- Call : +91 22 67436442

- exports@petrometflange.com

Stainless Steel Swage Nipples manufacturer in India

- Home /

- Stainless Steel Swage Nipples

Carbon Steel Reducing Nipple & SS 304 Hex Nipple supplier in Mumbai

What is Swage Nipple?

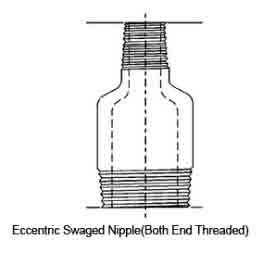

The Swage Nipple are basically forged pipe fittings which is also known as reducing nipple. They are usually of the standard MSS SP-95, which is common for materials stainless steel, carbon steel, and alloy steel. They are mainly used for changing the diameter of the pipe and for connecting two pipes having different sizes. There are basically two types of swage nipples, namely:

- Concentric swage nipple- Used for vertical pipelines

- Eccentric swage nipple- Used for the horizontal pipelines

There are also common thread swage nipples that have single-headed outer thread, double-headed outer thread, and flat-headed outer thread.

The Swage Nipple is manufactured from either bar material or seamless pipe. They have a suitable working pressure which is equivalent to the seamless straight pipe. They are available with different material specifications. There are different connection ends for the Swage Nipple, like plain both ends, plain small end, and plain large end. They are also available in the bevel and thread forms. Different material finishes can be customized on the Swage Nipple to give them extra protection from the surrounding conditions. Their dimensions can be customized according to the dimension of the pipe.

Why do we use Stainless Steel Swage Nipple?

The Stainless Steel Swage Nipple works in a similar way like that of the reducers. They can connect the buttwelded pipes to a smaller-sized socket weld or threaded pipe. They are basically a type of fitting which is used with a given size of tubing to the casting of other ones. There are two types of swage nipples used, namely concentric swage nipples that are used with the vertical pipes and eccentric swage nipples which go with the pipes lying horizontally.

Carbon Steel Concentric Swage Nipples Vs Alloy Steel Swage Nipple

The Carbon Steel Concentric Swage Nipples is made of carbon and iron, with alloying elements present in trace amounts. Due to its chemical composition, the swage nipples possess properties like hardness. However, it has low weldability, ductility, and also a low melting point. Depending on the carbon content of the Carbon Steel Concentric Swage Nipples, the properties can vary a bit. They are used to connect vertical pipes together.

The Alloy Steel Swage Nipple has a carbon, iron, and other alloying elements in high amounts. The chemical composition of the alloy steel helps to improve the properties of the steel, and that is why they possess improved hardness and durability. They can also resist corrosion effectively due to the presence of chromium in the alloy. They help in connecting pipes of different sizes and welds, together.

Difference between Socket Weld Vs Threaded Swage Nipple?

The Socket Weld Swage Nipples are connected to the piping system through fillet weld, whereas the Threaded Swage Nipple is screwed to the pipe, and it does not need any welds. The Socket Weld Swage Nipple is primarily used for last-lasting and strong connections, whereas the Threaded Swage Nipple helps connect those pipes that require frequent assembling and disassembling. One can find threaded fittings on those parts of the pipe where welding is not possible, due to safety risk or space constraint.

The Socket Weld Swage Nipple takes time to install, but they give a reliable connection. Whereas the Threaded Swage Nipples are not time consuming but are less reliable.

Stainless Steel Swage Nipples manufacturer in India

European Directive 2014/68/eu certified Stainless Steel Swage Nipples manufacturers in India offers wide selection of SS316 Threaded Nipple & ASTM A182 F304 Barrel Nipple in Mumbai

Table of Content

- Stainless Steel Swage Nipple Material Specification

- Swage Nipple Material

- Different connection ends of swage nipples

- Stainless Steel Pipe Nipple Pressure Rating

- Eccentric Swage Nipple Dimension

- Reducing Swage Nipple Dimensions

- Swage Nipple Price

- Stainless Steel Swage Nipple Dimensions

- Dimensional Tolerance of Swaged Nipple

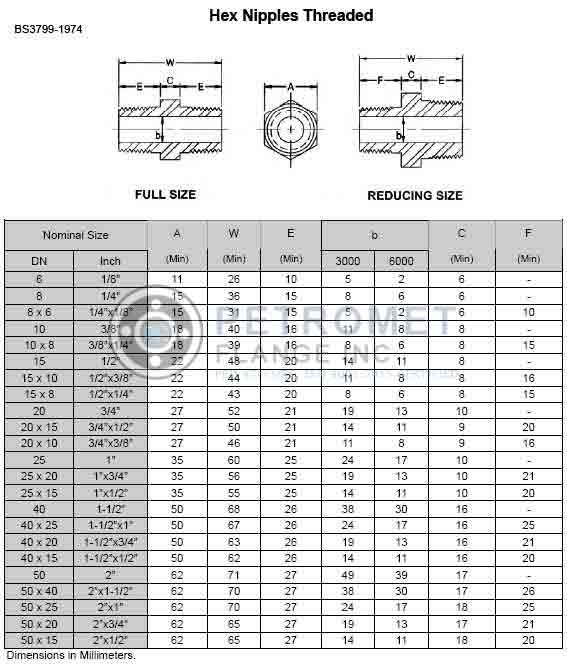

- Stainless Steel Hex Nipple Dimensions

- Stainless Steel Pipe Nipple Size Chart

- Stainless Steel Nipple Dimensions

- Packaging of Buttweld Swage Nipple

- Different Types of Stainless Steel Swage Nipples

- SS Threaded Nipple Sizes

- Stainless Steel Barrel Nipple Dimensions

- Difference Between Swage Nipple And Reducer

- Applications of Combination nipples

Stainless Steel Swage Nipple Material Specification

| Standards | ASME A182, ASME B16.9, ASME B16.11, MSS SP-43, MSS SP-95, BS3799 |

| Dimension | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size Range Provided By Manufacturer | 1/8"NB TO 4"NB IN |

| Class | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Type | Socketweld Fittings, Threaded - SCREWED (SCRD) – NPT, BSP, BSPT |

| Stainless Steel Nipple Range Provided By Manufacturer | Pipe Nipple, Hex Nipple, Swage Nipple, Barrel Nipple |

Well Known Carbon Steel Reducing Nipple exporters, supplier, wholesalers, distributor, stockists, importer, stockholders, dealers and Manufacturer in Mumbai

Swage Nipple Material

| Carbon Steel | ASTM A234 WPB / A420 WPL3/ A420 WPL6/ MSS-SP-75 WPHY 42/46/52/56/60/65/70 |

| Stainless Steel | Stainless Steel 304/ 304L/ 304H/ 316/ 316L/ 317/ 317L/ 321/ 310/ 347/ 904L |

| Alloy Steel | ASTM A182 / ASME SA182 F5, F9, F11, F12, F22, F91 |

| Titanium | ASTM B381 / ASME SB381, Titanium Gr. 1, Titanium Gr. 2, Titanium Gr. 4, Titanium Gr. 5, Titanium Gr. 7 ASTM R50250/GR.1 | R50400/GR.2 | R50550/GR.3 | R50700/GR.4 | GR.6 |R52400/GR.7 | R53400/GR.12 | R56320/GR.9 |R56400/GR.5 |

| Nickel Alloy | ASTM / ASME SB 336 UNS 2200 (Nickel 200), UNS 2201 (Nickel 201), UNS 4400 (Monel 400), UNS 8020 (Alloy 20 / 20 CB 3, UNS 8825 Inconel (825), UNS 6600 (Inconel 600), UNS 6601 ( Inconel 601), UNS 6625 (Inconel 625), UNS 10276 (Hastelloy C 276) |

| Copper Nickel | ASTM / ASME SB 61 / 62 / 151 / 152, Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640 |

| Alloy 20 | ASTM B462 / ASME SB462, Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Aluminium | 5052 /6061/ 6063 / 2017 / 7075 / etc. |

| Duplex and Super Duplex | ASTM A815, ASME SA815 UNS NO S31803, S32205. Werkstoff No. 1.4462 |

| 254 Smo | ASTM A182 / ASME SA182, SMO 254/6Mo, UNS S31254, DIN 1.4547 |

Manufacturing Swage Nipples accordance to A350-LF2, A105, A106, A234, A312, A403, ASTM A182/ ASME standards, wide range of ASTM A105, Close Nipple, Carbon Steel Combination nipples & A350 LF2 Running Nipple in MPT threads / male pipe thread

Different connection ends of swage nipples

| Type | Big End | Small End | Code |

| A | plain ends | plain ends | BEP |

| B | plain ends | beveled ends | LEP/SEB |

| C | threaded ends | LEP/SET | |

| D | beveled ends | plain ends | LEB/SEP |

| E | beveled ends | beveled ends | BEB |

| F | threaded ends | LEB/SET | |

| G | threaded ends | plain ends | LET/SEP |

| H | Thread | beveled ends | LET/SEB |

| I | threaded ends | BET |

Stainless Steel Pipe Nipple Pressure Rating

| Connection Type(inch) |

Pressure Rating psi (bar)* | Minimum Opening | Dimensions - in.(mm) | |

| A Hex | B | |||

| 1/4 NPT | 15,000 | 0.219 | 0.63 | 1.81 |

| (1034.20) | (5.54) | (16.00) | (46.02) | |

| 3/8 NPT | 15,000 | 0.297 | 0.75 | 1.88 |

| (1034.20) | (7.54) | (19.05) | (47.63) | |

| 1/2 NPT | 15,000 | 0.359 | 0.94 | 2.50 |

| (1034.20) | (9.12) | (23.88) | (63.50) | |

| 3/4 NPT | 10,000 | 0.609 | 1.19 | 2.50 |

| (689.46) | (14.47) | (30.23) | (63.50) | |

| 1 NPT | 10,000 | 0.765 | 1.38 | 3.19 |

| (689.46) | (19.43) | (35.05) | (81.03) | |

Eccentric Swage Nipple Dimension

| NPS | O.D. | End To End “A” | Thickness Of Wall | ||||||||

| Large End D1 | Small End D2 | T1 | T2 | ||||||||

| Schedule 40 (STD) | Schedule 80 (XS) | Schedule 160 | XXS | Schedule 40 (STD) | Schedule 80 (XS) | Schedule 160 | XXS | ||||

| 3-1/2”x1-1/2” | 101.6 | 48.3 | 203 | 5.7 | 8.1 | 3.7 | 5.1 | 7.1 | 10.2 | ||

| 3-1/2”x2” | 101.6 | 60.3 | 203 | 5.7 | 8.1 | 3.9 | 5.5 | 8.7 | 11.1 | ||

| 3-1/2”x2-1/2” | 101.6 | 73.0 | 203 | 5.7 | 8.1 | 5.2 | 7.0 | 9.5 | 14.0 | ||

| 3-1/2”x3” | 101.6 | 88.9 | 203 | 5.7 | 8.1 | 5.5 | 7.6 | 11.1 | 15.2 | ||

| 4”x1/4” | 114.3 | 13.7 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 2.2 | 3.0 | ||

| 4”x3/8” | 114.3 | 17.1 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 2.3 | 3.2 | ||

| 4”x1/2” | 114.3 | 21.3 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 2.8 | 3.7 | 4.8 | 7.5 |

| 4”x3/4” | 114.3 | 26.7 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 2.9 | 3.9 | 5.6 | 7.8 |

| 4”x1” | 114.3 | 33.4 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 3.4 | 4.5 | 6.4 | 9.1 |

| 4”x1-1/4” | 114.3 | 42.2 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 3.6 | 4.9 | 6.4 | 9.7 |

| 4”x1-1/2” | 114.3 | 48.3 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 3.7 | 5.1 | 7.1 | 10.2 |

| 4”x2” | 114.3 | 60.3 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 3.9 | 5.5 | 8.7 | 11.1 |

| 4”x2-1/2” | 114.3 | 73.0 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 5.2 | 7.0 | 9.5 | 14.0 |

| 4”x3” | 114.3 | 88.9 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 5.5 | 7.6 | 11.1 | 15.2 |

| 4”x3-1/2” | 114.3 | 101.6 | 229 | 6.0 | 8.6 | 13.5 | 17.1 | 5.7 | 8.1 | ||

Manufacturer of ASTM A182 F316L Stainless Steel Pipe Nipples and A350-LF2 Shoulder Pipe Nipple offers Eddy Current Testing / Non Destructive Testing

Reducing Swage Nipple Dimensions

| Nominal Pipe Size (NPS) | Outside Diameter | End To End “A” | Wall Thickness | ||||||||

| Large End D1 | Small End D2 | T1 | T2 | ||||||||

| Sch40 (STD) | Sch80 (XS) | Sch160 | XXS | Sch40 (STD) | Sch80 (XS) | Sch160 | XXS | ||||

| 1/4”x1/8” | 13.7 | 10.3 | 57 | 2.2 | 3.0 | 3.7 | 6.1 | 1.7 | 2.4 | ||

| 3/8”x1/8” | 17.1 | 10.3 | 64 | 2.3 | 3.2 | 4.0 | 6.4 | 1.7 | 2.4 | ||

| 3/8”x1/4” | 17.1 | 13.7 | 64 | 2.3 | 3.2 | 4.0 | 6.4 | 2.2 | 3.0 | ||

| 1/2”x1/8” | 21.3 | 10.3 | 70 | 2.8 | 3.7 | 4.8 | 7.5 | 1.7 | 2.4 | ||

| 1/2”x1/4” | 21.3 | 13.7 | 70 | 2.8 | 3.7 | 4.8 | 7.5 | 2.2 | 3.0 | ||

| 1/2”x3/8” | 21.3 | 17.1 | 70 | 2.8 | 3.7 | 4.8 | 7.5 | 2.3 | 3.2 | ||

| 3/4”x1/8” | 26.7 | 10.3 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 1.7 | 2.4 | ||

| 3/4’x1/4” | 26.7 | 13.7 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 2.2 | 3.0 | ||

| 3/4”x3/8” | 26.7 | 17.1 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 2.3 | 3.2 | ||

| 3/4”x1/2” | 26.7 | 21.3 | 76 | 2.9 | 3.9 | 5.6 | 7.8 | 2.8 | 3.7 | 4.8 | 7.5 |

| 1”x1/8” | 33.4 | 10.3 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 1.7 | 2.4 | ||

| 1”x1/4” | 33.4 | 13.7 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.2 | 3.0 | ||

| 1”x3/8” | 33.4 | 17.1 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.3 | 3.2 | ||

| 1”x1/2” | 33.4 | 21.3 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.8 | 3.7 | 4.8 | 7.5 |

| 1”x3/4” | 33.4 | 26.7 | 89 | 3.4 | 4.5 | 6.4 | 9.1 | 2.9 | 3.9 | 5.6 | 7.8 |

| 1-1/4”x1/8” | 42.2 | 10.3 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 1.7 | 2.4 | ||

| 1-1/4”x1/4” | 42.2 | 13.7 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.2 | 3.0 | ||

| 1-1/4”x3/8” | 42.2 | 17.1 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.3 | 3.2 | ||

| 1-1/4”x1/2” | 42.2 | 21.3 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.8 | 3.7 | 4.8 | 7.5 |

| 1-1/4”x3/4” | 42.2 | 26.7 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 2.9 | 3.9 | 5.6 | 7.8 |

| 1-1/4”x1” | 42.2 | 33.4 | 102 | 3.6 | 4.9 | 6.4 | 9.7 | 3.4 | 4.5 | 6.4 | 9.1 |

| 1-1/2”x1/8” | 48.3 | 10.3 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 1.7 | 2.4 | ||

| 1-1/2”x1/4” | 48.3 | 13.7 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.2 | 3.0 | ||

| 1-1/2”x3/8” | 48.3 | 17.1 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.3 | 3.2 | ||

| 1-1/2”x1/2” | 48.3 | 21.3 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.8 | 3.7 | 4.8 | 7.5 |

| 1-1/2”x3/4” | 48.3 | 26.7 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 2.9 | 3.9 | 5.6 | 7.8 |

| 1-1/2”x1” | 48.3 | 33.4 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 3.4 | 4.5 | 6.4 | 9.1 |

| 1-1/2”x1-1/4” | 48.3 | 42.2 | 114 | 3.7 | 5.1 | 7.1 | 10.2 | 3.6 | 4.9 | 6.4 | 9.7 |

| 2”x1/8” | 60.3 | 10.3 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 1.7 | 2.4 | ||

| 2”x1/4” | 60.3 | 13.7 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.2 | 3.0 | ||

| 2”x3/8” | 60.3 | 17.1 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.3 | 3.2 | ||

| 2”x1/2” | 60.3 | 21.3 | 165 | 3.9 | 5.5 | 8.7 | 11.1 | 2.8 | 3.7 | 4.8 | 7.5 |

Swage Nipple Price

| Stainless Steel Swage Nipples Price Per Piece in India | Swage Nipples Price in INR | Stainless Steel Concentric Swage Nipples Price in UAE Dirham | Stainless Steel Eccentric Swage Nipples Price in USD |

| STAINLESS STEEL GR SA403 WP316 SWAGE NIPPLE (CONC) S80S BLE/PSE 3INCH1-1/2 (CONCENTRIC) Per Kg | 3,026 | UAE Dirham 149.60 | $40.73 |

| STAINLESS STEEL GR SA403 WP316 SWAGE NIPPLE (CONC) S80 BLE/PSE 2X1INCH Per Kg | 2,644 | UAE Dirham 130.71 | $35.59 |

| CONC. SWAGE NIPPLE D.3/4 X 1/2 SCH. XXS PE/PE Stainless Steel 347 H Per Piece | 9,644 | UAE Dirham 476.81 | $129.80 |

Compare our price with other Stainless Steel Swage Nipples manufacturer in India. This is an approximate Price of SS 304 Hex Nipple in India.

Stainless Steel Swage Nipple Dimensions

| NOMINAL PIPE SIZE (NPS) | Outside Diameter | End To End "A | |

|---|---|---|---|

| In Inches | |||

| In Inches | Large End | Small End | In Inches |

| 1/4 X 1/8 | 0.540 | 0.405 | 2.25 |

| 3/8 X1/8 | 0.675 | 0.405 | 2.50 |

| 3/8 X 1/4 | 0.675 | 0.540 | 2.50 |

| 1/2 X 1/8 | 0.840 | 0.405 | 2.75 |

| 1/2 X 1/4 | 0.840 | 0.540 | 2.75 |

| 1/2 X 3/8 | 0.840 | 0.675 | 2.75 |

| 3/4 X 1/8 | 1.050 | 0.405 | 3.00 |

| 3/4 X 1/4 | 1.050 | 0.540 | 3.00 |

| 3/4 X 3/8 | 1.050 | 0.675 | 3.00 |

| 3/4 X 1/2 | 1.050 | 0.840 | 3.00 |

| 1 X 1/8 | 1.315 | 0.405 | 3.50 |

| 1 X 1/4 | 1.315 | 0.540 | 3.50 |

| 1 X 3/8 | 1.315 | 0.675 | 3.50 |

| 1 X 1/2 | 1.315 | 0.840 | 3.50 |

| 1 X 3/4 | 1.315 | 1.050 | 3.50 |

| 1-1/4 X 1/8 | 1.660 | 0.405 | 4.00 |

| 1-1/4 X 1/4 | 1.660 | 0.540 | 4.00 |

| 1-1/4 X 3/8 | 1.660 | 0.675 | 4.00 |

| 1-1/4 X 1/2 | 1.660 | 0.840 | 4.00 |

| 1-1/4 X 3/4 | 1.660 | 1.050 | 4.00 |

| 1-1/4 X 1 | 1.660 | 1.315 | 4.00 |

| 1-1/2 X 1/8 | 1.900 | 0.405 | 4.50 |

| 1-1/2 X 1/4 | 1.900 | 0.540 | 4.50 |

| 1-1/2 X 3/8 | 1.900 | 0.675 | 4.50 |

| 1-1/2 X 1/2 | 1.900 | 0.840 | 4.50 |

| 1-1/2 X 3/4 | 1.900 | 1.050 | 4.50 |

| 1-1/2 X 1 | 1.900 | 1.315 | 4.50 |

| 1-1/2 X 11/4 | 1.900 | 1.660 | 4.50 |

| 2 X 1/8 | 2.375 | 0.405 | 6.50 |

| 2 X 1/4 | 2.375 | 0.540 | 6.50 |

| 2 X 3/8 | 2.375 | 0.675 | 6.50 |

| 2 X 1/2 | 2.375 | 0.840 | 6.50 |

| 2 X 3/4 | 2.375 | 1.050 | 6.50 |

| 2 X 1 | 2.375 | 1.315 | 6.50 |

| 2 X 1-1/4 | 2.375 | 1.660 | 6.50 |

| 2 X 1-1/2 | 2.375 | 1.900 | 6.50 |

| 2-1/2 X 1/8 | 2.875 | 0.405 | 7.00 |

| 2-1/2 X 1/4 | 2.875 | 0.540 | 7.00 |

| 2-1/2 X 3/8 | 2.875 | 0.675 | 7.00 |

| 2-1/2 X 1/2 | 2.875 | 0.840 | 7.00 |

| 2-1/2 X 3/4 | 2.875 | 1.050 | 7.00 |

| 2-1/2 X 1 | 2.875 | 1.315 | 7.00 |

| 2-1/2 X 1-1/4 | 2.875 | 1.660 | 7.00 |

| 2-1/2 X 1-1/2 | 2.875 | 1.900 | 7.00 |

| 2-1/2 X 2 | 2.875 | 2.375 | 7.00 |

| 3 X 1/8 | 3.500 | 0.405 | 8.00 |

| 3 X 1/4 | 3.500 | 0.540 | 8.00 |

| 3 X 3/8 | 3.500 | 0.675 | 8.00 |

| 3 X 1/2 | 3.500 | 0.840 | 8.00 |

| 3 X 3/4 | 3.500 | 1.050 | 8.00 |

| 3 X 1 | 3.500 | 1.315 | 8.00 |

| 3 X 1-1/4 | 3.500 | 1.660 | 8.00 |

| 3 X 1-1/2 | 3.500 | 1.900 | 8.00 |

| 3 X 2 | 3.500 | 2.375 | 8.00 |

| 3 X 2-1/2 | 3.500 | 2.875 | 8.00 |

| 3-1/2 X 1/8 | 4.000 | 0.405 | 8.00 |

| 3-1/2 X 1/4 | 4.000 | 0.540 | 8.00 |

| 3-1/2 X 3/8 | 4.000 | 0.675 | 8.00 |

| 3-1/2 X 1/2 | 4.000 | 0.840 | 8.00 |

| 3-1/2 X 3/4 | 4.000 | 1.050 | 8.00 |

| 3-1/2 X 1 | 4.000 | 1.315 | 8.00 |

| 3-1/2 X 1-1/4 | 4.000 | 1.660 | 8.00 |

| 3-1/2 X 1-1/2 | 4.000 | 1.990 | 8.00 |

| 3-1/2 X 2 | 4.000 | 2.375 | 8.00 |

| 3-1/2 X 2-1/2 | 4.000 | 2.875 | 8.00 |

| 3-1/2 X 3 | 4.000 | 3.500 | 8.00 |

| 4 X 1/4 | 4.500 | 0.540 | 9.00 |

| 4 X 3/8 | 4.500 | 0.675 | 9.00 |

| 4 X 1/2 | 4.500 | 0.840 | 9.00 |

| 4 X 3/4 | 4.500 | 1.050 | 9.00 |

| 4 X 1 | 4.500 | 1.315 | 9.00 |

| 4 X 1-1/4 | 4.500 | 1.660 | 9.00 |

| 4 X 1-1/2 | 4.500 | 1.900 | 9.00 |

| 4 X 2 | 4.500 | 2.375 | 9.00 |

| 4 X 2-1/2 | 4.500 | 2.875 | 9.00 |

| 4 X 3 | 4.500 | 3.500 | 9.00 |

| 4 X 3-1/2 | 4.500 | 4.000 | 9.00 |

Dimensional Tolerance of Swaged Nipple

| Nominal Pipe Size (inch) | Overall Length (mm) | Outside diameter at end | Wall Thickness (prior to threading or grooving) | |

|---|---|---|---|---|

| Square Cut Ends (mm) | Other End Connection (mm) | |||

| 1/8” to 3/8” | ± 1.5 | + 0.40 – 0.80 |

± 0.80 | Not less than 87.5% of nominal wall thickness |

| 1/2” to 1-1/2” | ± 1.5 | + 0.40 – 0.80 |

+ 1.50 – 0.80 |

|

| 2” to 2-1/2” | ± 3.0 | ± 0.80 | + 1.50 – 0.80 |

|

| 3” to 4” | ± 3.0 | ± 0.80 | ± 1.50 | |

Class 2000, 3000 and 6000 A350 LF2 Shoulder Pipe Nipple, ASTM A182 F316 Grooved Pipe Nipples & Stainless Steel Swage Nipple manufacturer according to ASME B1.20.1.

Stainless Steel Hex Nipple Dimensions

Stainless Steel Pipe Nipple Size Chart

| Size | Threaded Tube DIN2440 | Threaded Tube BS 1387 | Length | |||||||

| O.D. | Wall thickness | O.D. B, mm | Wall thickness S, mm | Parallel nipples | Barrel/Taper nipples | |||||

| DN | inch | B, mm | S, mm | Light | Medium / Heavy | Light | Medium | Heavy | L,mm | L, mm |

| 6 | 1/8 | 10.2 | 2 | 10.2 | 10.2 | 1.6 | 2 | 16 | 30mm – 2500mm | |

| 8 | 1/4 | 13.5 | 2.35 | 13.6 | 13.9 | 1.8 | 2.3 | 2.9 | 18 | 30mm – 2500mm |

| 10 | 3/8 | 17.2 | 2.35 | 17.1 | 17.4 | 1.8 | 2.3 | 2.9 | 22 | 30mm – 2500mm |

| 15 | 1/2 | 21.3 | 2.65 | 21.4 | 21.7 | 2 | 2.6 | 3.2 | 25 | 30mm – 2500mm |

| 20 | 3/4 | 26.9 | 2.65 | 26.9 | 27.2 | 2.3 | 2.6 | 3.2 | 30 | 30mm – 2500mm |

| 25 | 1 | 33.7 | 3.25 | 33.8 | 34.2 | 2.6 | 3.2 | 4 | 35 | 30mm – 2500mm |

| 32 | 1 1/4 | 42.4 | 3.25 | 42.5 | 42.9 | 2.6 | 3.2 | 4 | 38 | 30mm – 2500mm |

| 40 | 1 1/2 | 48.3 | 3.25 | 48.4 | 48.8 | 2.9 | 3.2 | 4 | 38 | 30mm – 2500mm |

| 50 | 2 | 60.3 | 3.65 | 60.2 | 60.8 | 2.9 | 3.6 | 4.5 | 45 | 30mm – 2500mm |

| 65 | 2 1/2 | 76.1 | 3.65 | 76 | 76.6 | 3.2 | 3.6 | 4.5 | 55 | 30mm – 2500mm |

| 80 | 3 | 88.9 | 4.05 | 88.7 | 89.5 | 3.2 | 4 | 5 | 60 | 30mm – 2500mm |

| 100 | 4 | 114.3 | 4.5 | 113.9 | 114.9 | 3.6 | 4.5 | 5.4 | 70 | 30mm – 2500mm |

| 125 | 5 | 139.7 | 4.85 | 139.7 | 5 | 5.4 | 85 | 30mm – 2500mm | ||

| 150 | 6 | 165.1 | 4.85 | 165.1 | 5 | 5.4 | 100 | 30mm – 2500mm | ||

Stainless Steel Nipple Dimensions

| I.D. or Nominal Size | Outside Diameter | Length | ||

| NU | EUE | NU | EUE | |

| 1/8 | -- | -- | -- | -- |

| 1/4 | .540 | -- | 2 1/4 | -- |

| 3/8 | .675 | -- | 2 1/2 | -- |

| 1/2 | .840 | -- | 2 3/4 | -- |

| 3/4 | 1.050 | -- | 3 | -- |

| 1 | 1.315 | 1.469 | 3 1/2 | 4 1/2 |

| 1 1/4 | 1.660 | 1.812 | 4 | 6 |

Packaging of Buttweld Swage Nipple

- Packing is very crucial, especially in the case of international shipments, where the item must pass through several channels before arriving at its final destination, so we pay careful attention to packaging.

- Depending on the product, we pack it in a variety of ways. We pack our items in a variety of ways, including shrink wrapping, carton boxes, wooden pallets, wooden boxes, and wooden crates.

Different Types of Stainless Steel Swage Nipples

Stainless Steel Swage Nipples

Gi Grooved Pipe Nipples

Stainless Steel Barrel Nipple

Super Duplex Combination nipples

SS Barrel Nipple

A350 LF2 Combination nipples

SS Hex Nipple

Inconel Nipple

Alloy Steel Barrel Nipple

Stainless Steel Threaded Nipple

Stainless Steel Close Nipple

Duplex Shoulder Pipe Nipple

Carbon Steel Barrel Nipple

SS 304 Hex Nipple

Copper Concentric Swage Nipples

SS Reducing Nipple

ASTM A105 Nipple

Ductile Iron Swage Nipples

ASTM A182 F304 Eccentric Swage Nipples

ASTM A182 F316L Close Nipple

ASTM A182 F316 Eccentric Swage Nipples

Stainless Steel Hex Nipple

SS316 Nipple

UNS S31803 Swage Nipples

Stainless Steel Running Nipple

ASTM A182 F304L Threaded Nipple

Nickel Alloy Concentric Swage Nipples

Stainless Steel Nipple

A182 F11 Close Nipple

Titanium Seamless Pipe Nipple

Hastelloy Bsp Barrel Nipple

SS 304 Hex Nipple

MS Pipe Nipples

Stainless Steel Pipe Nipples

Aluminum Pipe Nipples

316 SS Grooved Pipe Nipples

SS Threaded Nipple Sizes

| Nominal Size | Weight/kg | ||

|---|---|---|---|

| DN | NPS | SCH80/ L=100 | SCH160 / L= 100 |

| 6 | 1/8 | 0.05 | – |

| 8 | 1/4 | 0.08 | – |

| 10 | 3/8 | 0.11 | – |

| 15 | 1/2 | 0.16 | 0.2 |

| 20 | 3/4 | 0.22 | 0.3 |

| 25 | 1 | 0.33 | 0.5 |

| 32 | 1 1/4 | 0.45 | 0.6 |

| 40 | 1 1/2 | 0.55 | 0.75 |

| 50 | 2 | 0.76 | 1.1 |

| 65 | 2 1/2 | 1.15 | 1.5 |

| 80 | 3 | 1.55 | 2.2 |

| 100 | 4 | 2.25 | 3.5 |

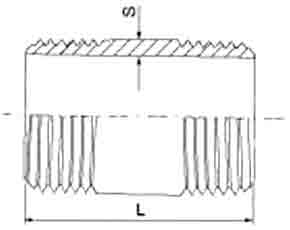

Stainless Steel Barrel Nipple Dimensions

| SIZE | 1/8" | 1/4" | 3/8" | 1/2" | 3/4" | 1" |

| S | 1.7 | 2.0 | 2.0 | 2.5 | 2.5 | 3.2 |

| L | 40.0 | 40.0 | 40.0 | 60.0 | 60.0 | 60.0 |

| SIZE | 1-1/4" | 1-1/2" | 2" | 2-1/2" | 3" | 4" |

| S | 3.2 | 3.2 | 3.6 | 3.6 | 4.0 | 4.5 |

| L | 80.0 | 80.0 | 100.0 | 100.0 | 120.0 | 120.0 |

Difference Between Swage Nipple And Reducer

The reducer has a wide size range. The current reducer size standard is from DN15 to DN3400 (from 1/2′′ to 136′′), whereas the swage nipple specification ranges from DN6 to DN300 (from 1/4′′ to 12′′). Reducers are made of seamless steel pipes or steel plates, and swage nipple is made of round bar steel or billet steel.

Applications of Combination nipples

- Nuclear Power

- Power Plants

- Oil And Gas Industry

- Ship Building

- Paper & Pulp

- Refineries

- Fossil Fuel Power Plants

- Marine Applications

Pipe Fittings Types

Pipe Fittings Material

Flanges Material

Other Products