- Call : +91 22 67436442

- exports@petrometflange.com

Carbon Steel Elbow manufacturer in India

- Home /

- Carbon Steel Elbow

Manufacturer of ASME B16.9 Elbow in Long/ Short Radius, refer dimensions and weight chart

What is Carbon Steel Elbow?

The Carbon Steel Elbow can be defined as curved pieces that help to connect the piping system. They basically join straight pipes, commonly at 45 degree or 90 degree. It is one of the best ways to avoid any kind of obstructions in the process of plumbing. The ends of the Carbon Steel Elbow are machined for buttwelding or socket welding.

The carbon steel alloy is a popular material that consists of less than 2% carbon and the Carbon Steel Elbow can be used for a wide range of applications. They are available in various standards. There are two types of Carbon Steel Elbow available, namely long radius elbow- the center line is at 1.5 times NPS from the end of the elbow and short radius elbow- the center line is equal to the NPS from the end of the elbow. Different types of coatings can be applied on Carbon Steel Elbow to enhance its appearance and improve its corrosion resisting properties.

Carbon Steel Long Radius Elbow Vs Carbon Steel Short Radius Elbow

The primary difference between Carbon Steel Long Radius Elbow and Carbon Steel Short Radius Elbow is in their radius of curvature. A short radius elbow gives the pipe a sharper turn when compared to the long radius elbow. Also, for long radius elbow, the radius of curvature = 1.5 times the Nominal Diameter of the pipe, whereas for short radius elbow, the radius of curvature = the Nominal Diameter of the pipe.

High Carbon Steel 90 Degree Elbow Vs Low Carbon Steel 180 Degree Elbow

The High Carbon Steel 90 Degree Elbow has higher carbon content of 0.61% to 1.5%. They have higher strength and the 90 degree elbow helps in changing the direction of flow at an angle of 90 degrees. The Low Carbon Steel 180 Degree Elbow has low carbon content of less than 0.3%, but they have high ductility. The 180 degree elbow helps in changing the flow direction at 180 degree angle.

Where to use Carbon Steel Elbow

The Carbon Steel Elbow is used in different piping systems to change the flow at different degrees. They are mostly available at 45 or 90 degrees. The sweep of the elbow determines how fast the directional changes are made.

What is the difference between Carbon Steel and Low Temperature Carbon Steel Elbow?

The Carbon Steel Elbow can be defined as curved pieces that help to connect the piping system. It is mainly used in caustic systems but not recommended for corrosive services. They can be used both above and below the ground.

Low Temperature Carbon Steel Elbow is used for changing flow direction in those conditions where the temperature can fall below -29 degrees C.

Carbon Steel Elbow manufacturer in India

European Directive 2014/68/eu certified DIN 2605 Carbon Steel Elbow manufacturers in Mumbai offers widest range of ASTM A234 WPB 45 Degree Elbow and A234 WPC Long Radius Elbow in India

Table of Content

- Carbon Steel Elbow Specification

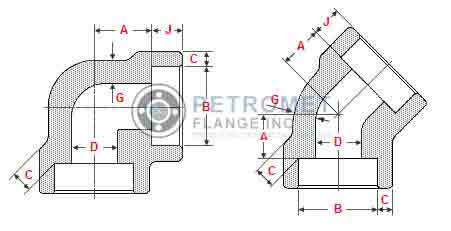

- Carbon Steel Elbow Dimensions

- Weight Of Carbon Steel Elbow

- Carbon Steel Elbow Price

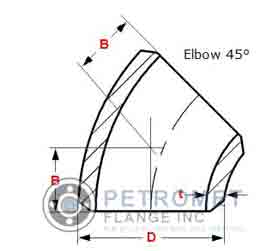

- Carbon Steel 45 Degree Elbow Dimensions

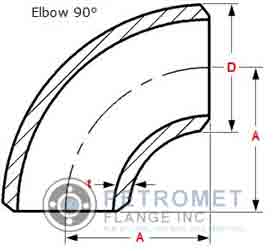

- Carbon Steel 90 Degree Elbow Dimensions

- Types of Carbon Steel Elbow

- Carbon Steel Long Radius Elbow Dimensions

- Carbon Steel Reducing Elbow Dimensions

- Carbon Steel Elbows Angularity Tolerances

- Carbon Steel Elbow Hs Code

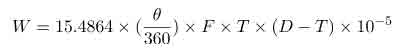

- Carbon Steel Elbow Weight Calculator

- Surface of Carbon Steel Elbows

- Carbon Steel Elbows Chemical Properties

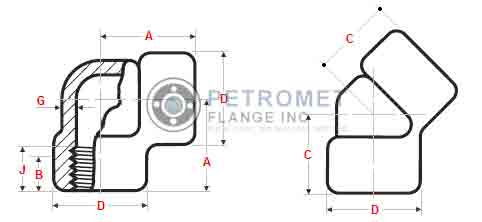

- Carbon Steel Threaded Elbow Dimensions

- Dimensions of Carbon Steel Socket Weld Elbow

- ASME B16.9 45°/90° Long Radius Elbow Dimensional Tolerance

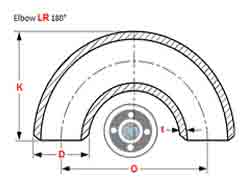

- Carbon Steel Butt weld 180 degree Long Radius Elbow Dimensions

- ASTM A234 WPA 180° Long Radius Elbow Dimensional Tolerance

- ASME B16.9 90°Short Radius Elbow Dimensional Tolerance

- Long Radius Elbow Equivalent Length

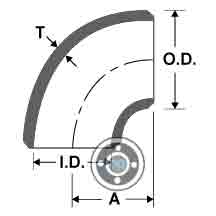

- What Is Long Radius And Short Radius Elbow

- Weight Of Long Radius Elbow

- ASTM A420 WPL6 Short Radius Elbow Weight

- Carbon Steel Short Radius Elbow Dimensions

- DIN 2605 Elbow Dimensions

- DIN 2605 Elbow Weight

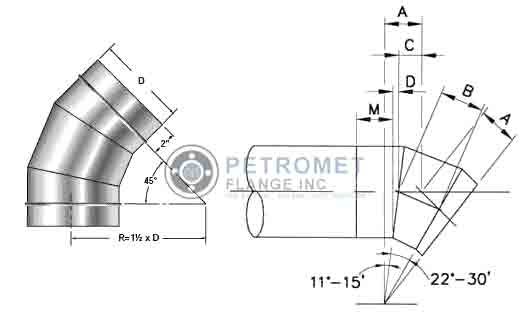

- A234 Gr WPB Mitered Elbow Dimensions

- WPHY 65 Mitered Elbows Equivalent Length

- What is Elbow Radius

- Our Supply Range For Elbows

- EN 10253-3 TYPE A Elbow Dimensions

- Application of Carbon Steel Weld Elbow

Carbon Steel Elbow Specification

| Size | NPS 1/2″ to 48″ |

| Schedule | Sch 20, 40, STD, 80, 160, XXS |

| Grade | WPB/C, WPHY 42, 46, 52, 60, 65, 70, WPL 3 |

| Bending Radius Provided By Manufacturer | R=1D, 3D, 2D, 5D, 8D, 6D, 10D |

| Manufacturing process | Push, Forge, Press, Cast, etc. |

| Connection | Welding |

| Origin & Mills | European, Japanese, USA, Korean, Ukraine, Indian, Russian |

| Thread Provided By Manufacturer | BSPT, NPT, BSPP |

| Application | Metallurgy, Gas, Petroleum, Chemical, Power, Construction, Shipbuilding etc |

Well known ASME B16.9 Elbow supplier, distributor, dealers, importer, stockists, exporters, wholesalers, stockholders and Manufacturer in Mumbai.

Carbon Steel Elbow Dimensions

| Nominal Pipe Size | Outside Diameter | 90° Elbows | 45° Elbows | 180° Returns | ||||

|---|---|---|---|---|---|---|---|---|

| (inches) | Long Radius | Short Radius | Long Radius | Long Radius | ||||

| (mm) | (inches) | Center to Face (inches) |

Center to Face (inches) |

Center to Face (inches) |

Radius (inches) |

Center to Center (inches) |

Back to face (inches) |

|

| 1/2 | 21.3 | 0.840 | 1 1/2 | - | 5/8 | 2 | 1 7/8 | |

| 3/4 | 26.7 | 1.050 | 1 1/8 | - | 7/16 | 2 1/4 | 1 11/16 | |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 | 7/8 | 3 | 2 3/16 | |

| 1 1/4 | 42.2 | 1.660 | 1 7/8 | 1 1/4 | 1 | 3 3/4 | 2 3/4 | |

| 1 1/2 | 48.3 | 1.900 | 2 1/4 | 1 1/2 | 1 1/8 | 3 | 4 1/2 | 3 1/4 |

| 2 | 60.3 | 2.375 | 3 | 2 | 1 3/8 | 4 | 6 | 4 3/16 |

| 2 1/2 | 73.0 | 2.875 | 3 3/4 | 2 1/2 | 1 3/4 | 5 | 7 1/2 | 5 3/16 |

| 3 | 88.9 | 3.500 | 4 1/2 | 3 | 2 | 6 | 9 | 6 1/4 |

| 3 1/2 | 101.6 | 4.000 | 5 1/4 | 3 1/2 | 2 1/4 | 7 | 10 1/2 | 7 1/4 |

| 4 | 114.3 | 4.500 | 6 | 4 | 2 1/2 | 8 | 12 | 8 1/4 |

| 5 | 141.3 | 5.563 | 7 1/2 | 5 | 3 1/8 | 10 | 15 | 10 5/16 |

| 6 | 168.3 | 6.625 | 9 | 6 | 3 3/4 | 12 | 18 | 12 5/16 |

| 8 | 219.1 | 8.625 | 12 | 8 | 5 | 12 | 24 | 16 5/16 |

| 10 | 273.1 | 10.750 | 15 | 10 | 6 1/4 | 15 | 30 | 20 3/8 |

| 12 | 323.9 | 12.750 | 18 | 12 | 7 1/2 | 18 | 36 | 24 3/8 |

Weight Of Carbon Steel Elbow

| NPS | KG | LBS |

| 1/2 | 0.04 | 0.09 |

| 3/4 | 0.04 | 0.09 |

| 1 | 0.11 | 0.25 |

| 1.1/4 | 0.17 | 0.38 |

| 1.1/2 | 0.18 | 0.4 |

| 2 | 0.37 | 0.81 |

| 2.1/2 | 0.79 | 1.75 |

| 3 | 1.19 | 2.63 |

| 3.1/2 | 1.59 | 3.5 |

| 4 | 2.04 | 4.5 |

| 5 | 3.4 | 7.5 |

| 6 | 5.44 | 12 |

| 8 | 10.43 | 23 |

| 10 | 19.5 | 43 |

| 12 | 28.12 | 62 |

| 14 | 36.29 | 80 |

| 16 | 45.36 | 100 |

| 18 | 57.15 | 126 |

| 20 | 72.57 | 160 |

| 22 | 89.36 | 197 |

| 24 | 107.95 | 238 |

| 26 | 124.74 | 275 |

| 30 | 166.47 | 367 |

| 36 | 240.86 | 531 |

Sch40/ Sch20 seamless butt weld ASTM A420 WPL6 90 Degree Elbow and WPHY 42 Short Radius Elbow manufacturer in India

Carbon Steel Elbow Price

| Carbon Steel Elbow Price Per Piece in India | Price Applicable for jan 2022 to june 2022 | Price Applicable for July 2022 to December 2022 |

| 90 ELBOWS ASTM A234 WPB B16.9 SMLS SIZE 18 STD Per Kg | US $0.66 | US $2.66 |

| CARBON STEEL : DN 40, 90 DEGREE ELBOWS (LR), SCH 40/STD, SA234 GR.WPB Per Kg | US $3.73 | US $5.73 |

| DN 250, 90 DEGREE ELBOWS (SR), SCH 40, SA234 GR.WPB Per Kg | US $1.05 | US $3.05 |

| DN 125, 90 DEGREE ELBOWS (LR), SCH 40/STD, SA234 GR.WPB Per Kg | US $0.88 | US $2.88 |

We are leading Carbon Steel Elbow manufacturer in India from last 20 years. We stock and export ASTM A234 WPB 45 Degree Elbow. Check Dimensions and Price list of Sch20 WPHY 42 Short Radius Elbow.

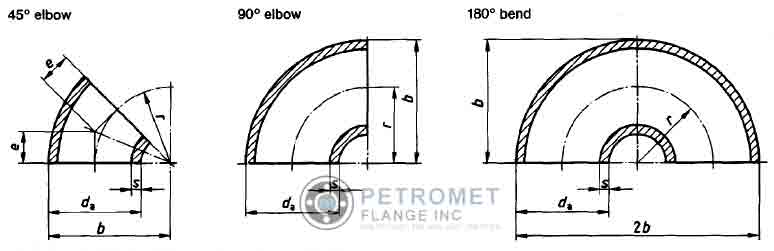

Carbon Steel 45 Degree Elbow Dimensions

| NPS | O.D. D |

45° LR B |

45° 3D B |

| 1/2 | 21.3 | 16 | |

| 3/4 | 26.7 | 19 | 24 |

| 1 | 33.4 | 22 | 31 |

| 1.1/4 | 42.2 | 25 | 39 |

| 1.1/2 | 48.3 | 29 | 47 |

| 2 | 60.3 | 35 | 63 |

| 2.1/2 | 73 | 44 | 79 |

| 3 | 88.9 | 51 | 95 |

| 3.1/2 | 101.6 | 57 | 111 |

| 4 | 114.3 | 64 | 127 |

| 5 | 141.3 | 79 | 157 |

| 6 | 168.3 | 95 | 189 |

| 8 | 219.1 | 127 | 252 |

| 10 | 273 | 159 | 316 |

| 12 | 323.8 | 190 | 378 |

| 14 | 355.6 | 222 | 441 |

| 16 | 406.4 | 254 | 505 |

| 18 | 457 | 286 | 568 |

| 20 | 508 | 318 | 632 |

| 22 | 559 | 343 | 694 |

| 24 | 610 | 381 | 757 |

| 26 | 660 | 406 | 821 |

| 28 | 711 | 438 | 883 |

| 30 | 762 | 470 | 946 |

| 32 | 813 | 502 | 1010 |

| 34 | 864 | 533 | 1073 |

| 36 | 914 | 565 | 1135 |

| 38 | 965 | 600 | 1200 |

| 40 | 1016 | 632 | 1264 |

| 42 | 1067 | 660 | 1326 |

| 44 | 1118 | 695 | 1389 |

| 46 | 1168 | 727 | 1453 |

| 48 | 1219 | 759 | 1516 |

Carbon Steel 90 Degree Elbow Dimensions

| NPS | O.D. D |

90° LR A |

90° 3D A |

| 1/2 | 21.3 | 38 | |

| 3/4 | 26.7 | 38 | 57 |

| 1 | 33.4 | 38 | 76 |

| 1.1/4 | 42.2 | 48 | 95 |

| 1.1/2 | 48.3 | 57 | 114 |

| 2 | 60.3 | 76 | 152 |

| 2.1/2 | 73 | 95 | 190 |

| 3 | 88.9 | 114 | 229 |

| 3.1/2 | 101.6 | 133 | 267 |

| 4 | 114.3 | 152 | 305 |

| 5 | 141.3 | 190 | 381 |

| 6 | 168.3 | 229 | 457 |

| 8 | 219.1 | 305 | 610 |

| 10 | 273 | 381 | 762 |

| 12 | 323.8 | 457 | 914 |

| 14 | 355.6 | 533 | 1067 |

| 16 | 406.4 | 610 | 1219 |

| 18 | 457 | 686 | 1372 |

| 20 | 508 | 762 | 1524 |

| 22 | 559 | 838 | 1676 |

| 24 | 610 | 914 | 1829 |

| 26 | 660 | 991 | 1981 |

| 28 | 711 | 1067 | 2134 |

| 30 | 762 | 1143 | 2286 |

| 32 | 813 | 1219 | 2438 |

| 34 | 864 | 1295 | 2591 |

| 36 | 914 | 1372 | 2743 |

| 38 | 965 | 1448 | 2896 |

| 40 | 1016 | 1524 | 3048 |

| 42 | 1067 | 1600 | 3200 |

| 44 | 1118 | 1676 | 3353 |

| 46 | 1168 | 1753 | 3505 |

| 48 | 1219 | 1829 | 3658 |

Check WPHY 52 180 Degree Elbow and ASTM A860 High Yield Mitered Elbow dimensions in accordance with ASME B16.28/ ASME B16.9

Types of Carbon Steel Elbow

Carbon Steel Elbow

ASME B16.9 Elbow

DIN 2605 Carbon Steel Elbow

Short Radius Elbow B16.9

Long Radius Elbow

Carbon Steel Buttweld Elbow

Carbon Steel Threaded Elbow

Carbon Steel Socket Weld Elbow

Carbon Steel Elbow

ASTM A234 WPB Pipe Elbow

ASTM A234 WPC Buttweld Elbow

ASTM A420 WPL6 Weld Elbow

WPHY 42 45 Degree Elbow

WPHY 65 90 Degree Elbow

WPHY 52 180 Degree Elbow

WPHY 70 Long Radius Elbow

ASTM A234 WPA Short Radius Elbow

ASTM A860 High Yield Mitered Elbow

Carbon Steel DIN 2605 Elbow

WPHY 65 30 degree pipe elbow

Carbon Steel Elbow 60 Degree

Carbon Steel Long Radius Elbow Dimensions

| Nominal Pipe Size |

Outside Diameter |

Pipe Schedule |

Wall Thickness |

Center To End |

Inside Diameter |

Weight Pounds |

| 1/2 | 0.84 | 40 | 0.109 | 1.5 | 0.622 | 0.16 |

| 3/4 | 1.05 | 40 | 0.113 | 1.5 | 0.824 | 0.17 |

| 1 | 1.32 | 40 | 0.133 | 1.5 | 1.049 | 0.4 |

| 1 1/4 | 1.66 | 40 | 0.14 | 1.88 | 1.38 | 0.55 |

| 1 1/2 | 1.9 | 40 | 0.145 | 2.25 | 1.61 | 0.8 |

| 2 | 2.38 | 40 | 0.154 | 3 | 2.07 | 1.6 |

| 2 1/2 | 2.88 | 40 | 0.203 | 3.75 | 2.47 | 3.2 |

| 3 | 3.5 | 40 | 0.216 | 4.5 | 3.07 | 4.8 |

| 3 1/2 | 4 | 40 | 0.226 | 5.25 | 3.55 | 6.6 |

| 4 | 4.5 | 40 | 0.237 | 6 | 4.03 | 8.9 |

| 5 | 5.56 | 40 | 0.258 | 7.5 | 5.05 | 15.1 |

| 6 | 6.62 | 40 | 0.28 | 9 | 6.07 | 24 |

| 8 | 8.62 | 40 | 0.322 | 12 | 7.98 | 47.8 |

| 10 | 10.75 | 40 | 0.365 | 15 | 10.02 | 83.4 |

| 12 | 12.75 | * | 0.375 | 18 | 12 | 123 |

| 14 | 14 | 30 | 0.375 | 21 | 13.25 | 155 |

| 16 | 16 | 30 | 0.375 | 24 | 15.25 | 206 |

| 18 | 18 | * | 0.375 | 27 | 17.25 | 262 |

| 20 | 20 | 20 | 0.375 | 30 | 19.25 | 324 |

| 24 | 24 | 20 | 0.375 | 36 | 23.25 | 466 |

| 30 | 30 | * | 0.375 | 45 | 29.25 | 720 |

| 36 | 36 | * | 0.375 | 54 | 35.25 | 1,039 |

| 42 | 42 | * | 0.375 | 63 | 41.25 | 1,420 |

| 48 | 48 | * | 0.375 | 72 | 47.25 | 2,000 |

Carbon Steel Reducing Elbow Dimensions

| Nominal Pipe Size | Center To End | Weight In Pounds |

| 2 X 1 | 3 | 1.2 |

| 2 X 1 1/4 | 3 | 1.3 |

| 2 X 1 1/2 | 3 | 1.4 |

| 2 1/2 X 1 1/4 | 3.75 | 2.5 |

| 2 1/2 X 1 1/2 | 3.75 | 2.6 |

| 2 1/2 X 2 | 3.75 | 2.8 |

| 3 X 1 1/2 | 4.5 | 3.3 |

| 3 X 2 | 4.5 | 3.6 |

| 3 X 2 1/2 | 4.5 | 4.2 |

| 3 1/2 X 2 | 5.25 | 4.5 |

| 3 1/2 X 2 1/2 | 5.25 | 5.5 |

| 3 1/2 X 3 | 5.25 | 6 |

| 4 X 2 | 6 | 6 |

| 4 X 2 1/2 | 6 | 6.8 |

| 4 X 3 | 6 | 7.7 |

| 4 X 3 1/2 | 6 | 8.4 |

| 5 X 2 1/2 | 7.5 | 10.7 |

| 5 X 3 | 7.5 | 11.8 |

| 5 X 3 1/2 | 7.5 | 12.6 |

| 5 X 4 | 7.5 | 13.4 |

| 6 X 3 | 9 | 16.8 |

| 6 X 3 1/2 | 9 | 17.8 |

| 6 X 4 | 9 | 18.9 |

| 6 X 5 | 9 | 21 |

| 8 X 4 | 12 | 33.1 |

| 8 X 5 | 12 | 36.2 |

| 8 X 6 | 12 | 39.7 |

| 10 X 5 | 15 | 58.5 |

| 10 X 6 | 15 | 63.2 |

| 10 X 8 | 15 | 73 |

| 12 X 6 | 18 | 86.5 |

| 12 X 8 | 18 | 98.4 |

| 12 X 10 | 18 | 113 |

Carbon Steel Elbows Angularity Tolerances

| ND | Max off angle | Max off plane |

| Q | P | |

| 1/2 a 4 | 1 | 2 |

| 5 a 8 | 2 | 4 |

| 10 a 12 | 3 | 5 |

| 14 a 16 | 3 | 7 |

| 18 a 24 | 4 | 10 |

| 26 a 30 | 5 | 10 |

| 32 a 42 | 5 | 13 |

| 44 a 48 | 5 | 20 |

Manufacturer of SCH 10 / SCH 40 WPHY 65 30 degree pipe elbow and ASTM A234 WPA Elbow 60 Degree with beveled ends according to ASME B16.9

Carbon Steel Elbow Hs Code

| Hs Code | 73079990 | Carbon steel elbows |

Carbon Steel Elbow Weight Calculator

Weight Calculator formula for Elbow is as below

- W = Weight in Kg

- F = Center to End (mm)

- D = Outside Diameter (mm)

- T = Wall Thickness (mm)

- θ = Angle

Surface of Carbon Steel Elbows

- Black Painted

- Varnished

- Epoxy Coated

- Galvanized

Carbon Steel Elbows Chemical Properties

| Grade | C | Mn | Si | S | P |

| A234 WPB | ≤0.3 | 0.29 - 1.06 | 0.1 | ≤0.058 | ≤0.05 |

| A420 WPL6 | ≤0.3 | 0.6 - 1.35 | 0.15 - 0.3 | ≤0.04 | ≤0.035 |

Carbon Steel Threaded Elbow Dimensions

| NPS | Min Thread Length | Outside Dia | Min WT | Center to End | ||

| B | J | D | G | 90° A |

45° C |

|

| 1/2 | 10.9 | 13.6 | 33 | 3.18 | 28 | 22 |

| 3/4 | 12.7 | 13.9 | 38 | 3.18 | 33 | 25 |

| 1 | 14.7 | 17.3 | 46 | 3.68 | 38 | 28 |

| 1.1/4 | 17 | 18 | 56 | 3.89 | 44 | 33 |

| 1.1/2 | 17.8 | 18.4 | 62 | 4.01 | 51 | 35 |

| 2 | 19 | 19.2 | 75 | 4.27 | 60 | 43 |

| 2.1/2 | 23.6 | 28.9 | 92 | 5.61 | 76 | 52 |

| 3 | 25.9 | 30.5 | 109 | 5.99 | 86 | 64 |

| 4 | 27.7 | 33 | 146 | 6.55 | 106 | 79 |

Dimensions of Carbon Steel Socket Weld Elbow

| NPS | Socket Bore | Depth Socket | Bore DIA | Socket WT | Body WT |

| B | J | D | C | G | |

| 1/2 | 21.95 21.70 |

10 | 16.6 15 |

4.65 4.10 |

3.75 |

| 3/4 | 27.30 27.05 |

13 | 21.7 20.2 |

4.90 4.25 |

3.90 |

| 1 | 34.05 33.80 |

13 | 27.4 25.9 |

5.70 5.00 |

4.55 |

| 1.1/4 | 42.80 42.55 |

13 | 35.8 34.3 |

6.05 5.30 |

4.85 |

| 1.1/2 | 48.90 48.65 |

13 | 41.7 40.1 |

6.35 5.55 |

5.10 |

| 2 | 61.35 61.10 |

16 | 53.5 51.7 |

6.95 6.05 |

5.55 |

| 2.1/2 | 74.20 73.80 |

16 | 64.2 61.2 |

8.75 7.65 |

7.00 |

| 3 | 90.15 89.80 |

16 | 79.5 46.4 |

9.50 8.30 |

7.60 |

| 4 | 115.80 115.45 |

19 | 103.8 100.7 |

10.70 9.35 |

8.55 |

| NPS | Center to bottom of socket A |

||||

| 90° | 45° | ||||

| 1/2 | 15.5 | 11.5 | |||

| 3/4 | 19.5 | 12.5 | |||

| 1 | 22 | 14 | |||

| 1.1/4 | 27 | 17 | |||

| 1.1/2 | 32 | 21 | |||

| 2 | 38 | 25 | |||

| 2.1/2 | 41.5 | 29 | |||

| 3 | 57.5 | 31.5 | |||

| 4 | 66.5 | 41.5 | |||

ASME B16.9 45°/90° Long Radius Elbow Dimensional Tolerance

| For all fittings | Elbows 90/45 deg | 180° Returns | |||||

| Nominal Pipe Size (NPS) | Outside Ø at Bevel |

Inside Ø at End |

Wall Thickness t / t1 |

Center to End Dim. A-B-C-M | Center to Center Dim. O |

Back to Face Dim. K |

Align- ment of Ends U |

| 1/2 a 2 1/2 | 1 | 0,8 | Not | 2 | 7 | 7 | 1 |

| 3 a 3 1/2 | 1 | 1,6 | less | 2 | 7 | 7 | 1 |

| 4 | +2 -1 | 1,6 | than | 2 | 7 | 7 | 1 |

| 5 a 6 | +3 -1 | 1,6 | 87,50% | 2 | 7 | 7 | 1 |

| 8 | 2 | 1,6 | of nominal | 2 | 7 | 7 | 1 |

| 10 | +4 -3 | 3,2 | tickness | 2 | 7 | 7 | 2 |

| 12 a 18 | +4 -3 | 3,2 | 3 | 10 | 7 | 2 | |

| 20 a 24 | +6 -5 | 4,8 | 3 | 10 | 7 | 2 | |

| 26 a 30 | +7 -5 | 4,8 | 3 | ||||

| 32 a 48 | +7 -5 | 4,8 | 5 | ||||

Carbon Steel Butt weld 180 degree Long Radius Elbow Dimensions

| NPS | O.D. D | 180° Long Radius | |

| Center to Center O |

Back to Face K |

||

| 1/2 | 21.3 | 76 | 48 |

| 3/4 | 26.7 | 76 | 51 |

| 1 | 33.4 | 76 | 56 |

| 1¼ | 42.2 | 95 | 70 |

| 1½ | 48.3 | 114 | 83 |

| 2 | 60.3 | 152 | 106 |

| 2½ | 73 | 190 | 132 |

| 3 | 88.9 | 229 | 159 |

| 3½ | 101.6 | 267 | 184 |

| 4 | 114.3 | 305 | 210 |

| 5 | 141.3 | 381 | 262 |

| 6 | 168.3 | 457 | 313 |

| 8 | 219.1 | 610 | 414 |

| 10 | 273 | 762 | 518 |

| 12 | 323.8 | 914 | 619 |

| 14 | 355.6 | 1067 | 711 |

| 16 | 406.4 | 1219 | 813 |

| 18 | 457 | 1372 | 914 |

| 20 | 508 | 1524 | 1016 |

| 22 | 559 | 1676 | 1118 |

| 24 | 610 | 1829 | 1219 |

ASTM A234 WPA 180° Long Radius Elbow Dimensional Tolerance

| For all fittings | 180° Returns | |||||

| Nominal Pipe Size (NPS) | Outside Ø at Bevel |

Inside Ø at End |

Wall Thickness t / t1 |

Center to Center Dim. O |

Back to Face Dim. K |

Align- ment of Ends U |

| 1/2 a 2 1/2 | 1 | 0,8 | Not | 7 | 7 | 1 |

| 3 a 3 1/2 | 1 | 1,6 | less | 7 | 7 | 1 |

| 4 | +2 -1 | 1,6 | than | 7 | 7 | 1 |

| 5 a 6 | +3 -1 | 1,6 | 87,50% | 7 | 7 | 1 |

| 8 | 2 | 1,6 | of nominal | 7 | 7 | 1 |

| 10 | +4 -3 | 3,2 | thickness | 7 | 7 | 2 |

| 12 a 18 | +4 -3 | 3,2 | 10 | 7 | 2 | |

| 20 a 24 | +6 -5 | 4,8 | 10 | 7 | 2 | |

| 26 a 30 | +7 -5 | 4,8 | ||||

| 32 a 48 | +7 -5 | 4,8 | ||||

ASME B16.9 90°Short Radius Elbow Dimensional Tolerance

| Nominal Pipe Size | 1/2 to 2½ | 3 to 3½ | 4 | 5 to 8 | 10 to 18 | 20 to 24 | 26 to 30 | 32 to 48 |

| Outside Diameter at Bevel (D) |

+ 1.6 - 0.8 |

1.6 | 1.6 | + 2.4 - 1.6 |

+ 4 - 3.2 |

+ 6.4 - 4.8 |

+ 6.4 - 4.8 |

+ 6.4 - 4.8 |

| Inside Diameter at End | 0.8 | 1.6 | 1.6 | 1.6 | 3.2 | 4.8 | + 6.4 - 4.8 |

+ 6.4 - 4.8 |

| Center-to-End (A) | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 5 |

| Wall Thickness (t) | Not less than 87.5% of Nominal Wall Thickness | |||||||

Long Radius Elbow Equivalent Length

| Fitting | Pipe Size (in) | Equivalent Length (ft) | Quantity | Total Length (ft) |

| Long Radius 90° Elbows | 4 | 4.6 | 3 | 13.8 |

What Is Long Radius And Short Radius Elbow

According to the radius of curvature, elbows are classified as long radius or short radius. The outer diameter of the pipe with a radius of curvature of 1.5 times, namely R = 1.5d, is referred to as a long radius elbow. A short radius elbow has a radius of curvature that is equal to the pipe's outside diameter, i.e. R = D, where D is the diameter of the elbow and R is the radius of curvature. The elbow's regular radius length is occasionally utilised to prevent resistance loss or wear; use elbows with low radius when installation position is constrained.

Weight Of Long Radius Elbow

| NPS | KG | LBS |

| 1/2 | 0.08 | 0.18 |

| 3/4 | 0.09 | 0.19 |

| 1 | 0.18 | 0.4 |

| 1.1/4 | 0.27 | 0.6 |

| 1.1/2 | 0.41 | 0.9 |

| 2 | 0.73 | 1.6 |

| 2.1/2 | 1.47 | 3.25 |

| 3 | 2.27 | 5 |

| 3.1/2 | 3.06 | 6.75 |

| 4 | 4.08 | 9 |

| 5 | 6.8 | 15 |

| 6 | 11.11 | 24.5 |

| 8 | 22.68 | 50 |

| 10 | 39.92 | 88 |

| 12 | 56.7 | 125 |

| 14 | 72.57 | 160 |

| 16 | 93.44 | 206 |

| 18 | 117.93 | 260 |

| 20 | 145.15 | 320 |

| 22 | 178.72 | 394 |

| 24 | 208.65 | 460 |

| 26 | 249.48 | 550 |

| 30 | 332.94 | 734 |

| 36 | 481.72 | 1062 |

ASTM A420 WPL6 Short Radius Elbow Weight

| NPS | KG | LBS |

| 1 | 0.11 | 0.25 |

| 1.1/4 | 0.18 | 0.4 |

| 1.1/2 | 0.25 | 0.56 |

| 2 | 0.45 | 1 |

| 2.1/2 | 0.97 | 2.13 |

| 3 | 1.36 | 3 |

| 3.1/2 | 2.04 | 4.5 |

| 4 | 2.83 | 6.25 |

| 5 | 4.35 | 9.6 |

| 6 | 8.16 | 18 |

| 8 | 15.42 | 34 |

| 10 | 26.31 | 58 |

| 12 | 36.29 | 80 |

| 14 | 47.63 | 105 |

| 16 | 59.87 | 132 |

| 18 | 75.75 | 167 |

| 20 | 95.25 | 210 |

| 22 | - | - |

| 24 | 135.17 | 298 |

Carbon Steel Short Radius Elbow Dimensions

| Nominal Pipe Size |

Center To End |

Outside Diameter |

Wall Thickness |

Inside Diameter |

Pipe Schedule |

Weight Pounds |

| 1 | 1 | 1.32 | 0.133 | 1.05 | 40 | 0.25 |

| 1 1/4 | 1.25 | 1.66 | 0.14 | 1.38 | 40 | 0.39 |

| 1 1/2 | 1.5 | 1.9 | 0.145 | 1.61 | 40 | 0.53 |

| 2 | 2 | 2.38 | 0.154 | 2.07 | 40 | 0.97 |

| 2 1/2 | 2.5 | 2.88 | 0.203 | 2.47 | 40 | 2 |

| 3 | 3 | 3.5 | 0.216 | 3.07 | 40 | 3 |

| 3 1/2 | 3.5 | 4 | 0.226 | 3.55 | 40 | 4.3 |

| 4 | 4 | 4.5 | 0.237 | 4.03 | 40 | 6.1 |

| 5 | 5 | 5.56 | 0.258 | 5.05 | 40 | 9.7 |

| 6 | 6 | 6.63 | 0.28 | 6.07 | 40 | 16.7 |

| 8 | 8 | 8.63 | 0.322 | 7.98 | 40 | 32.4 |

| 10 | 10 | 10.75 | 0.365 | 10.02 | 40 | 56.3 |

| 12 | 12 | 12.75 | 0.375 | 12 | * | 79.4 |

| 14 | 14 | 14 | 0.375 | 13.25 | 30 | 104 |

| 16 | 16 | 16 | 0.375 | 15.25 | 30 | 129 |

| 18 | 18 | 18 | 0.375 | 17.25 | * | 163 |

| 20 | 20 | 20 | 0.375 | 19.25 | 20 | 210 |

| 24 | 24 | 24 | 0.375 | 23.25 | 20 | 297 |

| 30 | 30 | 30 | 0.375 | 29.25 | * | 480 |

| 36 | 36 | 36 | 0.375 | 35.25 | * | 692 |

| 42 | 42 | 42 | 0.375 | 41.25 | * | 967 |

| 48 | 48 | 48 | 0.375 | 47.25 | * | 1,340 |

DIN 2605 Elbow Dimensions

| WDR | |||||||

| 3 | 4 | 5 | |||||

| DN1 | d1 | s | s | s | BA | r | b |

| 2 | 17.5 | 28 | |||||

| 15 | 21.3 | 2.0 | 3.2 | 4.0 | 3 | 28.0 | 38 |

| 5 | 42.5 | 53 | |||||

| 2 | 25.0 | 39 | |||||

| 20 | 26.9 | 2.3 | 3.2 | 4.0 | 3 | 29.0 | 43 |

| 5 | 57.5 | 71 | |||||

| 2 | 25.0 | 42 | |||||

| 25 | 33.7 | 2.6 | 3.2 | 4.0 | 3 | 38.0 | 56 |

| 5 | 72.5 | 90 | |||||

| 2 | 32.0 | 53 | |||||

| 32 | 42.4 | 2.6 | 3.6 | 4.0 | 3 | 48.0 | 69 |

| 5 | 92.5 | 114 | |||||

| 2 | 38.0 | 62 | |||||

| 40 | 48.3 | 2.6 | 4.0 | 5.0 | 3 | 57.0 | 82 |

| 5 | 107.5 | 132 | |||||

| 2 | 51 | 81 | |||||

| 50 | 60.3 | 2.9 | 4.5 | 5.6 | 3 | 76 | 106 |

| 5 | 135 | 165 | |||||

| 2 | 63 | 102 | |||||

| 65 | 76.1 | 2.9 | 5.0 | 7.1 | 3 | 95 | 133 |

| 5 | 175 | 213 | |||||

| 2 | 76 | 121 | |||||

| 80 | 88.9 | 3.2 | 5.6 | 8.0 | 3 | 114 | 159 |

| 5 | 205 | 250 | |||||

| 2 | 102 | 159 | |||||

| 100 | 114.3 | 3.6 | 6.3 | 8.8 | 3 | 152 | 210 |

| 5 | 270 | 327 | |||||

| 2 | 127 | 197 | |||||

| 125 | 139.7 | 4.0 | 6.3 | 10.0 | 3 | 190 | 260 |

| 5 | 330 | 400 | |||||

| 2 | 152 | 237 | |||||

| 150 | 168.3 | 4.5 | 7.1 | 11.0 | 3 | 229 | 313 |

| 5 | 390 | 474 | |||||

| 2 | 203 | 313 | |||||

| 200 | 219.1 | 6.3 | 8.0 | 12.5 | 3 | 305 | 414 |

| 5 | 510 | 620 | |||||

| 2 | 254 | 391 | |||||

| 250 | 273.0 | 6.3 | 8.8 | - | 3 | 381 | 518 |

| 5 | 650 | 787 | |||||

| 2 | 305 | 467 | |||||

| 300 | 323.9 | 7.1 | 10.0 | - | 3 | 457 | 619 |

| 5 | 775 | 937 | |||||

DIN 2605 Elbow Weight

| Nominal Pipe Size | Kilogram | LBS |

| 1/2 | 0.04 | 0.09 |

| 3/4 | 0.04 | 0.09 |

| 1 | 0.11 | 0.25 |

| 1.1/4 | 0.17 | 0.38 |

| 1.1/2 | 0.18 | 0.4 |

| 2 | 0.37 | 0.81 |

| 2.1/2 | 0.79 | 1.75 |

| 3 | 1.19 | 2.63 |

| 3.1/2 | 1.59 | 3.5 |

| 4 | 2.04 | 4.5 |

| 5 | 3.4 | 7.5 |

| 6 | 5.44 | 12 |

| 8 | 10.43 | 23 |

| 10 | 19.5 | 43 |

| 12 | 28.12 | 62 |

| 14 | 36.29 | 80 |

| 16 | 45.36 | 100 |

| 18 | 57.15 | 126 |

| 20 | 72.57 | 160 |

| 22 | 89.36 | 197 |

| 24 | 107.95 | 238 |

| 26 | 124.74 | 275 |

| 30 | 166.47 | 367 |

| 36 | 240.86 | 531 |

| NPS | KG | LBS |

A234 Gr WPB Mitered Elbow Dimensions

| DIA NOM |

A | C (1) |

B | D (1) |

M | |

|---|---|---|---|---|---|---|

| Min (3) | LR Ell Dim | |||||

| 3 | 2 | 2 | 1w | 1s | t | |

| 4 | 2i | 2i | 1t | 2y | u | |

| 6 | 3s | 3s | 2 | 3i | p | |

| 8 | 5 | 5 | 2p | 4s | d | |

| 10 | 6r | 6r | 3t | 5f | 1q | |

| 12 | 7i | 7i | 3g | 7w | 1r | |

| 14 | 8s | 8s | 4p | 8r | 1y | |

| 16 | 10 | 10 | 5r | 9i | 1o | |

| 18 | 11r | 11r | 5f | 10s | 1s | |

| 20 | 11i | 1 - 0i | 6o | 11f | 2 | |

| 22 | 1 - 0r | 1 - 1i | 6g | 1 - 1w | 2e | |

| 24 | 1 - 1r | 1 - 3 | 7f | 1 - 2r | 2y | |

| 26 | 1 - 1s | 1 - 4 | 8r | 1 - 3i | 2o | |

| 28 | 1 - 2s | 1 - 5y | 9q | 1 - 4q | 2s | |

| 30 | 1 - 3i | 1 - 6i | 9o | 1 - 5f | 2g | |

| 32 | 1 - 4i | 1 - 7f | 10y | 1 - 7 | 3e | |

| 34 | 1 - 5i | 1 - 9w | 11 | 1 - 8r | 3y | |

| 36 | 1 - 6r | 1 - 10r | 11i | 1 - 9i | 3o | |

| 38 | 1 - 7 | 1 - 11i | 1 - 0e | 1 - 10p | 3s | |

| 40 | 1 - 7s | 2 - 0s | 1 - 0d | 1 - 11f | 3g | |

| 42 | 1 - 8i | 2 - 2 | 1 - 1i | 2 - 1 | 4w | 8y |

| 44 | 1 - 9i | 2 - 3r | 1 - 2w | 2 - 2r | 4y | |

| 46 | 1 - 10i | 2 - 4i | 1 - 2d | 2 - 3y | 4o | |

| 48 | 1 - 11r | 2 - 5s | 1 - 3u | 2 - 4p | 4s | 9p |

| 50 | 2 - 0r | 2 - 7 | 1 - 4w | 2 - 5s | 4g | |

| 52 | 2 - 1 | 2 - 8r | 1 - 4s | 2 - 7 | 5w | |

| 54 | 2 - 1s | 2 - 9i | 1 - 5y | 2 - 8r | 5y | 10f |

| 56 | 2 - 2s | 2 - 10s | 1 - 6q | 2 - 9y | 5o | |

| 58 | 2 - 3i | 3 - 0 | 1 - 6s | 2 - 10i | 5s | |

| 60 | 2 - 4r | 3 - 1r | 1 - 7y | 2 - 11s | 5g | |

| 62 | 2 - 5r | 3 - 2i | 1 - 8 | 3 - 1 | 6w | |

| 64 | 2 - 6 | 3 - 3s | 1 - 8o | 3 - 2w | 6t | |

| 66 | 2 - 7 | 3 - 5 | 1 - 9t | 3 - 3y | 6o | |

| 68 | 2 - 7s | 3 - 6r | 1 - 10 | 3 - 4i | 6s | |

| 70 | 2 - 8i | 3 - 7i | 1 - 10p | 3 - 5s | 6g | |

| 72 | 2 - 9i | 3 - 8s | 1 - 11t | 3 - 6f | 7w | |

| 74 | 2 - 10r | 3 - 10 | 1 - 11f | 3 - 8e | 7y | |

| 76 | 2 - 11 | 3 - 11r | 2 - 0o | 3 - 9y | 7o | |

| 78 | 3 - 0 | 4 - 0u | 2 - 1e | 3 - 10i | 7s | 150 |

| 80 | 3 - 0s | 4 - 1q | 2 - 1d | 3 - 11s | 7g | |

| 82 | 3 - 1s | 4 - 2g | 2 - 2i | 9 - 0t | 8e | |

| 84 | 3 - 2i | 4 - 4e | 2 - 3w | 4 - 2w | 8y | |

| 86 | 3 - 3r | 4 - 5u | 2 - 3s | 4 - 3t | 8o | |

| 88 | 3 - 4r | 4 - 6g | 2 - 4u | 4 - 4i | 8s | |

| 90 | 3 - 5 | 4 - 7f | 2 - 5q | 4 - 5o | 8g | |

| 92 | 3 - 6 | 4 - 9e | 2 - 5o | 4 - 6f | 9w | |

| 94 | 3 - 7 | 4 - 10y | 2 - 5y | 4 - 8w | 9y | |

| 96 | 3 - 4i | 4 - 11p | 2 - 7 | 4 - 9r | 9o | |

| 98 | 3 - 8i | 5 - 0f | 2 - 7p | 4 - 10i | 9s | |

| 100 | 3 - 9 | 5 - 2w | 2 - 8t | 4 - 11q | 9g | |

| 102 | 3 - 10 | 5 - 3f | 2 - 8q | 5 - 0f | 10w | |

| 104 | 3 - 11 | 5 - 4p | 2 - 9o | 5 - 2q | 10t | |

| 106 | 3 - 11s | 5 - 5f | 2 - 10r | 5 - 3r | 10o | |

| 108 | 4 - 0i | 5 - 7w | 2 - 10f | 5 - 4u | 10s | |

| 110 | 4 - 1i | 5 - 8t | 2 - 11i | 5 - 5o | 10g | |

| 112 | 4 - 2r | 5 - 9o | 3 - 0e | 5 - 6d | 11w | |

| 114 | 4 - 3 | 5 - 10d | 3 - 0d | 5 - 8 | 11t | |

| 116 | 4 - 4 | 6 - 0q | 3 - 1u | 5 - 9e | 11i | |

| 118 | 4 - 5 | 6 - 1t | 3 - 2w | 5 - 10y | 11s | |

| 120 | 4 - 5s | 6 - 2o | 3 - 2s | 5 - 11p | 11g | |

| 122 | 4 - 6i | 6 - 3d | 3 - 3t | 6 - 0d | 12w | |

| 124 | 4 - 7y | 6 - 5q | 3 - 4 | 6 - 2 | 12y | |

| 126 | 4 - 8r | 6 - 6r | 3 - 4q | 6 - 3e | 12o | |

| 128 | 4 - 9 | 6 - 7i | 3 - 5r | 6 - 4y | 12s | |

| 130 | 4 - 10 | 6 - 8s | 3 - 6 | 6 - 5o | 12g | |

| 132 | 4 - 10s | 6 - 10 | 3 - 6o | 6 - 6s | 13w | |

| 134 | 4 - 11i | 6 - 11r | 3 - 7r | 6 - 8 | 13t | |

| 136 | 5 - 0i | 7 - 0i | 3 - 7q | 6 - 9w | 13i | |

| 138 | 5 - 1r | 7 - 1s | 3 - 8o | 6 - 10y | 13s | |

| 140 | 5 - 2r | 7 - 3 | 3 - 9r | 6 - 11i | 13g | |

WPHY 65 Mitered Elbows Equivalent Length

| Miter Fittings | Steel e = 0.05 mm |

Spiral Weld Steel e = 0.1 mm |

|---|---|---|

| Threaded Miter elbows | ||

| 90°, r/d=1 | 30 | 26 |

| 45°, r/d=1 | 16 | 14 |

| Welded Miter elbows | ||

| 90°, sharp bend | 55 | 49 |

| 90°, r/d=1 | 19 | 16 |

| 90°, r/d=1.5 | 13 | 12 |

| 90°, r/d=2 | 11 | 10 |

| 45°, sharp bend | 18 | 16 |

| 45°, r/d=1 | 14 | 12 |

| 45°, r/d=1.5 | 9.4 | 8.3 |

What is Elbow Radius

The radius of curvature of the elbow is split into two types: long radius elbows and short radius elbows. For process installation, there are two types of pipe sizes: pipe outer diameter and nominal size. The pipe's nominal size is denoted by the letters D, DN. It does not indicate either the inner or outer diameters of the pipe. It is developed and used in a nominal size. The manufacturing methods are separated into push elbows, extrusion elbows, and welded mitre elbows. The structure's lengths are 1.0D, 1.5D, and 2.0D.

Our Supply Range For Elbows

For Butt Weld Elbow

Standard: ASTM A234, MSS SP-75, ASTM A403

Manufacturing Standard: ASME B16.9, DIN2615, JIS B2312

Types: 45 degree, 90 degree, 180 degree

Size Range: 1/2”, 1”, 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16”, 20” to 48”.

Thickness: SCH 10, SCH 40, SCH 80

For Socket Weld and Threaded Elbow

Standard: ASTM A105, ASTM A182

Manufacturing Standard: ASME B16.11

Dimensions: 1/2”, 1”, 1/2”, 2” and up to 4”

Pressure Ratings: 2000#, 3000#, 6000#, 9000#

EN 10253-3 TYPE A Elbow Dimensions

| Nominal pipe size | Wall thickness | Outside diameter | Radius |

|---|---|---|---|

| 50 | 1.6 | 60.3 | 51 |

| 50 | 2 | 60.3 | 51 |

| 50 | 2.3 | 60.3 | 51 |

| 50 | 4 | 60.3 | 51 |

| 50 | 5.6 | 60.3 | 51 |

| 65 | 2.3 | 76.1 | 63 |

| 65 | 2.6 | 76.1 | 63 |

| 65 | 5 | 76.1 | 63 |

| 65 | 7.1 | 76.1 | 63 |

| 80 | 2 | 88.9 | 76 |

| 80 | 2.3 | 88.9 | 76 |

| 80 | 5.6 | 88.9 | 76 |

| 80 | 8 | 88.9 | 76 |

| 100 | 2 | 114.3 | 102 |

| 100 | 2.6 | 114.3 | 102 |

| 100 | 6.3 | 114.3 | 102 |

| 100 | 8.8 | 114.3 | 102 |

| 125 | 2 | 139.7 | 127 |

| 125 | 2.6 | 139.7 | 127 |

| 125 | 3.2 | 139.7 | 127 |

| 125 | 4 | 139.7 | 127 |

| 125 | 6.3 | 139.7 | 127 |

| 125 | 10 | 139.7 | 127 |

| 150 | 2 | 168.3 | 152 |

| 150 | 2.6 | 168.3 | 152 |

| 150 | 3.2 | 168.3 | 152 |

| 150 | 4.5 | 168.3 | 152 |

| 150 | 7.1 | 168.3 | 152 |

| 150 | 11 | 168.3 | 152 |

| 200 | 2 | 219.1 | 203 |

| 200 | 2.6 | 219.1 | 203 |

| 200 | 3.6 | 219.1 | 203 |

| 200 | 6.3 | 219.1 | 203 |

| 200 | 8 | 219.1 | 203 |

| 200 | 12.5 | 219.1 | 203 |

| 250 | 2 | 273 | 254 |

| 250 | 3.6 | 273 | 254 |

| 250 | 4 | 273 | 254 |

| 250 | 6.3 | 273 | 254 |

| 250 | 10 | 273 | 254 |

| 300 | 2.6 | 323.9 | 305 |

| 300 | 4 | 323.9 | 305 |

| 300 | 4.5 | 323.9 | 305 |

| 300 | 7.1 | 323.9 | 305 |

| 300 | 10 | 323.9 | 305 |

| 350 | 2.6 | 355.6 | 356 |

| 350 | 4 | 355.6 | 356 |

| 350 | 5 | 355.6 | 356 |

| 350 | 8 | 355.6 | 356 |

| 350 | 11 | 355.6 | 356 |

| 400 | 2.6 | 406.4 | 406 |

| 400 | 4 | 406.4 | 406 |

| 400 | 5 | 406.4 | 406 |

| 400 | 8.8 | 406.4 | 406 |

| 400 | 12.5 | 406.4 | 406 |

| 450 | 3.2 | 457 | 457 |

| 450 | 4 | 457 | 457 |

| 450 | 5 | 457 | 457 |

| 450 | 10 | 457 | 457 |

| 500 | 3.2 | 508 | 508 |

| 500 | 5 | 508 | 508 |

| 500 | 5.6 | 508 | 508 |

| 500 | 11 | 508 | 508 |

| 600 | 3.2 | 610 | 610 |

| 600 | 5.6 | 610 | 610 |

| 600 | 6.3 | 610 | 610 |

| 600 | 12.5 | 610 | 610 |

Application of Carbon Steel Weld Elbow

- Power Plants

- Oil And Gas Industry

- Ship Building

- Refineries

- Marine Applications

- Nuclear Power

- Fossil Fuel Power Plants

- Paper & Pulp

Pipe Fittings Types

Pipe Fittings Material

Flanges Material

Other Products