- Call : +91 22 67436442

- exports@petrometflange.com

Weldo Flange

- Home /

- Weldo Flange

Integrally forged ASTM A105N Reinforced Nipoflange and Carbon Steel A350 LF2 Promat Weldoflange manufacturer in India

What is Nippo Flanges?

The Nippo Flanges are basically created by combining a weld neck flange along with a weldolet or a nipolet. There are branched connections on one of the sides of the run pipe which is the main welding connection and on the other side, there is a flanged connection. The design of the flanged connection is customized according to the specific requirements, according to standards like DIN, ANSI, etc.

The Nippo Flanges are available in forged, threaded, and screwed type. Their production technique involves forging, heat treating, and machining. They are available in different types of faces, including the raised face, ring type joint facing, flat face, etc. Depending on the material grade with which the Nippo Flanges are made, they can be used in a wide variety of environments. Usually, they are found in bitumen upgraders, heavy oil refineries, petrochemical industry equipment, etc. The seamless variants are popularly used in the nuclear plants. They are available with different pressure ratings, upto 2500#.

The Nippo Flanges are also used extensively for linking up the reinforced fittings together. They are available in different sizes that generally range from ⅛” to 4”. They come with fine finishes and are also resistant to corrosions. Clients can get the Nippo Flanges in various grades, dimensions and patterns according to their requirements. It is durable, low-maintenance, and a high-performing flange that comes at an affordable price.

What is Weldoflange?

Weldoflange can be described as a flange that possesses the features of a weld neck flange and a welding outlet. They are mostly made of a single metal piece, without any welding, which improves their strength and toughness in the design. This means that the welding outlet along with the weld neck flange are manufactured as a single piece. These flanges work as branched connections that 90 degrees branches from the run pipe. To give the best performance, they should be compliant to different standards like ANSI, ASME, etc., and also the pressure ratings. The Weldoflange is known for its exceptional performance and that is why they are used for meeting various demands. They are available in different material grades and thus are used in different environments accordingly. Common uses of Weldoflange are in oil and gas pipeline, chemical industry, plumbing, water supply system, structural pipes, etc.

Difference Between Nipoflange vs Weldoflange

There is only one difference between the Nipo Flange and the Weldoflange, which is for nipo flange one of the sides has branched connections at 90 degrees angle from the run pipe and on the other side there is a flanged connection that connects the main pipe or other devices. However, for weldoflange, it only has branched connections with branches at 90 degrees angle from the run pipe. Other than this, both the flanges are similar in their working, design, etc.

Where to we Use Nippo Flanges

Depending on the material grade of the Nippo flange, they can be used in different applications. For example, the carbon steel nip flanges are used for branched connections, but in case there is a requirement for light weight or corrosive resistive nipo flange, then alloy steel material ones can be used. Also, the reinforced nipo flanges that are made of the nickel alloy, are used in different applications, like sea water equipment, cooling system, oil refinery equipment, etc. The composition of the nipo alloy determines its strength and pressure requirements, which in turn helps to understand where they shall be used.

What are the standard of Weldoflange

The dimensional standard of Weldoflange is determined according to the custom drawings, like ANSI B16.5, ANSI B16.47 Series A & B, etc. They are available in different classes from 150 LBS to 2500 LBS, and various DIN standards. They also have different BS standards, like BS10, BS1560, BS4504.

Weldo Flange

European Directive 2014/68/eu certified Stainless Steel Weldo Flange manufacturers in Mumbai offers widest range of ASTM A182 F304 Weld o Flange, Promat Contoured Bodied Flange and A182 F316 Nipo flange rtj in India

Table of Content

Weldo Flange Specification

| Dimensions | ASME B16.5, ASME B16.47 Series A & B, MSS SP44 |

| Size | 1/2" to 48" |

| Class | 300 LBS, 150 LBS, 900 LBS, 600 LBS, 1500 LBS, 2500 LBS |

| JIS | 5K, 16 K 10 K, 20 K, 40 K, 30 K, 63 K |

|---|---|

| UNI | 6Bar 16Bar 10Bar 25Bar 40Bar |

| Coating/Surface Treatment By Manufacturer | Antirust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

| EN | 6Bar 25Bar 10Bar 40Bar 16Bar |

| BS | BS4504 , BS4504, BS1560, BS10 |

| Flange Face Type Provided By Manufacturer | RF (Raised Face), RTJ (Ring Type Joint) |

| Value Added Services | CNC Machining, Customised Flanges |

| Making Methods Provided By Manufacturer | Casting And Forging Rolling And Cutting |

| Flanges Test | Hydrostatic testing machine/ UI trasonic flaw detector/ X-ray detector/ Direct-reading Spectrograph/ Magnetic particle detector |

| Flanges Equipment | Pushing Machine/ electric bevelling machine/ Press machine/ Bending machine/ Sand-blasting machine etc |

| Outer diameters | 1/2” to 24” |

| Standards Provided By Manufacturer | EN-1092, DIN, API7S-43, API605, B16.48, ISO70051, MSS S44, ANSI/ASME B16.5, B16.47 Series A & B, BS4504, BS 10, API7S-15, JISB2220, BS1560-3.1, ASME/ANSI B16.5/16.36/16.47A/16.47B, EN1092 |

Material Grade Of Nipo / Weldo Flange

| Stainless Steel | ASTM A182 Gr. 304, 304L, 309, 316, 310, 316L, 317L, 321, 347, 904L |

| Duplex Steel | ASTM A 182, ASME SA 182 UNS NO S31803, S32205. Werkstoff No. 1.4462 |

| Carbon Steel | High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80), A181 LF2, A105N, ASTM A350 LF2 / ASME SA350, ASTM/ASME A/SA105 A/SA105N & ASTM A105 / ASME SA105, P235GH, P245GH, P250GH, RST37.2, C22.8, S235JR, ST37, A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706 |

| Copper Nickel | Cupro Nickel 70/30 (C71500), Copper Nickel 90/10 (C70600 ), ASTM / ASME SB 62 / 151 / 61 / 152, UNS C71640 |

| Nickel Alloy | ASTM / ASME SB 564 UNS 4400 (MONEL 400 ), UNS 2200 ( NICKEL 200 ), UNS 8825 INCONEL (825), UNS 2201 (NICKEL 201 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 6600 (INCONEL 600 ), UNS 10276 ( HASTELLOY C 276 ) |

| Alloy Steel | F11, F12, F5, F9, F22, F91 |

| Other | Titanium, Aluminium, 254 SMO |

Types Of Weldo Flange / Nipoflange

Stainless Steel 304 Nipo Flange

316 Stainless Steel Weldoflange

Stainless Steel Weldo Flange

Super Duplex Nipoflange

ASTM A105N Reinforced Nipoflange

ASTM A182 F304 Weld o Flange

Carbon Steel A350 LF2 Promat Weldoflange

A182 F316 Nipo flange rtj

Alloy Steel Promat Contoured Bodied Flange Branch Fittings

ASTM A182 F11 Weldoflange Fittings

Nickel Alloy Promat Nipoflange

Carbon Steel Promat Reinforced Nipoflange

Duplex Promat Contoured Bodied Flange

Inconel Weld o Flange

Hastelloy Nipo flange

Manufacturing Weldo Flange with a combination of welding neck flange, nipolet, and weldolet, supplier of Alloy Steel Promat Contoured Bodied Flange Branch Fittings and ASTM A182 F11 Weldoflange Fittings offers hydrostatic testing to confirm the integrity of weldments

Nipo Flange Weight Chart

| NPS (Inches) |

DN (mm) |

FLANGE OD A MM |

FLANGE THICKNESS D MM |

SLIP ON FLANGE WEIGHT (KGS) | WELD NECK FLANGE WEIGHT (KGS) | BLIND FLANGE WEIGHT (KGS) |

| 1/ 2 | 15 | 88.9 | 11.2 | 0.4 | 0.5 | 0.4 |

| 3/ 4 | 20 | 98.6 | 12.7 | 0.6 | 0.7 | 0.6 |

| 1 | 25 | 108 | 14.2 | 0.8 | 1 | 0.9 |

| 1 1/ 4 | 32 | 117.3 | 15.7 | 1 | 1.3 | 1.2 |

| 1 1/ 2 | 40 | 127 | 17.5 | 1.3 | 1.7 | 1.5 |

| 2 | 50 | 152.4 | 19.1 | 2.1 | 2.6 | 2.4 |

| 2 1/ 2 | 65 | 177.8 | 22.4 | 3.3 | 4.1 | 3.9 |

| 3 | 80 | 190.5 | 23.9 | 3.9 | 4.9 | 4.9 |

| 3 1/ 2 | 90 | 215.9 | 23.9 | 4.8 | 6.1 | 6.2 |

| 4 | 100 | 228.6 | 23.9 | 5.3 | 6.8 | 7.0 |

| 5 | 125 | 254 | 23.9 | 6.1 | 8.6 | 8.6 |

| 6 | 150 | 279.4 | 25.4 | 7.5 | 10.6 | 11.3 |

| 8 | 200 | 342.9 | 28.4 | 12.1 | 17.6 | 19.6 |

| 10 | 250 | 406.4 | 30.2 | 16.5 | 24 | 28.6 |

| 12 | 300 | 482.6 | 31.8 | 26.2 | 36.5 | 43.2 |

| 14 | 350 | 533.4 | 35.1 | 34.6 | 48.4 | 58.1 |

| 16 | 400 | 596.9 | 36.6 | 44.8 | 60.6 | 76.1 |

| 18 | 450 | 635 | 39.6 | 48.9 | 68.3 | 93.7 |

| 20 | 500 | 698.5 | 42.9 | 61.9 | 84.5 | 122.0 |

| 24 | 600 | 812.8 | 47.8 | 86.9 | 115 | 185.0 |

Weldo Flange Price List

| Weldo Flange Price Per Piece in India | Nipoflange Price in INR | Promat Weldoflange Price in UAE Dirham | Weld o Flange Price in USD |

| CARBON STEEL GRADE .A 105 1.25 IN WELDO FLANGE Per Kg | 9,021 | UAE Dirham 445.43 | $121.27 |

| NIPOFLANGE ASTM A105N Per Piece | 39,534 | UAE Dirham 1952.07 | $531.47 |

| NIPOFLANGE DN 50MM. X DN 300MM Per Kg | 2,508 | UAE Dirham 123.84 | $33.72 |

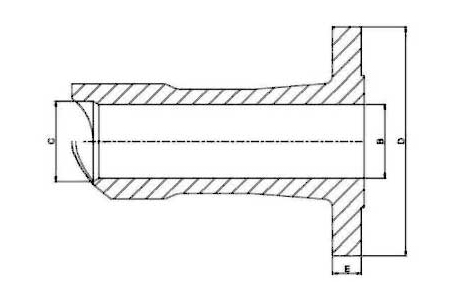

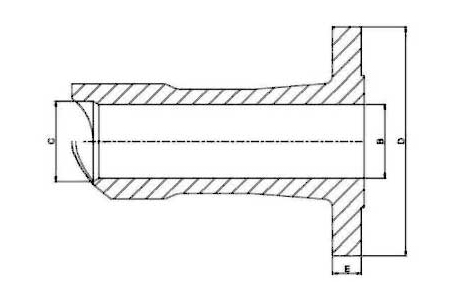

Weldo / Nipo Flange Dimensions Branch ½”

RATING |

NOMINAL PIPE SIZE FROM 3/4" TO 36" |

|||||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

|

STD |

15,8 |

18,5 |

0,9 |

|||

150# |

XS |

13,8 |

17,6 |

88,9 |

11,2 |

0,9 |

160 |

11,7 |

11,7 |

0,9 |

|||

XXS |

6,4 |

6,4 |

0,9 |

|||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

|

STD |

15,8 |

18,5 |

1,2 |

|||

300# |

XS |

13,8 |

17,6 |

95,3 |

14,3 |

1,2 |

160 |

11,7 |

11,7 |

1,2 |

|||

XXS |

6,4 |

6,4 |

1,2 |

|||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

|

STD |

15,8 |

18,5 |

1,3 |

|||

600# |

XS |

13,8 |

17,6 |

95,3 |

14,3 |

1,3 |

160 |

11,7 |

11,7 |

1,3 |

|||

XXS |

6,4 |

6,4 |

1,3 |

|||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

|

STD |

15,8 |

18,5 |

2,4 |

|||

900# |

XS |

13,8 |

17,6 |

120,6 |

22,4 |

2,4 |

160 |

11,7 |

11,7 |

2,4 |

|||

XXS |

6,4 |

6,4 |

2,4 |

|||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

|

STD |

15,8 |

18,5 |

2,4 |

|||

1500# |

XS |

13,8 |

17,6 |

120,6 |

22,4 |

2,4 |

160 |

11,7 |

11,7 |

2,4 |

|||

XXS |

6,4 |

6,4 |

2,4 |

|||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

|

STD |

15,8 |

18,5 |

3,6 |

|||

2500# |

XS |

13,8 |

17,6 |

133,4 |

30,2 |

3,6 |

160 |

11,7 |

11,7 |

3,6 |

|||

XXS |

6,4 |

6,4 |

3,6 |

|||

Manufacturer of Raised/ rtj/ flat face Promat Nipoflange and Weldo Flange compliance to ANSI B31.8/ BS 5500 Pressure Vessels

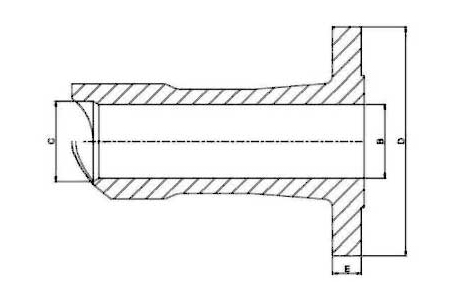

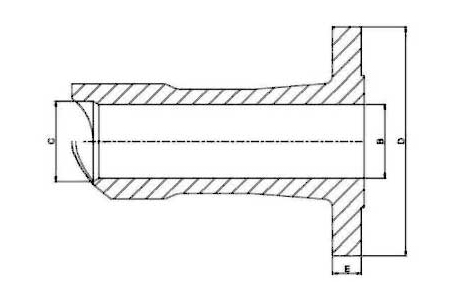

Branch ¾” Weldo / Nipo Flange Dimensions

RATING |

NOMINAL PIPE SIZE FROM 1" TO 36" |

||||||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

||

STD |

21 |

23,8 |

1,2 |

||||

150# |

XS |

18,9 |

22,8 |

98,6 |

12,7 |

1,2 |

|

160 |

15,6 |

15,6 |

1,4 |

||||

XXS |

11,1 |

11,1 |

1,5 |

||||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

||

STD |

21 |

23,8 |

1,7 |

||||

300# |

XS |

18,9 |

22,8 |

117,4 |

15,8 |

1,9 |

|

160 |

15,6 |

15,6 |

2 |

||||

XXS |

11,1 |

11,1 |

2,1 |

||||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

||

STD |

21 |

23,8 |

2 |

||||

600# |

XS |

18,9 |

22,8 |

117,4 |

15,8 |

2,1 |

|

160 |

15,6 |

15,6 |

2,2 |

||||

XXS |

11,1 |

11,1 |

2,2 |

||||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

||

STD |

21 |

23,8 |

3,1 |

||||

900# |

XS |

18,9 |

22,8 |

130 |

25,4 |

3,2 |

|

160 |

15,6 |

15,6 |

3,2 |

||||

XXS |

11,1 |

11,1 |

3,3 |

||||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

||

STD |

21 |

23,8 |

3,1 |

||||

1500# |

XS |

18,9 |

22,8 |

130 |

25,4 |

3,2 |

|

160 |

15,6 |

15,6 |

3,2 |

||||

XXS |

11,1 |

11,1 |

3,3 |

||||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

||

STD |

21 |

23,8 |

4,4 |

||||

2500# |

XS |

18,9 |

22,8 |

139,7 |

31,8 |

4,5 |

|

160 |

15,6 |

15,6 |

4,5 |

||||

XXS |

11,1 |

11,1 |

4,6 |

||||

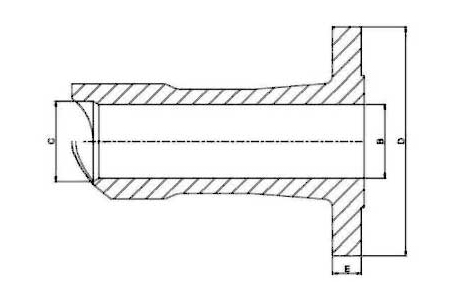

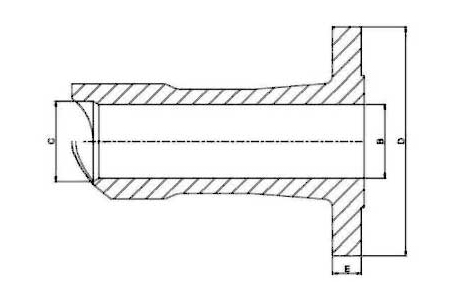

Branch 1" Weldo Flange Dimensions

RATING |

NOMINAL PIPE SIZE FROM 1.1/2" TO 36" |

|||||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

|

STD |

26,6 |

30 |

1,7 |

|||

150# |

XS |

24,3 |

28,8 |

108 |

14,3 |

1,7 |

160 |

20,7 |

20,7 |

2 |

|||

XXS |

15,2 |

15,2 |

2,2 |

|||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

|

STD |

26,6 |

30 |

2,3 |

|||

300# |

XS |

24,3 |

28,8 |

124 |

17,6 |

2,5 |

160 |

20,7 |

20,7 |

2,6 |

|||

XXS |

15,2 |

15,2 |

2,8 |

|||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

|

STD |

26,6 |

30 |

2,6 |

|||

600# |

XS |

24,3 |

28,8 |

124 |

17,6 |

2,7 |

160 |

20,7 |

20,7 |

2,8 |

|||

XXS |

15,2 |

15,2 |

3 |

|||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

|

STD |

26,6 |

30 |

4,5 |

|||

900# |

XS |

24,3 |

28,8 |

149,4 |

28,5 |

4,6 |

160 |

20,7 |

20,7 |

4,7 |

|||

XXS |

15,2 |

15,2 |

4,8 |

|||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

|

STD |

26,6 |

30 |

4,5 |

|||

1500# |

XS |

24,3 |

28,8 |

149,4 |

28,5 |

4,6 |

160 |

20,7 |

20,7 |

4,7 |

|||

XXS |

15,2 |

15,2 |

4,8 |

|||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

|

STD |

26,6 |

30 |

6,1 |

|||

2500# |

XS |

24,3 |

28,8 |

158,8 |

35,1 |

6,2 |

160 |

20,7 |

20,7 |

6,2 |

|||

XXS |

15,2 |

15,2 |

6,3 |

|||

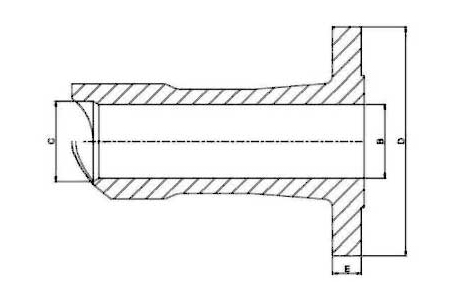

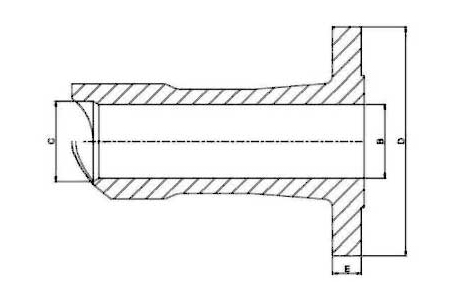

Nipo Flange Dimensions Branch 1½”

RATING |

NOMINAL PIPE SIZE FROM 2" TO 36" |

||||||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

||

STD |

40,9 |

44,6 |

3,1 |

||||

150# |

XS |

38,1 |

43,2 |

127 |

17,5 |

3,3 |

|

160 |

34 |

34 |

3,5 |

||||

XXS |

28 |

28 |

3,8 |

||||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

||

STD |

40,9 |

44,6 |

4,1 |

||||

300# |

XS |

38,1 |

43,2 |

155,5 |

20,6 |

4,5 |

|

160 |

34 |

34 |

4,7 |

||||

XXS |

28 |

28 |

5 |

||||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

||

STD |

40,9 |

44,6 |

4,9 |

||||

600# |

XS |

38,1 |

43,2 |

155,5 |

22,4 |

5 |

|

160 |

34 |

34 |

5,2 |

||||

XXS |

28 |

28 |

5,5 |

||||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

||

STD |

40,9 |

44,6 |

7,2 |

||||

900# |

XS |

38,1 |

43,2 |

177,8 |

31,8 |

7,4 |

|

160 |

34 |

34 |

7,6 |

||||

XXS |

28 |

28 |

7,9 |

||||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

||

STD |

40,9 |

44,6 |

7,2 |

||||

1500# |

XS |

38,1 |

43,2 |

177,8 |

31,8 |

7,4 |

|

160 |

34 |

34 |

7,6 |

||||

XXS |

28 |

28 |

7,9 |

||||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

||

STD |

40,9 |

44,6 |

12 |

||||

2500# |

XS |

38,1 |

43,2 |

203,2 |

44,5 |

12 |

|

160 |

34 |

34 |

12,2 |

||||

XXS |

28 |

28 |

12,5 |

||||

Check ANSI 150/ 300/ 600/ 2500 Mild Steel Promat Reinforced Nipoflange and Titanium Weldo Flange temperature & price in Mumbai

Weldo / Nipo Flange Dimensions Branch 2″

RATING |

NOMINAL PIPE SIZE FROM 3" TO 36" |

||||||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

||

STD |

52,5 |

56,4 |

4,1 |

||||

150# |

XS |

49,2 |

54,8 |

152,4 |

19,1 |

4,8 |

|

160 |

42,8 |

42,8 |

5,1 |

||||

XXS |

38,2 |

38,2 |

5,5 |

||||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

||

STD |

52,5 |

56,4 |

5,5 |

||||

300# |

XS |

49,2 |

54,8 |

165,1 |

22,4 |

5,8 |

|

160 |

42,8 |

42,8 |

6,1 |

||||

XXS |

38,2 |

38,2 |

6,5 |

||||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

||

STD |

52,5 |

56,4 |

6,2 |

||||

600# |

XS |

49,2 |

54,8 |

165,1 |

25,4 |

6,5 |

|

160 |

42,8 |

42,8 |

7 |

||||

XXS |

38,2 |

38,2 |

7,2 |

||||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

||

STD |

52,5 |

56,4 |

13 |

||||

900# |

XS |

49,2 |

54,8 |

215,9 |

38,1 |

13,3 |

|

160 |

42,8 |

42,8 |

13,6 |

||||

XXS |

38,2 |

38,2 |

13,9 |

||||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

||

STD |

52,5 |

56,4 |

13 |

||||

1500# |

XS |

49,2 |

54,8 |

215,9 |

38,1 |

13,3 |

|

160 |

42,8 |

42,8 |

13,6 |

||||

XXS |

38,2 |

38,2 |

13,9 |

||||

Bore schedule |

B |

C |

D |

E |

Weight [kg] |

||

STD |

52,5 |

56,4 |

18,4 |

||||

2500# |

XS |

49,2 |

54,8 |

235 |

50,8 |

18,6 |

|

160 |

42,8 |

42,8 |

19 |

||||

XXS |

38,2 |

38,2 |

19,3 |

||||

Branch 3" Weldo Flange Dimensions

RATING |

NOMINAL PIPE SIZE FROM 4" TO 36" |

||||

Bore schedule |

Length |

D |

E |

Weight [kg] |

|

150# |

10-STD |

115 |

7,5 |

||

XS-80 |

115 |

191 |

23,9 |

7,5 |

|

160-XXS |

145 |

8 |

|||

Bore schedule |

Length |

D |

E |

Weight [kg] |

|

300# |

10-STD |

125 |

10 |

||

XS-80 |

125 |

210 |

28,5 |

10 |

|

160-XXS |

150 |

11 |

|||

Bore schedule |

Length |

D |

E |

Weight [kg] |

|

600# |

10-STD |

135 |

13,5 |

||

XS-80 |

135 |

210 |

38,2 |

13,5 |

|

160-XXS |

165 |

14,5 |

|||

Bore schedule |

Length |

D |

E |

Weight [kg] |

|

900# |

10-STD |

155 |

17 |

||

XS-80 |

155 |

241 |

44,5 |

17 |

|

160-XXS |

180 |

18 |

|||

Bore schedule |

Length |

D |

E |

Weight [kg] |

|

1500# |

10-STD |

170 |

25 |

||

XS-80 |

170 |

267 |

54,1 |

25 |

|

160-XXS |

200 |

26 |

|||

Bore schedule |

Length |

D |

E |

Weight [kg] |

|

2500# |

10-STD |

220 |

45,5 |

||

XS-80 |

220 |

305 |

72,9 |

45,5 |

|

160-XXS |

250 |

51 |

|||

Nipo Flange Dimensions Branch 4″

RATING |

NOMINAL PIPE SIZE FROM 5" TO 36" |

||||

Bore schedule |

Length |

D |

E |

Weight [kg] |

|

150# |

10-STD |

130 |

11,5 |

||

XS-80 |

130 |

229 |

23,9 |

11,5 |

|

160-XXS |

160 |

13 |

|||

Bore schedule |

Length |

D |

E |

Weight [kg] |

|

300# |

10-STD |

140 |

16 |

||

XS-80 |

140 |

254 |

31,8 |

16 |

|

160-XXS |

170 |

17 |

|||

Bore schedule |

Length |

D |

E |

Weight [kg] |

|

600# |

10-STD |

160 |

24 |

||

XS-80 |

160 |

273 |

44,5 |

24 |

|

160-XXS |

195 |

26 |

|||

Bore schedule |

Length |

D |

E |

Weight [kg] |

|

900# |

10-STD |

170 |

28 |

||

XS-80 |

170 |

292 |

50,8 |

28 |

|

160-XXS |

205 |

29,5 |

|||

Bore schedule |

Length |

D |

E |

Weight [kg] |

|

1500# |

10-STD |

180 |

38 |

||

XS-80 |

180 |

311 |

60,2 |

38 |

|

160-XXS |

215 |

40 |

|||

Bore schedule |

Length |

D |

E |

Weight [kg] |

|

2500# |

10-STD |

250 |

70,5 |

||

XS-80 |

250 |

356 |

82,4 |

70,5 |

|

160-XXS |

281 |

72 |

|||

Branch 6" Weldo / Nipo Flange Dimensions

RATING |

NOMINAL PIPE SIZE FROM 8" TO 36" |

||||

Bore schedule |

Length |

D |

E |

Weight [kg] |

|

150# |

10-STD |

150 |

23,5 |

||

XS-80 |

170 |

279 |

25,4 |

25 |

|

160-XXS |

195 |

27 |

|||

Bore schedule |

Length |

D |

E |

Weight [kg] |

|

300# |

10-STD |

160 |

36,6 |

||

XS-80 |

175 |

318 |

36,6 |

37,5 |

|

160-XXS |

205 |

39 |

|||

Bore schedule |

Length |

D |

E |

Weight [kg] |

|

600# |

10-STD |

185 |

49,5 |

||

XS-80 |

200 |

356 |

54,1 |

51 |

|

160-XXS |

230 |

53,2 |

|||

Bore schedule |

Length |

D |

E |

Weight [kg] |

|

900# |

10-STD |

210 |

62,5 |

||

XS-80 |

225 |

381 |

62 |

64,3 |

|

160-XXS |

250 |

66 |

|||

Bore schedule |

Length |

D |

E |

Weight [kg] |

|

1500# |

10-STD |

240 |

87,5 |

||

XS-80 |

255 |

394 |

88,9 |

89 |

|

160-XXS |

285 |

91,2 |

|||

Bore schedule |

Length |

D |

E |

Weight [kg] |

|

2500# |

10-STD |

340 |

186 |

||

XS-80 |

360 |

483 |

114,3 |

189 |

|

160-XXS |

385 |

192,5 |

|||

Nipoflange Applications

- Nuclear Power

- Power Plants

- Oil And Gas Industry

- Paper & Pulp

- Refineries

- Fossil Fuel Power Plants

- Ship Building

- Marine Applications

Flanges Types

Pipe Fittings Material

Flanges Material

Other Products