- Call : +91 22 67436442

- exports@petrometflange.com

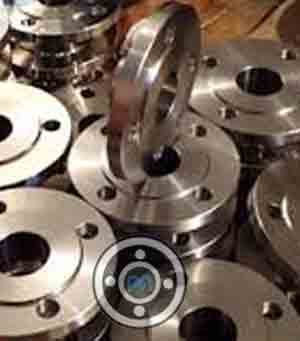

ASTM A182 F9 Flanges

- Home /

- ASTM A182 F9 Flanges

Alloy Steel F9 Slip On Flanges and SA 182 Gr F9 Blind Flange manufacturer in India

What is ASTM A182 F9 Flange?

The ASTM A182 F9 is basically a forging material specification that defines the F9 grade alloy steel and they are mainly used for making flanges that are used in various high temperature and high pressure applications. The addition of chromium and molybdenum in the steel alloy helps in enhancing its ductility. Some of the mechanical properties present in the ASTM A182 F9 Flange are:

- High tensile strength

- Good corrosion resistance

- Increased hardness

- Improved toughness

The ASTM A182 F9 material is also very versatile and hence they are used in several industries, such as pharmaceuticals, pharma equipment, sea water equipment, heat exchangers, condensers, chemical equipment, power generation, off-shore oil drilling companies and many more. They are thinner in size and hence are perfect for compact spaces. The ASTM A182 F9 Flanges are available with three different types of flange face, namely

- Raised face flange- It is the most common and widely used in oil and gas pipelines.

- Ring type joint face flange- they are used for high pressure and high temperature services.

- Flat face flange- they are used for less critical applications.

SA182 F9 Socket Weld Flange vs A182 F9 Weld Neck Flanges

The SA182 F9 Socket Weld Flange is widely used for small pipes that contain fluids and gases at high pressure. These flanges are basically attached by inserting the socket end to the pipe and then a fillet weld is applied for welding around the top region. This helps in a smooth bore and better fluid or gas flow occurs inside the pipe.

The A182 F9 Weld Neck Flanges are typically used for several critical situations, like high pressure and wide fluctuations in temperature and pressure. They are also used in high temperature conditions and with volatile and/or hazardous fluids. It can prove to be useful even when the temperature is below the sub-zero range.

ASTM A182 F9 Flanges

A182 Gr F9 Weld Neck Flange manufacturers in India offers widest range of SA 182 F9 Orifice Flanges and Alloy Steel F9 Forged Flanges in Mumbai in Class 300/ 600/ 900

ASTM A182 Gr F9 Slip on Flange Vs SA 182 F9 Blind Flange

The ASTM A182 Gr F9 Slip on Flange looks like a ring that is placed over the end of the pipe. They should be slid into the pipe before the welding process takes place. They are double weld on both outside and inside to avoid any kind of leakage. ASTM A182 Gr F9 Slip on Flange has a low material cost and comes with easy installation. They are suited for non-critical applications.

The SA 182 F9 Blind Flange looks like a solid disk that helps in creating a stop in the connection by blocking off the pipeline. Also known as a blank flange, they are used in areas where the piping system is not under usage. They come without any hub or centre hole, known as bore.

Table of Content

Material Specification of ASTM A182 F9 Flanges

| Size Range | 1/2″ to 48″ |

|---|---|

| Test | Magnetic particle detector, X-ray detector, Ultrasonic flaw detector, Direct-reading Spectrograph, Hydrostatic testing machine |

| Origin | Japan / West Europe / Indian / USA / Korean |

| DIN Pressure Calculation | 25Bar 40Bar 16Bar 6Bar 10Bar / PN64 PN10 PN25 PN16 PN6 PN40 |

| Chart of Pressure Rating | 300 LBS, 2500 LBS, 1500 LBS, 900 LBS, 150 LBS, 600 LBS |

| JIS | 40 K, 16 K, 5K, 10 K, 30 K, 20 K, 63 K |

| Manufacturer of Connect / Flange Face Type | LJF, RF, RTJ, FF, Small Tongue, Large Tongue & Groove |

| Standards Provided By Manufacturer | ISO70051, MSS S44, BS1560-3.1, API7S-43, B16.48, ANSI/ASME B16.5, B16.47 Series A & B, BS4504, JISB2220, ASME/ANSI B16.5/16.36/16.47A/16.47B, API605, BS 10, EN-1092, DIN, API7S-15, EN1092 |

| Manufacturer of | GOST, JIS, ANSI, DIN, UNI, BS, AWWA, AS2129, SABS, NFE, EN etc. |

| UNI / EN | 16Bar 6Bar 40Bar 10Bar 25Bar |

| Common Types By Manufacturer | Threaded / Screwed / Forged / Plate |

| Production technique Used By Manufacturer | Heat treated, Forged and machined |

| Coating | Zinc Plated, Anti-rust Paint, Yellow Transparent, Oil Black Paint, Cold and Hot Dip Galvanized |

| Equipment | Pushing Machine, Press machine, Sand-blasting machine, Bending machine, electric bevelling machine etc |

Leading A182 F9 Class 2 Flange wholesalers, supplier, distributor, importer, stockists, dealers, stockholders, exporters and Manufacturer in Mumbai

ASME SA182 F9 Steel Weld Neck Flange Dimension Table

| Flange NPS | H | Inside Diameter |

Flat Face Thickness (T2) |

Outside Diameter |

Raised Face (RF) |

Raised Face (R) |

H1 | Raised Face Thickness (T) |

T1 | Bolt Circle (BC) |

Bolt Hole (B) |

No. of Bolt Holes |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2" | 1.19" | 0.62" | 1.82" | 3.50" | .063" | 1.38" | 0.84" | 1.88" | .38" | 2.38" | .62" | 4 |

| 1-1/4" | 2.31" | 1.38" | 2.19" | 4.62" | .063" | 2.50" | 1.66" | 2.25" | .56" | 3.50" | .62" | 4 |

| 3/4" | 1.50" | 0.82" | 2.00" | 3.88" | .063" | 1.69" | 1.05" | 2.06" | .44" | 2.75" | .62" | 4 |

| 1-1/2" | 2.56" | 1.61" | 2.38" | 5.00" | .063" | 2.88" | 1.90" | 2.44" | .62" | 3.88" | .62" | 4 |

| 1" | 1.94" | 1.05" | 2.13" | 4.25" | .063" | 2.00" | 1.32" | 2.19" | .50" | 3.12" | .62" | 4 |

| 2" | 3.06" | 2.07" | 2.44" | 6.00" | .063" | 3.62" | 2.38" | 2.50" | .69" | 4.75" | .75" | 4 |

| 2-1/2" | 3.56" | 2.47" | 2.69" | 7.00" | .063" | 4.12" | 2.88" | 2.75" | .82" | 5.50" | .75" | 4 |

| 3" | 4.25" | 3.07" | 2.69" | 7.50" | .063" | 5.00" | 3.50" | 2.75" | .88" | 6.00" | .75" | 4 |

| 4" | 5.31" | 4.03" | 2.94" | 9.00" | .063" | 6.19" | 4.50" | 3.00" | .88" | 7.50" | .75" | 8 |

| 5" | 6.44" | 5.05" | 3.44" | 10.00" | .063" | 7.31" | 5.56" | 3.50" | .88" | 8.50" | .88" | 8 |

| 3-1/2" | 4.81" | 3.55" | 2.75" | 8.50" | .063" | 5.50" | 4.00" | 2.81" | .88" | 7.00" | .75" | 8 |

| 6" | 7.56" | 6.07" | 3.44" | 11.00" | .063" | 8.50" | 6.63" | 3.50" | .94" | 9.50" | .88" | 8 |

| 8" | 9.69" | 7.98" | 3.94" | 13.50" | .063" | 10.62" | 8.63" | 4.00" | 1.06" | 11.75" | .88" | 8 |

| 22" | 24.25" | 21.25" | 5.82" | 29.50" | .063" | 25.25" | 22.00" | 5.88" | 1.75" | 27.25" | 1.38" | 20 |

| 10" | 12.00" | 10.02" | 3.94" | 16.00" | .063" | 12.75" | 10.75" | 4.00" | 1.13" | 14.25" | 1.00" | 12 |

| 12" | 14.38" | 12.00" | 4.44" | 19.00" | .063" | 15.00" | 12.75" | 4.50" | 1.19" | 17.00" | 1.00" | 12 |

| 16" | 18.00" | 15.25" | 4.94" | 23.50" | .063" | 18.50" | 16.00" | 5.00" | 1.38" | 21.25" | 1.12" | 16 |

| 18" | 19.88" | 17.25" | 5.44" | 25.00" | .063" | 21.00" | 18.00" | 5.50" | 1.50" | 22.75" | 1.25" | 16 |

| 14" | 15.75" | 13.25" | 4.94" | 21.00" | .063" | 16.25" | 14.00" | 5.00" | 1.32" | 18.75" | 1.12" | 12 |

| 20" | 22.00" | 19.25" | 5.63" | 27.50" | .063" | 23.00" | 20.00" | 5.69" | 1.63" | 25.00" | 1.25" | 20 |

| 24" | 26.12" | 23.25" | 5.94" | 32.00" | .063" | 27.25" | 24.00" | 6.00" | 1.82" | 29.50" | 1.38" | 20 |

Our large fleet of heavy goods vehicles enable us to deliver F9 Steel Lap Joint Flange and BS10 ASTM A182 Gr F9 Threaded Flange throughout India quickly

Dimension of A182 F9 Cl2 Blind Flange

| Size in Inch | Size in mm | ISO Stud Size | RF Height | Outer Dia. | RF Dia. | Hole Size | PCD | No of Bolts | Bolt Size UNC | Flange Thickness | RF Stud Length | Weight in kg |

| D | A | C | E | B | ||||||||

| 1/2 | 15 | M20 | 7 | 135 | 34.9 | 7/8 | 88.9 | 4 | 3/4 | 30.2 | 120 | 3.2 |

| 3/4 | 20 | M20 | 7 | 140 | 42.9 | 7/8 | 95.2 | 4 | 3/4 | 31.8 | 125 | 3.7 |

| 1 | 25 | M24 | 7 | 160 | 50.8 | 1 | 108 | 4 | 7/8 | 35 | 140 | 5 |

| 1 1/4 | 32 | M27 | 7 | 185 | 63.5 | 1 1/8 | 130.2 | 4 | 1 | 38.1 | 150 | 7.8 |

| 1 1/2 | 40 | M30 | 7 | 205 | 73 | 1 1/4 | 146 | 4 | 1 1/8 | 44.5 | 170 | 10.5 |

| 2 | 50 | M27 | 7 | 235 | 92.1 | 1 1/8 | 171.4 | 8 | 1 | 50.9 | 180 | 18 |

| 2 1/2 | 65 | M30 | 7 | 265 | 104.8 | 1 1/4 | 196.8 | 8 | 1 1/8 | 57.2 | 195 | 25.5 |

| 3 | 80 | M33 | 7 | 305 | 127 | 1 3/8 | 228.6 | 8 | 1 1/4 | 66.7 | 220 | 39 |

| 4 | 100 | M39 | 7 | 355 | 157.2 | 1 5/8 | 273 | 8 | 1 1/2 | 76.2 | 255 | 61.5 |

| 5 | 125 | M45 | 7 | 420 | 185.7 | 1 7/8 | 323.8 | 8 | 1 3/4 | 92.1 | 300 | 102 |

| 6 | 150 | M52 | 7 | 485 | 215.9 | 2 1/8 | 368.3 | 8 | 2 | 108 | 345 | 157 |

| 8 | 200 | M52 | 7 | 550 | 269.9 | 2 1/8 | 438.2 | 12 | 2 | 127 | 380 | 241 |

| 10 | 250 | M64 | 7 | 675 | 323.8 | 2 5/8 | 539.8 | 12 | 2 1/2 | 165.1 | 490 | 470 |

| 12 | 300 | M72 | 7 | 760 | 381 | 2 7/8 | 619.1 | 12 | 2 3/4 | 184.2 | 540 | 575 |

SA182 F9 Slip on Flange Dimension Table

| Size in Inch | Size in mm | No of Bolts | Outer Dia. | Hub OD | ISO Stud Size | Flange Length | RF Height | Flange Thick. | RF Dia. | PCD | Hole Size | Socket Bore | Weight in kg |

| A | C | D | F | B | E | G | H | ||||||

| 1/2 | 15 | 4 | 90 | 30 | M14 | 14 | 2 | 9.6 | 34.9 | 60.3 | 5/8 | 22.2 | 0.8 |

| 1 | 25 | 4 | 110 | 49 | M14 | 16 | 2 | 12.7 | 50.8 | 79.4 | 5/8 | 34.5 | 0.9 |

| 3/4 | 20 | 4 | 100 | 38 | M14 | 14 | 2 | 11.2 | 42.9 | 69.9 | 5/8 | 27.7 | 0.9 |

| 1 1/4 | 32 | 4 | 115 | 59 | M14 | 19 | 2 | 14.3 | 63.5 | 88.9 | 5/8 | 43.2 | 1.4 |

| 2 | 50 | 4 | 150 | 78 | M16 | 24 | 2 | 17.5 | 92.1 | 120.7 | 3/4 | 61.9 | 2.3 |

| 1 1/2 | 40 | 4 | 125 | 65 | M14 | 21 | 2 | 15.9 | 73 | 98.4 | 5/8 | 49.5 | 1.4 |

| 2 1/2 | 65 | 4 | 180 | 90 | M16 | 27 | 2 | 20.7 | 104.8 | 139.7 | 3/4 | 74.6 | 3.2 |

| 3 | 80 | 4 | 190 | 108 | M16 | 29 | 2 | 22.3 | 127 | 152.4 | 3/4 | 90.7 | 3.7 |

| 4 | 100 | 8 | 230 | 135 | M16 | 32 | 2 | 22.3 | 157.2 | 190.5 | 3/4 | 116.1 | 5.9 |

| 3 1/2 | 90 | 8 | 215 | 122 | M16 | 30 | 2 | 22.3 | 139.7 | 177.8 | 3/4 | 103.4 | 5 |

| 5 | 125 | 8 | 255 | 164 | M20 | 35 | 2 | 22.3 | 185.7 | 215.9 | 7/8 | 143.8 | 6.8 |

| 8 | 200 | 8 | 345 | 246 | M20 | 43 | 2 | 27 | 269.9 | 298.5 | 7/8 | 221.5 | 13.7 |

| 10 | 250 | 12 | 405 | 305 | M24 | 48 | 2 | 28.6 | 323.8 | 362 | 1 | 276.2 | 19.5 |

| 6 | 150 | 8 | 280 | 192 | M20 | 38 | 2 | 23.9 | 215.9 | 241.3 | 7/8 | 170.7 | 8.6 |

| 12 | 300 | 12 | 485 | 365 | M24 | 54 | 2 | 30.2 | 381 | 431.8 | 1 | 327 | 29 |

| 24 | 600 | 20 | 815 | 663 | M33 | 81 | 2 | 46.1 | 692.2 | 749.3 | 1 3/8 | 616 | 100 |

| 16 | 400 | 16 | 595 | 457 | M27 | 62 | 2 | 35 | 469.9 | 539.8 | 1 1/8 | 410.5 | 54 |

| 18 | 450 | 16 | 635 | 505 | M30 | 67 | 2 | 38.1 | 533.4 | 577.9 | 1 1/4 | 461.8 | 59 |

| 14 | 350 | 12 | 535 | 400 | M27 | 56 | 2 | 33.4 | 412.8 | 476.3 | 1 1/8 | 359.2 | 41 |

| 20 | 500 | 20 | 700 | 559 | M30 | 71 | 2 | 41.3 | 584.2 | 635 | 1 1/4 | 513.1 | 75 |

ASTM A182 F9 Flanges Price List

| ASTM A182 Grade F9 Flanges Price Per Piece in India | ASTM A182 F9 Flanges Price in INR | SA182 F9 Flanges Price in UAE Dirham | ASME SA182 F9 Flange Price in USD |

| SORF FLANGE DN25 SA182 F9 Per Unit | 2,417 | UAE Dirham 117.46 | $31.98 |

| 4inch ASTM A182 F9 Steel Blind Flange Per Unit | 3401.05 | UAE Dirham 165.28 | $45 |

| ASTM A182 F9 Steel Flange Per kg | 642.42 | UAE Dirham 31.22 | $8.50 |

Petromet Flange Inc is a ASTM A182 F9 Flange Manufacturer in India According to ASME B16.5 Standards. SA182 F9 Cl1 Forged Flanges Provides in a Variety of Industry Applications. This is the estimated cost of F9 Alloy Steel Pipe Flanges in India.

Pressure Rating of F9 Alloy Steel Pipe Flanges

| Temperature °F | Class 150 | Class 600 | Class 1500 | Class 400 | Class 900 | Class 300 | Class 2500 |

| -20 to 100 | 275 | 1440 | 3600 | 960 | 2160 | 720 | 6000 |

| 300 | 205 | 1080 | 2700 | 720 | 1620 | 540 | 4500 |

| 200 | 230 | 1200 | 3000 | 800 | 1800 | 600 | 5000 |

| 400 | 190 | 995 | 2485 | 660 | 1490 | 495 | 4140 |

| 600 | 140 | 875 | 2185 | 580 | 1310 | 435 | 3640 |

| 650 | 125 | 860 | 2150 | 575 | 1290 | 430 | 3580 |

| 500 | 170 | 930 | 2330 | 620 | 1395 | 465 | 3880 |

| 700 | 110 | 850 | 2125 | 565 | 1275 | 425 | 3540 |

| 750 | 95 | 830 | 2075 | 555 | 1245 | 415 | 3460 |

| 850 | 65 | 790 | 1980 | 530 | 1190 | 395 | 3300 |

| 800 | 80 | 805 | 2015 | 540 | 1210 | 405 | 3360 |

| 900 | 50 | 780 | 1945 | 520 | 1165 | 390 | 3240 |

| 950 | 35 | 765 | 1910 | 510 | 1145 | 380 | 3180 |

| 1000 | 20 | 640 | 1605 | 430 | 965 | 320 | 2675 |

| 1100 | 20 | 515 | 1285 | 345 | 770 | 255 | 2145 |

| 1150 | 20 | 400 | 995 | 265 | 595 | 200 | 1655 |

| 1050 | 20 | 615 | 1545 | 410 | 925 | 310 | 2570 |

| 1200 | 20 | 310 | 770 | 205 | 465 | 155 | 1285 |

| 1250 | 20 | 225 | 565 | 150 | 340 | 115 | 945 |

| 1300 | 20 | 170 | 430 | 115 | 255 | 85 | 715 |

| 1400 | 20 | 95 | 240 | 65 | 145 | 50 | 400 |

| 1350 | 20 | 125 | 310 | 80 | 185 | 60 | 515 |

| 1450 | 15 | 70 | 170 | 45 | 105 | 35 | 285 |

| 1500 | 10 | 55 | 135 | 35 | 80 | 25 | 230 |

BS 10 Table E/ / EN 1092 Raised Face ASTM A182 F9 Alloy Steel Socket Weld Flange and ANSI B16.5 SA182F9 Long Weld Neck Flange manufacturer in India

A182 F9 Class 2 Flange Weight Chart

| NPS (Nominal Pipe Size) | Loose (Lap Joint) | NPT (Threaded) | SORF (Slip On) | BLRF (Blind) | SWRF (Socket Weld) | WRNR (Weld Neck) |

|---|---|---|---|---|---|---|

| ½ | 1 | 1 | 1 | 2 | 2 | 2 |

| 1 | 2 | 2 | 2 | 2 | 2 | 3 |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 |

| 1½ | 3 | 3 | 3 | 4 | 3 | 4 |

| 2½ | 8 | 8 | 8 | 7 | 8 | 10 |

| 2 | 5 | 5 | 5 | 5 | 5 | 6 |

| 3 | 9 | 9 | 9 | 9 | 9 | 11.5 |

| 4 | 13 | 13 | 13 | 17 | 13 | 16.5 |

| 3½ | 11 | 12 | 11 | 13 | 11 | 12 |

| 5 | 15 | 15 | 15 | 20 | 15 | 21 |

| 8 | 30 | 30 | 30 | 47 | 30 | 42 |

| 6 | 19 | 19 | 19 | 27 | 19 | 26 |

| 10 | 43 | 43 | 43 | 70 | 43 | 54 |

| 24 | 275 | 220 | 220 | 430 | 220 | 268 |

| 14 | 105 | 90 | 90 | 140 | 90 | 114 |

| 12 | 64 | 64 | 64 | 123 | 64 | 88 |

| 16 | 140 | 98 | 106 | 180 | 98 | 140 |

| 20 | 195 | 165 | 165 | 285 | 165 | 197 |

| 18 | 160 | 130 | 130 | 220 | 130 | 165 |

| 22 | 245 | 185 | 185 | 355 | 185 | 225 |

Thickness Chart of SA182 F9 Cl1 Forged Flanges

| Nom Pipe Size | OD | Sch 10 | Sch 20 | Sch 30 | STD Wall | Sch 40 | Sch 60 | EXT Hvy | Sch 80 | Sch 100 | Sch 120 | Sch 140 | Sch 160 | XX Hvy |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ½ | 0.84 | 0.083 | 0.109 | 0.109 | 0.147 | 0.147 | 0.188 | 0.294 | ||||||

| ¾ | 1.05 | 0.083 | 0.113 | 0.113 | 0.154 | 0.154 | 0.219 | 0.308 | ||||||

| 1 | 1.315 | 0.109 | 0.133 | 0.133 | 0.179 | 0.179 | 0.25 | 0.358 | ||||||

| 1 ¼ | 1.66 | 0.109 | 0.14 | 0.14 | 0.191 | 0.191 | 0.25 | 0.382 | ||||||

| 1 ½ | 1.9 | 0.109 | 0.145 | 0.145 | 0.2 | 0.2 | 0.281 | 0.4 | ||||||

| 2 | 2.375 | 0.109 | 0.154 | 0.154 | 0.218 | 0.218 | 0.344 | 0.436 | ||||||

| 2 ½ | 2.875 | 0.12 | 0.203 | 0.203 | 0.276 | 0.276 | 0.375 | 0.552 | ||||||

| 3 | 3.5 | 0.12 | 0.216 | 0.216 | 0.3 | 0.3 | 0.438 | 0.6 | ||||||

| 3 ½ | 4 | 0.12 | 0.226 | 0.226 | 0.318 | 0.318 | 0.636 | |||||||

| 4 | 4.5 | 0.12 | 0.237 | 0.237 | 0.337 | 0.337 | 0.438 | 0.531 | 0.674 | |||||

| 5 | 5.563 | 0.134 | 0.258 | 0.258 | 0.375 | 0.375 | 0.5 | 0.625 | 0.75 | |||||

| 6 | 6.625 | 0.134 | 0.28 | 0.28 | 0.432 | 0.432 | 0.562 | 0.719 | 0.864 | |||||

| 8 | 8.625 | 0.148 | 0.25 | 0.277 | 0.322 | 0.322 | 0.406 | 0.5 | 0.5 | 0.594 | 0.719 | 0.812 | 0.906 | 0.875 |

| 10 | 10.75 | 0.165 | 0.25 | 0.307 | 0.365 | 0.365 | 0.5 | 0.5 | 0.594 | 0.719 | 0.844 | 1 | 1.125 | 1 |

| 12 | 12.75 | 0.18 | 0.25 | 0.33 | 0.375 | 0.406 | 0.562 | 0.5 | 0.688 | 0.844 | 1 | 1.125 | 1.312 | 1 |

| 14 | 14 | 0.25 | 0.312 | 0.375 | 0.375 | 0.438 | 0.594 | 0.5 | 0.75 | 0.938 | 1.094 | 1.25 | 1.406 | |

| 16 | 16 | 0.25 | 0.312 | 0.375 | 0.375 | 0.5 | 0.656 | 0.5 | 0.844 | 1.031 | 1.219 | 1.438 | 1.594 | |

| 18 | 18 | 0.25 | 0.312 | 0.438 | 0.375 | 0.562 | 0.75 | 0.5 | 0.938 | 1.156 | 1.375 | 1.562 | 1.781 | |

| 20 | 20 | 0.25 | 0.375 | 0.5 | 0.375 | 0.594 | 0.812 | 0.5 | 1.031 | 1.281 | 1.5 | 1.75 | 1.969 | |

| 22 | 22 | 0.25 | 0.375 | 0.5 | ||||||||||

| 24 | 24 | 0.25 | 0.375 | 0.562 | 0.375 | 0.688 | 0.969 | 0.5 | 1.219 | 1.531 | 1.812 | 2.062 | 2.344 | |

| 26 | 26 | 0.375 | 0.5 | |||||||||||

| 30 | 30 | 0.312 | 0.5 | 0.625 | 0.375 | 0.5 | ||||||||

| 36 | 36 | 0.312 | 0.5 | 0.625 | 0.375 | 0.75 | 0.5 | |||||||

| 40 | 40 | 0.375 | 0.5 | |||||||||||

| 42 | 42 | 0.375 | 0.5 | |||||||||||

| 48 | 48 | 0.375 | 0.5 |

A182 F9 Chemical Composition

| Grade | Carbon | Chromium | Silicone | Phosphorus | Sulfur | Manganese | Molybdenum |

| Alloy Steel F9 | 0.15 max | 8-10 | 0.5-1.0 | 0.03 | 0.03 | 0.3-0.6 | 0.9-1.1 |

SA182 F9 Mechanical Composition

| Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 380 | 585 | 20 % |

ASTM A182 F9 Equivalent

| STANDARD | DIN WERKSTOFF NR. | UNS | DIN |

| Alloy Steel F9 | 1.7386 | K90941 | X 12 CrMo 9 1 |

Check AS/NZ 4087 Alloy Steel SA182 F9 Plate Flange and BS4504 PN16 ASTM A182 Gr F9 Spectacle Blind Flange pressure rating, dimensions & price list

Thermal Properties of SA A182 F9 Material

| Property | Temperature | Value |

|---|---|---|

| Coefficient of thermal expansion | 23.0 °C | 1.1E-5 - 1.4E-5 1/K |

| Melting point | 1382 - 1529 °C | |

| Specific heat capacity | 23.0 °C | 448 - 502 J/(kg·K) |

| Thermal conductivity | 23.0 °C | 36 - 43 W/(m·K) |

Various Types of ASTM A182 F9 Flanges

15 NB ASTM A182 Gr F9 Slip On Flange

SA182 F9 SWRF Flanges

ASTM A182 Gr F9 Nipoflange Flanges

150 LBS SA182 Grade F9 Tongue & Groove Flange

ASME SA182 F9 WNRF Flange

900 LBS ASTM A182 Grade F9 Lapped Joint Flange

ASTM A182 Gr F9 Threaded Flange

2500 LBS SA182 Gr F9 Girth Flanges

Alloy Steel F9 Spectacle Blind Flange

A182 Gr F9 SORF Flanges

ASTM A182 Gr F9 Reducing Flanges

600 LBS ASME SA182 F9 Steel Weld Neck Flange

ASTM A182 F9 Blind Flange

5000 NB A182 Grade F9 Socket Weld Flange

Alloy Steel F9 BLRF Flanges

1500 LBS A182 F9 Orifice Flanges

ASTM A182 F9 Ring Joint Flange

300 LBS ASTM A182 Grade F9 Screwed Flange

ASME SA182 F9 Long Weld Neck Flange

ASTM A182 Gr F9 Expander Flanges

A182 F9 Cl2 Blind Flange

F9 Alloy Steel Pipe Flanges

A182 F9 Class 2 Flange

SA182 F9 Cl1 Forged Flanges

Density of A182 F9 Material

| Density | 7.8 - 7.9 g/cm³ |

A182 F9 Class 2 Flange Applications

- Oil and Gas Industries

- Cement Industries

- Chemical Industries

- Food Processing Industries

- Pipeline

- Paper Industries

- Power Industries

- Ship Building Industries

Flanges Material

Pipe Fittings Material

Other Products