30 Flanges

- Shipbuilding

- Power generation plants

- Desalination plants

- Offshore mining

- Food processing plants

Benefits of Copper Nickel 70/30 Flanges

- Dimensionally stable

- Impermeable

- Erosion resistant

- Durable and long-lasting

- Resistant to marine organisms

- Easy to modify and fix

- Excellent mechanical properties

Classification of Copper Nickel Flange Forging

Open-die Drop Forging

Impression-die Forging

Loose Tooling Forging

Manufacturing Process Of Copper Nickel Forged Flanges

Difference between ANSI and DIN Copper Nickel Flanges?

ANSI is a US standard, while DIN is a European Union standard. ANSI or DIN certified flanges are available depending on the location.

Dimensions are measured in inches and pressure is measured in pounds per square inch (psi) according to ANSI standards. Dimensions for DIN, on the other hand, are measured in metric units with pressure in bars.

Flanges Material

Pipe Fittings Material

Other Products