- Call : +91 22 67436442

- exports@petrometflange.com

Buttweld Fittings manufacturer in India

- Home /

- Buttweld Fittings manufacturer in India

ASME B16.9 Fittings & A106 Bends supplier in Mumbai

What is Buttweld Pipe Fittings?

A Buttweld Pipe Fittings can be defined as weldable pipe fitting that helps in performing a wide range of tasks, like changing the flow direction, combining or dividing the flow, reducing the pipe size, and also attaching any kind of auxiliary equipment. The Buttweld Pipe Fittings are an important part of the piping industry. They are available in nominal sizes with definite schedules. Also, their dimensions and tolerances are defined according to the ASME B16.9 standard.

The Buttweld Pipe Fittings are made of stainless or carbon steel, and they have several advantages compared to the forged pipe fittings. Some benefits would include:

- The connection is more robust.

- It comes with a continuous metal structure which enhances the pipe’s strength.

- It offers seamless flow inside the pipe, when the fittings are matched with the pipe schedules.

There are different types of buttweld pipe fittings available like tee, reducer, cross, caps, elbows, etc. They are structurally different and hence can be used for a wide range of uses, across different industries.

Seamless Vs Welded Pipe Fittings

There are several differences between the Seamless Pipe Fittings and the Welded Pipe Fittings, like:

- The seamless pipe fitting can resist corrosion more effectively compared to the welded fittings. It is because the seamless variants do not have any joints like the welded ones, when corrosion attacks can happen.

- The welded fittings are more affordable than the seamless ones.

- The surface consistency of welded fittings is higher than that of the seamless fitting.

- The seamless variants can be formed at once by the rolling process. The welded variants are made by bending steel plates and then applying various welding methods.

- The seamless fitting come with a higher strength and pressure capacity compared to the welded fittings. Thus, the seamless ones are used in more high-pressure applications.

- Seamless fittings are capable of withstanding more severe conditions than the welded fitting and thus they are preferred for various services across different industries.

How are Buttweld fittings made?

Buttweld pipe fitting are made by the hot forming process which bends and forms to shape. Firstly, the material is cut according to the length and then it is heated and molded to give the desired shape. The heat treatment helps to remove residual stress, along with obtaining various mechanical properties, as desired. There are a wide range of processes used for manufacturing different types of buttweld fittings. For example, buttweld tees are manufactured by extrusion method, elbows by mandrel method, and caps by the deep drawing method.

Where to use Weldable Pipe Fittings?

The weldable pipe fittings are made of different materials like carbon steel and stainless steel. They are the joining components which help to assemble different piping components. They are affordable than buutweld fittings, and are primarily used in less critical applications. They can fit in places where there is a space constraint.

Buttweld Fittings manufacturer in India

European Directive 2014/68/eu certified Buttweld Fittings manufacturers in India offers widest selection of Return Bend and ASME B16.9 3D/5D Elbow in Mumbai

Table of Content

- Buttweld Fittings Specification

- ASME B16.9 Fittings dimensions

- Buttweld Fittings Weight Chart

- Pipe Fittings Size Chart

- Buttweld Fittings Price

- What Are Advantages Of Butt Welding Over Flanges?

- What Is A Seamless Pipe Fitting?

- Various Types of Buttweld Fittings

- How Are Pipe Fittings Measured?

- What Does “schedule” Mean For Pipe Fittings ?

- Why are pipe fittings sometimes heavier and thicker than the pipes they connect to?

- What to Check During Pipe Fittings Dimension Inspection?

- Buttweld Fitting Manufacturing Process

- Non-destructive Tests For Fittings

- Buttweld Fittings Tolerance

- Applications of Buttweld Fittings

- List Of Machineries For Manufacturing Pipe Fittings

- Difference Between Seamless And Welded Fittings

- DIN 2617 Cap Dimensions & Weight Chart

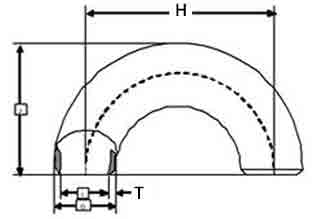

- 180 Degree Elbow Dimensions & Weight Chart

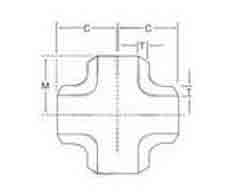

- Reducing Cross Dimensions

Buttweld Fittings Specification

| Size | NPS 1/2″ to 48″ |

| Schedule | Sch 20, 40, STD, 80, 160, XXS |

| Grade | WPB/C, WPHY 42, 46, 52, 60, 65, 70, WPL 3 |

| Bending Radius Provided By Manufacturer | R=1D, 3D, 2D, 5D, 8D, 6D, 10D |

| Manufacturing process | Push, Forge, Press, Cast, etc. |

| Connection | Welding |

| Origin & Mills | European, Japanese, USA, Korean, Ukraine, Indian, Russian |

| Thread Provided By Manufacturer | BSPT, NPT, BSPP |

| Application | Metallurgy, Gas, Petroleum, Chemical, Power, Construction, Shipbuilding etc |

ASME B16.9 Fittings Dimensions

| Nominal Pipe Sizes |

O.D. | 90° Elbows | 45° Elbows | 180° Returns | ||||

|---|---|---|---|---|---|---|---|---|

| (inches) | LR | SR | LR | LR | ||||

| (Millimetre) | (inch) | Center to Face (inch) |

Center to Face (inch) |

Center to Face (inch) |

Radii (inch) |

Center to Center (inch) |

Back to face (inch) |

|

| 1/2 | 21.3 | 0.840 | 1 1/2 | – | 5/8 | 2 | 1 7/8 | |

| 3/4 | 26.7 | 1.050 | 1 1/8 | – | 7/16 | 2 1/4 | 1 11/16 | |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 | 7/8 | 3 | 2 3/16 | |

| 1 1/4 | 42.2 | 1.660 | 1 7/8 | 1 1/4 | 1 | 3 3/4 | 2 3/4 | |

| 1 1/2 | 48.3 | 1.900 | 2 1/4 | 1 1/2 | 1 1/8 | 3 | 4 1/2 | 3 1/4 |

| 2 | 60.3 | 2.375 | 3 | 2 | 1 3/8 | 4 | 6 | 4 3/16 |

| 2 1/2 | 73.0 | 2.875 | 3 3/4 | 2 1/2 | 1 3/4 | 5 | 7 1/2 | 5 3/16 |

| 3 | 88.9 | 3.500 | 4 1/2 | 3 | 2 | 6 | 9 | 6 1/4 |

| 3 1/2 | 101.6 | 4.000 | 5 1/4 | 3 1/2 | 2 1/4 | 7 | 10 1/2 | 7 1/4 |

| 4 | 114.3 | 4.500 | 6 | 4 | 2 1/2 | 8 | 12 | 8 1/4 |

| 5 | 141.3 | 5.563 | 7 1/2 | 5 | 3 1/8 | 10 | 15 | 10 5/16 |

| 6 | 168.3 | 6.625 | 9 | 6 | 3 3/4 | 12 | 18 | 12 5/16 |

| 8 | 219.1 | 8.625 | 12 | 8 | 5 | 12 | 24 | 16 5/16 |

| 10 | 273.1 | 10.750 | 15 | 10 | 6 1/4 | 15 | 30 | 20 3/8 |

| 12 | 323.9 | 12.750 | 18 | 12 | 7 1/2 | 18 | 36 | 24 3/8 |

Buttweld Fittings Weight Chart

| NPS (Normal Pipe Size) | Ave. I.D. (Inside Daimeter) |

O.D. (Outside Diameter) | Maximum W.P. psi |

Minimum WALL |

Normal Weight Chart |

| 1/4" | .344 | .540 | 780 | .088 | .086 |

| 3/8" | .473 | .675 | 620 | .091 | .115 |

| 3/4" | .804 | 1.050 | 480 | .113 | .226 |

| 1" | 1.029 | 1.315 | 450 | .133 | .333 |

| *1-1/4" | 1.360 | 1.660 | 370 | .140 | .450 |

| *1-1/2" | 1.590 | 1.900 | 330 | .145 | .537 |

| *2" | 2.047 | 2.375 | 280 | .154 | .720 |

| 1/2" | .602 | .840 | 590 | .109 | .170 |

| 2-1/2" | 2.445 | 2.875 | 300 | .203 | 1.136 |

| *3" | 3.042 | 3.500 | 260 | .216 | 1.488 |

| 3-1/2" | 3.521 | 4.000 | 240 | .226 | 1.789 |

| *4" | 3.998 | 4.500 | 220 | .237 | 2.118 |

| 5" | 5.016 | 5.563 | 190 | .258 | 2.874 |

| *6" | 6.031 | 6.625 | 180 | .280 | 3.733 |

| *8" | 7.942 | 8.625 | 160 | .322 | 5.619 |

| *20" | 18.743 | 20.000 | 120 | .593 | 24.183 |

| *10" | 9.976 | 10.750 | 140 | .365 | 7.966 |

| *12" | 11.889 | 12.750 | 130 | .406 | 10.534 |

| *16" | 14.940 | 16.000 | 130 | .500 | 16.286 |

| *18" | 16.809 | 18.000 | 130 | .562 | 20.587 |

| *14" | 13.073 | 14.000 | 130 | .437 | 12.462 |

| *24" | 22.544 | 24.000 | 120 | .687 | 33.652 |

Pipe Fittings Size Chart

| NOMINAL PIPE SIZE | OUTSIDE DIAMETER | CENTER TO END | ||

|---|---|---|---|---|

| Inch. | OD | A | B | C |

| 1/2 | 21.3 | 38 | 16 | – |

| 3/4 | 26.7 | 29 | 11 | – |

| 1 | 33.4 | 38 | 22 | 25 |

| 1 1/4 | 42.2 | 48 | 25 | 32 |

| 1 1/2 | 48.3 | 57 | 29 | 38 |

| 2 | 60.3 | 76 | 35 | 51 |

| 2 1/2 | 73 | 95 | 44 | 64 |

| 3 | 88.9 | 114 | 51 | 76 |

| 3 1/2 | 101.6 | 133 | 57 | 89 |

| 4 | 114.3 | 152 | 64 | 102 |

| 5 | 141.3 | 190 | 79 | 127 |

| 6 | 168.3 | 229 | 95 | 152 |

| 8 | 219.1 | 305 | 127 | 203 |

| 10 | 273.1 | 381 | 159 | 254 |

| 12 | 323.9 | 457 | 190 | 305 |

| 14 | 355.6 | 533 | 222 | 356 |

| 16 | 406.4 | 610 | 254 | 406 |

| 18 | 457.2 | 686 | 286 | 457 |

| 20 | 508 | 762 | 318 | 508 |

| 22 | 559 | 838 | 343 | 559 |

| 24 | 610 | 914 | 381 | 610 |

| 26 | 660 | 991 | 406 | 660 |

| 28 | 711 | 1067 | 438 | 711 |

| 30 | 762 | 1143 | 470 | 762 |

| 32 | 813 | 1219 | 502 | 813 |

| 34 | 864 | 1295 | 533 | 864 |

| 36 | 914 | 1372 | 565 | 914 |

| 38 | 965 | 1448 | 600 | 965 |

| 40 | 1016 | 1524 | 632 | 1016 |

| 42 | 1067 | 1600 | 660 | 1067 |

| 44 | 1118 | 1676 | 695 | 1118 |

| 46 | 1168 | 1753 | 727 | 1168 |

| 48 | 1219 | 1829 | 759 | 1219 |

1/2" - 32" NB seamless butt weld Fittings and ASME B16.9 Pipe Fittings manufacturer in India in alloy, stainless and carbon steel

Buttweld Fittings Price

| Buttweld Fitting Price Per Piece in India | ASME B16.9 Pipe Fitting Price in INR | ASME B16.9 Fitting Price in UAE Dirham | Pipe Fitting Price in USD |

| 1-1/2 NB SCH 80 A 403 WP 304/304 L 90 DEG SR Per Kg | 365 | UAE Dirham 18.02 | $4.91 |

| CARBON STEEL GR A234 WPB STUB END STD WT Per Kg | 1,719 | UAE Dirham 23.11 | $84.88 |

| MILD STEEL SEAMLESS BUTTWELD FITTING A234 GR WPB Per Piece | 43 | UAE Dirham 2.12 | $0.58 |

What Are Advantages Of Butt Welding Over Flanges?

- Flanges bolt together pipes, whereas butt weld fitting weld together pipes.

- Butt weld fittings require 10% to 75% less material than flanged connections, depending on size, resulting in lower material cost and weight.

- Welded construction allows for greater design flexibility; this system takes up less space, is more compact, and has greater strength.

- Butt weld fittings have optimum flow characteristics because they lack pockets and sharp corners, resulting in less frictional resistance, no pressure loss, and less turbulence.

What Is a Seamless Pipe Fitting?

A butt weld pipe fitting is intended to be welded on-site at its end(s) to connect pipe(s) and allow for changes in direction, pipe diameter, branching, or ending. This fitting is then used as part of a fluid transport system.

Check Long Radius Bends and schedule 40 Pipe Fitting dimensions in accordance with ASME B16.9/ B16.28/ MSS SP-25

Various Types of Buttweld Fittings

Buttweld Fittings

ASME B16.9 Fittings

A106 Bends

ASME B16.9 3D Elbow

ASME B16.9 Pipe Fittings

ASME B16.9 Seamless Pipe Fittings

ASME B16.9 Weld Fittings

Buttweld Pipe Fittings

ANSI B16.9 Fittings

Pipe Fittings

Seamless Buttweld Pipe Fittings

Seamless Buttweld Fittings

Pipe Weld Fittings

Seamless Pipe Fittings

Welded Pipe Fittings

Buttweld Elbow

Buttweld End Cap

Buttweld Tee

90 Degree Pipe Elbow

90 Degree Elbow

180 Degree Elbow

180 Degree Pipe Elbow

180 Degree Black Pipe Elbow

180 Degree Steel Pipe Elbow

Long Radius Elbow

Long Radius Pipe Elbow

Short Radius Elbow

Aluminum Short Radius Pipe Elbow

Equal Pipe Tee

Reducing Tee

Buttweld Concentric Reducer

Buttweld Reducer

Eccentric Buttweld Reducer

Pipe Eccentric Reducer

Pipe End Cap

Long Stub End

Long Collar Stub End

Short Stub End

Short Pattern Stub End

Stub End Short Collar

Lap Joint Stub End

Pipe Lap Joint Stub End

Jis Lap Joint Stub End

Equal Cross

Reducing Pipe Cross

Reducing Cross

Lateral Tee

Reducing Lateral Tee

45 Degree Lateral Tee

45 Degree Pipe Elbow

45 Degree Steel Pipe Elbow

45 Degree Black Pipe Elbow

45 Degree Elbow

ASME B16.9 Seamless Fittings

ASME B16.9 Welded fittings

EN 10253-4 Fittings

EN 10253-2 Elbow

DIN 2617 Cap

EN 10253-2 Reducer

En 10253-2 Concentric Reducer

How Are Pipe Fittings Measured?

- The diameter, wall thickness, and shape or configuration of pipe fitting are all measured.

- The outside diameter of a pipe or fitting is referred to as its diameter.

- Nominal Pipe Size is the North American standard (NPS). Diameter Nominal is the International Standard (DN). Pipes and fittings are manufactured in similar sizes all over the world; they are simply labelled differently.

- Outside diameters are slightly larger than indicated size from 12 in to 12 in "Nominal Pipe Size"; inside diameters get smaller as schedules grow.

What Does “schedule” Mean For Pipe Fittings ?

- The term schedule, often abbreviated as sch, refers to the wall thickness of a pipe or pipe fitting in North America. Higher schedules imply thicker walls that can withstand greater pressures.

- These wall thicknesses are defined by pipe standards: SCH 5, 10, 5S, 10S, 30, 40, 40S, 20, 60, 80S, XS, 100, 80, 120, 160, 140, STD, and XXS.

- Higher schedules are heavier and require more material, and are thus more expensive to manufacture and install.

ASME B16.9 Schedule 10/ Schedule 80S ASME B16.9 Weld Fittings, and ASME B16.9 Seamless Pipe Fittings manufacturer in India

Why are pipe fittings sometimes heavier and thicker than the pipes they connect to?

- To meet performance requirements or for manufacturing reasons, fitting are sometimes thicker than connecting pipes.

- When compared to a pipe, stress is very different due to fitting geometry. Extra material is frequently required to compensate for such additional stress, particularly in tees and tight curve elbows.

What to Check During Pipe Fittings Dimension Inspection?

- Diameter

- Length

- Thickness schedule no

- Straightness & perpendicularity of the ends of the fitting

- Degree of elbows & bends

- And Concentricity of reducer

Buttweld Fitting Manufacturing Process

- Selection of raw material: metal; plate or pipe.

- Cutting

- Heating

- Forming

- Welding: for fittings that are not simple elbows, returns, bends, reducers or caps.

- Inspection and tests: according to standards and client requirements.

- Coating (if required).

- Preparation of documentation.

- Shipping.

ISO 9001:2015 certified Buttweld Fittings manufacturers in India offers large selection of NB-3642.2 ANSI/ ASME B16.28 Pipe Fittings in Mumbai

Non-destructive Tests For Fittings

- Dye or liquid penetrant

- Ferrite content

- Hydrostatic

- Magnetic particles

- Macrography

- Micrography

- Pneumatic pressure

- Positive material identification

- Radiography

Buttweld Fittings Tolerance

| Buttweld Fittings ASME B16.9 Tolerance (Elbow, Cap, Tee, Reducer) | 90 Deg. & 45 Deg.

Elbow and Tee |

Pipe Reducer

& Lap Joint Stub End |

Pipe Cap | |||

| Buttweld Fitting Dimension (NPS) | Outside

Diameter at Bevel |

Inside

Diameter at End |

WallThickness T | Center-to-End

Dimension A ,C ,B |

Over-all

Length H |

Over-all

Length F |

| 1/2 to 2-1/2 | +0.06 | Not less than 87.5%

of nominal thickness |

+/- 0.06 | +/- 0.06 | +/- 0.12 | |

| -0.03 | ||||||

| 3 to 3-1/2 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.12 | |

| 4 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.12 | |

| 5 to 8 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.25 | |

| 10 to 18 | +0.16 | +/- 0.12 | +/- 0.09 | +/- 0.09 | +/- 0.25 | |

| -0.12 | ||||||

| 20 to 24 | +0.25 | +/- 0.19 | +/- 0.09 | +/- 0.09 | +/- 0.25 | |

| -0.19 | ||||||

| 26 to 30 | +0.25 | +/- 0.19 | +/- 0.12 | +/- 0.19 | +/- 0.38 | |

| -0.19 | ||||||

| 32 to 48 | +0.25 | +/- 0.19 | +/- 0.19 | +/- 0.19 | +/- 0.38 | |

| -0.19 | ||||||

Applications of Buttweld Fittings

- Food Processing and Dairy Industries

- High Pressure Applications

- Chemical Refinery

- Oil and Gas Industry

- Nuclear Power Plants

- Water Pipe Line

- Paper & Pulp

- High Temperature Application

List Of Machineries For Manufacturing Pipe Fittings

- Radial Driling Machine

- Tee Cold Forming Machines

- Elbow Cold Forming Machines

- Oil Fired Heat Treatment Furnace

- Heat Treatment For Forged Fittings

- Portable Temperature Indicator

- Tee Beveling Machine

- CNC Lath

- Hydraulic Press 150 Tons Capacity

- Hydraulic Press 300 Tons Capacity

Difference Between Seamless And Welded Fittings

Seamless elbows are formed from seamless steel pipes using hot pushing, pressing, or extrusion methods, and they have no welds. Welded elbows smaller than DN600 are typically formed of welded steel pipes and are produced in the same manner as seamless elbows. The elbows, however, have a welded seam. Welding elbows with diameters more than DN600 are composed of steel plates and have two welds.

DIN 2617 Cap Dimensions & Weight Chart

| Outside diameter | Height | Wall thickness | Weight |

| mm | mm | mm | kg |

| D | s1 | ||

| 21,3 | 25,0 | 2,0 | 0,060 |

| 26,9 | 32,0 | 2,3 | 0,070 |

| 33,7 | 38,0 | 2,6 | 0,110 |

| 3,2 | 0,130 | ||

| 42,4 | 38,0 | 2,6 | 0,130 |

| 3,6 | 0,170 | ||

| 48,3 | 38,0 | 2,6 | 0,200 |

| 4,0 | 0,230 | ||

| 60,3 | 38,0 | 2,9 | 0,280 |

| 4,5 | 0,320 | ||

| 76,1 | 38,0 | 2,9 | 0,340 |

| 5,0 | 0,390 | ||

| 88,9 | 51,0 | 3,2 | 0,530 |

| 5,6 | 0,700 | ||

| 108,0 | 64,0 | 3,6 | 1,000 |

| 114,3 | 64,0 | 3,6 | 1,000 |

| 6,3 | 1,500 | ||

| 133,0 | 76,0 | 4,0 | 1,600 |

| 139,7 | 76,0 | 4,0 | 1,700 |

| 6,3 | 2,500 | ||

| 159,0 | 90,0 | 4,5 | 2,400 |

| 168,3 | 89,0 | 4,5 | 2,650 |

| 7,1 | 3,550 | ||

| 219,0 | 100,0 | 6,3 | 5,550 |

| 8,0 | 6,700 | ||

| 273,0 | 127,0 | 6,3 | 8,800 |

| 323,9 | 152,0 | 7,1 | 14,000 |

| 355,6 | 165,0 | 8,0 | 16,500 |

| 406,4 | 178,0 | 8,8 | 18,200 |

| 508,0 | 229,0 | 11,0 | 38,000 |

180 Degree Elbow Dimensions & Weight Chart

| Nom. Pipe Size | Pipe Sched. or No. | Center- to-Center Dimen. | Back- to- Face | Outside Dia. | Inside Dia. | Wall Thick. | Approx. Weight (lb.) |

| H | J | OD | ID | T | |||

| STANDARD WEIGHT | |||||||

| 1/2 | 40 | 3 | 1 7/8 | 0.840 | 0.622 | 0.109 | 0.3 |

| 3/4 | 40 | 2 1/2 | 1 11/16 | 1.050 | 0.824 | 0.113 | 0.3 |

| 1 | 40 | 3 | 2 3/16 | 1.315 | 1.049 | 0.133 | 0.7 |

| 1 1/4 | 40 | 3 3/4 | 2 3/4 | 1.660 | 1.380 | 0.140 | 1 |

| 1 1/2 | 40 | 4 1/2 | 3 1/4 | 1.900 | 1.610 | 0.145 | 1.5 |

| 2 | 40 | 6 | 4 3/16 | 2.375 | 2.067 | 0.154 | 3 |

| 2 1/2 | 40 | 7 1/2 | 5 3/16 | 2.875 | 2.469 | 0.203 | 6 |

| 3 | 40 | 9 | 6 1/4 | 3.500 | 3.068 | 0.216 | 9 |

| 3 1/2 | 40 | 10 1/2 | 7 1/4 | 4.000 | 3.548 | 0.226 | 12 |

| 4 | 40 | 12 | 8 1/4 | 4.500 | 4.026 | 0.237 | 17 |

| 5 | 40 | 15 | 10 5/16 | 5.563 | 5.047 | 0.258 | 28 |

| 6 | 40 | 18 | 12 5/16 | 6.625 | 6.065 | 0.280 | 46 |

| 8 | 40 | 24 | 16 5/16 | 8.625 | 7.981 | 0.322 | 90 |

| 10 | 40 | 30 | 20 3/8 | 10.750 | 10.020 | 0.365 | 156 |

| 12 | – | 36 | 24 3/8 | 12.750 | 12.000 | 0.375 | 236 |

| 14 | 30 | 42 | 28 | 14.000 | 13.250 | 0.375 | 294 |

| 16 | 30 | 48 | 32 | 16.000 | 15.250 | 0.375 | 404 |

| 18 | – | 54 | 36 | 18.000 | 17.250 | 0.375 | 512 |

| 20 | 20 | 60 | 40 | 20.000 | 19.250 | 0.375 | 617 |

| 24 | 20 | 72 | 48 | 24.000 | 23.250 | 0.375 | 886 |

Reducing Cross Dimensions

| Nominal Diameter | Outside Diameter | Center to End | |||||

| D1 | D2 | ||||||

| DN | NPS | Series A | Series B | Series A | Series B | C | M |

| 15*15 | 1/2*1/2 | 21.3 | 18 | 21.3 | 18 | 25 | 25 |

| 15*10 | 1/2*3/8 | 21.3 | 18 | 17.3 | 14 | 25 | 25 |

| 15*8 | 1/2*1/4 | 21.3 | 18 | 13.7 | 10 | 25 | 25 |

| 20*20 | 3/4*3/4 | 26.9 | 25 | 26.9 | 25 | 29 | 29 |

| 20*15 | 3/4*1/2 | 26.9 | 25 | 21.3 | 18 | 29 | 29 |

| 20*10 | 3/4*3/8 | 26.9 | 25 | 17.3 | 14 | 29 | 29 |

| 25*25 | 1*1 | 33.7 | 32 | 33.7 | 32 | 38 | 38 |

| 25*20 | 1*3/4 | 33.7 | 32 | 26.9 | 25 | 38 | 38 |

| 25*15 | 1*1/2 | 33.7 | 32 | 21.3 | 18 | 38 | 38 |

| 32*32 | 1.1/4*1.1/4 | 42.4 | 38 | 42.4 | 38 | 48 | 48 |

| 32*25 | 1.1/4*1 | 42.4 | 38 | 33.7 | 32 | 48 | 48 |

| 32*20 | 1.1/4*3/4 | 42.4 | 38 | 26.9 | 25 | 48 | 48 |

| 32*15 | 1.1/4*1/2 | 42.4 | 38 | 21.3 | 18 | 48 | 48 |

| 40*40 | 1.1/2*1.1/2 | 48.3 | 45 | 48.3 | 45 | 57 | 57 |

| 40*32 | 1.1/2*1.1/4 | 48.3 | 45 | 42.4 | 38 | 57 | 57 |

| 40*25 | 1.1/2*1 | 48.3 | 45 | 33.7 | 32 | 57 | 57 |

| 40*20 | 1.1/2*3/4 | 48.3 | 45 | 26.9 | 25 | 57 | 57 |

| 40*15 | 1.1/2*1/2 | 48.3 | 45 | 21.3 | 18 | 57 | 57 |

| 50*50 | 2*2 | 60.3 | 57 | 60.3 | 57 | 64 | 64 |

| 50*40 | 2*1.1/2 | 60.3 | 57 | 48.3 | 45 | 64 | 60 |

| 50*32 | 2*1.1/4 | 60.3 | 57 | 42.4 | 38 | 64 | 57 |

| 50*25 | 2*1 | 60.3 | 57 | 33.7 | 32 | 64 | 51 |

| 50*20 | 2*3/4 | 60.3 | 57 | 26.9 | 25 | 64 | 44 |

| 65*65 | 2/1/2*2.1/2 | 73.0 | 76 | 73.0 | 76 | 76 | 76 |

| 65*50 | 2/1/2*2 | 73.0 | 76 | 60.3 | 57 | 76 | 70 |

| 65*40 | 2/1/2*1.1/2 | 73.0 | 76 | 48.3 | 45 | 76 | 67 |

| 65*32 | 2/1/2*1.1/4 | 73.0 | 76 | 42.4 | 38 | 76 | 64 |

| 65*25 | 2/1/2*1 | 73.0 | 76 | 33.7 | 32 | 76 | 57 |

| 80*80 | 3*3 | 88.9 | 89 | 88.9 | 89 | 86 | 86 |

| 80*65 | 3*2.1/2 | 88.9 | 89 | 73.0 | 76 | 86 | 83 |

| 80*50 | 3*2 | 88.9 | 89 | 60.3 | 57 | 86 | 76 |

| 80*40 | 3*1.1/2 | 88.9 | 89 | 48.3 | 45 | 86 | 73 |

| 80*32 | 3*1.1/4 | 88.9 | 89 | 42.4 | 38 | 86 | 70 |

| 90*90 | 3.1/2*3.1/2 | 101.6 | - | 101.6 | - | 95 | 95 |

| 90*80 | 3.1/2*3 | 101.6 | - | 88.9 | 89 | 95 | 92 |

| 90*65 | 3.1/2*2.1/2 | 101.6 | - | 73.0 | 76 | 95 | 89 |

| 90*50 | 3.1/2*2 | 101.6 | - | 60.3 | 57 | 95 | 83 |

| 90*40 | 3.1/2*1.1/2 | 101.6 | - | 48.3 | 45 | 95 | 79 |

| 100*100 | 4*4 | 114.3 | 108 | 114.3 | 108 | 105 | 105 |

| 100*90 | 4*3.1/2 | 114.3 | 108 | 101.6 | - | 105 | 102 |

| 100*80 | 4*3 | 114.3 | 108 | 88.9 | 89 | 105 | 98 |

| 100*65 | 4*2.1/2 | 114.3 | 108 | 73.0 | 76 | 105 | 95 |

| 100*50 | 4*2 | 114.3 | 108 | 60.3 | 57 | 105 | 89 |

| 100*40 | 4*1.1/2 | 114.3 | 108 | 48.3 | 45 | 105 | 86 |

| 125*125 | 5*5 | 141.3 | 133 | 141.3 | 133 | 124 | 124 |

| 125*100 | 5*4 | 141.3 | 133 | 114.3 | 108 | 124 | 117 |

| 125*90 | 5*3.1/2 | 141.3 | - | 101.6 | - | 124 | 114 |

| 125*80 | 5*3 | 141.3 | 133 | 88.9 | 89 | 124 | 111 |

| 125*65 | 5*2.1.2 | 141.3 | 133 | 73.0 | 76 | 124 | 108 |

| 125*50 | 5*2 | 141.3 | 133 | 60.3 | 57 | 124 | 105 |

| 150*150 | 6*6 | 168.3 | 159 | 168.3 | 159 | 143 | 143 |

| 150*125 | 6*5 | 168.3 | 159 | 141.3 | 133 | 143 | 137 |

| 150*100 | 6*4 | 168.3 | 159 | 114.3 | 108 | 143 | 130 |

| 150*90 | 6*3.1/2 | 168.3 | - | 101.6 | - | 143 | 127 |

| 150*80 | 6*3 | 168.3 | 159 | 88.9 | 89 | 143 | 124 |

| 150*65 | 6*2.1/2 | 168.3 | 159 | 73.0 | 76 | 143 | 121 |

| 200*200 | 8*8 | 219.1 | 219 | 219.1 | 219 | 178 | 178 |

| 200*150 | 8*6 | 219.1 | 219 | 168.3 | 159 | 178 | 168 |

| 200*125 | 8*5 | 219.1 | 219 | 141.4 | 133 | 178 | 162 |

| 200*100 | 8*4 | 219.1 | 219 | 114.3 | 108 | 178 | 156 |

| 200*90 | 8*3.1/2 | 219.1 | - | 101.6 | - | 178 | 152 |

| 250*250 | 10*10 | 273.0 | 273 | 273.0 | 273 | 216 | 216 |

| 250*200 | 10*8 | 273.0 | 273 | 219.1 | 219 | 216 | 203 |

| 250*150 | 10*6 | 273.0 | 273 | 168.3 | 159 | 216 | 194 |

| 250*125 | 10*5 | 273.0 | 273 | 141.3 | 133 | 216 | 191 |

| 250*100 | 10*4 | 273.0 | 273 | 114.3 | 108 | 216 | 184 |

| 300*300 | 12*12 | 323.9 | 325 | 323.9 | 325 | 254 | 254 |

| 300*250 | 12*10 | 323.9 | 325 | 273.0 | 273 | 254 | 241 |

| 300*200 | 12*8 | 323.9 | 325 | 219.1 | 219 | 254 | 229 |

| 300*150 | 12*6 | 323.9 | 325 | 168.3 | 159 | 254 | 219 |

| 300*125 | 12*5 | 323.9 | 325 | 141.3 | 133 | 254 | 216 |

| 350*350 | 14*14 | 355.6 | 377 | 355.6 | 377 | 279 | 279 |

| 350*300 | 14*12 | 355.6 | 377 | 323.9 | 325 | 279 | 270 |

| 350*250 | 14*10 | 355.6 | 377 | 273.0 | 273 | 279 | 257 |

| 350*200 | 14*8 | 355.6 | 377 | 219.1 | 219 | 279 | 248 |

| 350*150 | 14*6 | 355.6 | 377 | 168.3 | 159 | 279 | 238 |

| 400*400 | 16*16 | 406.4 | 426 | 406.4 | 426 | 305 | 305 |

| 400*350 | 16*14 | 406.4 | 426 | 355.6 | 377 | 305 | 305 |

| 400*300 | 16*12 | 406.4 | 426 | 323.9 | 325 | 305 | 295 |

| 400*250 | 16*10 | 406.4 | 426 | 273.0 | 273 | 305 | 283 |

| 400*200 | 16*8 | 406.4 | 426 | 219.1 | 219 | 305 | 273 |

| 400*150 | 16*6 | 406.4 | 426 | 168.3 | 159 | 305 | 264 |

| 450*450 | 18*18 | 457 | 480 | 457 | 480 | 343 | 343 |

| 450*400 | 18*16 | 457 | 480 | 406.4 | 426 | 343 | 330 |

| 450*350 | 18*14 | 457 | 480 | 355.6 | 377 | 343 | 330 |

| 450*300 | 18*12 | 457 | 480 | 323.9 | 325 | 343 | 321 |

| 450*250 | 18*10 | 457 | 480 | 273.0 | 273 | 343 | 308 |

| 450*200 | 18*8 | 457 | 480 | 219.1 | 219 | 343 | 298 |

| 500*500 | 20*20 | 508 | 530 | 508 | 530 | 381 | 381 |

| 500*450 | 20*20 | 508 | 530 | 457 | 480 | 381 | 368 |

| 500*400 | 20*20 | 508 | 530 | 406.4 | 426 | 381 | 356 |

| 500*350 | 20*20 | 508 | 530 | 355.6 | 377 | 381 | 356 |

| 500*300 | 20*20 | 508 | 530 | 323.9 | 325 | 381 | 346 |

| 500*250 | 20*20 | 508 | 530 | 273.0 | 273 | 381 | 333 |

| 500*200 | 20*20 | 508 | 530 | 219.1 | 219 | 381 | 324 |

Pipe Fittings Types

Pipe Fittings Material

Flanges Material

Other Products