- Call : +91 22 67436442

- exports@petrometflange.com

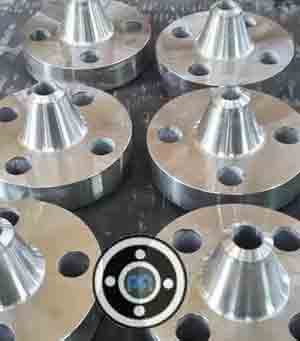

Nickel alloy flanges manufacturer in India

- Home /

- Nickel alloy flanges

ASTM B564 Flange Supplier in Mumbai

What is Nickel alloy flanges and uses

The Nickel alloy flanges have nickel as the main metal along with the combination of other materials for getting some enhanced features. They are known for their high strength and can effectively resist different types of corrosion. Due to their features, they are widely used in various equipment spanning across several industries. The material is very versatile and comes with increased toughness. They are resistant to oxidation as well. They Nickel alloy flanges are used in heat exchangers, condensers, pharmaceutical equipment, and power generation industries. They are one of the most highly stressed flanges. The dimensions of these flanges can be customized as per the requirements.

what is astm b564 flange

The astm b564 can be defined as the specification that covers forged fittings made of nickel alloy. The material specification also includes flanges and forging products. The material is available in various grades, and their features depend on their individual chemical composition. There are different types of astm b564 flanges available, and each of them are used for different purposes according to their structure. For example, the astm b564 threaded elbows are primarily used in small diameter pipes. They help to offer flexibility in changing the direction of flow of the pipe run. The elbows are available at 90 degrees and 45 degrees angle.

ASTM B462 forged flange and forging

The ASTM B462 can be defined as the specification for forged flange and forgings. They also cover rolled pipe flanges, valves, and different piping parts which are intended for use in high temperature applications, especially those that require good resistance to corrosion. This is because the material is able to retain its form even after prolonged exposure to heat, and they can also avoid damage by oxidation. The ASTM B462 forged flange and forging are specifically designed to withstand the harsh environments of hot sulfuric acid. However, the flanges can also withstand services that include any other types of acids.

Inconel 601 flange vs incoloy x750 flange

The Inconel 601 flange is made of nickel chromium alloy with an added aluminum. The chemical composition of the flanges makes it resistant to oxidation and other forms of corrosion occurring in high temperatures.

The incoloy x750 flange is also made of nickel chromium alloy but they are made precipitation hardenable due to the additions of materials like aluminum and titanium. They have high strength and more corrosion resisting properties. They also have a higher creep rupture strength at 700 degrees C.

difference between Incoloy 800h flange and incoloy 800ht flanges

The Incoloy 800HT Flanges has the same chemical composition as that of Incoloy 800h flange, however the difference between them is in the quantities of carbon, aluminum, and titanium. The Incoloy 800H flange possesses more carbon, but Incoloy 800HT flanges contain higher quantities of aluminum and titanium. The Incoloy 800H flanges are widely used in different types of corrosive environments due to the high carbon content, where the Incoloy 800HT flanges are popularly used in applications like hydrocarbon processing, heat-treat furnaces, etc.

Difference between incoloy 330-flange and hastelloy c22-flange

The incoloy 330-flange is made of a nickel and chromium based alloy that cannot be hardened by the heat treatment. It shows enhanced strength at high temperature and also possesses good corrosion resisting capabilities. They also have high durability and good workability.

The hastelloy c22-flange also has nickel and chromium in its alloy, but in stress amounts. They mainly consist of molybdenum. They are widely used in the beverage industry, and chlorination system because of their varied corrosion resisting properties. They are oxidation resistant too.

hastelloy b2-flange vs hastelloy x flanges

The hastelloy b2-flange has a trace amount of carbon in its chemical composition. Thus, they resist the formation of grain boundary carbide precipitation during the welding procedure. They are popularly used in as-welded conditions across various chemical processing applications.

The hastelloy x flanges are made of a super alloy consisting of materials like chromium, iron, nickel and molybdenum. They are known for their corrosion resistance property and durability. They show good oxidation and heat resistance. They are non-magnetic and possess superior strength.

Table of Content

- Nickel Alloy Flanges Specification List

- Price List of Nickel Alloy Flanges

- Various Types of Nickel Alloy Flanges

- Pressure Rating of ASTM B564 Nickel Alloy Flanges

- ANSI B16.5 Ni Alloy Flanges Dimensions

- Weight Chart of Ni Alloy Flange

- Nickel Alloy Pipe Flanges Chemical Composition

- Nickel Flanges Mechanical Properties

- High Nickel Alloy Pipe Flanges Equivalent Properties

- Nickel Flanges Applications

Nickel Alloy Flanges Specification List

| Size Range | 1/2″ to 48″ |

|---|---|

| DIN Pressure Calculation | 25Bar 40Bar 16Bar 6Bar 10Bar / PN64 PN10 PN25 PN16 PN6 PN40 |

| JIS | 40 K, 16 K, 5K, 10 K, 30 K, 20 K, 63 K |

| Chart of Pressure Rating | 300 LBS, 2500 LBS, 1500 LBS, 900 LBS, 150 LBS, 600 LBS |

| Production technique Used By Manufacturer | Heat treated, Forged and machined |

| Manufacturer of Connect / Flange Face Type | LJF, RF, RTJ, FF, Small Tongue, Large Tongue & Groove |

| Standards Provided By Manufacturer | ISO70051, MSS S44, BS1560-3.1, API7S-43, B16.48, ANSI/ASME B16.5, B16.47 Series A & B, BS4504, JISB2220, ASME/ANSI B16.5/16.36/16.47A/16.47B, API605, BS 10, EN-1092, DIN, API7S-15, EN1092 |

| Test | Magnetic particle detector, X-ray detector, Ultrasonic flaw detector, Direct-reading Spectrograph, Hydrostatic testing machine |

| UNI / EN | 16Bar 6Bar 40Bar 10Bar 25Bar |

| Other Grades | Inconel 601 / Inconel x750 / Incoloy 800h / Incoloy 800ht / Incoloy 300 / Hastelloy C22 / Hastelloy B2 / Hastelloy X |

| Coating | Zinc Plated, Anti-rust Paint, Yellow Transparent, Oil Black Paint, Cold and Hot Dip Galvanized |

| Origin | Japan / West Europe / Indian / USA / Korean |

| Equipment | Pushing Machine, Press machine, Sand-blasting machine, Bending machine, electric bevelling machine etc |

| Manufacturer of | GOST, JIS, ANSI, DIN, UNI, BS, AWWA, AS2129, SABS, NFE, EN etc. |

| Common Types By Manufacturer | Threaded / Screwed / Forged / Plate |

ASME SB564 weld neck flange and Nickel alloy Slip on Flange Manufacturer

Price List of Nickel Alloy Flanges

| Nickel Alloy Flanges Price Per Piece in India | ASTM B564 Nickel Flanges Price in INR | Nickel Alloy Flanges Price in UAE Dirham | Ni Flange Price in USD |

| NICKEL ALLOY INC.601.2-BL-RJ FLANGES Per Unit | 24,128 | UAE Dirham 1187.69 | $323.44 |

| 1/2 150# FF BL FLANGE B564 ALLOY C22 Per Kg | 19,219 | UAE Dirham 946.05 | $257.70 |

Various Types of Nickel Alloy Flanges

Nickel Alloy Pipe Flanges

Nickel Alloy Flanges

High Nickel Alloy Pipe Flanges

Nickel Flanges

Ni Alloy Slip On Flange

High Nickel Alloy SORF Flanges

ASTM B564 Nickel Alloy BLRF Flanges

Nickel Threaded Flange

Nickel Alloy Ring Joint Flange

ASTM B564 Nickel Alloy Spectacle Blind Flange

High Nickel Alloy Weld Neck Flanges

ANSI B16.5 Ni Alloy SWRF Flanges

Nickel Nipoflange

Nickel Alloy Blind Flange

Ni Alloy Tongue & Groove Flange

High Nickel Alloy WNRF Flange

Nickel Expander Flanges

Ni Alloy Girth Flanges

ASTM B564 Nickel Alloy Orifice Flanges

Nickel Alloy Socket Weld Flange

ANSI B16.5 Ni Alloy Lapped Joint Flange

Nickel Alloy Long Weld Neck Flange

Nickel Screwed Flange

ANSI B16.5 Ni Alloy Reducing Flanges

ASTM B462 forged flange and forging stockist and exporter in India, Also Check Price List of Nickel Alloy Forging

Pressure Rating of ASTM B564 Nickel Alloy Flanges

| Temperature °F | Class 150 | Class 600 | Class 1500 | Class 400 | Class 900 | Class 300 | Class 2500 |

| -20 to 100 | 275 | 1440 | 3600 | 960 | 2160 | 720 | 6000 |

| 300 | 205 | 1080 | 2700 | 720 | 1620 | 540 | 4500 |

| 200 | 230 | 1200 | 3000 | 800 | 1800 | 600 | 5000 |

| 400 | 190 | 995 | 2485 | 660 | 1490 | 495 | 4140 |

| 600 | 140 | 875 | 2185 | 580 | 1310 | 435 | 3640 |

| 650 | 125 | 860 | 2150 | 575 | 1290 | 430 | 3580 |

| 500 | 170 | 930 | 2330 | 620 | 1395 | 465 | 3880 |

| 700 | 110 | 850 | 2125 | 565 | 1275 | 425 | 3540 |

| 750 | 95 | 830 | 2075 | 555 | 1245 | 415 | 3460 |

| 850 | 65 | 790 | 1980 | 530 | 1190 | 395 | 3300 |

| 800 | 80 | 805 | 2015 | 540 | 1210 | 405 | 3360 |

| 900 | 50 | 780 | 1945 | 520 | 1165 | 390 | 3240 |

| 950 | 35 | 765 | 1910 | 510 | 1145 | 380 | 3180 |

| 1000 | 20 | 640 | 1605 | 430 | 965 | 320 | 2675 |

| 1100 | 20 | 515 | 1285 | 345 | 770 | 255 | 2145 |

| 1150 | 20 | 400 | 995 | 265 | 595 | 200 | 1655 |

| 1050 | 20 | 615 | 1545 | 410 | 925 | 310 | 2570 |

| 1200 | 20 | 310 | 770 | 205 | 465 | 155 | 1285 |

| 1250 | 20 | 225 | 565 | 150 | 340 | 115 | 945 |

| 1300 | 20 | 170 | 430 | 115 | 255 | 85 | 715 |

| 1400 | 20 | 95 | 240 | 65 | 145 | 50 | 400 |

| 1350 | 20 | 125 | 310 | 80 | 185 | 60 | 515 |

| 1450 | 15 | 70 | 170 | 45 | 105 | 35 | 285 |

| 1500 | 10 | 55 | 135 | 35 | 80 | 25 | 230 |

ANSI B16.5 Ni Alloy Flanges Dimensions

| Normal Pipe Size (NPS) Of Flanges | (I.D.) Inside Diameter | Thickness Of Raised Face (RF) (T) |

Outside Daimeter (O.D.) | Raised Face (R) |

RF (Raised Face) |

Holes Of Bolts (B) |

H | T1 | Thickness Of Flat Face (FF) (T2) |

BC (Circle Of Bolt) | Bolts Holes Numbers |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 0.88 | 0.88 | 3.75 | 1.38 | .063 | 0.62 | 1.50 | 0.50 | 0.82 | 2.62 | 4 |

| 1 | 1.36 | 1.06 | 4.88 | 2.00 | .063 | 0.75 | 2.12 | 0.63 | 1.00 | 3.50 | 4 |

| 3/4 | 1.09 | 1.00 | 4.62 | 1.69 | .063 | 0.75 | 1.88 | .056 | 0.94 | 3.25 | 4 |

| 1-1/4 | 1.70 | 1.06 | 5.25 | 2.50 | .063 | 0.75 | 2.50 | 0.69 | 1.00 | 3.88 | 4 |

| 2 | 2.44 | 1.31 | 6.50 | 3.62 | .063 | 0.75 | 3.31 | 0.82 | 1.25 | 5.00 | 8 |

| 1-1/2 | 1.95 | 1.19 | 6.12 | 2.88 | .063 | 0.88 | 2.75 | 0.75 | 1.13 | 4.50 | 4 |

| 2-1/2 | 2.94 | 1.50 | 7.50 | 4.12 | .063 | 0.88 | 3.94 | 0.94 | 1.44 | 5.88 | 8 |

| 3 | 3.57 | 1.69 | 8.25 | 5.00 | .063 | 0.88 | 4.62 | 1.06 | 1.63 | 6.62 | 8 |

| 3-1/2 | 4.07 | 1.75 | 9.00 | 5.50 | .063 | 0.88 | 5.25 | 1.13 | 1.69 | 7.25 | 8 |

| 4 | 4.57 | 1.88 | 10.00 | 6.19 | .063 | 0.88 | 5.75 | 1.19 | 1.82 | 7.88 | 8 |

| 5 | 5.66 | 2.00 | 11.00 | 7.31 | .063 | 0.88 | 7.00 | 1.32 | 1.94 | 9.25 | 8 |

| 18 | 18.18 | 3.50 | 28.00 | 21.00 | .063 | 1.38 | 21.00 | 2.32 | 3.44 | 24.75 | 24 |

| 6 | 6.72 | 2.06 | 12.50 | 8.50 | .063 | 0.88 | 8.12 | 1.38 | 2.00 | 10.62 | 12 |

| 8 | 8.72 | 2.44 | 15.00 | 10.62 | .063 | 1.00 | 10.25 | 1.56 | 2.38 | 13.00 | 12 |

| 10 | 10.88 | 2.62 | 17.50 | 12.75 | .063 | 1.12 | 12.62 | 1.82 | 2.56 | 15.25 | 16 |

| 12 | 12.88 | 2.88 | 20.50 | 15.00 | .063 | 1.25 | 14.75 | 1.94 | 2.82 | 17.75 | 16 |

| 14 | 14.14 | 3.00 | 23.00 | 16.25 | .063 | 1.25 | 16.75 | 2.06 | 2.94 | 20.25 | 20 |

| 20 | 20.20 | 3.75 | 30.50 | 23.00 | .063 | 1.38 | 23.12 | 2.44 | 3.69 | 27.00 | 24 |

| 16 | 16.16 | 3.25 | 25.50 | 18.50 | .063 | 1.38 | 19.00 | 2.19 | 3.19 | 22.50 | 20 |

| 22 | 22.22 | 4.00 | 33.00 | 25.25 | .063 | 1.63 | 25.25 | 2.57 | 3.94 | 29.25 | 24 |

| 24 | 24.25 | 4.19 | 36.00 | 27.25 | .063 | 1.62 | 27.62 | 2.69 | 4.13 | 32.00 | 24 |

High Temperature Alloy flange and Nickel Alloy Slip On/ Blind and Socket Weld Flange Dimensions and Weight Chart

Weight Chart of Ni Alloy Flange

| NPS (Nominal Pipe Size) | Loose (Lap Joint) | NPT (Threaded) | SORF (Slip On) | BLRF (Blind) | SWRF (Socket Weld) | WRNR (Weld Neck) |

|---|---|---|---|---|---|---|

| ½ | 1 | 1 | 1 | 2 | 2 | 2 |

| 1 | 2 | 2 | 2 | 2 | 2 | 3 |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 |

| 1½ | 3 | 3 | 3 | 4 | 3 | 4 |

| 2½ | 8 | 8 | 8 | 7 | 8 | 10 |

| 2 | 5 | 5 | 5 | 5 | 5 | 6 |

| 3 | 9 | 9 | 9 | 9 | 9 | 11.5 |

| 4 | 13 | 13 | 13 | 17 | 13 | 16.5 |

| 3½ | 11 | 12 | 11 | 13 | 11 | 12 |

| 5 | 15 | 15 | 15 | 20 | 15 | 21 |

| 8 | 30 | 30 | 30 | 47 | 30 | 42 |

| 6 | 19 | 19 | 19 | 27 | 19 | 26 |

| 10 | 43 | 43 | 43 | 70 | 43 | 54 |

| 24 | 275 | 220 | 220 | 430 | 220 | 268 |

| 14 | 105 | 90 | 90 | 140 | 90 | 114 |

| 12 | 64 | 64 | 64 | 123 | 64 | 88 |

| 16 | 140 | 98 | 106 | 180 | 98 | 140 |

| 20 | 195 | 165 | 165 | 285 | 165 | 197 |

| 18 | 160 | 130 | 130 | 220 | 130 | 165 |

| 22 | 245 | 185 | 185 | 355 | 185 | 225 |

Nickel Alloy Pipe Flanges Chemical Composition

| Superalloy Grade | C | S | Mo | Si | Ti | Ni | Cu | Cr | Mn | Fe |

| Nickel 200 | 0.08 | 0.005 | … | 0.18 | … | 99.5(a) | 0.13 | … | 0.18 | 0.2 |

| Nickel 201 | 0.01 | 0.005 | … | 0.18 | … | 99.6(a) | 0.13 | … | 0.18 | 0.2 |

| Hastelloy B | 0.05 max | … | 28 | 1 | … | 61 | … | 1 | 1 | 5 |

| Hastelloy D | 0.12 | … | … | 9.25 | … | 82 | 3 | 1 | 0.9 | 2 |

| Inconel 600 | 0.08 | 0.008 | … | 0.25 | … | 76.0(a) | 0.25 | 15.5 | 0.5 | 8 |

| Inconel 800 | 0.05 | 0.008 | … | 0.5 | 0.38 | 32.5 | 0.38 | 21 | 0.75 | 46 |

| Hastelloy C-276 | 0.01 | 0.02 | 16 | 0.03 | … | 57 | … | 15.5 | 0.5 | 5.5 |

| Hastelloy G | 0.03 | 0.02 | 6.5 | 0.5 | … | 44 | 2 | 22.25 | 1.5 | 19.5 |

| Monel 400 | 0.15 | 0.012 | … | 0.25 | … | 66.5(a) | 31.5 | … | 1 | 1.25 |

| Monel K-500 | 0.13 | 0.005 | … | 0.25 | 0.6 | 66.5(a) | 29.5 | … | 0.75 | 1 |

| Inconel 625 | 0.05 | 0.008 | 9 | 0.25 | 0.2 | 61.0(a) | … | 21.5 | 0.25 | 2.5 |

| Incoloy 825 | 0.03 | 0.015 | 3 | 0.25 | 0.9 | 42 | 2.25 | 21.5 | 0.5 | 30 |

Check ASTM B564 material properties and Ni Alloy BLRF/ SORF/ WNRF/ RTJ Flange Price Ex Mumbai

Nickel Flanges Mechanical Properties

| Superalloy grade | Yield Strength (in ksi) |

Brinell | Elongation % | Tensile Strength (in ksi) | Rockwell |

| Nickel 200 | 15 | 90-120 | 35 | 55 | – |

| Nickel 201 | 12 | 90-120 | 35 | 50 | – |

| Monel 400 | 25 | 110-149 | 35 | 70 | – |

| Monel K-500 | 100 | 265-346 | 17 | 140 | – |

| Hastelloy B-2 | 51 | – | 40 | 110 | C22 |

| Hastelloy D-205 | 49 | – | 57 | 114 | C30-39 |

| Inconel 600 | 30 | 120-170 | 35 | 80 | – |

| Inconel 800 | 30 | 120-184 | 30 | 75 | – |

| Hastelloy C-276 | 60 | 50 | 115 | 184 | |

| Inconel 625 | 39 | 180 | 30 | 98 | – |

| Incoloy 825 | 35 | 120-180 | 30 | 85 | – |

| Hastelloy G-30 | 51 | – | 56 | 100 | – |

| 20Cb-3 | 35 | 160 | 30 | 80 | B84-90 |

High Nickel Alloy Pipe Flanges Equivalent Properties

| Superalloy grade | UNS Equivalent |

| Nickel 200 | N02200 |

| Nickel 201 | N02201 |

| Monel 400 | N04400 |

| Monel K-500 | N05500 |

| Hastelloy B-2 | N10665 |

| Hastelloy D-205 | – |

| Inconel 600 | N06600 |

| Inconel 800 | N08800 |

| Hastelloy C-276 | N10276 |

| Inconel 625 | N06025 |

| Incoloy 825 | N08825 |

| Hastelloy G-30 | N06030 |

| 20Cb-3 | N08020 |

Nickel Flanges Applications

- Marine Applications

- Paper & Pulp

- Fossil Fuel Power Plants

- Refineries

- Oil And Gas Industry

- Nuclear Power

- Power Plants

- Ship Building

Flanges Material

Pipe Fittings Material

Other Products