- Call : +91 22 67436442

- exports@petrometflange.com

Stainless Steel 304L Pipe Fittings

- Home /

- Stainless Steel 304L Pipe Fittings

SA 403 WP 304L Elbow & ASTM A403 Gr WP304L Tee manufacturer in India

What is Stainless Steel 304L Pipe Fittings?

The Stainless Steel 304L Pipe Fittings are made of 18% chromium and 8% nickel and several other elements in the alloy. They have a high strength and are capable of resisting high temperatures. The Stainless Steel 304L Pipe Fittings can be forged and they are available with the outer diameter’s size range of 1/16” to 2”. They can effectively withstand high temperature and high pressure.

The Stainless Steel 304L materials are popular for their high strength- their min yield strength is 250 MPa, and their min tensile strength comes around 515 MPa. Their performance remains unaffected upto the temperature of 870 degrees C. The wrought products of the Stainless Steel 304L material are available and they give better performances in high temperature and high pressure environments. The carbon content is really low in the Stainless Steel 304L Pipe Fittings which makes the welding operations very smooth here.

At the time of welding, the chances of carbide precipitate formation is very low. The chemical composition also helps in avoiding intergranular corrosion as well as localized corrosion. Due to all these properties, the fittings are used in a wide range of applications in the marine, pharmaceuticals, medical, and many more industries. These fittings are available in seamless and welded variants, where the former is used for precise applications and the later can be used for any application.

304L Stainless Steel Socket Weld Fittings Vs Stainless Steel 304L Threaded Fittings

The 304L Stainless Steel Socket Weld Fittings is a pipe attachment wherein the pipe is put into the recessed area of the fitting. They are mainly used for the pipes with a smaller diameter, generally whose nominal diameter is less than or equal to NPS 2. The 304L Stainless Steel Socket Weld Fittings have great structural strength and they also possess good leakage integrity.

The Stainless Steel 304L Threaded Fittings are connected to the piping system by either internal or external threads. Their diameters are often less than or equal to 4” in most of the cases and it is the most traditional pipe connection used till today. They are easy to install, simple to use and are mostly preferred in places where frequent maintenance is required. This is because they can be assembled and disassembled easily.

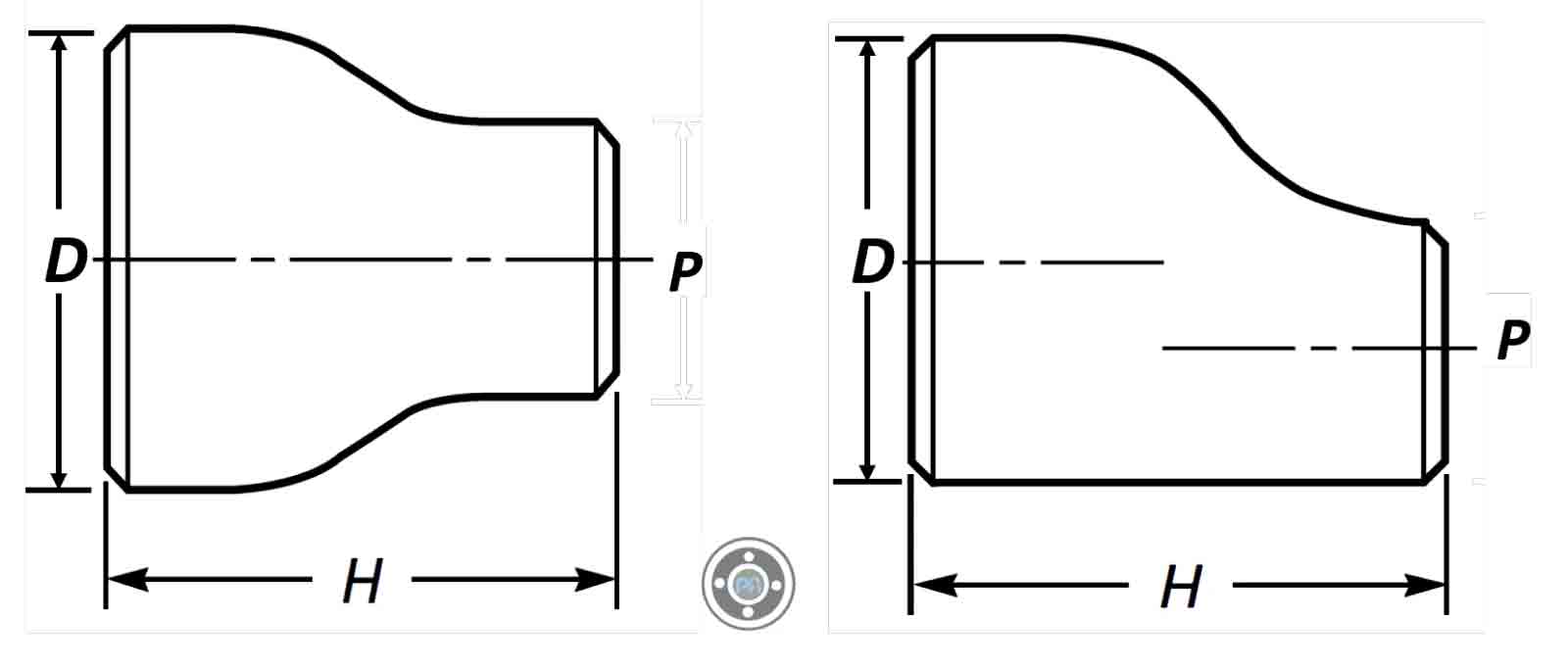

ASTM A403 WP304L Reducer Vs Asme Sa403 WP304L End Cap

The ASTM A403 WP304L Reducer is a pipe fitting that is primarily used in process piping. It helps to reduce the size of the pipe for a larger to a smaller bpre. It basically helps to meet the hydraulic flow requirements of the piping system. Or, they can help the existing pipe to adapt to a different size.

The Asme Sa403 WP304L End Cap is a protective fitting that helps to protect the ends of the piping system. They are available in various shapes, sizes and can be customized according to the dimensions of the pipe. They are mainly used for that area of the piping system, which is not in active use.

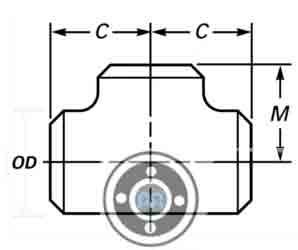

UNS S30403 Tee and Din 1.4306 Elbow

The UNS S30403 Tee looks like the alphabet T. It comes with two branches and one main pipe line. The branches are located at 90 degrees to the main connection pipe, and they can help to combine or divide the flow. The UNS S30403 Tee also helps in adjusting the rate of flow and changing its direction. There are two types of tee fittings, namely equal tee where diameter of the branch pipe is same as the main connection pipe, and reducing tee where the branch’s diameters are smaller compared to the main pipe connection.

The Din 1.4306 Elbow is specifically designed to change the direction of flow in different angles. They are available with 45 degrees and 90 degrees bend and the direction of pipe run can be changed by installing them accordingly.

Stainless Steel 304L Pipe Fittings

European Directive 2014/68/eu certified 304L Stainless Steel Pipe Fittings manufacturers in Mumbai offers large selection of ASTM A403 WP304L Stub End and SS 304L Eccentric / Concentric Reducer in India

Table of Content

- Stainless Steel 304L Pipe Fittings Specification

- SUS 304L Buttweld Fittings Dimensions

- Size Chart of 304L SS Reducer

- 304l SS Socket Weld Fittings

- 304l Stainless Steel Threaded Fittings

- SS 304l Forged Fittings

- Din 1.4306 Tee Dimensions

- Price List of Stainless Steel 304L Pipe Fittings

- A403 WP304L Elbow

- UNS S30403 Tee

- 304L Stainless Steel Reducer

- Stainless Steel 304L Elbow Weight Chart

- Size range of ASTM A403 WP304L Fittings

- Types of Stainless Steel 304L Pipe Fittings

- 304L Stainless Weld Fittings Chemical Properties

- Mechanical Properties of 304L SS Elbow

- Physical Properties of A182 F304L Forged Fitting

- Equivalent Grade of SS 304L Hex Nipple

- Tolerance Chart of 304L stainless steel fittings

- Value Added Services of Asme Sa403 WP304L Fitting

- SS 304L Buttweld Fittings Applications

- Heat Resistance of 304L SS Weld Fittings

Stainless Steel 304L Pipe Fittings Specification

| 304L ss weld fittings Specifications | ASTM A403 |

|---|---|

| Stainless Steel 304L Pipe Fittings Sizes | 304L stainless steel Seamless Fittings: 1/2" - 10" ASME B16 9 304L ss Welded Fittings: 1/2" - 48" |

| ASTM A403 WP304L Buttweld Fittings Dimensions | ASME B16.28, ASME/ANSI B16.9, BS4504, MSS-SP-43, BS1560, BS4504, BS10 |

| 304L stainless fittings Thickness | SCH30, SCH10, SCH 160, SCH20, SCH60, XS, STD SCH40, SCH 80, SCH 120, SCH 140, SCH 100, XXS available with NACE MR 01-75 |

| 304L stainless steel fittings Type Manufacturer | DN15-DN1200 |

| a403 grade wp304L fittings Connection | Welding |

| Bending Radius Provided By Manufacturer | R=1D, 3D, 2D, 5D, 8D, 6D, 10D or Custom Stainless Steel 304L Pipe Fittings |

| Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) 304L stainless steel fittings |

| Stainless Steel 304L Elbow Manufacturer | Angle : 22.5 deg, 45 deg, 30deg, 90 deg, 1.0D, 180 deg, 1.5D, 3D, 2.5D, 2.0D, 4D, 6D, 5D, 7D-40D . Standard: ASME B16.28, GB, ASME B16.9, MSS SP-75 JISB2311 DIN2605 JISB2312 JISB2313, ASME B16.25, BS, ISO |

| stainless steel 304L fittings Manufacturing process | Push, Forge, Press, Cast, etc. |

| Test Certificates By SS 304L Pipe Fittings Manufacturer | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| 304L pipe fittings Origin & Mills | European, Japanese, USA, Korean, Ukraine, Indian, Russian |

| Specialized manufacturer of | UNS S30403 Stub End, 90º Elbows, Tees, Pipe Cap, Crosses, 45º Elbows, Reducers, Pipe Bend |

| Application of Industrial stainless steel 304L fittings |

|

| ASTM A182 Gr 304L Fittings Thread By Manufacturer | BSPT, NPT, BSPP |

| SS 304L Forged Fittings Pressure Rating | Threaded end - 3000lb/ 2000lb/ 6000lbs Socket weld end- 6000/ 3000/ 9000lbs |

| Dimension Specification | MSS SP-79, 95, 83, 97, BS 3799, ASME 16.11 |

| 304l ss socket weld fittings Manufacturer | Half Coupling, Union, Tee, Cross, Coupling, Cap, Outlet, Welding Outlet, Boss, Insert |

Biggest SS 304L Pipe Fittings dealers, stockholders, wholesalers, supplier, importer, stockists, distributor, exporters and Manufacturer in Mumbai

SUS 304L Buttweld Fittings Dimensions

| Nominal Pipe Size | Outside Diameter | 90° Elbows | 45° Elbows | 180° Returns | ||||

|---|---|---|---|---|---|---|---|---|

| (inches) | Long Radius | Short Radius | Long Radius | Long Radius | ||||

| (mm) | (inches) | Center to Face (inches) | Center to Face (inches) | Center to Face (inches) | Radius (inches) | Center to Center (inches) | Back to face (inches) | |

| 1/2 | 21.3 | 0.840 | 1 1/2 | - | 5/8 | 2 | 1 7/8 | |

| 3/4 | 26.7 | 1.050 | 1 1/8 | - | 7/16 | 2 1/4 | 1 11/16 | |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 | 7/8 | 3 | 2 3/16 | |

| 1 1/4 | 42.2 | 1.660 | 1 7/8 | 1 1/4 | 1 | 3 3/4 | 2 3/4 | |

| 1 1/2 | 48.3 | 1.900 | 2 1/4 | 1 1/2 | 1 1/8 | 3 | 4 1/2 | 3 1/4 |

| 2 | 60.3 | 2.375 | 3 | 2 | 1 3/8 | 4 | 6 | 4 3/16 |

| 2 1/2 | 73.0 | 2.875 | 3 3/4 | 2 1/2 | 1 3/4 | 5 | 7 1/2 | 5 3/16 |

| 3 | 88.9 | 3.500 | 4 1/2 | 3 | 2 | 6 | 9 | 6 1/4 |

| 3 1/2 | 101.6 | 4.000 | 5 1/4 | 3 1/2 | 2 1/4 | 7 | 10 1/2 | 7 1/4 |

| 4 | 114.3 | 4.500 | 6 | 4 | 2 1/2 | 8 | 12 | 8 1/4 |

| 5 | 141.3 | 5.563 | 7 1/2 | 5 | 3 1/8 | 10 | 15 | 10 5/16 |

| 6 | 168.3 | 6.625 | 9 | 6 | 3 3/4 | 12 | 18 | 12 5/16 |

| 8 | 219.1 | 8.625 | 12 | 8 | 5 | 12 | 24 | 16 5/16 |

| 10 | 273.1 | 10.750 | 15 | 10 | 6 1/4 | 15 | 30 | 20 3/8 |

| 12 | 323.9 | 12.750 | 18 | 12 | 7 1/2 | 18 | 36 | 24 3/8 |

Sch40 (Std) seamless butt weld SA 403 WP 304L Pipe Bend/ Return Bends and ASTM A403 WP304L Long/ Short Radius Elbow manufacturer in India

Size Chart of 304L SS Reducer

| NOMINAL PIPE SIZE | END TO END | OUTSIDE DIAMETER | |

|---|---|---|---|

| Inch | H | D | P |

| 3/4 x 1/2 | 38 | 26.7 | 21.3 |

| 3/4 x 3/8 | 38 | 26.7 | 17.1 |

| 1 x 3/4 | 51 | 33.4 | 26.7 |

| 1 x 1/2 | 51 | 33.4 | 21.3 |

| 1 1/4 x 1 | 51 | 42.2 | 33.4 |

| 1 1/4 x 3/4 | 51 | 42.2 | 26.7 |

| 1 1/4 x 1/2 | 51 | 42.2 | 21.3 |

| 1 1/2 x 1 1/2 | 64 | 48.3 | 42.2 |

| 1 1/2 x 1 | 64 | 48.3 | 33.4 |

| 1 1/2 x 3/4 | 64 | 48.3 | 26.7 |

| 1 1/2 x 1/2 | 64 | 48.3 | 21.3 |

| 2 x 1 1/2 | 76 | 60.3 | 48.2 |

| 2 x 1 1/4 | 76 | 60.3 | 42.2 |

| 2 x 1 | 76 | 60.3 | 33.4 |

| 2 x 3/4 | 76 | 60.3 | 26.7 |

| 2 1/2 x 2 | 89 | 73 | 60.3 |

| 2 1/2 x 1 1/2 | 89 | 73 | 48.3 |

| 2 1/2 x 1 1/4 | 89 | 73 | 42.2 |

| 2 1/2 x 1 | 89 | 73 | 33.4 |

| 3 x 2 1/2 | 89 | 88.9 | 73 |

| 3 x 2 | 89 | 88.9 | 60.3 |

| 3 x 1 1/2 | 89 | 88.9 | 48.3 |

| 3 x 1 1/4 | 89 | 88.9 | 42.2 |

| 3 1/2 x 3 | 102 | 101.6 | 88.9 |

| 3 1/2 x 21/2 | 102 | 101.6 | 73 |

| 3 1/2 x 2 | 102 | 101.6 | 60.3 |

| 3 1/2 x 1 1/2 | 102 | 101.6 | 48.3 |

| 3 1/2 x 1 1/4 | 102 | 101.6 | 42.2 |

| 4 x 3 1/2 | 102 | 114.3 | 101.6 |

| 4 x 3 | 102 | 114.3 | 88.9 |

| 4 x 2 1/2 | 102 | 114.3 | 73 |

| 4 x 2 | 102 | 114.3 | 60.3 |

| 4 x 1 1/2 | 102 | 114.3 | 48.3 |

| 5 x 4 | 127 | 141.3 | 114.3 |

| 5 x 3 1/2 | 127 | 141.3 | 101.6 |

| 5 x 3 | 127 | 141.3 | 88.9 |

| 5 x 2 1/2 | 127 | 141.3 | 73 |

| 5 x 2 | 127 | 141.3 | 60.3 |

| 6 x 5 | 140 | 168.3 | 141.3 |

| 6 x 4 | 140 | 168.3 | 114.3 |

| 6 x 3 1/2 | 140 | 168.3 | 101.6 |

| 6 x 3 | 140 | 168.3 | 88.9 |

| 6 x 2 1/2 | 140 | 168.3 | 73 |

| 8 x 6 | 152 | 219.1 | 168.3 |

| 8 x 5 | 152 | 219.1 | 141.3 |

| 8 x 4 | 152 | 219.1 | 114.3 |

| 8 x 3 1/2 | 152 | 219.1 | 101.6 |

| 10 x 8 | 178 | 273.1 | 219.1 |

| 10 x 6 | 178 | 273.1 | 168.1 |

| 10 x 5 | 178 | 273.1 | 141.3 |

| 10 x 4 | 178 | 273.1 | 114.3 |

| 12 x 10 | 203 | 323.9 | 273.1 |

| 12 x 8 | 203 | 323.9 | 219.1 |

| 12 x 6 | 203 | 323.9 | 168.3 |

| 12 x 5 | 203 | 323.9 | 141.3 |

| 14 x 12 | 330 | 355.6 | 323.9 |

| 14 x 10 | 330 | 355.6 | 273.1 |

| 14 x 8 | 330 | 355.6 | 219.1 |

| 14 x 6 | 330 | 355.6 | 168.3 |

| 16 x 14 | 356 | 406.4 | 355.6 |

| 16 x 12 | 356 | 406.4 | 323.9 |

| 16 x 10 | 356 | 406.4 | 273.1 |

| 16 x 8 | 356 | 406.4 | 219.1 |

| 16 x 6 | 356 | 406.4 | 168.3 |

| 18 x 16 | 381 | 457 | 406.4 |

| 18 x 14 | 381 | 457 | 355.6 |

| 18 x 12 | 381 | 457 | 323.9 |

| 18 x 10 | 381 | 457 | 273.1 |

| 18 x 8 | 381 | 457 | 219.1 |

| 20 x 18 | 508 | 508 | 457 |

| 20 x 16 | 508 | 508 | 406.4 |

| 20 x 14 | 508 | 508 | 355.6 |

| 20 x 12 | 508 | 508 | 323.9 |

| 20 x 10 | 508 | 508 | 273.1 |

| 20 x 8 | 508 | 508 | 219.1 |

| 22 x 20 | 508 | 559 | 508 |

| 22 x 18 | 508 | 559 | 457 |

| 22 x 16 | 508 | 559 | 406.4 |

| 22 x 14 | 508 | 559 | 355.6 |

| 22 x 12 | 508 | 559 | 323.9 |

| 24 x 10 | 508 | 559 | 273.1 |

| 24 x 22 | 508 | 610 | 559 |

| 24 x 20 | 508 | 610 | 508 |

| 24 x 18 | 508 | 610 | 457 |

| 24 x 16 | 508 | 610 | 406.4 |

| 24 x 14 | 508 | 610 | 355.6 |

| 24 x 12 | 508 | 610 | 323.9 |

| 24 x 10 | 508 | 610 | 273.1 |

304l SS Socket Weld Fittings

ASME B16.11 A182 F304l Socket Weld Elbow

304L SS SW Tee

UNS S30400 Socket Weld Half Coupling

304l Stainless Steel Threaded Fittings

SS 304L Threaded Elbow

A182 Grade F304L Threaded Reducing Tee

UNS S30400 Threaded Coupling

SS 304l Forged Fittings

304L Stainless Steel Forged Equal Tee

SS 304L Forged Elbow

ASTM A182 F304L Coupling

Schedule 10/10S/40/40S BW 1.4307 Stainless Steel Reducing Tee, Cap and ASTM A403 WP304L Elbow material manufacturer in India

Din 1.4306 Tee Dimensions

| NOMINAL PIPE SIZE | LENGTH | CENTER TO END | OUTSIDE DIAMETER |

|---|---|---|---|

| Inch. | M | C | OD |

| 1/2 | 25 | 25 | 21.3 |

| 3/4 | 29 | 29 | 26.7 |

| 1 | 38 | 38 | 33.4 |

| 1 1/4 | 48 | 48 | 42.2 |

| 1 1/2 | 57 | 57 | 48.3 |

| 2 | 64 | 64 | 60.3 |

| 2 1/2 | 76 | 76 | 73 |

| 3 | 86 | 86 | 88.9 |

| 3 1/2 | 95 | 95 | 101.6 |

| 4 | 105 | 105 | 114.3 |

| 5 | 124 | 124 | 141.3 |

| 6 | 143 | 143 | 168.3 |

| 8 | 178 | 178 | 219.1 |

| 10 | 216 | 216 | 273.1 |

| 12 | 254 | 254 | 323.9 |

| 14 | 279 | 279 | 355.6 |

| 16 | 305 | 305 | 406.4 |

| 18 | 343 | 343 | 457.2 |

| 20 | 381 | 381 | 508 |

| 22 | 419 | 419 | 559 |

| 24 | 432 | 432 | 610 |

| 26 | 495 | 495 | 660 |

| 28 | 521 | 521 | 711 |

| 30 | 559 | 559 | 762 |

| 32 | 597 | 597 | 813 |

| 34 | 635 | 635 | 864 |

| 36 | 673 | 673 | 914 |

| 38 | 711 | 711 | 965 |

| 40 | 749 | 749 | 1016 |

| 42 | 711 | 762 | 1067 |

| 44 | 762 | 813 | 1118 |

| 46 | 800 | 851 | 1168 |

| 48 | 838 | 889 | 1219 |

Price List of Stainless Steel 304L Pipe Fittings

| Stainless Steel 304L Pipe Fittings Price Per Piece in India | UNS S30400 Fittings Price in INR | ASTM A403 WP304L Fittings Price in UAE Dirham | Din 1.4301 Weld Fittings Price in USD |

| 6" Nb Sch10s Cap Butt Weld 304l Stainless Steel Per Piece | 6008.81 | UAE Dirham 298.06 | $81.15 |

| 1" X 1/2" Nb Sch10s Concentric Reducer 304l Welded Stainless Steel Per Piece | 858.35 | UAE Dirham 42.57 | $11.59 |

| 3" Nb Sch10s Equal Tee 304l Welded Stainless Steel Per Piece | 3490.41 | UAE Dirham 173.11 | $47.13 |

| 5" Nb Sch10s 45° Long Radius Elbow Butt Weld 304l Stainless Steel Per Piece | 3771.84 | UAE Dirham 187.07 | $50.93 |

| 1" Nb Sch10s 90° Short Radius Elbow 304l Welded Stainless Steel Per Piece | 794.66 | UAE Dirham 39.41 | $10.73 |

| 3" Nb Sch10s Stub End Type A 304l Welded Stainless Steel Per Piece | 4408.01 | UAE Dirham 218.62 | $59.52 |

Check our price with other SS 304L Pipe Fittings manufacturer in India Before Purchasing. This is an approximate Price of A403 Grade WP304L Fittings in India. Feel free to contact us latest Stocklist of A182 F304L Forged Fitting in Mumbai.

A403 WP304L Elbow

2-1/2" Nb Sch10s 90° Long Radius Elbow 304l Stainless Steel

2" Nb Sch10s Stainless Steel 304L Elbow

4" Nb Sch10s 45° Long Radius Elbow 304l Stainless Steel

UNS S30403 Tee

6" Nb Sch10s Equal Tee 304l Stainless Steel

1-1/4" X 1" Nb Sch10s Reducing Tee 304l Stainless Steel

3" Nb Sch10s Equal Tee 304l Stainless Steel

304L Stainless Steel Reducer

1-1/4" X 1/2" Nb Sch10s Concentric Reducer 304l Stainless Steel

1" X 1/2" Nb Sch10s Eccentric Reducer 304l Stainless Steel

2" X 1/2" Nb Sch10s Concentric Reducer 304l Stainless Steel

Manufacturer of ASME B16.9 SCH10 SS 304L Buttweld Fittings, and A403 WP304L Equal/ Unequal Tee Fittings in Seamless & Welded

Stainless Steel 304L Elbow Weight Chart

| NPS | KG | LBS |

| 1/2 | 0.11 | 0.25 |

| 3/4 | 0.11 | 0.25 |

| 1 | 0.23 | 0.5 |

| 1¼ | 0.41 | 0.9 |

| 1½ | 0.52 | 1.15 |

| 2 | 1 | 2.2 |

| 2½ | 1.81 | 4 |

| 3 | 2.95 | 6.5 |

| 3½ | 3.79 | 8.35 |

| 4 | 6.12 | 13.5 |

| 5 | 9.98 | 22 |

| 6 | 15.88 | 35 |

| 8 | 32.21 | 71 |

| 10 | 48.53 | 107 |

| 12 | 72.57 | 160 |

| 14 | 92.99 | 205 |

| 16 | 125.19 | 276 |

| 18 | 154.22 | 340 |

| 20 | 190.51 | 420 |

| 22 | 235.87 | 520 |

| 24 | 272.16 | 600 |

| 26 | 330.67 | 729 |

| 30 | 442.25 | 975 |

| 36 | 640.47 | 1412 |

Size range of ASTM A403 WP304L Fittings

| GRADE | SCHEDULE | NOM. PIPE SIZE |

|---|---|---|

| WP-S | SCH 10S | 1/2″ - 12″ |

| SCH 40S | 1/2″ - 12″ | |

| SCH 80S | 1/2″ - 12″ |

Types of Stainless Steel 304L Pipe Fittings

ASME SA403 WP304L 90° Long Radius Elbow

SCH 120 Din 1.4306 90° Short Radius Elbow

SA403 WP304L 45° Long Radius Elbow

UNS S30403 45° Short Radius Elbow

SS 304L 180° Long Radius Elbow

450 NB SCH 20 a403 gr WP304L 180° Short Radius Elbow

ASTM a403 wp304L 1D Elbow

304L stainless steel 1.5D Elbow

SCH 80 304L SS 3D Elbow

Stainless Steel 304L 5D Elbow

SCH XXS a403 grade WP304L 10D ELBOW

SA403 Gr WP304L Seamless Buttwelding 45° and 90° Elbows

ASTM A 403 WP 304L Welded Elbows

SCH 100 SA403 Grade WP304L Seamless Buttwelding 180° Returns

a403 WP304L Straight Tees and Crosses

UNS S30403 Reducing Outlet Tees and Reducing Outlet Crosses

SCH 140 a403 WP304L Equal Tee

304L stainless steel Reducing Tee

Din 1.4306 Equal Cross

ASME SA403 WP304L Reducing Cross

SCH STD SA403 WP304L Reducers

304L SS Concentric Reducer

SCH 160 Stainless Steel 304L Eccentric Reducer

ASTM a403 wp304L Stub End

SCH 30 a403 gr WP304L Lap Joint Stub Ends

SA403 Grade WP304L Long Stubend

SS 304L Short Stubend

SCH 40 a403 grade WP304L Pipe Cap

ASTM A 403 WP 304L End Cap

SCH 60 SA403 Gr WP304L Collar

UNS S30403 Swage Nipple

SS 304L Pipe Nipples

Din 1.4306 Barrel Nipple

SCH XS 304L stainless steel Reducing Nipple

15 NB SCH 10 304L SS Bend

a403 WP304L Long Radius Bend

304L Stainless Weld Fittings Chemical Properties

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 304L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.03 max | 18 - 20 | - | 8 - 13 | - |

Mechanical Properties of 304L SS Elbow

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi - 75000 , MPa - 515 | Psi - 30000 , MPa - 205 | 35 % |

Physical Properties of A182 F304L Forged Fitting

| Density lbm/in3 |

Thermal Conductivity (BTU/h ft. °F) |

Electrical Resistivity (in x 10-6) |

Modulus of Elasticity (psi x 106 |

Coefficient of Thermal Expansion (in/in)/ °F x 10-6 |

Specific Heat (BTU/lb/ °F) |

Melting Range (°F) |

|---|---|---|---|---|---|---|

| at 68°F: 0.285 | 9.4 at 212°F | 28.3 at 68°F | 28 | 9.4 at 32 – 212°F | 0.1200 at 68°F to 212°F | 2500 to 2590 |

| 12.4 at 932 °F | 39.4 at 752°F | 10.2 at 32 – 1000°F | ||||

| 49.6 at 1652 °F | 10.4 at 32 – 1500°F |

Equivalent Grade of SS 304L Hex Nipple

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304L | 1.4306 / 1.4307 | S30403 | SUS 304L | 3304S11 | 03-18-11 | Z3CN18-10 | X2CrNi18-9 / X2CrNi19-11 |

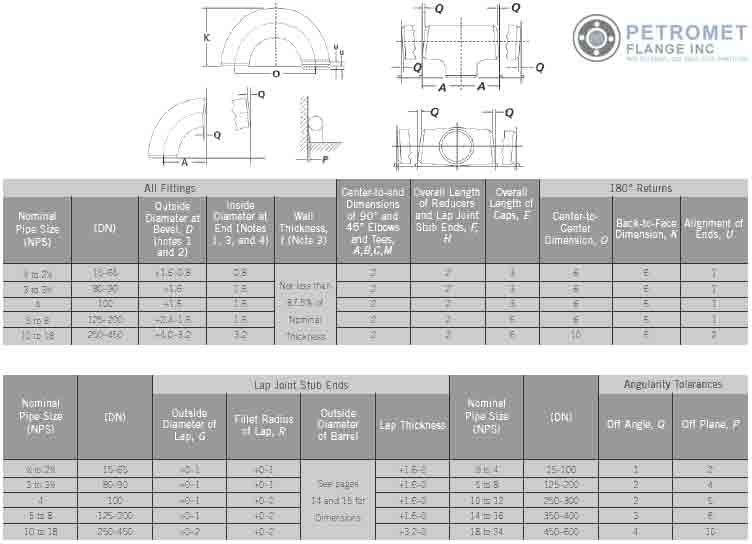

Tolerance Chart of 304L stainless steel fittings

Value Added Services of Asme Sa403 WP304L Fitting

- Micro and Macro Test

- PMI Testing

- Pitting Resistance Test

- Flattening Test

- Flaring Test

- Hardness Test

SS 304L Buttweld Fittings Applications

- Oil & Gas Industry

- Nuclear Power

- Fossil Fuel Power Plants

- Paper & Pulp

- Power Plants

- Ship Building

- Refineries

- Marine Applications

- Industrial Boilers

Heat Resistance of 304L SS Weld Fittings

| Heat Resistance | 800-1580°F |

Pipe Fittings Material

Flanges Material

Other Products