- Call : +91 22 67436442

- exports@petrometflange.com

Stainless Steel 904L Fittings manufacturer in India

- Home /

- Stainless Steel 904L Pipe Fittings

Looking for 904L Fittings manufacturers in India? We produce AISI 904L Buttweld and Forged Pipe Fittings according to ASTM B366 UNS N08904 and A403 WP904L standard.

What is Stainless Steel 904L Pipe Fittings?

The Stainless Steel 904L material is ideal to be used in severely corrosive environments. The Stainless Steel 904L Pipe Fittings are known for their resistance to crevice corrosion and stress corrosion cracking. Their corrosion resistance capacity is much stronger than the Stainless Steel 316L and 317L material grades. They have high content of nickel and molybdenum in their chemical composition which enhances the corrosion resistance property of the Stainless Steel 904L Pipe Fittings. The high copper content helps in increasing its resistance against strong acids like sulfuric acid. It can resist pitting in chloride environments.

The Stainless Steel 904L Pipe Fittings remain non-magnetic in various environments. They also possess some excellent properties such as high formability and weldability. Due to all these enhanced properties, the Stainless Steel 904L Pipe Fittings are extensively used in scrubber assemblies, and equipment for producing fertilizers. These Pipe Fittings are costly due to the presence of expensive elements like nickel and molybdenum, that too in a high percentage.

904L Stainless Steel Forged Fittings Vs ASTM A182 F904L Buttweld Fittings

- The 904L Stainless Steel Forged Fittings are made from solid blocks of steel, whereas the ASTM A182 F904L Buttweld Fittings are manufactured from seamless or welded steel pipes.

- The forged fittings are machined to get the desired shape, whereas the buttweld fittings are bent, cut and shaped from the given steel pipes of either seamless or welded variants.

- The forged fittings are ideal for smaller pipes that have a diameter between 2 to 4 inches. The buttweld fittings are used for bigger pipes.

Stainless Steel 904L Tee Vs ASTM A403 WP904L Stub End

The Stainless Steel 904L Tee is a pipe fittings that looks like the alphabet T, and comes with two branches located 90 degrees to the main connection line. It can perform a number of functions, including, combining and dividing the flow, changing the flow direction, and controlling the flow rate. There are two types of tees, namely equal and unequal tees.

The ASTM A403 WP904L Stub End is a pipe fittings that is used along with lap joint flanges. They are used for making flanged connections, and can be used as a replacement for weld neck flanges.

UNS N08904 Swage Nipples Vs DIN 1.4539 Barrel Nipple

The UNS N08904 Swage Nipples are mainly used for bringing the fluid flow from one size of the pipe to another. They can be beveled, threaded, or even have a plain end. It mainly helps to change the pipe’s diameter and make a connection between two pipes of different sizes.

The DIN 1.4539 Barrel Nipple are pipe nipple which are basically tapered NPT threaded at each end. They come with an unthreaded section in the middle. It is a short piece of pipe that can easily connect with other pipes and fittings.

Where to use 904L Elbow?

The are used for changing the direction of the pipe run. They are used in severely corrosive environments where the 316L and 317L material grades are inadequate, like in chemical industries.

Stainless Steel 904L Fittings manufacturer in India

904L Fittings manufacturers in India offers wide selection of AISI 904L Elbow and UNS N08904 Stub End in Mumbai

Table of Content

- Specification of Stainless Steel 904L Pipe Fittings

- 904l Stainless Steel Fittings Dimensions

- Pressure Rating Of Asme Sa403 904L BW Fittings

- SS 904L Fittings Thickness Chart

- 904L Stainless Steel Forged Fittings

- SS 904L Socket Weld Fittings

- Stainless Steel 904L Threaded Fittings

- Din 1.4539 Elbow Size Chart

- Size Chart of UNS N08904 Reducer

- Stainless Steel 904L Pipe Fittings Price List

- ASTM A403 WP904L Buttweld Fittings Chemical Composition

- Mechanical Properties of ASME SA403 WP904L Pipe Fitting

- Equivalent Grade of 904L Stainless Steel Fittings

- SA403 Grade WP904L Fittings Physical Properties

- 904L Stainless Steel Elbow

- 904L SS Reducer

- Stainless Steel 904L Tee

- Heat Resistance of UNS N08904 End Cap

- Different Welding Process of A403 gr wp904L Fittings

- Various Types of Stainless Steel 904L Pipe Fittings

- Applications of 904L SS Pipe Fitting

- Stainless Steel 904L Stub End Melting Point

Specification of Stainless Steel 904L Pipe Fittings

| 904l stainless steel fittings Specifications | ASTM A403 |

|---|---|

| Stainless Steel 904L Pipe Fittings Sizes | 904L Stainless Steel Seamless Fitting: 1/2" - 10" ASME B16 9 Din 1.4539 Welded Fitting: 1/2" - 48" |

| Bending Radius Provided By Manufacturer | R=1D, 3D, 2D, 5D, 8D, 6D, 10D or Custom Stainless Steel 904L Pipe Fittings |

| Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) ASTM A403 WP904L Fittings |

| Stainless Steel 904L Pipe Fittings Thickness | SCH30, SCH10, SCH 160, SCH20, SCH60, XS, STD SCH40, SCH 80, SCH 120, SCH 140, SCH 100, XXS available with NACE MR 01-75 |

| SS 904L Pipe Fitting Type Manufacturer | DN15-DN1200 |

| Stainless Steel 904L Fittings Connection | Welding |

| 904l stainless steel fittings Dimensions | ASME B16.28, ASME/ANSI B16.9, BS4504, MSS-SP-43, BS1560, BS4504, BS10 |

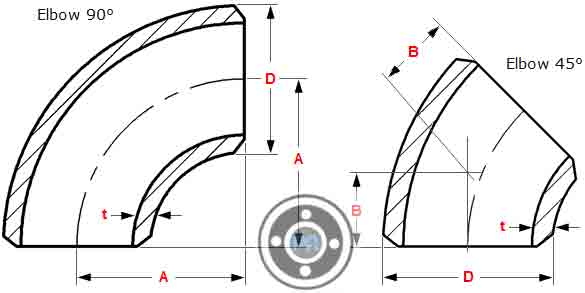

| 904L Stainless Steel Elbow Manufacturer | Angle : 22.5 deg, 45 deg, 30deg, 90 deg, 1.0D, 180 deg, 1.5D, 3D, 2.5D, 2.0D, 4D, 6D, 5D, 7D-40D . Standard: ASME B16.28, GB, ASME B16.9, MSS SP-75 JISB2311 DIN2605 JISB2312 JISB2313, ASME B16.25, BS, ISO |

| Stainless Steel 904L Pipe Fittings Manufacturing process | Push, Forge, Press, Cast, etc. |

| ASME B16.9 904L Stainless Steel pipe fitting Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Stainless Steel 904L Pipe Fittings Origin & Mills | European, Japanese, USA, Korean, Ukraine, Indian, Russian |

| Specialized manufacturer of | A403 gr wp904L Stub End, 90º Elbows, Tees, Pipe Cap, Crosses, 45º Elbows, Reducers, Pipe Bend |

| Application of Industrial 904L Stainless Steel weld fittings |

|

| Stainless Steel 904L Threaded Fitting Thread Provided By Manufacturer | BSPT, NPT, BSPP |

| 904L Stainless Steel Forged Fitting Pressure Rating | Threaded end - 3000lb/ 2000lb/ 6000lbs Socket weld end- 6000/ 3000/ 9000lbs |

| Dimension Specification | MSS SP-79, 95, 83, 97, BS 3799, ASME 16.11 |

| Stainless Steel 904L Products Manufacturer | Half Coupling, Union, Tee, Cross, Coupling, Cap, Outlet, Welding Outlet, Boss, Insert |

Biggest Stainless Steel 904l Pipe Fittings supplier, wholesalers, dealers, stockholders, distributor, importer, stockists and exporters. We are leading Stainless Steel 904L Buttweld Fittings manufacturers in Mumbai.

904l Stainless Steel Fittings Dimensions

| Nominal Pipe Size | Outside Diameter | 90° Elbows | 45° Elbows | 180° Returns | ||||

|---|---|---|---|---|---|---|---|---|

| (inches) | Long Radius | Short Radius | Long Radius | Long Radius | ||||

| (mm) | (inches) | Center to Face (inches) | Center to Face (inches) | Center to Face (inches) | Radius (inches) | Center to Center (inches) | Back to face (inches) | |

| 1/2 | 21.3 | 0.840 | 1 1/2 | - | 5/8 | 2 | 1 7/8 | |

| 3/4 | 26.7 | 1.050 | 1 1/8 | - | 7/16 | 2 1/4 | 1 11/16 | |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 | 7/8 | 3 | 2 3/16 | |

| 1 1/4 | 42.2 | 1.660 | 1 7/8 | 1 1/4 | 1 | 3 3/4 | 2 3/4 | |

| 1 1/2 | 48.3 | 1.900 | 2 1/4 | 1 1/2 | 1 1/8 | 3 | 4 1/2 | 3 1/4 |

| 2 | 60.3 | 2.375 | 3 | 2 | 1 3/8 | 4 | 6 | 4 3/16 |

| 2 1/2 | 73.0 | 2.875 | 3 3/4 | 2 1/2 | 1 3/4 | 5 | 7 1/2 | 5 3/16 |

| 3 | 88.9 | 3.500 | 4 1/2 | 3 | 2 | 6 | 9 | 6 1/4 |

| 3 1/2 | 101.6 | 4.000 | 5 1/4 | 3 1/2 | 2 1/4 | 7 | 10 1/2 | 7 1/4 |

| 4 | 114.3 | 4.500 | 6 | 4 | 2 1/2 | 8 | 12 | 8 1/4 |

| 5 | 141.3 | 5.563 | 7 1/2 | 5 | 3 1/8 | 10 | 15 | 10 5/16 |

| 6 | 168.3 | 6.625 | 9 | 6 | 3 3/4 | 12 | 18 | 12 5/16 |

| 8 | 219.1 | 8.625 | 12 | 8 | 5 | 12 | 24 | 16 5/16 |

| 10 | 273.1 | 10.750 | 15 | 10 | 6 1/4 | 15 | 30 | 20 3/8 |

| 12 | 323.9 | 12.750 | 18 | 12 | 7 1/2 | 18 | 36 | 24 3/8 |

PED approved manufacturers in Mumbai offers widest range of ASTM A403 904L Eccentric / Concentric Reducer and SS 904L Long/ Short Radius Elbow in India

Pressure Rating Of Asme Sa403 904L BW Fittings

| Normal Size Of Pipe (inches) | Pipe Sch | OD (inch) | Wall Thick. (inch) | Temperature(oF) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 | 200 | 300 | 400 | 500 | 600 | 650 | 700 | 750 | ||||

| Allowable Stress(psi) | ||||||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | 13500 | 13200 | 12900 | 12600 | ||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 | 1783 | 1743 | 1703 | 1664 |

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | 2475 | 2420 | 2365 | 2310 | |

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | 3632 | 3552 | 3471 | 3390 | |

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 | 1317 | 1287 | 1258 | 1229 |

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | 1862 | 1821 | 1779 | 1738 | |

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | 2717 | 2657 | 2597 | 2536 | |

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 | 1108 | 1083 | 1059 | 1034 |

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | 1605 | 1569 | 1534 | 1498 | |

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | 2654 | 2595 | 2536 | 2477 | |

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 | 1052 | 1028 | 1005 | 982 |

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | 1491 | 1458 | 1425 | 1391 | |

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | 2253 | 2203 | 2153 | 2103 | |

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 | 891 | 871 | 851 | 831 |

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | 1291 | 1262 | 1233 | 1204 | |

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | 2111 | 2064 | 2017 | 1970 | |

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 | 780 | 763 | 746 | 728 |

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | 1154 | 1129 | 1103 | 1077 | |

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | 2000 | 1955 | 1911 | 1866 | |

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 | 709 | 693 | 677 | 661 |

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | 1115 | 1090 | 1065 | 1040 | |

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | 1925 | 1883 | 1840 | 1797 | |

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 | 623 | 610 | 596 | 582 |

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | 985 | 963 | 941 | 919 | |

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | 1858 | 1817 | 1775 | 1734 | |

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 | 565 | 553 | 540 | 528 |

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | 937 | 916 | 895 | 874 | |

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | 1850 | 1809 | 1768 | 1727 | |

SS 904L Fittings Thickness Chart

| GRADE | SCHEDULE | NOM. PIPE SIZE |

|---|---|---|

| WP-S | SCH 10S | 1/2″ - 12″ |

| SCH 40S | 1/2″ - 12″ | |

| SCH 80S | 1/2″ - 12″ |

904L Stainless Steel Forged Fittings

904L Stainless Steel Forged Equal Tee

SS 904L Forged Elbow

ASTM A182 F904L Coupling

SS 904L Socket Weld Fittings

ASME B16.11 A182 F904L Socket Weld Elbow

904L SS SW Tee

UNS N08904 Socket Weld Half Coupling

Stainless Steel 904L Threaded Fittings

SS 904L Threaded Elbow

A182 Grade F904L Threaded Reducing Tee

UNS N08904 Threaded Coupling

Din 1.4539 Elbow Size Chart

| NPS | O.D. D | 90° 3D Center to End A | 45° 3D Center to End B | 45° Long Rad Center to End B | 90° Long Rad Center to End A |

| 18 | 457 | 1372 | 568 | 286 | 686 |

| 20 | 508 | 1524 | 632 | 318 | 762 |

| 22 | 559 | 1676 | 694 | 343 | 838 |

| 24 | 610 | 1829 | 757 | 381 | 914 |

| 26 | 660 | 1981 | 821 | 406 | 991 |

| 28 | 711 | 2134 | 883 | 438 | 1067 |

| 30 | 762 | 2286 | 946 | 470 | 1143 |

| 32 | 813 | 2438 | 1010 | 502 | 1219 |

| 34 | 864 | 2591 | 1073 | 533 | 1295 |

| 36 | 914 | 2743 | 1135 | 565 | 1372 |

| 38 | 965 | 2896 | 1200 | 600 | 1448 |

| 40 | 1016 | 3048 | 1264 | 632 | 1524 |

| 42 | 1067 | 3200 | 1326 | 660 | 1600 |

| 44 | 1118 | 3353 | 1389 | 695 | 1676 |

| 46 | 1168 | 3505 | 1453 | 727 | 1753 |

| 48 | 1219 | 3658 | 1516 | 759 | 1829 |

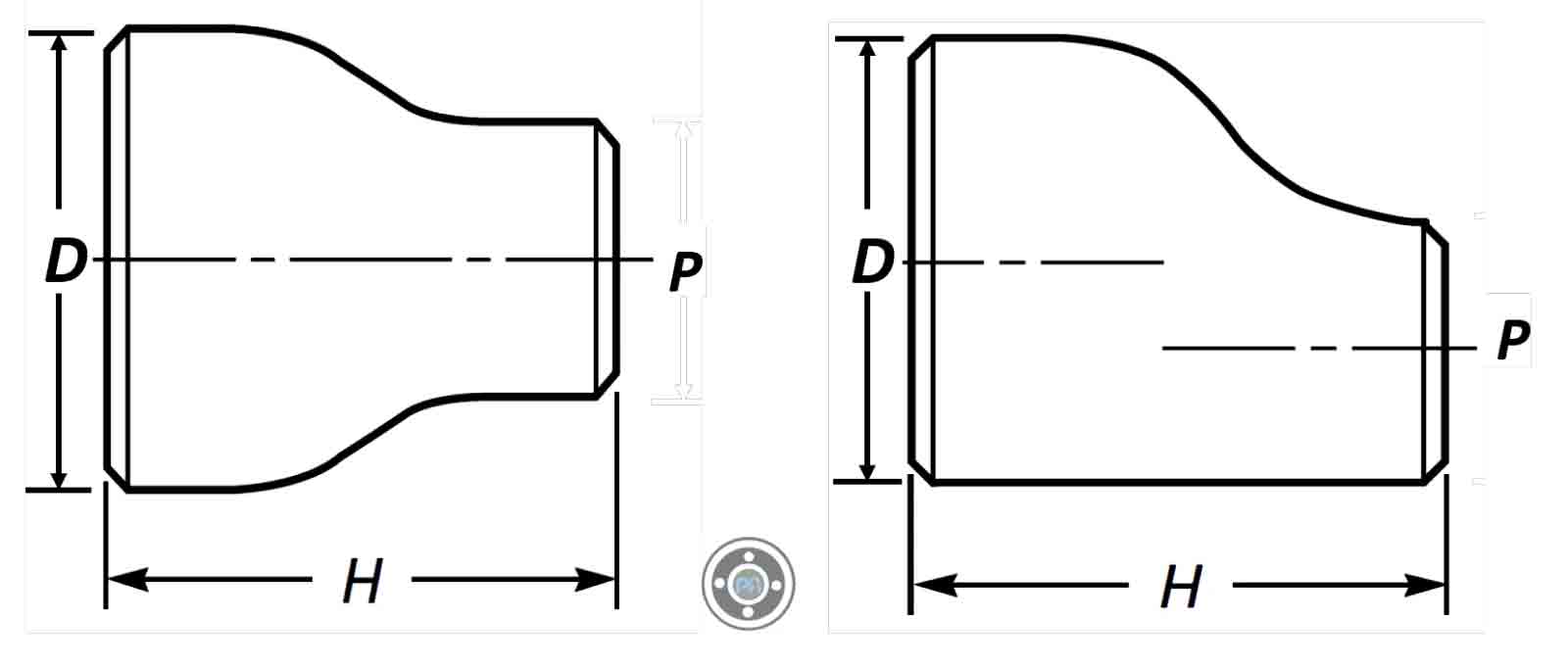

Size Chart of UNS N08904 Reducer

| NOMINAL PIPE SIZE | END TO END | OUTSIDE DIAMETER | |

|---|---|---|---|

| Inch | H | D | P |

| 3/4 x 1/2 | 38 | 26.7 | 21.3 |

| 3/4 x 3/8 | 38 | 26.7 | 17.1 |

| 1 x 3/4 | 51 | 33.4 | 26.7 |

| 1 x 1/2 | 51 | 33.4 | 21.3 |

| 1 1/4 x 1 | 51 | 42.2 | 33.4 |

| 1 1/4 x 3/4 | 51 | 42.2 | 26.7 |

| 1 1/4 x 1/2 | 51 | 42.2 | 21.3 |

| 1 1/2 x 1 1/2 | 64 | 48.3 | 42.2 |

| 1 1/2 x 1 | 64 | 48.3 | 33.4 |

| 1 1/2 x 3/4 | 64 | 48.3 | 26.7 |

| 1 1/2 x 1/2 | 64 | 48.3 | 21.3 |

| 2 x 1 1/2 | 76 | 60.3 | 48.2 |

| 2 x 1 1/4 | 76 | 60.3 | 42.2 |

| 2 x 1 | 76 | 60.3 | 33.4 |

| 2 x 3/4 | 76 | 60.3 | 26.7 |

| 2 1/2 x 2 | 89 | 73 | 60.3 |

| 2 1/2 x 1 1/2 | 89 | 73 | 48.3 |

| 2 1/2 x 1 1/4 | 89 | 73 | 42.2 |

| 2 1/2 x 1 | 89 | 73 | 33.4 |

| 3 x 2 1/2 | 89 | 88.9 | 73 |

| 3 x 2 | 89 | 88.9 | 60.3 |

| 3 x 1 1/2 | 89 | 88.9 | 48.3 |

| 3 x 1 1/4 | 89 | 88.9 | 42.2 |

| 3 1/2 x 3 | 102 | 101.6 | 88.9 |

| 3 1/2 x 21/2 | 102 | 101.6 | 73 |

| 3 1/2 x 2 | 102 | 101.6 | 60.3 |

| 3 1/2 x 1 1/2 | 102 | 101.6 | 48.3 |

| 3 1/2 x 1 1/4 | 102 | 101.6 | 42.2 |

| 4 x 3 1/2 | 102 | 114.3 | 101.6 |

| 4 x 3 | 102 | 114.3 | 88.9 |

| 4 x 2 1/2 | 102 | 114.3 | 73 |

| 4 x 2 | 102 | 114.3 | 60.3 |

| 4 x 1 1/2 | 102 | 114.3 | 48.3 |

| 5 x 4 | 127 | 141.3 | 114.3 |

| 5 x 3 1/2 | 127 | 141.3 | 101.6 |

| 5 x 3 | 127 | 141.3 | 88.9 |

| 5 x 2 1/2 | 127 | 141.3 | 73 |

| 5 x 2 | 127 | 141.3 | 60.3 |

| 6 x 5 | 140 | 168.3 | 141.3 |

| 6 x 4 | 140 | 168.3 | 114.3 |

| 6 x 3 1/2 | 140 | 168.3 | 101.6 |

| 6 x 3 | 140 | 168.3 | 88.9 |

| 6 x 2 1/2 | 140 | 168.3 | 73 |

| 8 x 6 | 152 | 219.1 | 168.3 |

| 8 x 5 | 152 | 219.1 | 141.3 |

| 8 x 4 | 152 | 219.1 | 114.3 |

| 8 x 3 1/2 | 152 | 219.1 | 101.6 |

| 10 x 8 | 178 | 273.1 | 219.1 |

| 10 x 6 | 178 | 273.1 | 168.1 |

| 10 x 5 | 178 | 273.1 | 141.3 |

| 10 x 4 | 178 | 273.1 | 114.3 |

| 12 x 10 | 203 | 323.9 | 273.1 |

| 12 x 8 | 203 | 323.9 | 219.1 |

| 12 x 6 | 203 | 323.9 | 168.3 |

| 12 x 5 | 203 | 323.9 | 141.3 |

| 14 x 12 | 330 | 355.6 | 323.9 |

| 14 x 10 | 330 | 355.6 | 273.1 |

| 14 x 8 | 330 | 355.6 | 219.1 |

| 14 x 6 | 330 | 355.6 | 168.3 |

| 16 x 14 | 356 | 406.4 | 355.6 |

| 16 x 12 | 356 | 406.4 | 323.9 |

| 16 x 10 | 356 | 406.4 | 273.1 |

| 16 x 8 | 356 | 406.4 | 219.1 |

| 16 x 6 | 356 | 406.4 | 168.3 |

| 18 x 16 | 381 | 457 | 406.4 |

| 18 x 14 | 381 | 457 | 355.6 |

| 18 x 12 | 381 | 457 | 323.9 |

| 18 x 10 | 381 | 457 | 273.1 |

| 18 x 8 | 381 | 457 | 219.1 |

| 20 x 18 | 508 | 508 | 457 |

| 20 x 16 | 508 | 508 | 406.4 |

| 20 x 14 | 508 | 508 | 355.6 |

| 20 x 12 | 508 | 508 | 323.9 |

| 20 x 10 | 508 | 508 | 273.1 |

| 20 x 8 | 508 | 508 | 219.1 |

| 22 x 20 | 508 | 559 | 508 |

| 22 x 18 | 508 | 559 | 457 |

| 22 x 16 | 508 | 559 | 406.4 |

| 22 x 14 | 508 | 559 | 355.6 |

| 22 x 12 | 508 | 559 | 323.9 |

| 24 x 10 | 508 | 559 | 273.1 |

| 24 x 22 | 508 | 610 | 559 |

| 24 x 20 | 508 | 610 | 508 |

| 24 x 18 | 508 | 610 | 457 |

| 24 x 16 | 508 | 610 | 406.4 |

| 24 x 14 | 508 | 610 | 355.6 |

| 24 x 12 | 508 | 610 | 323.9 |

| 24 x 10 | 508 | 610 | 273.1 |

EN 10253-4 Type A/ Type B SUS 904L Buttweld Fittings and Equal/ Unequal Tee manufacturer in India

Stainless Steel 904L Pipe Fittings Price List

| Stainless Steel 904L Pipe Fittings Price Per Piece in India | 904L SS BW Fittings Price in INR | ASTM A403 WP904L Fittings Price in UAE Dirham | Stainless Steel 904L Weld Fittings Price in USD |

| 2-1/2" Nb Sch40 Stub End Type A 904L Stainless Steel Per Piece | 1781.88 | UAE Dirham 87.89 | $23.93 |

| 5" Nb Sch100 45° Long Radius Elbow 904L Stainless Steel Per Piece | 1711.14 | UAE Dirham 84.41 | $22.98 |

| 2" Nb Sch40s Cap Seamless 904L Stainless Steel Per Piece | 1566.68 | UAE Dirham 77.28 | $21.04 |

| 1-1/2" X 1/2" Nb Sch40 Concentric Reducer 904L Stainless Steel Per Piece | 1539.13 | UAE Dirham 75.92 | $20.67 |

| 2-1/2" Nb Sch40s Equal Tee 904L Seamless Stainless Steel Per Piece | 1667.21 | UAE Dirham 82.24 | $22.39 |

Compare our price with other 904L Stainless Steel Elbow Manufacturer in India. This is an approximate Price of ASTM A403 WP904l Buttweld Fittings in India. Feel free to contact us for latest price list of Stainless Steel 904L Threaded Fittings in Mumbai.

ASTM A403 WP904L Buttweld Fittings Chemical Composition

| Grade | Carbon | Manganese | Silicon | Phosphorus | Sulfur | Chromium | Molybdenum | Nickel | Copper |

| SS 904L | 0.020 max | 2.00 max | 1.00 max | 0.040 max | 0.030 max | 19.00 - 23.00 | 4.00 - 5.00 max | 23.00 - 28.00 | 1.00 - 2.00 |

Mechanical Properties of ASME SA403 WP904L Pipe Fitting

| Density | Elongation | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength |

| 7.95 g/cm3 | 35 % | 1350 °C (2460 °F) | Psi - 32000 , MPa - 220 | Psi - 71000 , MPa - 490 |

Equivalent Grade of 904L Stainless Steel Fittings

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | KS | AFNOR | EN |

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

SA403 Grade WP904L Fittings Physical Properties

Grade | Density | Elastic Modulus | Mean Co-eff of Thermal Expansion (µm/m/°C) | Thermal Conductivity | Specific Heat 0-100°C | Elec Resistivity | |||

0-100°C | 0-315°C | 0-538°C | At 20°C | At 500°C | |||||

904L | 7900 | 190 | 15 | - | - | 11.5 | - | 500 | 952 |

We supply 904L Stainless Steel Coupling and ASME SB 366 UNS N08904 Forged Fittings with Radiography and Eddy Current Testing

904L Stainless Steel Elbow

2-1/2" Nb SCH 10 90° Long Radius Elbow 904L Stainless Steel

2" Nb SCH 80 90° SR Elbow 904L Stainless Steel

4" Nb SCH 120 45° Long Radius Elbow 904L Stainless Steel

904L SS Reducer

1-1/4" X 1/2" Nb Sch160 Concentric Reducer 904L Stainless Steel

1" X 1/2" Nb Sch60 Eccentric Reducer 904L Stainless Steel

2" X 1/2" Nb Sch20 Concentric Reducer 904L Stainless Steel

Stainless Steel 904L Tee

6" Nb SCH 30 Tee 904L Stainless Steel

1-1/4" X 1" Nb SCH 100 Reducing Tee 904L Stainless Steel

3" Nb SCH 80 Equal Tee 904L Stainless Steel

Heat Resistance of UNS N08904 End Cap

| Heat Resistance | 400°C |

Different Welding Process of A403 gr wp904L Fittings

- TIG-Welding

- Laser Bean Welding

- Arc Welding (E)

- Submerged Arc Welding (SAW)

- MAG-Welding Solid Wire

Various Types of Stainless Steel 904L Pipe Fittings

SCH 10 Stainless Steel 904L 180° Long Radius Elbow

UNS N08904 Collar

904L Stainless Steel 45° Short Radius Elbow

SCH 20 A403 wp904L Short Stubend

ASTM A403 WP904L Swage Nipple

A403 gr wp904L Stainless Steel Reducing Cross

ASTM A182 904L Stainless Steel 180° Short Radius Elbow

SCH 30 ASME SA403 WP904L Equal Cross

Din 1.4539 Long Stubend

SCH 60 Stainless Steel 904L Long Radius Bend

SCH 120 SA403 Gr WP904L Pipe Cap

A403 grade WP904L 90° Long Radius Elbow

Stainless Steel 904L Lap Joint Stub Ends

A403 grade WP904L Concentric Reducer

Stainless Steel 904L Welded Elbows

ASTM A182 904L 1.5D Elbow

SCH XS 904L SS Pipe Nipples

ASME SA403 WP904L End Cap

904L Stainless Steel Seamless Buttwelding 45° and 90° Elbows

904L Stainless Steel Stub End

15 NB SCH 100 ss 904L 90° Short Radius Elbow

ASTM A182 904L Stainless Steel Barrel Nipple

SCH XXS Stainless Steel 904L Reducers

904L Stainless Steel Bend

SS 904L Equal Tee

SCH 140 904L SS Reducing Outlet Tees and Reducing Outlet Crosses

A403 wp904L Straight Tees and Crosses

SCH STD Stainless Steel 904L Seamless Buttwelding 180° Returns

Din 1.4539 10D ELBOW

SCH 160 904L Stainless Steel Eccentric Reducer

SCH 80 SA403 Gr WP904L 1D Elbow

ss 904L Reducing Nipple

ASTM A403 WP904L 3D Elbow

450 NB SCH 40 A403 gr wp904L Stainless Steel 5D Elbow

SA403 WP904L Reducing Tee

UNS N08904 45° Long Radius Elbow

Applications of 904L SS Pipe Fitting

- Textile machinery

- Home appliances

- Water waste projects

- Energy industries

- Pharmaceutical processing industry

- Modern architecture

- Oil and gas industry

- Pulp and paper industry

- Power plants

- Dairy and food processing

Stainless Steel 904L Stub End Melting Point

| Melting Point | 1300-1390 ℃ |

Pipe Fittings Material

Flanges Material

Other Products