- Call : +91 22 67436442

- exports@petrometflange.com

Stainless Steel 304L Flanges

- Home /

- Stainless Steel 304L Flanges

AISI 304L Blind Flange and ASTM A182 F304L WNRF/ SORF Flange manufacturer in India

What is Stainless Steel 304L Flanges?

The Stainless Steel 304L material consists of several elements in its alloy like carbon, silicon, chromium, nickel. Sulfur, phosphorus, etc., which gives the material its unique properties. It has the same 18% chromium and 8% nickel like that of the SS 304 material, but it comes with a lower carbon content. The grades of these stainless steel mostly vary according to the change in the total amount of carbon content. There are different types of Stainless Steel 304L Flanges available and each of them have separate usage depending on their structure. The Stainless Steel 304L material belongs to the A182 specification, which is for forged and rolled alloy stainless steel flanges. The equipment made with the material is mostly used for high temperature applications.

Due to the presence of low carbon content in the material, it acquires less carbide precipitate during the welding process. Also, there would be less chances of intergranular and localized corrosion. These flanges are available with different pressure ratings, ranging between 150 to 2500, and the pressure number from PN6 through PN64. The Stainless Steel 304L Flanges come with high temperature tolerance, which makes them capable of operating at up to 870 degrees C. The flanges are available in different shapes, sizes, and can be custom-made according to the requirements specified by the clients. They also possess different specifications, standards, and dimensions. These SS 304L flanges are available in the size range of ½” to 48”, which is for their nominal bore size.

Due to the low carbon content in Stainless Steel 304L material, all conventional welding methods can be used on them. And because of this, forming joint connections with the Stainless Steel 304L Flanges becomes very easy and hence they are used across various industries, especially the petroleum industry. The presence of a healthy dose of chromium helps in improving the corrosion resistance properties of the flanges.

ASTM A182 F304L Slip on Flanges Vs 304L Stainless Steel Blind Flange?

The ASTM A182 F304L Slip on Flange is a common variety of forged flange which is low in carbon content compared to the 304 grade and easy to install. They should be slid inside the pipe before the welding process. Double welds are done on the inner and outer side to ensure a leak-proof connection. Also the 304L grade is less degradable compared to the 304 grade. They are used in low pressure pipelines or in those connections that have a very little risk of leakage.

The 304L Stainless Steel Blind Flange is a popular piping component of SS 304L grade material, which is known for its carbide precipitate eliminating capabilities. They look like a plate with bolts holes around it. They are particularly designed to stop the flow inside the pipe or seal a given nozzle of the valve. The Welding process is easier with 304L Stainless Steel Blind Flange as there is no need for annealing weld joints before using the completed metal form. It helps in saving time and energy. They promote easy access to the pipe in case any maintenance work is required inside the piping line.

UNS S30403 Weld Neck Flange Vs SA 182 F304l Threaded Flange

The UNS S30403 material is used for high-temperature applications and the weld neck type of flange is ideal for severe and critical conditions. The UNS S30403 Weld Neck Flange is thus capable of bearing high temperature, high pressure, wide fluctuation, etc., type of conditions. They are also used for fluids that are volatile and hazardous in nature.They are a circular fitting with protruding rims present around their circumference.

The SA 182 F304l Threaded Flange does not need welding on the joints for establishing connection with the piping system. Infact, they are used in those areas of a pipe where welding might not be possible. For example, highly explosive areas and potential risk zones might make a difficult area for welding and there threaded flanges might be used.

What is installation process of 304l Flange?

The installation of a 304L flange depends on the type of flange one is using. For example, there are flanges that need welded connections and for them various welding methods might be used for joining them with the piping system. Similarly, there are non-welding flanges like the threaded flanges, which are screwed together to make a piping connection. Thus individual SS 304L flanges have their specific installation procedure.

Stainless Steel 304L Flanges

ASME B16.5 SA182 F304L Slip On Flange manufacturers in Mumbai offers widest range of Stainless Steel 304L Weld Neck Flange and EN 1.4307 Reducing Flanges in India

Table of Content

- Stainless Steel 304L Flanges Specification

- SS 304L Flanges Weight Table

- A182 304L Flange Pressure Ratings

- 304L Stainless Steel Flange Dimensions

- Dimension of ASTM A182 Grade F304L Slip on Flanges

- 304L SS Blind Flange Dimensions Chart

- Price list of Stainless Steel 304L Flanges

- 304L Stainless Steel Weld Neck Flange Tolerance Chart In Mm

- A182 F304l Chemical Composition

- ASTM A182 F304l Equivalent

- 304l Flange Mechanical Properties

- Physical Properties of 304L SS RTJ Flange

- Different Types of Stainless Steel 304L Flanges

- ASME SA 182 F304l Flanges Yield Strength

- AISI 304l Flange Melting Point

- Heat Treatment of 304 Stainless Steel Weld Neck Flange

- Applications of DIN 1.4307 Flanges

- Stock List of 304L Stainless Steel Flanges

- Mechanical Difference Between 304 Vs 304L Stainless Steel Flanges

- Welding of SS 304L Flanges

Stainless Steel 304L Flanges Specification

| Size Chart | 1/2″(15 NB) to 48″ (1200NB) |

|---|---|

| Pressure Rating Chart ANSI | 150 LBS, 300 LBS, 2500 LBS, 900 LBS, 600 LBS, 1500 LBS |

| Origin | Japan / West Europe / Indian / USA / Korean |

| JIS | 16 K, 5K, 10 K, 20 K, 30 K, 40 K, 63 K |

| UNI / EN | 16Bar 6Bar 40Bar 10Bar 25Bar |

| Coating | Yellow Transparent, Anti-rust Paint, Oil Black Paint, Zinc Plated, Cold and Hot Dip Galvanized |

| Manufacturer of Connect Type/ Flange Face Type | RF, FF, RTJ, LJF, Small Tongue, Large Tongue & Groove |

| DIN Pressure Calculation | 25Bar 40Bar 16Bar 6Bar 10Bar / PN64 PN10 PN25 PN16 PN6 PN40 |

| Common Types By Manufacturer | Threaded / Screwed / Forged / Plate |

| Manufacturer of | GOST, JIS, ANSI, DIN, UNI, SABS, NFE, BS, AS2129, AWWA, EN etc. |

| Production technique Used By Manufacturer | Forged, Heat treated and machined |

| Standards Provided By Manufacturer | BS4504, BS 10, ANSI/ASME B16.5, B16.47 Series A & B, API7S-43, API605, B16.48, ISO70051, MSS SP44, EN-1092, DIN, BS1560-3.1, ASME/ANSI B16.5/16.36/16.47A/16.47B, API7S-15, JISB2220, EN1092 |

| Equipment | Bending machine, Press machine, Pushing Machine, Sand-blasting machine, electric bevelling machine etc |

| Test | Direct-reading Spectrograph, Magnetic particle detector, X-ray detector, Ultrasonic flaw detector, Hydrostatic testing machine |

Well known Stainless Steel 304L Flanges stockholders, distributor, wholesalers, importer, stockists, supplier, dealers, exporters and Manufacturer in Mumbai

SS 304L Flanges Weight Table

| NPS (Nominal Pipe Size) | Loose (Lap Joint) | NPT (Threaded) | SORF (Slip On) | BLRF (Blind) | SWRF (Socket Weld) | WRNR (Weld Neck) |

|---|---|---|---|---|---|---|

| ½ | 1 | 1 | 1 | 2 | 2 | 2 |

| 1 | 2 | 2 | 2 | 2 | 2 | 3 |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 |

| 1½ | 3 | 3 | 3 | 4 | 3 | 4 |

| 2½ | 8 | 8 | 8 | 7 | 8 | 10 |

| 2 | 5 | 5 | 5 | 5 | 5 | 6 |

| 3 | 9 | 9 | 9 | 9 | 9 | 11.5 |

| 4 | 13 | 13 | 13 | 17 | 13 | 16.5 |

| 3½ | 11 | 12 | 11 | 13 | 11 | 12 |

| 5 | 15 | 15 | 15 | 20 | 15 | 21 |

| 8 | 30 | 30 | 30 | 47 | 30 | 42 |

| 6 | 19 | 19 | 19 | 27 | 19 | 26 |

| 10 | 43 | 43 | 43 | 70 | 43 | 54 |

| 24 | 275 | 220 | 220 | 430 | 220 | 268 |

| 14 | 105 | 90 | 90 | 140 | 90 | 114 |

| 12 | 64 | 64 | 64 | 123 | 64 | 88 |

| 16 | 140 | 98 | 106 | 180 | 98 | 140 |

| 20 | 195 | 165 | 165 | 285 | 165 | 197 |

| 18 | 160 | 130 | 130 | 220 | 130 | 165 |

| 22 | 245 | 185 | 185 | 355 | 185 | 225 |

Manufacturing ASME B16.47 Series B Class 150 SS DIN 1.4307 Socket Weld Flange and 304L Stainless Steel Orifice Flanges for Offshore Oil & Gas Platforms

A182 304L Flange Pressure Ratings

| Temperature °F | Class 150 | Class 600 | Class 1500 | Class 400 | Class 900 | Class 300 | Class 2500 |

| -20 to 100 | 275 | 1440 | 3600 | 960 | 2160 | 720 | 6000 |

| 300 | 205 | 1080 | 2700 | 720 | 1620 | 540 | 4500 |

| 200 | 230 | 1200 | 3000 | 800 | 1800 | 600 | 5000 |

| 400 | 190 | 995 | 2485 | 660 | 1490 | 495 | 4140 |

| 600 | 140 | 875 | 2185 | 580 | 1310 | 435 | 3640 |

| 650 | 125 | 860 | 2150 | 575 | 1290 | 430 | 3580 |

| 500 | 170 | 930 | 2330 | 620 | 1395 | 465 | 3880 |

| 700 | 110 | 850 | 2125 | 565 | 1275 | 425 | 3540 |

| 750 | 95 | 830 | 2075 | 555 | 1245 | 415 | 3460 |

| 850 | 65 | 790 | 1980 | 530 | 1190 | 395 | 3300 |

| 800 | 80 | 805 | 2015 | 540 | 1210 | 405 | 3360 |

| 900 | 50 | 780 | 1945 | 520 | 1165 | 390 | 3240 |

| 950 | 35 | 765 | 1910 | 510 | 1145 | 380 | 3180 |

| 1000 | 20 | 640 | 1605 | 430 | 965 | 320 | 2675 |

| 1100 | 20 | 515 | 1285 | 345 | 770 | 255 | 2145 |

| 1150 | 20 | 400 | 995 | 265 | 595 | 200 | 1655 |

| 1050 | 20 | 615 | 1545 | 410 | 925 | 310 | 2570 |

| 1200 | 20 | 310 | 770 | 205 | 465 | 155 | 1285 |

| 1250 | 20 | 225 | 565 | 150 | 340 | 115 | 945 |

| 1300 | 20 | 170 | 430 | 115 | 255 | 85 | 715 |

| 1400 | 20 | 95 | 240 | 65 | 145 | 50 | 400 |

| 1350 | 20 | 125 | 310 | 80 | 185 | 60 | 515 |

| 1450 | 15 | 70 | 170 | 45 | 105 | 35 | 285 |

| 1500 | 10 | 55 | 135 | 35 | 80 | 25 | 230 |

304L Stainless Steel Flange Dimensions

| Normal Pipe Size (NPS) Of Flanges | (I.D.) Inside Diameter | Thickness Of Raised Face (RF) (T) |

Outside Daimeter (O.D.) | Raised Face (R) |

RF (Raised Face) |

Holes Of Bolts (B) |

H | T1 | Thickness Of Flat Face (FF) (T2) |

BC (Circle Of Bolt) | Bolts Holes Numbers |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 0.88 | 0.88 | 3.75 | 1.38 | .063 | 0.62 | 1.50 | 0.50 | 0.82 | 2.62 | 4 |

| 1 | 1.36 | 1.06 | 4.88 | 2.00 | .063 | 0.75 | 2.12 | 0.63 | 1.00 | 3.50 | 4 |

| 3/4 | 1.09 | 1.00 | 4.62 | 1.69 | .063 | 0.75 | 1.88 | .056 | 0.94 | 3.25 | 4 |

| 1-1/4 | 1.70 | 1.06 | 5.25 | 2.50 | .063 | 0.75 | 2.50 | 0.69 | 1.00 | 3.88 | 4 |

| 2 | 2.44 | 1.31 | 6.50 | 3.62 | .063 | 0.75 | 3.31 | 0.82 | 1.25 | 5.00 | 8 |

| 1-1/2 | 1.95 | 1.19 | 6.12 | 2.88 | .063 | 0.88 | 2.75 | 0.75 | 1.13 | 4.50 | 4 |

| 2-1/2 | 2.94 | 1.50 | 7.50 | 4.12 | .063 | 0.88 | 3.94 | 0.94 | 1.44 | 5.88 | 8 |

| 3 | 3.57 | 1.69 | 8.25 | 5.00 | .063 | 0.88 | 4.62 | 1.06 | 1.63 | 6.62 | 8 |

| 3-1/2 | 4.07 | 1.75 | 9.00 | 5.50 | .063 | 0.88 | 5.25 | 1.13 | 1.69 | 7.25 | 8 |

| 4 | 4.57 | 1.88 | 10.00 | 6.19 | .063 | 0.88 | 5.75 | 1.19 | 1.82 | 7.88 | 8 |

| 5 | 5.66 | 2.00 | 11.00 | 7.31 | .063 | 0.88 | 7.00 | 1.32 | 1.94 | 9.25 | 8 |

| 18 | 18.18 | 3.50 | 28.00 | 21.00 | .063 | 1.38 | 21.00 | 2.32 | 3.44 | 24.75 | 24 |

| 6 | 6.72 | 2.06 | 12.50 | 8.50 | .063 | 0.88 | 8.12 | 1.38 | 2.00 | 10.62 | 12 |

| 8 | 8.72 | 2.44 | 15.00 | 10.62 | .063 | 1.00 | 10.25 | 1.56 | 2.38 | 13.00 | 12 |

| 10 | 10.88 | 2.62 | 17.50 | 12.75 | .063 | 1.12 | 12.62 | 1.82 | 2.56 | 15.25 | 16 |

| 12 | 12.88 | 2.88 | 20.50 | 15.00 | .063 | 1.25 | 14.75 | 1.94 | 2.82 | 17.75 | 16 |

| 14 | 14.14 | 3.00 | 23.00 | 16.25 | .063 | 1.25 | 16.75 | 2.06 | 2.94 | 20.25 | 20 |

| 20 | 20.20 | 3.75 | 30.50 | 23.00 | .063 | 1.38 | 23.12 | 2.44 | 3.69 | 27.00 | 24 |

| 16 | 16.16 | 3.25 | 25.50 | 18.50 | .063 | 1.38 | 19.00 | 2.19 | 3.19 | 22.50 | 20 |

| 22 | 22.22 | 4.00 | 33.00 | 25.25 | .063 | 1.63 | 25.25 | 2.57 | 3.94 | 29.25 | 24 |

| 24 | 24.25 | 4.19 | 36.00 | 27.25 | .063 | 1.62 | 27.62 | 2.69 | 4.13 | 32.00 | 24 |

Dimension of ASTM A182 Grade F304L Slip on Flanges

| Size in Inch | Size in mm | No of Bolts | Outer Dia. | Hub OD | ISO Stud Size | Flange Length | RF Height | Flange Thick. | RF Dia. | PCD | Hole Size | Socket Bore | Weight in kg |

| A | C | D | F | B | E | G | H | ||||||

| 1/2 | 15 | 4 | 90 | 30 | M14 | 14 | 2 | 9.6 | 34.9 | 60.3 | 5/8 | 22.2 | 0.8 |

| 1 | 25 | 4 | 110 | 49 | M14 | 16 | 2 | 12.7 | 50.8 | 79.4 | 5/8 | 34.5 | 0.9 |

| 3/4 | 20 | 4 | 100 | 38 | M14 | 14 | 2 | 11.2 | 42.9 | 69.9 | 5/8 | 27.7 | 0.9 |

| 1 1/4 | 32 | 4 | 115 | 59 | M14 | 19 | 2 | 14.3 | 63.5 | 88.9 | 5/8 | 43.2 | 1.4 |

| 2 | 50 | 4 | 150 | 78 | M16 | 24 | 2 | 17.5 | 92.1 | 120.7 | 3/4 | 61.9 | 2.3 |

| 1 1/2 | 40 | 4 | 125 | 65 | M14 | 21 | 2 | 15.9 | 73 | 98.4 | 5/8 | 49.5 | 1.4 |

| 2 1/2 | 65 | 4 | 180 | 90 | M16 | 27 | 2 | 20.7 | 104.8 | 139.7 | 3/4 | 74.6 | 3.2 |

| 3 | 80 | 4 | 190 | 108 | M16 | 29 | 2 | 22.3 | 127 | 152.4 | 3/4 | 90.7 | 3.7 |

| 4 | 100 | 8 | 230 | 135 | M16 | 32 | 2 | 22.3 | 157.2 | 190.5 | 3/4 | 116.1 | 5.9 |

| 3 1/2 | 90 | 8 | 215 | 122 | M16 | 30 | 2 | 22.3 | 139.7 | 177.8 | 3/4 | 103.4 | 5 |

| 5 | 125 | 8 | 255 | 164 | M20 | 35 | 2 | 22.3 | 185.7 | 215.9 | 7/8 | 143.8 | 6.8 |

| 8 | 200 | 8 | 345 | 246 | M20 | 43 | 2 | 27 | 269.9 | 298.5 | 7/8 | 221.5 | 13.7 |

| 10 | 250 | 12 | 405 | 305 | M24 | 48 | 2 | 28.6 | 323.8 | 362 | 1 | 276.2 | 19.5 |

| 6 | 150 | 8 | 280 | 192 | M20 | 38 | 2 | 23.9 | 215.9 | 241.3 | 7/8 | 170.7 | 8.6 |

| 12 | 300 | 12 | 485 | 365 | M24 | 54 | 2 | 30.2 | 381 | 431.8 | 1 | 327 | 29 |

| 24 | 600 | 20 | 815 | 663 | M33 | 81 | 2 | 46.1 | 692.2 | 749.3 | 1 3/8 | 616 | 100 |

| 16 | 400 | 16 | 595 | 457 | M27 | 62 | 2 | 35 | 469.9 | 539.8 | 1 1/8 | 410.5 | 54 |

| 18 | 450 | 16 | 635 | 505 | M30 | 67 | 2 | 38.1 | 533.4 | 577.9 | 1 1/4 | 461.8 | 59 |

| 14 | 350 | 12 | 535 | 400 | M27 | 56 | 2 | 33.4 | 412.8 | 476.3 | 1 1/8 | 359.2 | 41 |

| 20 | 500 | 20 | 700 | 559 | M30 | 71 | 2 | 41.3 | 584.2 | 635 | 1 1/4 | 513.1 | 75 |

API 605 Class 300/ 600/ 900 AISI 304L Lap Joint Flange and BS4504 UNS S30403 Spectacle Blind Flange manufacturer in India

304L SS Blind Flange Dimensions Chart

| Size in Inch | Size in mm | ISO Stud Size | RF Height | Outer Dia. | RF Dia. | Hole Size | PCD | No of Bolts | Bolt Size UNC | Flange Thickness | RF Stud Length | Weight in kg |

| D | A | C | E | B | ||||||||

| 1/2 | 15 | M20 | 7 | 135 | 34.9 | 7/8 | 88.9 | 4 | 3/4 | 30.2 | 120 | 3.2 |

| 3/4 | 20 | M20 | 7 | 140 | 42.9 | 7/8 | 95.2 | 4 | 3/4 | 31.8 | 125 | 3.7 |

| 1 | 25 | M24 | 7 | 160 | 50.8 | 1 | 108 | 4 | 7/8 | 35 | 140 | 5 |

| 1 1/4 | 32 | M27 | 7 | 185 | 63.5 | 1 1/8 | 130.2 | 4 | 1 | 38.1 | 150 | 7.8 |

| 1 1/2 | 40 | M30 | 7 | 205 | 73 | 1 1/4 | 146 | 4 | 1 1/8 | 44.5 | 170 | 10.5 |

| 2 | 50 | M27 | 7 | 235 | 92.1 | 1 1/8 | 171.4 | 8 | 1 | 50.9 | 180 | 18 |

| 2 1/2 | 65 | M30 | 7 | 265 | 104.8 | 1 1/4 | 196.8 | 8 | 1 1/8 | 57.2 | 195 | 25.5 |

| 3 | 80 | M33 | 7 | 305 | 127 | 1 3/8 | 228.6 | 8 | 1 1/4 | 66.7 | 220 | 39 |

| 4 | 100 | M39 | 7 | 355 | 157.2 | 1 5/8 | 273 | 8 | 1 1/2 | 76.2 | 255 | 61.5 |

| 5 | 125 | M45 | 7 | 420 | 185.7 | 1 7/8 | 323.8 | 8 | 1 3/4 | 92.1 | 300 | 102 |

| 6 | 150 | M52 | 7 | 485 | 215.9 | 2 1/8 | 368.3 | 8 | 2 | 108 | 345 | 157 |

| 8 | 200 | M52 | 7 | 550 | 269.9 | 2 1/8 | 438.2 | 12 | 2 | 127 | 380 | 241 |

| 10 | 250 | M64 | 7 | 675 | 323.8 | 2 5/8 | 539.8 | 12 | 2 1/2 | 165.1 | 490 | 470 |

| 12 | 300 | M72 | 7 | 760 | 381 | 2 7/8 | 619.1 | 12 | 2 3/4 | 184.2 | 540 | 575 |

Price list of Stainless Steel 304L Flanges

| 304L Stainless Steel Flanges Price Per Piece in India | SS 304L Pipe Flanges Price in INR | ASTM A182 F304L Flanges Price in UAE Dirham | Stainless Steel 304L Flange Price in USD |

| FLANGES STAINLESS STEEL WN RF, 150#, 10S BORE, A182 GR. 304L Per KG | 419 | UAE Dirham 20.37 | $5.55 |

| SA 182 F304L ANSI B16.5 DN80, 150# SORF Per Kg | 502 | UAE Dirham 24.40 | $6.64 |

| FLANGES SS SW RF, 300#, 40S BORE, A182 GR 304L Per Kg | 240 | UAE Dirham 11.67 | $3.18 |

| FLANGES STAINLESS STEEL SA 182 F304L ANSI B16.5 DN100, 150# BLRF Per Kg | 432 | UAE Dirham 21.00 | $5.72 |

Before Buying Compare our price with other SS 304L Flanges manufacturer in India. This is an approximate Price of A182 304L Flange in India. Feel free to contact us latest Stocklist of 304L Stainless Steel Flange in Mumbai.

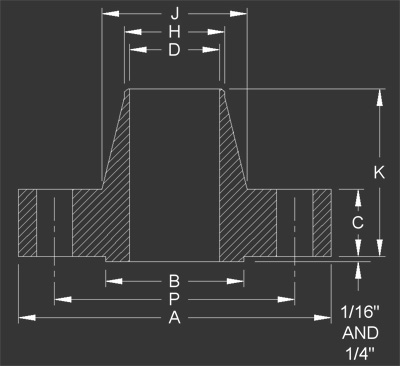

304L Stainless Steel Weld Neck Flange Tolerance Chart In Mm

| Flange | Tolerance Table | |

|---|---|---|

| D | Inside Diameter (I.D.) |

|

| K | Length of hub |

|

| B | Diameter of contact face |

|

| A | O.D. (Outside Diameter) |

|

| J | Diameter of hub at base |

|

| P | Drilling |

|

| Eccentricity of bolt circle with respect to facing |

|

|

| H | Diameter of hub at point of welding |

|

| C | Thickness |

|

Check EN 1092-2 PN40 AISI 304L Stainless Steel Threaded Flange and 1.4307 Stainless Steel Forged Flange ASTM specification & price list

A182 F304l Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 304L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.03 max | 18 - 20 | - | 8 - 13 | - |

ASTM A182 F304l Equivalent

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304L | 1.4306 / 1.4307 | S30403 | SUS 304L | 3304S11 | 03-18-11 | Z3CN18-10 | X2CrNi18-9 / X2CrNi19-11 |

304l Flange Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi - 75000 , MPa - 515 | Psi - 30000 , MPa - 205 | 35 % |

Physical Properties of 304L SS RTJ Flange

| Density lbm/in3 |

Thermal Conductivity (BTU/h ft. °F) |

Electrical Resistivity (in x 10-6) |

Modulus of Elasticity (psi x 106 |

Coefficient of Thermal Expansion (in/in)/ °F x 10-6 |

Specific Heat (BTU/lb/ °F) |

Melting Range (°F) |

|---|---|---|---|---|---|---|

| at 68°F: 0.285 | 9.4 at 212°F | 28.3 at 68°F | 28 | 9.4 at 32 – 212°F | 0.1200 at 68°F to 212°F | 2500 to 2590 |

| 12.4 at 932 °F | 39.4 at 752°F | 10.2 at 32 – 1000°F | ||||

| 49.6 at 1652 °F | 10.4 at 32 – 1500°F |

Different Types of Stainless Steel 304L Flanges

Stainless Steel 304L Weld Neck Flanges

300 LBS SA182 Gr F304L WNRF Flange

Stainless Steel UNS S30403 Socket Weld Flange

600 LBS 304L SS SWRF Flanges

SA182 Grade F304L Slip On Flange

150 LBS 304L SS SORF Flanges

DIN 1.4306 Blind Flange

900 LBS SS 304L BLRF Flanges

ASME SA182 F304L Lapped Joint Flange

ASTM A182 Gr F304L Orifice Flanges

304L Stainless Steel Spectacle Blind Flange

2500 LBS Stainless Steel 304L Tongue & Groove Flange

A182 F304L Nipoflange Flanges

1500 LBS ASTM A182 F304L Long Weld Neck Flange

A182 Gr F304L Reducing Flanges

SS 304L Ring Joint Flange

5000 NB 304L Stainless Steel Girth Flanges

ASTM A182 F304L Stainless Steel Expander Flanges

15 NB UNS S30403 Screwed Flange

ASTM A182 Grade F304L Threaded Flange

304L Stainless Steel Flanges

ASME SA 182 F304l Flanges Yield Strength

| Yield Strength | 25 ksi |

AISI 304l Flange Melting Point

| Melting Point | 1450 °C |

Heat Treatment of 304 Stainless Steel Weld Neck Flange

Rapid cooling following heating to 1010-1120°C can be used for solution treatment or annealing.

Applications of DIN 1.4307 Flanges

- Marine Applications

- Fossil Fuel Power Plants

- Paper & Pulp

- Refineries

- Nuclear Power

- Oil And Gas Industry

- Power Plants

- Ship Building

Stock List of 304L Stainless Steel Flanges

| 304L SS Spectacle Blind Flanges | Stainless Steel 304L Socket Weld Flange |

| UNS S30403 Industrial Flanges | 304L Stainless Steel Flanges |

| SS 304L WNRF Flanges | ASTM A182 F304L Weld Neck Flange |

| A182 F304L Threaded Flanges | DIN 1.4306 Pipe Flanges |

| ASTM A182 Gr F304L Lap Joint Flanges | SS 304L Socket Weld Flanges |

| Stainless Steel UNS S30403 Reducing Flanges | SS 304L Plate Flange |

| Stainless Steel 304L Lap Joint Flange | 304L Stainless Steel RTJ Flange |

| 304L Stainless Steel Ring Type Joint Flanges | 304L Stainless Steel Flange |

| ASME SA182 F304L Slip On Flanges | Stainless Steel 304L Flanges |

| SA182 Grade F304L Socket Weld Flanges | 304L Stainless Steel Pipe Flange |

| SA182 Gr F304L Screwed Flanges | ASTM A182 F304L Stainless Steel Lap Joint Flanges |

| SS 304L Forged Flanges | 304L Stainless Steel Blind Flanges |

| ASME SA182 F304L Pipe Flange | A182 Gr F304L Blind Flanges |

| ASTM A182 Grade F304L Orifice Flanges | Stainless Steel 304L Lapped joint Flanges |

Mechanical Difference Between 304 Vs 304L Stainless Steel Flanges

When compared to "normal" grade 304 stainless steel alloy, grade 304L has a modest but significant drop in important mechanical performance attributes. The ultimate tensile strength (UTS) of 304L, for example, is about 85 ksi (586 MPa), which is lower than the UTS of ordinary grade 304 stainless steel, which is 90 ksi (620 MPa). As a result, a 304L SS flange would be structurally weaker than a regular 304 flange.

Welding of SS 304L Flanges

Both with and without fillers, the fusion welding performance of stainless steel 304 is excellent. Grade 308 stainless steel filler rods and electrodes are recommended for stainless steel 304. The recommended filler for 304L is 308L.

Flanges Material

Pipe Fittings Material

Other Products