- Call : +91 22 67436442

- exports@petrometflange.com

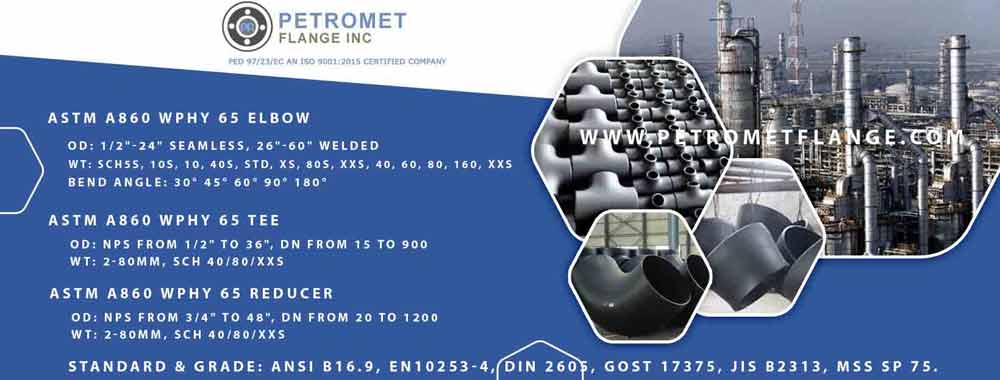

WPHY 65 Fittings

- Home /

- WPHY 65 Fittings

Carbon Steel WPHY 65 Pipe Tee and ASTM A860 WPHY 65 Elbow manufacturer in India

What is WPHY 65 Fittings?

The WPHY 65 material is a carbon-based stainless steel that comes with a minimum yield strength of around 448 MPa. The manufacturers can manufacture the WPHY 65 Fittings in various types and dimensions. These fittings are available in either welded, seamless, or fabricated forms, with different bending radiuses. The WPHY 65 material is basically wrought carbon steel alloy that has different types of elements like magnesium, sulfur, etc., in trace quantities. The unique mechanical and physical properties of the fittings, like high strength, are attained from the chemical composition of the material. It also has high durability, made with accurate dimensions and is known for its cost effectiveness.

Due to the high yield strength of the material, they are extensively used in various high-pressure requirements. The tensile strength of the material also ranges between 515 Mpa and 690 Mpa. They offer excellent corrosion resistance with good toughness. They are very cost-effective as they have a very high service life. They give exceptional performance under loads and are highly tolerant to pressure which makes the fittings perfect to be used in power generation, and off-shore industries.

The WPHY 65 Fittings are used in a wide range of applications, including sour services, for various industries. They are also quite popular in the oil and gas, and petrochemical industries. The surfaces of these materials can be treated with various coatings, to improve their appearance and also their corrosion resisting properties. The WPHY 65 Fittings are available in a wide range of configurations, and they perform different functions in the piping system.

ASTM A860 WPHY 65 90 Degree Elbow Vs WPHY 65 45 Degree Elbow

Both, the ASTM A860 WPHY 65 90 Degree Elbow and the WPHY 65 45 Degree Elbow Helps in connecting two pipes with same or different nominal diameters. The difference between them being in the turn of the pipe to the 45 degree or 90 degree direction.. With a 45 degree elbow, the direction of the fluid can be changed to 45 degrees, whereas the direction changes to 90 degrees in case of the 90 degree elbow. Also, the 45 degree elbow produces much more friction compared to the 90 degree elbow.

MSS SP 75 WPHY 65 Tee Vs A860 Grade WPHY 65 Cross

The MSS SP 75 WPHY 65 Tee helps in collecting and distributing the fluid for the main run pipe. It looks like the alphabet T, with two branches located at 90 degrees in the center, and one inlet. There are two types of MSS SP 75 WPHY 65 Tee, namely equal tee and reducing tee. The diameter of the branch pipe and the run pipe varies with the type of tee selected.

The A860 Grade WPHY 65 Cross is a four way pipe fitting with one inlet and three outlets. It can also have a vice-versa setting. It is commonly used in firewater sprinkler lines and not in any process piping used for transporting the liquids.

How many types of High Yield WPHY 65 Reducers are there?

There are two types of High Yield WPHY 65 Reducers, namely:

- Concentric reducers which look like a cone and are used for joining sections of the pipe on the same axis.

- Eccentric reducers have edges connected to the connecting pipe. The structure of the reducer allows it to align with a side of the inlet.

WPHY 65 Fittings

High-Yield 65000 PSI WPHY 65 Reducing/ Equal/ Unequal/ Lateral Tee and WPHY 65 Fittings manufacturer in India, Certified By European Directive 2014/68/eu & ISO

Table of Content

- WPHY 65 Fittings Specification

- Size Range of MSS SP 75 WPHY 65 Fittings

- A860 WPHY X65 Elbow

- MSS SP-75 WPHY 65 Reducer

- WPHY Grade 65 Tee

- Price List of WPHY 65 Fittings

- Carbon Steel API 5L X65 Fittings Dimensions

- Pressure Rating of WPHY 65 Buttweld Fittings

- ASTM A860 WPHY 65 Chemical Composition

- WPHY 65 Mechanical Properties

- Physical Properties of A860 WPHY 65 3D Buttweld Tee

- A860 WPHY X65 3D Elbow Thermal Properties

- Various Types of WPHY 65 Fittings

- Sizes of CS WPHY Gr 65 Reducer

- Dimensions Table of MSS SP75 WPHY 65 Reducer

- A860 Grade WPHY 65 Tee Dimensions Table

- Weight Chart of Carbon Steel X65 Tee

- WPHY Gr 65 High Yield Elbow Weight

- Tolerance of CS Grade 65 Elbow

- We sale Carbon Steel X65 Fittings

- MSS SP 75 WPHY 65 Fittings Applications

- Value Added Services of WPHY 65 Pipe Fittings

WPHY 65 Fittings Specification

| WPHY 65 Fittings Specifications | ASTM A860 |

|---|---|

| MSS SP75 WPHY 65 Fittings Sizes | Carbon Steel X65 Seamless Fittings: 1/2" - 10" ASME B16 9 Carbon Steel API 5L X65 Welded Fittings: 1/2" - 48" |

| Bending Radius Provided By Manufacturer | R=1D, 3D, 2D, 5D, 8D, 6D, 10D or Custom WPHY 65 Fittings |

| MSS SP 75 WPHY 65 Fittings Dimensions | ASME B16.28, ASME/ANSI B16.9, BS4504, MSS-SP-43, BS1560, BS4504, BS10 |

| A860 Gr WPHY 65 Buttweld Fittings Thickness | SCH30, SCH10, SCH 160, SCH20, SCH60, XS, STD SCH40, SCH 80, SCH 120, SCH 140, SCH 100, XXS available with NACE MR 01-75 |

| Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) WPHY 65 Fittings |

| ASTM A860 MSS SP 75 WPHY 65 Fittings Type Manufacturer | DN15-DN1200 |

| A860 WPHY X65 Elbow Manufacturer | Angle : 22.5 deg, 45 deg, 30deg, 90 deg, 1.0D, 180 deg, 1.5D, 3D, 2.5D, 2.0D, 4D, 6D, 5D, 7D-40D . Standard: ASME B16.28, GB, ASME B16.9, MSS SP-75 JISB2311 DIN2605 JISB2312 JISB2313, ASME B16.25, BS, ISO |

| ASTM A860 WPHY 65 Fittings Manufacturing process | Push, Forge, Press, Cast, etc. |

| WPHY 65 Fittings Connection | Welding |

| Test Certificates Provided By WPHY 65 Fittings Manufacturers | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Application of Industrial A860 Grade WPHY 65 Weld Fittings |

|

| MSS SP75 WPHY 65 Material Origin & Mills | European, Japanese, USA, Korean, Ukraine, Indian, Russian |

| Specialized manufacturer of | Carbon Steel X65 Stub End, 90º Elbows, Tees, Pipe Cap, Crosses, 45º Elbows, Reducers, Pipe Bend |

| WPHY 65 Fittings Thread Provided By Manufacturer | BSPT, NPT, BSPP |

| Dimension Specification | MSS SP-79, 95, 83, 97, BS 3799, ASME 16.11 |

| Carbon Steel Grade 65 Fittings Pressure Rating | Threaded end - 3000lb/ 2000lb/ 6000lbs Socket weld end- 6000/ 3000/ 9000lbs |

| Carbon Steel Grade 65 Products Manufacturer | Half Coupling, Union, Tee, Cross, Coupling, Cap, Outlet, Welding Outlet, Boss, Insert |

Leading WPHY 65 Fittings wholesalers, supplier, distributor, importer, stockists, dealers, stockholders, exporters and Manufacturer in Mumbai

Size Range of MSS SP 75 WPHY 65 Fittings

| Standard | ANSI / ASTM A860 |

|---|---|

| Sizes | 1/2’’~48’’(Seamless); 16’’~72’’(Welded) |

| Wall thickness | Sch5~Sch160\XXS |

A860 WPHY X65 Elbow

20INCH SCH60 90 DEGREE LR WPHY-65 ASME B16.9

10Inch A860 WPHY X65 Elbow, ASME B16.9

DN150 Carbon Steel X65 Long Radius 90 Degree Elbow

MSS SP-75 WPHY 65 Reducer

Concentric Reducer 18″ x 16″ Sch. XS SA860 WPHY 65

MSS SP75 65 Concentric Reducer

A860 MSS SP 75 WPHY 65 Reducer 12 inch SCH80

WPHY Grade 65 Tee

48" STD ASTM A860 WPHY 65 Tee

6" Sch 40 WPHY Grade 65 Tee

ASME B16.9 4" seamless wphy 65 Tee

Manufacturer of MSS SP75 WPHY 65 Eccentric / Concentric Reducers, Split / Flanged Tee, Pipe Bend according to DIN 2616, check WPHY 65 material chemical composition & equivalent

Price List of WPHY 65 Fittings

| Carbon Steel Grade 65 Pipe Fittings Price Per Piece in India | WPHY 65 Fittings Price in INR | API 5L X65 Buttweld Fittings Price in UAE Dirham | A860 MSS SP 75 WPHY 65 Weld Fittings Price in USD |

| 90 ELBOWS ASTM A860 WPHY 65 SIZE:30 INCH THK. 20.6 MM ASME B16.9 Per Kg | 308 | UAE Dirham 15.19 | $4.14 |

| REDUCING TEES ASTM A860 WPHY 65 SIZE:48 INCH X 24 INCH THK. 32.2 MM X SCH.80 ASME B16.9 Per Kg | 367 | UAE Dirham 18.10 | $4.93 |

| CAP ASTM 860 WPHY 65 SIZE:48 INCH THK. 30.2 MM ASME B16.9 Per Kg | 351 | UAE Dirham 17.31 | $4.71 |

| ASTM A860 WPHY65 8 X SCH. 140, EQ. TEE Per Kg | 278 | UAE Dirham 13.71 | $3.73 |

Petromet Flange Inc is of WPHY 65 Fittings Manufacturers in India as per ASME B16.9 Standards. WPHY Grade 65 Tee Offer Seamless Flow in various industries applications. This is an approximate Price of MSS SP 75 WPHY 65 Fittings in India.

Carbon Steel API 5L X65 Fittings Dimensions

| Nominal Pipe Size | Outside Diameter | 90° Elbows | 45° Elbows | 180° Returns | ||||

|---|---|---|---|---|---|---|---|---|

| (inches) | Long Radius | Short Radius | Long Radius | Long Radius | ||||

| (mm) | (inches) | Center to Face (inches) |

Center to Face (inches) |

Center to Face (inches) |

Radius (inches) |

Center to Center (inches) |

Back to face (inches) |

|

| 1/2 | 21.3 | 0.840 | 1 1/2 | - | 5/8 | 2 | 1 7/8 | |

| 3/4 | 26.7 | 1.050 | 1 1/8 | - | 7/16 | 2 1/4 | 1 11/16 | |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 | 7/8 | 3 | 2 3/16 | |

| 1 1/4 | 42.2 | 1.660 | 1 7/8 | 1 1/4 | 1 | 3 3/4 | 2 3/4 | |

| 1 1/2 | 48.3 | 1.900 | 2 1/4 | 1 1/2 | 1 1/8 | 3 | 4 1/2 | 3 1/4 |

| 2 | 60.3 | 2.375 | 3 | 2 | 1 3/8 | 4 | 6 | 4 3/16 |

| 2 1/2 | 73.0 | 2.875 | 3 3/4 | 2 1/2 | 1 3/4 | 5 | 7 1/2 | 5 3/16 |

| 3 | 88.9 | 3.500 | 4 1/2 | 3 | 2 | 6 | 9 | 6 1/4 |

| 3 1/2 | 101.6 | 4.000 | 5 1/4 | 3 1/2 | 2 1/4 | 7 | 10 1/2 | 7 1/4 |

| 4 | 114.3 | 4.500 | 6 | 4 | 2 1/2 | 8 | 12 | 8 1/4 |

| 5 | 141.3 | 5.563 | 7 1/2 | 5 | 3 1/8 | 10 | 15 | 10 5/16 |

| 6 | 168.3 | 6.625 | 9 | 6 | 3 3/4 | 12 | 18 | 12 5/16 |

| 8 | 219.1 | 8.625 | 12 | 8 | 5 | 12 | 24 | 16 5/16 |

| 10 | 273.1 | 10.750 | 15 | 10 | 6 1/4 | 15 | 30 | 20 3/8 |

| 12 | 323.9 | 12.750 | 18 | 12 | 7 1/2 | 18 | 36 | 24 3/8 |

Check API 5LWPHY 65 Cross Fittings, 45/ 90/ 180 Degree Elbow, Pipe Cap and WPHY 65 High Yield Return Bends dimensions in accordance with ASME B16.9/ ASME B16.28

Pressure Rating of WPHY 65 Buttweld Fittings

| Normal Size Of Pipe (inches) |

Pipe Sch | OD

(inch) |

Wall Thick. (inch) |

Temperature (oF) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 | 200 | 300 | 400 | 500 | 600 | 650 | 700 | 750 | ||||

| Allowable Stress (psi) | ||||||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | 13500 | 13200 | 12900 | 12600 | ||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 | 1783 | 1743 | 1703 | 1664 |

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | 2475 | 2420 | 2365 | 2310 | |

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | 3632 | 3552 | 3471 | 3390 | |

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 | 1317 | 1287 | 1258 | 1229 |

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | 1862 | 1821 | 1779 | 1738 | |

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | 2717 | 2657 | 2597 | 2536 | |

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 | 1108 | 1083 | 1059 | 1034 |

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | 1605 | 1569 | 1534 | 1498 | |

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | 2654 | 2595 | 2536 | 2477 | |

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 | 1052 | 1028 | 1005 | 982 |

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | 1491 | 1458 | 1425 | 1391 | |

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | 2253 | 2203 | 2153 | 2103 | |

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 | 891 | 871 | 851 | 831 |

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | 1291 | 1262 | 1233 | 1204 | |

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | 2111 | 2064 | 2017 | 1970 | |

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 | 780 | 763 | 746 | 728 |

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | 1154 | 1129 | 1103 | 1077 | |

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | 2000 | 1955 | 1911 | 1866 | |

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 | 709 | 693 | 677 | 661 |

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | 1115 | 1090 | 1065 | 1040 | |

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | 1925 | 1883 | 1840 | 1797 | |

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 | 623 | 610 | 596 | 582 |

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | 985 | 963 | 941 | 919 | |

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | 1858 | 1817 | 1775 | 1734 | |

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 | 565 | 553 | 540 | 528 |

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | 937 | 916 | 895 | 874 | |

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | 1850 | 1809 | 1768 | 1727 | |

ASTM A860 WPHY 65 Chemical Composition

| C | Mn | S | P | Si | Ni | Cr | Mo | Cu | Ti | V | Cb | Al |

| 0.20 | 1.00-1.45 | 0.03 | 0.01 | 0.15-0.40 | 0.50 | 0.30 | 0.25 | 0.35 | 0.05 | 0.10 | 0.06 |

WPHY 65 Mechanical Properties

| Element | Tensile Strength(Min PSI) | Yield Strength (Min PSI) | Elongation(%, in 2in.) |

| WPHY 65 | 77000 PSI | 65000 PSI | 20 % |

Physical Properties of A860 WPHY 65 3D Buttweld Tee

| Property | Temperature | Value |

| Charpy impactenergy | 23.0 °C | 40 J |

| Elastic modulus | 23.0 °C | 200 - 215 GPa |

| Elongation A50 | 23.0 °C | 0.28 |

| Hardness, Brinell | 23.0 °C | 235 [-] |

| Hardness, RockwellC | 23.0 °C | 22 [-] |

| Poisson's ratio | 23.0 °C | 0.29 [-] |

| Tensile strength | 23.0 °C | 530 - 705 MPa |

| Yield strengthRp0.2 | 23.0 °C | 450 MPa |

A860 WPHY X65 3D Elbow Thermal Properties

| Property | Temperature | Value |

| Coefficient of thermal expansion | 23.0 °C | 1.33E-5 1/K |

| Melting point | 1382 - 1529 °C | |

| Specific heat capacity | 23.0 °C | 510 - 553 J/(kg·K) |

| Thermal conductivity | 23.0 °C | 14 - 16 W/(m·K) |

Manufacturer of Seamless Butt weld WPHY 65 Short Radius Elbow and LR Elbow according to ASME B16.9

Various Types of WPHY 65 Fittings

CS Grade 65 High Yield Reducers

API 5L 65 Lap Joint Stub Ends

SCH 20 A860 MSS SP 75 WPHY 65 Equal Tee

ASTM A860 MSS SP 75 WPHY 65 Pipe Cap

SCH 80 Carbon WPHY 65 90° Short Radius Elbow

CS WPHY 65 10D ELBOW

SCH 10 Carbon Steel Grade 65 Long Stubend

MSS SP75 WPHY 65 Reducing Outlet Tees and Reducing Outlet Crosses

SCH 140 API 5L X65 Barrel Nipple

Carbon Steel API 5L X65 Collar

Grade 65 1D Elbow

SCH 30 WPHY Grade 65 Stub End

15 NB SCH 100 ASTM A860 Grade WPHY 65 Concentric Reducer

MSS SP-75 Gr WPHY 65 End Cap

A860 Grade WPHY 65 Welded Elbows

ASTM A860 Gr WPHY 65 Pipe Nipples

SCH STD WPHY Gr 65 Swage Nipple

MSS SP 75 WPHY 65 Straight Tees and Crosses

SCH XXS MSS SP75 WPHY Grade 65 1.5D Elbow

SCH 120 CS 65 Short Stubend

A860 Gr WPHY 65 180° Long Radius Elbow

MSS SP75 WPHY Gr 65 Reducing Nipple

A860 WPHY 65 Equal Cross

Gr 65 Carbon Steel 3D Elbow

SCH 60 Carbon Steel X65 45° Short Radius Elbow

Carbon Steel WPHY 65 90° Long Radius Elbow

ASTM A860 WPHY Gr 65 Long Radius Bend

Carbon 65 5D Elbow

SCH 160 Grade WPHY 65 Seamless Buttwelding 180° Returns

MSS SP75 65 Reducing Tee

450 NB SCH 40 API 5L WPHY 65 Bend

ASTM A860 WPHY Grade 65 180° Short Radius Elbow

CS Gr 65 High Yield Eccentric Reducer

Gr 65 Reducing Cross

SCH XS ASTM A860 WPHY 65 Seamless Buttwelding 45° and 90° Elbows

WPHY 65 45° Long Radius Elbow

Sizes of CS WPHY Gr 65 Reducer

| NOMINAL PIPE SIZE | END TO END | OUTSIDE DIAMETER | |

|---|---|---|---|

| Inch | H | D | P |

| 3/4 x 1/2 | 38 | 26.7 | 21.3 |

| 3/4 x 3/8 | 38 | 26.7 | 17.1 |

| 1 x 3/4 | 51 | 33.4 | 26.7 |

| 1 x 1/2 | 51 | 33.4 | 21.3 |

| 1 1/4 x 1 | 51 | 42.2 | 33.4 |

| 1 1/4 x 3/4 | 51 | 42.2 | 26.7 |

| 1 1/4 x 1/2 | 51 | 42.2 | 21.3 |

| 1 1/2 x 1 1/2 | 64 | 48.3 | 42.2 |

| 1 1/2 x 1 | 64 | 48.3 | 33.4 |

| 1 1/2 x 3/4 | 64 | 48.3 | 26.7 |

| 1 1/2 x 1/2 | 64 | 48.3 | 21.3 |

| 2 x 1 1/2 | 76 | 60.3 | 48.2 |

| 2 x 1 1/4 | 76 | 60.3 | 42.2 |

| 2 x 1 | 76 | 60.3 | 33.4 |

| 2 x 3/4 | 76 | 60.3 | 26.7 |

| 2 1/2 x 2 | 89 | 73 | 60.3 |

| 2 1/2 x 1 1/2 | 89 | 73 | 48.3 |

| 2 1/2 x 1 1/4 | 89 | 73 | 42.2 |

| 2 1/2 x 1 | 89 | 73 | 33.4 |

| 3 x 2 1/2 | 89 | 88.9 | 73 |

| 3 x 2 | 89 | 88.9 | 60.3 |

| 3 x 1 1/2 | 89 | 88.9 | 48.3 |

| 3 x 1 1/4 | 89 | 88.9 | 42.2 |

| 3 1/2 x 3 | 102 | 101.6 | 88.9 |

| 3 1/2 x 21/2 | 102 | 101.6 | 73 |

| 3 1/2 x 2 | 102 | 101.6 | 60.3 |

| 3 1/2 x 1 1/2 | 102 | 101.6 | 48.3 |

| 3 1/2 x 1 1/4 | 102 | 101.6 | 42.2 |

| 4 x 3 1/2 | 102 | 114.3 | 101.6 |

| 4 x 3 | 102 | 114.3 | 88.9 |

| 4 x 2 1/2 | 102 | 114.3 | 73 |

| 4 x 2 | 102 | 114.3 | 60.3 |

| 4 x 1 1/2 | 102 | 114.3 | 48.3 |

| 5 x 4 | 127 | 141.3 | 114.3 |

| 5 x 3 1/2 | 127 | 141.3 | 101.6 |

| 5 x 3 | 127 | 141.3 | 88.9 |

| 5 x 2 1/2 | 127 | 141.3 | 73 |

| 5 x 2 | 127 | 141.3 | 60.3 |

| 6 x 5 | 140 | 168.3 | 141.3 |

| 6 x 4 | 140 | 168.3 | 114.3 |

| 6 x 3 1/2 | 140 | 168.3 | 101.6 |

| 6 x 3 | 140 | 168.3 | 88.9 |

| 6 x 2 1/2 | 140 | 168.3 | 73 |

| 8 x 6 | 152 | 219.1 | 168.3 |

| 8 x 5 | 152 | 219.1 | 141.3 |

| 8 x 4 | 152 | 219.1 | 114.3 |

| 8 x 3 1/2 | 152 | 219.1 | 101.6 |

| 10 x 8 | 178 | 273.1 | 219.1 |

| 10 x 6 | 178 | 273.1 | 168.1 |

| 10 x 5 | 178 | 273.1 | 141.3 |

| 10 x 4 | 178 | 273.1 | 114.3 |

| 12 x 10 | 203 | 323.9 | 273.1 |

| 12 x 8 | 203 | 323.9 | 219.1 |

| 12 x 6 | 203 | 323.9 | 168.3 |

| 12 x 5 | 203 | 323.9 | 141.3 |

| 14 x 12 | 330 | 355.6 | 323.9 |

| 14 x 10 | 330 | 355.6 | 273.1 |

| 14 x 8 | 330 | 355.6 | 219.1 |

| 14 x 6 | 330 | 355.6 | 168.3 |

| 16 x 14 | 356 | 406.4 | 355.6 |

| 16 x 12 | 356 | 406.4 | 323.9 |

| 16 x 10 | 356 | 406.4 | 273.1 |

| 16 x 8 | 356 | 406.4 | 219.1 |

| 16 x 6 | 356 | 406.4 | 168.3 |

| 18 x 16 | 381 | 457 | 406.4 |

| 18 x 14 | 381 | 457 | 355.6 |

| 18 x 12 | 381 | 457 | 323.9 |

| 18 x 10 | 381 | 457 | 273.1 |

| 18 x 8 | 381 | 457 | 219.1 |

| 20 x 18 | 508 | 508 | 457 |

| 20 x 16 | 508 | 508 | 406.4 |

| 20 x 14 | 508 | 508 | 355.6 |

| 20 x 12 | 508 | 508 | 323.9 |

| 20 x 10 | 508 | 508 | 273.1 |

| 20 x 8 | 508 | 508 | 219.1 |

| 22 x 20 | 508 | 559 | 508 |

| 22 x 18 | 508 | 559 | 457 |

| 22 x 16 | 508 | 559 | 406.4 |

| 22 x 14 | 508 | 559 | 355.6 |

| 22 x 12 | 508 | 559 | 323.9 |

| 24 x 10 | 508 | 559 | 273.1 |

| 24 x 22 | 508 | 610 | 559 |

| 24 x 20 | 508 | 610 | 508 |

| 24 x 18 | 508 | 610 | 457 |

| 24 x 16 | 508 | 610 | 406.4 |

| 24 x 14 | 508 | 610 | 355.6 |

| 24 x 12 | 508 | 610 | 323.9 |

| 24 x 10 | 508 | 610 | 273.1 |

Dimensions Table of MSS SP75 WPHY 65 Reducer

| Nominal Pipe Size |

Outside Diameter |

Reducers | ||

|---|---|---|---|---|

| Reduced from (inches) |

(inches) | (mm) | Concentric & Eccentric Length (inches) |

Reduced to (inches) |

| 1/2 | 0.840 | 21.3 | 1 1/2 | 1/4 |

| 1 1/2 | 3/8 | |||

| 3/4 | 1.050 | 26.7 | 2 | 3/8 |

| 2 | 1/2 | |||

| 1 | 1.315 | 33.4 | 2 | 3/8 |

| 2 | 1/2 | |||

| 2 | 3/4 | |||

| 1 1/4 | 1.660 | 42.2 | 2 | 1/2 |

| 2 | 3/4 | |||

| 2 | 1 | |||

| 1 1/2 | 1.900 | 48.3 | 2 1/2 | 1/2 |

| 2 1/2 | 3/4 | |||

| 2 1/2 | 1 | |||

| 2 1/2 | 1 1/4 | |||

| 2 | 2.375 | 60.3 | 3 | 3/4 |

| 3 | 1 | |||

| 3 | 1 1/4 | |||

| 3 | 1 1/2 | |||

| 2 1/2 | 2.875 | 73.0 | 3 1/2 | 1 |

| 3 1/2 | 1 1/4 | |||

| 3 1/2 | 1 1/2 | |||

| 3 1/2 | 2 | |||

| 3 | 3.500 | 88.9 | 3 1/2 | 1 |

| 3 1/2 | 1 1/2 | |||

| 3 1/2 | 2 | |||

| 3 1/2 | 2 1/2 | |||

| 3 1/2 | 4.000 | 101.6 | 4 | 1 1/4 |

| 4 | 1 1/2 | |||

| 4 | 2 | |||

| 4 | 2 1/2 | |||

| 4 | 3 | |||

| 4 | 4.500 | 114.3 | 4 | 1 1/2 |

| 4 | 2 | |||

| 4 | 2 1/2 | |||

| 4 | 3 | |||

| 4 | 3 1/2 | |||

| 5 | 5.563 | 141.3 | 5 | 2 |

| 5 | 2 1/2 | |||

| 5 | 3 | |||

| 5 | 3 1/2 | |||

| 5 | 4 | |||

| 6 | 6.625 | 168.3 | 5 1/2 | 2 1/2 |

| 5 1/2 | 3 | |||

| 5 1/2 | 3 1/2 | |||

| 5 1/2 | 4 | |||

| 5 1/2 | 5 | |||

| 8 | 8.625 | 219.1 | 6 | 3 |

| 6 | 3 1/2 | |||

| 6 | 4 | |||

| 6 | 5 | |||

| 6 | 6 | |||

| 10 | 10.750 | 273.1 | 7 | 4 |

| 7 | 5 | |||

| 7 | 6 | |||

| 7 | 8 | |||

| 12 | 12.750 | 323.9 | 8 | 5 |

| 8 | 6 | |||

| 8 | 8 | |||

| 8 | 10 | |||

A860 Grade WPHY 65 Tee Dimensions Table

| NOMINAL PIPE SIZE | LENGTH | CENTER TO END | OUTSIDE DIAMETER |

|---|---|---|---|

| Inch. | M | C | OD |

| 1/2 | 25 | 25 | 21.3 |

| 3/4 | 29 | 29 | 26.7 |

| 1 | 38 | 38 | 33.4 |

| 1 1/4 | 48 | 48 | 42.2 |

| 1 1/2 | 57 | 57 | 48.3 |

| 2 | 64 | 64 | 60.3 |

| 2 1/2 | 76 | 76 | 73 |

| 3 | 86 | 86 | 88.9 |

| 3 1/2 | 95 | 95 | 101.6 |

| 4 | 105 | 105 | 114.3 |

| 5 | 124 | 124 | 141.3 |

| 6 | 143 | 143 | 168.3 |

| 8 | 178 | 178 | 219.1 |

| 10 | 216 | 216 | 273.1 |

| 12 | 254 | 254 | 323.9 |

| 14 | 279 | 279 | 355.6 |

| 16 | 305 | 305 | 406.4 |

| 18 | 343 | 343 | 457.2 |

| 20 | 381 | 381 | 508 |

| 22 | 419 | 419 | 559 |

| 24 | 432 | 432 | 610 |

| 26 | 495 | 495 | 660 |

| 28 | 521 | 521 | 711 |

| 30 | 559 | 559 | 762 |

| 32 | 597 | 597 | 813 |

| 34 | 635 | 635 | 864 |

| 36 | 673 | 673 | 914 |

| 38 | 711 | 711 | 965 |

| 40 | 749 | 749 | 1016 |

| 42 | 711 | 762 | 1067 |

| 44 | 762 | 813 | 1118 |

| 46 | 800 | 851 | 1168 |

| 48 | 838 | 889 | 1219 |

Weight Chart of Carbon Steel X65 Tee

| NPS | KG | LBS |

| 1/2 | 0.16 | 0.35 |

| 3/4 | 0.2 | 0.45 |

| 1 | 0.34 | 0.75 |

| 1¼ | 0.59 | 1.3 |

| 1½ | 0.91 | 2 |

| 2 | 1.59 | 3.5 |

| 2½ | 2.72 | 6 |

| 3 | 3.18 | 7 |

| 3½ | 4.08 | 9 |

| 4 | 5.44 | 12 |

| 5 | 9.53 | 21 |

| 6 | 15.42 | 34 |

| 8 | 24.95 | 55 |

| 10 | 38.56 | 85 |

| 12 | 54.43 | 120 |

| 14 | 74.84 | 165 |

| 16 | 88.45 | 195 |

| 18 | 112.94 | 249 |

| 20 | 155.13 | 342 |

| 22 | 187.79 | 414 |

| 24 | 239.5 | 528 |

| 26 | 349.27 | 770 |

| 30 | 480.81 | 1060 |

| 36 | 675.85 | 1490 |

WPHY Gr 65 High Yield Elbow Weight

| NPS | KG | LBS |

| 1/2 | 0.11 | 0.25 |

| 3/4 | 0.11 | 0.25 |

| 1 | 0.23 | 0.5 |

| 1¼ | 0.41 | 0.9 |

| 1½ | 0.52 | 1.15 |

| 2 | 1 | 2.2 |

| 2½ | 1.81 | 4 |

| 3 | 2.95 | 6.5 |

| 3½ | 3.79 | 8.35 |

| 4 | 6.12 | 13.5 |

| 5 | 9.98 | 22 |

| 6 | 15.88 | 35 |

| 8 | 32.21 | 71 |

| 10 | 48.53 | 107 |

| 12 | 72.57 | 160 |

| 14 | 92.99 | 205 |

| 16 | 125.19 | 276 |

| 18 | 154.22 | 340 |

| 20 | 190.51 | 420 |

| 22 | 235.87 | 520 |

| 24 | 272.16 | 600 |

| 26 | 330.67 | 729 |

| 30 | 442.25 | 975 |

| 36 | 640.47 | 1412 |

Tolerance of CS Grade 65 Elbow

| WPHY 65 Tolerance | 90 Deg And 45 Deg Elbows And Pipe Tee |

Reducer (Concentric/ Eccentric) & Lap Joint Stub End (Long / Short) |

Pipe End Caps | |||

| Nominal Pipe Sizes (NPS) Of ASME B16.9 | O. (Outside) D. (Daimeter) at Bevel |

I. (Inside) D.(Daimeter) at End |

Wall Thickness Of T | Center-to-End Dimension A ,C ,B |

Over-all Length Of H |

Over-all Length Of F |

| 1/2 to 2-1/2 | +0.06 | Not less than 87.5% of nominal thickness |

+/- 0.06 | +/- 0.06 | +/- 0.12 | |

| -0.03 | ||||||

| 3 to 3-1/2 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.12 | |

| 4 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.12 | |

| 5 to 8 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.25 | |

| 10 to 18 | +0.16 | +/- 0.12 | +/- 0.09 | +/- 0.09 | +/- 0.25 | |

| -0.12 | ||||||

| 20 to 24 | +0.25 | +/- 0.19 | +/- 0.09 | +/- 0.09 | +/- 0.25 | |

| -0.19 | ||||||

| 26 to 30 | +0.25 | +/- 0.19 | +/- 0.12 | +/- 0.19 | +/- 0.38 | |

| -0.19 | ||||||

| 32 to 48 | +0.25 | +/- 0.19 | +/- 0.19 | +/- 0.19 | +/- 0.38 | |

| -0.19 | ||||||

We sale Carbon Steel X65 Fittings

| CS WPHY Grade 65 Long Radius Bend | A860 WPHY 65 CS Pipe Cap |

| API 5L 65 Elbow Pipe Fittings | Grade 65 Eccentric Reducer |

| ASTM A860 WPHY 65 Reducer | WPHY 65 Reducing Cross |

| Gr 65 Carbon Steel 45 Deg Short Radius Elbow | MSS SP75 65 Seamless Pipe Fitting |

| Gr 65 Seamless Bend Pipe | Carbon Steel WPHY Grade 65 End Cap |

| CS WPHY 65 180 Deg Short Radius Elbow | Carbon Steel API 5L X65 End Pipe Cap |

| WPHY Grade 65 High Yield Concentric Reducer Fittings | CS Gr 65 High Yield Pipe Bends |

| API 5LWPHY Gr 65 Pipe End Cap | WPHY Gr 65 Carbon Steel Equal Tee Fittings |

| Carbon 65 Pipe Reducer | API 5L WPHY 65 BW Tee Fittings |

| ASTM A860 Gr WPHY 65 Buttweld Elbow | Carbon Steel Grade 65 Pipe Tee Fittings |

| WPHY Gr 65 High Yield 90 Deg Short Radius Elbow | Carbon Steel WPHY Gr 65 Straight Cross |

| CS Gr 65 High Yield Eccentric Reducer | API 5L WPHY Grade 65 180 Deg Long Radius Elbow |

| CS WPHY Gr 65 Equal Cross | ASTM A860 Grade WPHY 65 Seamless Butt Weld Fittings |

| ASTM A860 WPHY 65 45 Deg Long Radius Elbow | CS 65 Pipe Cross |

| MSS SP75 65 Pipe Nipple | CS Grade 65 High Yield Lateral Tee |

| WPHY Grade 65 CS Stubends Fittings | Grade 65 Welded Pipe Fittings |

| CS Grade 65 High Yield 5D Bend | Carbon Steel X65 Stub End |

| WPHY Grade 65 Carbon Steel Seamless Tee Fittings | Gr 65 Carbon Steel Cross |

| CS Grade 65 High Yield U Bend | CS WPHY 65 High Yield Reducing Tee Fittings |

| Gr 65 Buttweld Fittings | API 5L X65 Tees |

| API 5L X65 Elbow Fittings | Carbon WPHY 65 90 Deg Long Radius Elbow |

MSS SP 75 WPHY 65 Fittings Applications

- High Pressure Applications

- Chemical Refinery

- Paper & Pulp

- High Temperature Application

- Oil and Gas Industry

- Food Processing and Dairy Industries

- Nuclear Power Plants

- Water Pipe Line

Value Added Services of WPHY 65 Pipe Fittings

- Eddy current examining

- Small tests

- Hydrostatic analysis

- X-ray test

- Firmness test

- Large-scale test

- Chemical examination

- Prompt test

- Positive material recognition

- Impact analysis

- Pitting protection test

Pipe Fittings Material

Flanges Material

Other Products