- Call : +91 22 67436442

- exports@petrometflange.com

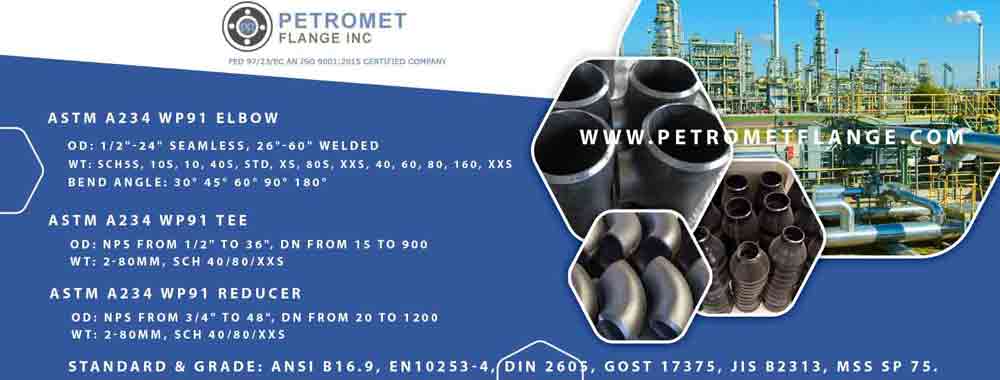

ASTM A234 WP91 Fittings

- Home /

- ASTM A234 WP91 Fittings

Alloy Steel WP91 Elbow and SA 234 Gr WP91 Tee manufacturer in India

What is ASTM A234 WP91 Fittings?

The ASTM A234 WP91 Fittings are made from high-quality alloy steel and they are used for different types of piping works. These fittings are mostly used in pressure piping and fabrication of pressure vessels for services at moderate to high temperatures. It is a buttweld fitting that comes with several advantages, like:

- It offers leak-proof connections.

- A continuous metal structure between the pipe helps to increase the overall strength of the piping system.

- They have a smooth inner surface that encourages better flow.

- Also, the fittings promote gradual directional changes that help the piping system to reduce pressure loss, turbulence, etc. It also minimizes corrosion and abrasion of the material.

- As the fittings are buttwelded, they utilize minimum space.

The ASTM A234 WP91 Fittings comes with shorter bends and sharper curves, and hence are best suited for environments where space is a constraint. It is a reliable and convenient piece of piping accessory that is used across several industries like agriculture, electronics, breweries, irrigation, and many more. They are known for their high performance in the application that require abrasion resistance and moderate to low corrosion resistance. This fitting is available in different forms like tee, reducers, caps, couplings, etc., and each of them perform different functions according to their structure in a similar environment. Some other important characteristics of ASTM A234 WP91 Fittings would include durability, stability, high strength, and they are made accurate according to the dimensions specified.

ASTM A234 Grade WP91 Elbow Vs ASME SA 234 WP91 Equal Tee

The ASTM A234 Grade WP91 Elbow is mainly used for changing the angle or direction of the flow. They are mostly available in 45 degree and 90 degree angle, and they help to change the pipe run accordingly. The sweep of the elbow helps determine how easily the transaction or directional change is done.

The ASME SA 234 WP91 Equal Tee is shaped like the alphabet T, and it helps to branch the piping system. They primarily help transport two phase fluid mixtures for the cases where the size of the header pipe and branch are the same. It means that the branch diameter of the equal tee is the same as that of the diameter of the run pipe. Here the branch would have the same distance as the run pipe.

SA234 WP91 Long Stub End Vs A234 Gr WP91 Short Stub End

The main difference between SA234 WP91 Long Stub End and A234 Gr WP91 Short Stub End is in its hub length. The SA234 WP91 Long Stub End has greater hub length compared to the A234 Gr WP91 Short Stub End. The long stub ends are elongated whereas the short stub ends are the perfect alternative to welded flanges. They perform similar functions as that of the backup rotating flanges.

ASTM A234 WP91 Fittings

AN ISO 9001:2015 certified ASTM A234 WP91 Fittings manufacturers in India offers widest range of A234 Gr WP91 Reducing/ Unequal/ Lateral Tee and Eccentric / Concentric Reducer in Mumbai

Where to use Sa234 Gr WP91 Reducer?

The Sa234 Gr WP91 Reducer is mainly used for reducing the size of the main run pipe from a larger to a smaller bore, which is the inner diameter. The change in pipe size helps to meet the flow requirement of the piping system. It also helps in adapting the existing piping available of a different size. In other words, the reducer helps in connecting pipes of different sizes seamlessly, without interrupting the flow.

Table of Content

- Specification List of ASTM A234 WP91 Fittings

- ASTM A234 Grade WP91 Elbow

- Alloy Steel Grade WP91 Tee

- Chromium A234 Grade WP91 Reducer

- Pressure Rating of Alloy Steel Grade WP91 Fittings

- UNS K90901 Fittings Dimensions Table

- ASTM A234 WP91 Fittings Price List

- ASTM A234 WP91 Chemical Composition

- ASME SA 234 WP91 Mechanical Properties

- Elongation Requirements of UNS K90901 Pipe Fittings

- Physical Properties of WNR 1.4903 Fittings

- Heat Treatment of Alloy Steel Grade WP91 Fittings

- Different Types of ASTM A234 WP91 Fittings

- Applicable Standards of Chromium A234 Grade WP91 Buttweld Fittings

- SA234 WP91 Fittings For Sale

- Weight of Werkstoff 1.4903 Tee

- ASTM A234 Chrome Moly WP91 Reducer Dimensions Table

- A234 WP91 Cl1 Elbow Weight Chart

- Dimensions of Chromium A234 Grade WP91 Tee

- Applications of DIN 1.4903 Butweld Fittings

- Alloy steel Gr WP91 Weld Fittings Inspection and Testing

Specification List of ASTM A234 WP91 Fittings

| ASTM A234 WP91 Fittings Specifications | ASTM A234 |

|---|---|

| Chrome Moly A234-WP91 Fittings Thickness | SCH30, SCH10, SCH 160, SCH20, SCH60, XS, STD SCH40, SCH 80, SCH 120, SCH 140, SCH 100, XXS available with NACE MR 01-75 |

| ASTM A234 Gr WP91 Fittings Sizes | WNR 1.4903 Seamless Fittings: 1/2" - 10"

ASME B16 9 ASME SA 234 Grade WP91 Welded Fittings: 1/2" - 48" |

| A234 WP91 Fittings Type Manufacturer | DN15-DN1200 |

| Alloy Steel Grade WP91 Tee Connection | Welding |

| ASME B16.9 A234 WP91 Material Test Certificates | EN 10204/3.1B

Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Bending Radius Provided By Manufacturer | R=1D, 3D, 2D, 5D, 8D, 6D, 10D or Custom Werkstoff 1.4903 Pipe Bend |

| Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) ASTM A234 WP91 Fittings |

| ASTM A234 Gr WP91 Fittings Dimensions | ASME B16.28, ASME/ANSI B16.9, BS4504, MSS-SP-43, BS1560, BS4504, BS10 |

| ASTM A234 Grade WP91 Elbow Manufacturer | Angle : 22.5 deg, 45 deg, 30deg, 90 deg, 1.0D, 180 deg, 1.5D, 3D, 2.5D, 2.0D, 4D, 6D, 5D, 7D-40D .

Standard: ASME B16.28, GB, ASME B16.9, MSS SP-75 JISB2311 DIN2605 JISB2312 JISB2313, ASME B16.25, BS, ISO |

| SA234 Gr WP91 Fittings Manufacturing process | Push, Forge, Press, Cast, etc. |

| Specialized ASTM A234 WP91 Fittings Manufacturer of | Stub End, 90º Elbows, Tees, Pipe Cap, Crosses, 45º Elbows, Reducers, Pipe Bend |

| ASME SA 234 WP91 Buttweld Fittings Thread Provided By Manufacturer | BSPT, NPT, BSPP |

| ASME SA 234 WP91 Fittings Origin & Mills | European, Japanese, USA, Korean, Ukraine, Indian, Russian |

| ASTM A234 WP91 Fittings Pressure Rating | Threaded end - 3000lb/ 2000lb/ 6000lbs

Socket weld end- 6000/ 3000/ 9000lbs |

| A234 grade WP91 crmo Products Manufacturer | Half Coupling, Union, Tee, Cross, Coupling, Cap, Outlet, Welding Outlet, Boss, Insert |

| Dimension Specification | MSS SP-79, 95, 83, 97, BS 3799, ASME 16.11 |

| Application of Industrial ASTM A234 WP91 Gr Cl1 Fittings |

|

Biggest Werkstoff 1.4903 Pipe Fittings supplier, exporters, stockists, distributor, importer, stockholders, wholesalers, dealers and Manufacturer in Mumbai

ASTM A234 Grade WP91 Elbow

A234 WP91 4 Inch 90 Degree Elbow

A234 WP91 1.5D LR SCH40 Elbow

ASTM A234 Grade WP91 Elbow

Alloy Steel Grade WP91 Tee

ASTM A234 alloy steel WP91 Tee

UNS K90901 Reducing Tee b16.9 BW

ANSI Alloy Steel Grade WP91 Tee

Chromium A234 Grade WP91 Reducer

WNR 1.4903 20*16 STD Concentric Reducer

ASTM A234 WP91 Eccentric Reducer

B16.9 ASME SA234 WP91 Butt weld Reducer SCH 40

Main advantage of SA 234 WP91 Elbow and Cross Fittings is the reduction in pipe diameter, manufacturing ASTM A234 WP91 Buttweld Cap, 3D Bend and Return Bends accordance to ASME standards

Pressure Rating of Alloy Steel Grade WP91 Fittings

| Normal Size Of Pipe (inches) |

Pipe Sch | OD

(inch) |

Wall Thick. (inch) |

Temperature(oF) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 | 200 | 300 | 400 | 500 | 600 | 650 | 700 | 750 | ||||

| Allowable Stress(psi) | ||||||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | 13500 | 13200 | 12900 | 12600 | ||||

| 1" | 40 | 1.315 | 0.133 | 2205 | 2205 | 2205 | 2047 | 1902 | 1783 | 1743 | 1703 | 1664 |

| 80 | 1.315 | 0.179 | 3061 | 3061 | 3061 | 2841 | 2640 | 2475 | 2420 | 2365 | 2310 | |

| 160 | 1.315 | 0.250 | 4493 | 4493 | 4493 | 4170 | 3874 | 3632 | 3552 | 3471 | 3390 | |

| 1 1/2" | 40 | 1.900 | 0.145 | 1629 | 1629 | 1629 | 1512 | 1404 | 1317 | 1287 | 1258 | 1229 |

| 80 | 1.900 | 0.200 | 2303 | 2303 | 2303 | 2138 | 1986 | 1862 | 1821 | 1779 | 1738 | |

| 160 | 1.900 | 0.281 | 3362 | 3362 | 3362 | 3120 | 2899 | 2717 | 2657 | 2597 | 2536 | |

| 2" | 40 | 2.375 | 0.154 | 1371 | 1371 | 1371 | 1272 | 1182 | 1108 | 1083 | 1059 | 1034 |

| 80 | 2.375 | 0.218 | 1985 | 1985 | 1985 | 1843 | 1712 | 1605 | 1569 | 1534 | 1498 | |

| 160 | 2.375 | 0.344 | 3283 | 3283 | 3283 | 3047 | 2831 | 2654 | 2595 | 2536 | 2477 | |

| 3" | 40 | 3.500 | 0.216 | 1301 | 1301 | 1301 | 1208 | 1122 | 1052 | 1028 | 1005 | 982 |

| 80 | 3.500 | 0.300 | 1844 | 1844 | 1844 | 1712 | 1590 | 1491 | 1458 | 1425 | 1391 | |

| 160 | 3.500 | 0.438 | 2787 | 2787 | 2787 | 2587 | 2403 | 2253 | 2203 | 2153 | 2103 | |

| 4" | 40 | 4.500 | 0.237 | 1102 | 1102 | 1102 | 1023 | 950 | 891 | 871 | 851 | 831 |

| 80 | 4.500 | 0.337 | 1596 | 1596 | 1596 | 1482 | 1377 | 1291 | 1262 | 1233 | 1204 | |

| 160 | 4.500 | 0.531 | 2611 | 2611 | 2611 | 2424 | 2552 | 2111 | 2064 | 2017 | 1970 | |

| 5" | 40 | 5.563 | 0.258 | 965 | 965 | 965 | 896 | 832 | 780 | 763 | 746 | 728 |

| 80 | 5.563 | 0.375 | 1428 | 1428 | 1428 | 1325 | 1231 | 1154 | 1129 | 1103 | 1077 | |

| 160 | 5.563 | 0.625 | 2474 | 2474 | 2474 | 2296 | 2133 | 2000 | 1955 | 1911 | 1866 | |

| 6" | 40 | 6.625 | 0.280 | 877 | 877 | 877 | 814 | 756 | 709 | 693 | 677 | 661 |

| 80 | 6.625 | 0.432 | 1379 | 1379 | 1379 | 1280 | 1189 | 1115 | 1090 | 1065 | 1040 | |

| 160 | 6.625 | 0.719 | 2382 | 2382 | 2382 | 2211 | 2054 | 1925 | 1883 | 1840 | 1797 | |

| 8" | 40 | 8.625 | 0.322 | 771 | 771 | 771 | 716 | 665 | 623 | 610 | 596 | 582 |

| 80 | 8.625 | 0.500 | 1218 | 1218 | 1218 | 1131 | 1050 | 985 | 963 | 941 | 919 | |

| 160 | 8.625 | 0.906 | 2298 | 2298 | 2298 | 2133 | 1982 | 1858 | 1817 | 1775 | 1734 | |

| 10" | 40 | 10.750 | 0.365 | 699 | 699 | 699 | 649 | 603 | 565 | 553 | 540 | 528 |

| 80 | 10.750 | 0.594 | 1159 | 1159 | 1159 | 1075 | 999 | 937 | 916 | 895 | 874 | |

| 160 | 10.750 | 1.125 | 2289 | 2289 | 2289 | 2124 | 1974 | 1850 | 1809 | 1768 | 1727 | |

UNS K90901 Fittings Dimensions Table

| Nominal Pipe Size | Outside Diameter | 90° Elbows | 45° Elbows | 180° Returns | ||||

|---|---|---|---|---|---|---|---|---|

| (inches) | Long Radius | Short Radius | Long Radius | Long Radius | ||||

| (mm) | (inches) | Center to Face (inches) |

Center to Face (inches) |

Center to Face (inches) |

Radius (inches) |

Center to Center (inches) |

Back to face (inches) |

|

| 1/2 | 21.3 | 0.840 | 1 1/2 | - | 5/8 | 2 | 1 7/8 | |

| 3/4 | 26.7 | 1.050 | 1 1/8 | - | 7/16 | 2 1/4 | 1 11/16 | |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 | 7/8 | 3 | 2 3/16 | |

| 1 1/4 | 42.2 | 1.660 | 1 7/8 | 1 1/4 | 1 | 3 3/4 | 2 3/4 | |

| 1 1/2 | 48.3 | 1.900 | 2 1/4 | 1 1/2 | 1 1/8 | 3 | 4 1/2 | 3 1/4 |

| 2 | 60.3 | 2.375 | 3 | 2 | 1 3/8 | 4 | 6 | 4 3/16 |

| 2 1/2 | 73.0 | 2.875 | 3 3/4 | 2 1/2 | 1 3/4 | 5 | 7 1/2 | 5 3/16 |

| 3 | 88.9 | 3.500 | 4 1/2 | 3 | 2 | 6 | 9 | 6 1/4 |

| 3 1/2 | 101.6 | 4.000 | 5 1/4 | 3 1/2 | 2 1/4 | 7 | 10 1/2 | 7 1/4 |

| 4 | 114.3 | 4.500 | 6 | 4 | 2 1/2 | 8 | 12 | 8 1/4 |

| 5 | 141.3 | 5.563 | 7 1/2 | 5 | 3 1/8 | 10 | 15 | 10 5/16 |

| 6 | 168.3 | 6.625 | 9 | 6 | 3 3/4 | 12 | 18 | 12 5/16 |

| 8 | 219.1 | 8.625 | 12 | 8 | 5 | 12 | 24 | 16 5/16 |

| 10 | 273.1 | 10.750 | 15 | 10 | 6 1/4 | 15 | 30 | 20 3/8 |

| 12 | 323.9 | 12.750 | 18 | 12 | 7 1/2 | 18 | 36 | 24 3/8 |

Manufacturer of Alloy Steel WP91 5D Elbow and Equal Tee Fittings offers Radiography & Eddy Current Testing, check sa234 wp91 material chemical composition and specification

ASTM A234 WP91 Fittings Price List

| ASTM A234 WP91 Fittings Price Per Piece in India | WNR 1.4903 Fittings Price in INR | Alloy Steel WP91 Buttweld Fittings Price in UAE Dirham | UNS K90901 Pipe Fittings Price in USD |

| ASTM A234 WP91 ELBOW 32 THK 27.75MM Per Kg | 433 | UAE Dirham 21.24 | $5.78 |

| ASTM A234 GR WP91 UNEQUAL TEE 38 24 THK 32.95MM X SCH 60 BEVELLED END Per Kg | 477 | UAE Dirham 23.39 | $6.37 |

| A234 WP91 ECCENTRIC REDUCER 38 36 THK 32.95MM X THK 31.21MM ASME B16.9 Per Kg | 478 | UAE Dirham 23.44 | $6.38 |

| ASTM A234 GR WP91 45 DEG LR ELBOW 38 THK 32.95 MM BEVELLED END Per Kg | 504 | UAE Dirham 24.72 | $6.73 |

Get Werkstoff 1.4903 Pipe Fittings At Best Price, India, Ask for a Live Quote Now For Alloy Steel cl1 WP91 Reducing Tee. Leading ASTM A234 WP91 Fittings Manufacturer in India

ASTM A234 WP91 Chemical Composition

| Grade | Carbon | Manganese | Silicon | Sulfur | Phosphorus | Chromium | Molybdenum |

| A234 WP91 | 0.05-0.2 | 0.3-0.8 | 0.5-1 | ≤0.030 | ≤0.030 | 1-1.5 | 0.44-0.65 |

ASME SA 234 WP91 Mechanical Properties

| Grade | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation % |

| A234 WP91 | 415 – 585 | ≥205 | ≥20 |

Elongation Requirements of UNS K90901 Pipe Fittings

| Longitundinal | Transverse | |

| Standard round specimen, or small proportioanl specimen, min % in 4 D |

22 | 14 |

| Rectangular speicmen for wall thickness 5/16″ and over, and for all small sizes tested in full section; min % in 2 in. |

30 | 20 A |

| Rectangular speicimen for wall thickness less than 5/16″; min % in 2 in (1/2″ wide specimen) |

B | B |

Physical Properties of WNR 1.4903 Fittings

| Temperature | Modulus of Elasticity | Thermal Conductivity | Linear Expansivity | Specific Heat | Density | |||

|---|---|---|---|---|---|---|---|---|

| °C | °F | GPa | 103ksi | W/mK | 10-6/°C | 10-6/°F | J/kg*K | kg/m3 |

| 20 | 68 | 218 | 31.6 | 26 | 0.0 | 0.0 | 440 | 7770 |

| 50 | 122 | 216 | 31.3 | 26 | 10.6 | 5.9 | 460 | |

| 100 | 212 | 213 | 30.9 | 27 | 10.9 | 6.1 | 480 | |

| 150 | 302 | 210 | 30.5 | 27 | 11.1 | 6.2 | 490 | |

| 200 | 392 | 207 | 30.0 | 28 | 11.3 | 6.3 | 510 | |

| 250 | 482 | 203 | 29.5 | 28 | 11.5 | 6.4 | 530 | |

| 300 | 572 | 199 | 28.9 | 28 | 11.7 | 6.5 | 550 | |

| 350 | 662 | 195 | 28.3 | 29 | 11.8 | 6.6 | 570 | |

| 400 | 752 | 190 | 27.0 | 29 | 12.1 | 6.7 | 630 | |

| 450 | 842 | 186 | 27.0 | 29 | 12.1 | 6.7 | 630 | |

| 500 | 932 | 181 | 26.3 | 30 | 12.3 | 6.8 | 660 | |

| 550 | 1022 | 175 | 25.4 | 30 | 12.4 | 6.9 | 710 | |

| 600 | 1112 | 168 | 24.4 | 30 | 12.6 | 7.0 | 770 | |

| 650 | 1202 | 162 | 23.5 | 30 | 12.7 | 7.1 | 860 | |

Heat Treatment of Alloy Steel Grade WP91 Fittings

| Heat Treatment | 1791°C - 1664°C |

Schedule 10 ASTM A234 Grade WP91 Short Radius 90 Degree Elbow and Alloy Steel WP91 LR Elbow manufacturer in India according to ASME B16.9

Different Types of ASTM A234 WP91 Fittings

A234 grade WP91 crmo 45° Long Radius Elbow

SCH 10 AS A234 WP91 90° Short Radius Elbow

A234 WP91 Equal Cross

SCH 120 Chromium A234 Grade WP91 180° Short Radius Elbow

ASTM A234 Chrome Moly WP91 5D Elbow

SCH 60 ASTM A234 WP91 Gr Cl1 Bend

Chromium A234 Grade WP91 Long Radius Bend

AS Grade WP91 Reducing Outlet Tees and Reducing Outlet Crosses

SCH 160 Alloy Steel Grade WP91 Short Stubend

SCH XS Chrome Moly A234-WP91 3D Elbow

Alloy Steel Grade WP91 Barrel Nipple

A234 WP91 Cl1 Reducing Tee

DIN 1.4903 Concentric Reducer

SCH 30 WNR 1.4903 Lap Joint Stub Ends

SCH STD ASTM A234 Chrome Moly WP91 Collar

Alloy steel Gr WP91 Reducing Cross

Alloy steel Gr WP91 1.5D Elbow

ASTM A234 WP91 Gr Cl1 Eccentric Reducer

SCH XXS Alloy Steel cl1 WP91 10D ELBOW

Alloy Steel cl1 WP91 Reducing Nipple

ASTM A234 WP91 Pipe Cap

UNS K90901 Welded Elbows

Chrome Moly A234-WP91 Stub End

SCH 80 UNS K90901 Reducers

ASME SA 234 WP91 Seamless Buttwelding 45° and 90° Elbows

Alloy Steel WP91 180° Long Radius Elbow

A234 WP91 Cl1 Equal Tee

450 NB SCH 40 Werkstoff 1.4903 Pipe Nipples

15 NB SCH 100 SA234 Gr WP91 1D Elbow

Werkstoff 1.4903 End Cap

ASME SA234 WP91 Seamless Buttwelding 180° Returns

ASTM A234 Gr WP91 90° Long Radius Elbow

WNR 1.4903 Swage Nipple

SCH 140 SA234 WP91 45° Short Radius Elbow

A234 grade WP91 crmo Long Stubend

SCH 20 ASME SA 234 Grade WP91 Straight Tees and Crosses

Applicable Standards of Chromium A234 Grade WP91 Buttweld Fittings

- ASME B16.9 for large Bore

- ASME B16.25 for butt weld ends

- ASME B16.11 for small Bore (socket welded)

- ASME B16.28 for small radius elbow

SA234 WP91 Fittings For Sale

| UNS K90901 Elbow Pipe Fittings | A234 grade WP91 crmo End Pipe Cap |

| ASTM A234 Weldable Pressure 91 Gr Cl1 180 Deg Short Radius Elbow | Alloy steel Gr WP91 Lateral Tee |

| A234 WP91 Equal Cross | Alloy Steel Weldable Pressure 91 Welded Pipe Fittings |

| AS A234 Weldable Pressure 91 Seamless Pipe Fitting | Alloy Steel Grade WP91 Pipe End Cap |

| SA234 Gr WP91 Eccentric Reducer | Chromium A234 Grade Weldable Pressure 91 Pipe Nipple |

| Alloy Steel cl1 WP91 Elbow Fittings | A234 grade Weldable Pressure 91 crmo 90 Deg Short Radius Elbow |

| Chromium A234 Grade Weldable Pressure 91 Buttweld Fittings | DIN 1.4903 Eccentric Reducer |

| ASME SA 234 Weldable Pressure 91 180 Deg Long Radius Elbow | ASME SA 234 Grade WP91 Pipe Cross |

| Alloy Steel cl1 Weldable Pressure 91 90 Deg Long Radius Elbow | WNR 1.4903 Pipe Reducer |

| A234 Weldable Pressure 91 U Bend | ASME SA234 WP91 Equal Tee Fittings |

| Chrome Moly A234-Weldable Pressure 91 5D Bend | Werkstoff 1.4903 Concentric Reducer Fittings |

| A234 WP91 Cl1 45 Deg Long Radius Elbow | AS A234 Weldable Pressure 91 Pipe Tee Fittings |

| ASTM A234 Chrome Moly WP91 Stubends Fittings | ASTM A234 Gr Weldable Pressure 91 BW Tee Fittings |

| ASTM A234 Chrome Moly WP91 Seamless Tee Fittings | ASTM A234 WP91 Reducer |

| UNS K90901 45 Deg Short Radius Elbow | Alloy steel Gr Weldable Pressure 91 Pipe Bends |

| Werkstoff 1.4903 Stub End | UNS K90901 Pipe Cap |

| AS Grade WP91 Long Radius Bend | WNR 1.4903 Cross |

| Chrome Moly A234-WP91 Seamless Butt Weld Fittings | DIN 1.4903 Reducing Tee Fittings |

| WNR 1.4903 Reducing Cross | AS Grade Weldable Pressure 91 Seamless Bend Pipe |

| Werkstoff 1.4903 End Cap | Alloy Steel Grade WP91 Straight Cross |

| ASTM A234 Weldable Pressure 91 Gr Cl1 Tees | SA234 WP91 Buttweld Elbow |

Weight of Werkstoff 1.4903 Tee

| NPS | KG | LBS |

| 1/2 | 0.16 | 0.35 |

| 3/4 | 0.2 | 0.45 |

| 1 | 0.34 | 0.75 |

| 1¼ | 0.59 | 1.3 |

| 1½ | 0.91 | 2 |

| 2 | 1.59 | 3.5 |

| 2½ | 2.72 | 6 |

| 3 | 3.18 | 7 |

| 3½ | 4.08 | 9 |

| 4 | 5.44 | 12 |

| 5 | 9.53 | 21 |

| 6 | 15.42 | 34 |

| 8 | 24.95 | 55 |

| 10 | 38.56 | 85 |

| 12 | 54.43 | 120 |

| 14 | 74.84 | 165 |

| 16 | 88.45 | 195 |

| 18 | 112.94 | 249 |

| 20 | 155.13 | 342 |

| 22 | 187.79 | 414 |

| 24 | 239.5 | 528 |

| 26 | 349.27 | 770 |

| 30 | 480.81 | 1060 |

| 36 | 675.85 | 1490 |

ASTM A234 Chrome Moly WP91 Reducer Dimensions Table

| Nominal Pipe Size |

Outside Diameter |

Reducers | ||

|---|---|---|---|---|

| Reduced from (inches) |

(inches) | (mm) | Concentric & Eccentric Length (inches) |

Reduced to (inches) |

| 1/2 | 0.840 | 21.3 | 1 1/2 | 1/4 |

| 1 1/2 | 3/8 | |||

| 3/4 | 1.050 | 26.7 | 2 | 3/8 |

| 2 | 1/2 | |||

| 1 | 1.315 | 33.4 | 2 | 3/8 |

| 2 | 1/2 | |||

| 2 | 3/4 | |||

| 1 1/4 | 1.660 | 42.2 | 2 | 1/2 |

| 2 | 3/4 | |||

| 2 | 1 | |||

| 1 1/2 | 1.900 | 48.3 | 2 1/2 | 1/2 |

| 2 1/2 | 3/4 | |||

| 2 1/2 | 1 | |||

| 2 1/2 | 1 1/4 | |||

| 2 | 2.375 | 60.3 | 3 | 3/4 |

| 3 | 1 | |||

| 3 | 1 1/4 | |||

| 3 | 1 1/2 | |||

| 2 1/2 | 2.875 | 73.0 | 3 1/2 | 1 |

| 3 1/2 | 1 1/4 | |||

| 3 1/2 | 1 1/2 | |||

| 3 1/2 | 2 | |||

| 3 | 3.500 | 88.9 | 3 1/2 | 1 |

| 3 1/2 | 1 1/2 | |||

| 3 1/2 | 2 | |||

| 3 1/2 | 2 1/2 | |||

| 3 1/2 | 4.000 | 101.6 | 4 | 1 1/4 |

| 4 | 1 1/2 | |||

| 4 | 2 | |||

| 4 | 2 1/2 | |||

| 4 | 3 | |||

| 4 | 4.500 | 114.3 | 4 | 1 1/2 |

| 4 | 2 | |||

| 4 | 2 1/2 | |||

| 4 | 3 | |||

| 4 | 3 1/2 | |||

| 5 | 5.563 | 141.3 | 5 | 2 |

| 5 | 2 1/2 | |||

| 5 | 3 | |||

| 5 | 3 1/2 | |||

| 5 | 4 | |||

| 6 | 6.625 | 168.3 | 5 1/2 | 2 1/2 |

| 5 1/2 | 3 | |||

| 5 1/2 | 3 1/2 | |||

| 5 1/2 | 4 | |||

| 5 1/2 | 5 | |||

| 8 | 8.625 | 219.1 | 6 | 3 |

| 6 | 3 1/2 | |||

| 6 | 4 | |||

| 6 | 5 | |||

| 6 | 6 | |||

| 10 | 10.750 | 273.1 | 7 | 4 |

| 7 | 5 | |||

| 7 | 6 | |||

| 7 | 8 | |||

| 12 | 12.750 | 323.9 | 8 | 5 |

| 8 | 6 | |||

| 8 | 8 | |||

| 8 | 10 | |||

A234 WP91 Cl1 Elbow Weight Chart

| NPS | KG | LBS |

| 1/2 | 0.11 | 0.25 |

| 3/4 | 0.11 | 0.25 |

| 1 | 0.23 | 0.5 |

| 1¼ | 0.41 | 0.9 |

| 1½ | 0.52 | 1.15 |

| 2 | 1 | 2.2 |

| 2½ | 1.81 | 4 |

| 3 | 2.95 | 6.5 |

| 3½ | 3.79 | 8.35 |

| 4 | 6.12 | 13.5 |

| 5 | 9.98 | 22 |

| 6 | 15.88 | 35 |

| 8 | 32.21 | 71 |

| 10 | 48.53 | 107 |

| 12 | 72.57 | 160 |

| 14 | 92.99 | 205 |

| 16 | 125.19 | 276 |

| 18 | 154.22 | 340 |

| 20 | 190.51 | 420 |

| 22 | 235.87 | 520 |

| 24 | 272.16 | 600 |

| 26 | 330.67 | 729 |

| 30 | 442.25 | 975 |

| 36 | 640.47 | 1412 |

Dimensions of Chromium A234 Grade WP91 Tee

| NOMINAL PIPE SIZE | LENGTH | CENTER TO END | OUTSIDE DIAMETER |

|---|---|---|---|

| Inch. | M | C | OD |

| 1/2 | 25 | 25 | 21.3 |

| 3/4 | 29 | 29 | 26.7 |

| 1 | 38 | 38 | 33.4 |

| 1 1/4 | 48 | 48 | 42.2 |

| 1 1/2 | 57 | 57 | 48.3 |

| 2 | 64 | 64 | 60.3 |

| 2 1/2 | 76 | 76 | 73 |

| 3 | 86 | 86 | 88.9 |

| 3 1/2 | 95 | 95 | 101.6 |

| 4 | 105 | 105 | 114.3 |

| 5 | 124 | 124 | 141.3 |

| 6 | 143 | 143 | 168.3 |

| 8 | 178 | 178 | 219.1 |

| 10 | 216 | 216 | 273.1 |

| 12 | 254 | 254 | 323.9 |

| 14 | 279 | 279 | 355.6 |

| 16 | 305 | 305 | 406.4 |

| 18 | 343 | 343 | 457.2 |

| 20 | 381 | 381 | 508 |

| 22 | 419 | 419 | 559 |

| 24 | 432 | 432 | 610 |

| 26 | 495 | 495 | 660 |

| 28 | 521 | 521 | 711 |

| 30 | 559 | 559 | 762 |

| 32 | 597 | 597 | 813 |

| 34 | 635 | 635 | 864 |

| 36 | 673 | 673 | 914 |

| 38 | 711 | 711 | 965 |

| 40 | 749 | 749 | 1016 |

| 42 | 711 | 762 | 1067 |

| 44 | 762 | 813 | 1118 |

| 46 | 800 | 851 | 1168 |

| 48 | 838 | 889 | 1219 |

Applications of DIN 1.4903 Butweld Fittings

- Pharmaceutical Equipment

- Petrochemicals

- Chemical Equipment

- Power Generation

- Gas Processing

- Sea Water Equipment

- Pulp and Paper Industry

Alloy steel Gr WP91 Weld Fittings Inspection and Testing

- Hardness Test

- Pitting Resistance Test

- Chemical Analysis

- Flattening Test

- Micro and Macro Test

- Flaring Test

- Intergranular Corrosion Test

- Positive Material Identification

Pipe Fittings Material

Flanges Material

Other Products