- Call : +91 22 67436442

- exports@petrometflange.com

Stainless Steel Lap Joint Flange

- Home /

- Stainless Steel Lap Joint Flange

Looking for Lap Joint Flange manufacturers in India? We produce Loose Flange in AS, Carbon Steel, SS, Inconel, Hastelloy, Nickel, Titanium, Copper, and Aluminium Alloy

What Is Lap Joint Flange?

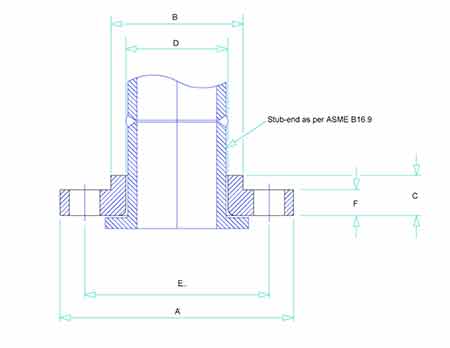

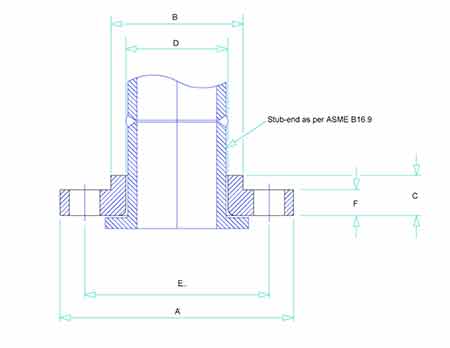

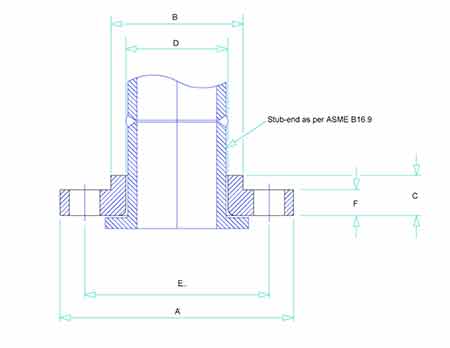

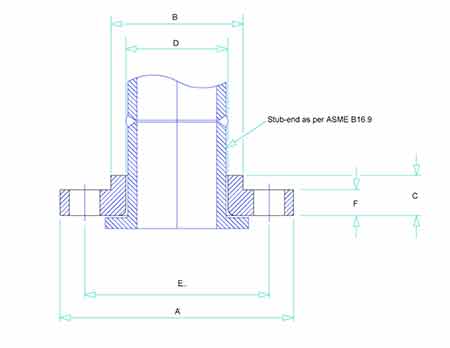

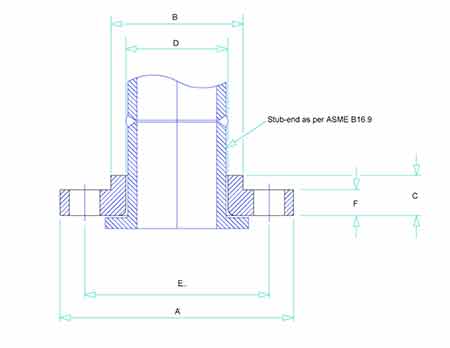

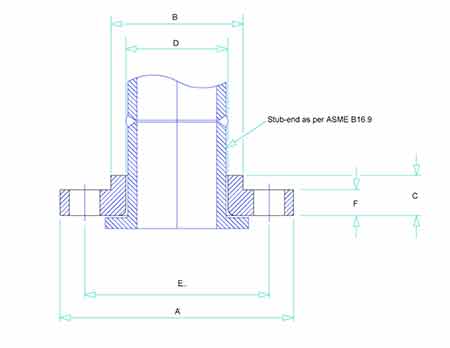

A Lap Joint Flange can be described as a two component assembly, which comes with a stub end and a ring flange placed on top of it. The stub end is basically buttwelded to the pipe, and the flange ring is rotated so that it can be perfectly aligned with the mating flange. They are mostly used for flanges that are hard to adjust or large. They are used in similar sizes and pressure classes as that of the weld neck flange.

The cost and the application environment where the Lap Joint Flange can be efficiently used depend on the material grade. They are available in customizable dimensions, which makes it easy to integrate them with any existing pipe or piping components. However, it is essential to remember that the biggest limitation of Lap Joint Flange is in its pressure ratings. They undoubtedly bear greater pressure than the slip-on flanges, but they are not perfect to be used in high pressure applications.

One of the best things about Lap Joint Flange is that the flange can be realigned and rotated freely. This helps in ensuring proper connection and it also ensures that the maintenance process is carried faster. As it does not require fillet weld for joining with the pipe, this reduces the installation time and helps in saving money. They can be used in highly corrosive or erossive processes as its parts can be replaced easily which ensures cost-effective operation.

Is A Stainless Steel Lap Joint Flange is Raised Face?

The Lap Joint Flange comes with a unique design due to which it always has a flat face that is accompanied by a smooth surface. But when accompanied by stub ends, the resultant sealing would have a raised face. It is because the stub end’s sealing face is above the bolting surface of the flange. Thus, the Stainless Steel Lap Joint Flange is Raised Face.

How To Install Carbon Steel Lap Joint Flange

The installation process of the Carbon Steel Lap Joint Flange is fairly simple. All you need is a few screws and you can install the flange to the pipe. The bolts are placed through the holes present in the flange and then they are tightened clockwise to improve their grip.

What Are The Advantages And Disadvantages Of A Lap Joint Pipe Flanges?

The Lap Joint Pipe Flanges come with a two-piece configuration, which has its own benefits. The stub end can be made from expensive material grade while the backing flange can be made from common carbon steel. This makes the flanges very cost-effective. Also, as the flange is not welded to the pipe, it can be rotated to be aligned and bolt the holes. This makes assembling and disassembling easier. Thus, they are ideal for piping operations that require frequent disassembling for inspections or maintenance.

There are also some Disadvantages Of Lap Joint Pipe Flanges, due to the design, contaminants might get collected easily, which could result in crevice corrosion. Also the longitudinal stress might accumulate and exceed the basic stress limit of the given standard. Thus, they are always used for mild services. Also, sometimes the material grade of the stub end might be different from that of the flange to save some cost, but this might cause galvanic corrosion in some cases.

Loose Flange Vs Lap Joint Flange

The loose flange is a synonym of the lap joint flange, and hence there is no difference between them.

Stainless Steel Lap Joint Flange

European Directive 2014/68/eu certified Carbon Steel ASTM A105 Vanstone Flange manufacturers in India offers widest selection of A182 F316 Stainless Steel Raised Face Lap Joint Flange and A516 Gr.70 LJ Flange in Mumbai

Table of Content

- Stainless Steel Lap Joint Flange Specification

- Different Material Grade For Loose Flange

- Lap Joint Flange Types

- Lap Joint Flange Price

- How To Make Lap Joint Flanges

- Stainless Steel Lap Joint Flange Surface Finish

- Lap Joint Flanges Limitations

- Facing Types of Lap Joint Flange

- Lap Joint Flange Weight

- 150 Lb Lap Joint Flange Dimensions

- 300# Lap Joint Flanges Dimensions

- Class 600 Lap Joint Flanges Dimensions

- Class 900 Lapped Joint Flange Dimensions

- Class 1500 Vanstone Flange Dimensions

- Class 2500 Lap Joint Flanges Dimensions

- PN10 Lap Joint Flange Dimensions

- PN16 Lap Joint Flange Dimensions

- Stainless Steel Lap Joint Flange Benefits

- Carbon Steel Lap Joint Flanges Applications

- Stud Bolt length for Lap Joint Flange

Stainless Steel Lap Joint Flange Specification

| Dimensions | ASME B16.5, ASME B16.47 Series A & B, MSS SP44 |

| Size | 1/2" to 48" |

| Class | 300 LBS, 150 LBS, 900 LBS, 600 LBS, 1500 LBS, 2500 LBS |

| JIS | 5K, 16 K 10 K, 20 K, 40 K, 30 K, 63 K |

|---|---|

| UNI | 6Bar 16Bar 10Bar 25Bar 40Bar |

| Coating/Surface Treatment By Manufacturer | Antirust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

| EN | 6Bar 25Bar 10Bar 40Bar 16Bar |

| BS | BS4504 , BS4504, BS1560, BS10 |

| Flanges Face Type Provided By Manufacturer | RF (Raised Face), RTJ (Ring Type Joint) |

| Value Added Services | CNC Machining, Customised Flanges |

| Making Methods Provided By Manufacturer | Casting And Forging Rolling And Cutting |

| Flanges Test | Hydrostatic testing machine/ UI trasonic flaw detector/ X-ray detector/ Direct-reading Spectrograph/ Magnetic particle detector |

| Flanges Equipment | Pushing Machine/ electric bevelling machine/ Press machine/ Bending machine/ Sand-blasting machine etc |

| Outer diameters | 1/2” to 24” |

| Standards Provided By Manufacturer | EN-1092, DIN, API7S-43, API605, B16.48, ISO70051, MSS S44, ANSI/ASME B16.5, B16.47 Series A & B, BS4504, BS 10, API7S-15, JISB2220, BS1560-3.1, ASME/ANSI B16.5/16.36/16.47A/16.47B, EN1092 |

Different Material Grade For Loose Flange

| Stainless Steel | ASTM A182 Gr. 304, 304L, 309, 316, 310, 316L, 317L, 321, 347, 904L |

| Duplex Steel | ASTM A 182, ASME SA 182 UNS NO S31803, S32205. Werkstoff No. 1.4462 |

| Carbon Steel | High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80), A181 LF2, A105N, ASTM A350 LF2 / ASME SA350, ASTM/ASME A/SA105 A/SA105N & ASTM A105 / ASME SA105, P235GH, P245GH, P250GH, RST37.2, C22.8, S235JR, ST37, A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706 |

| Copper Nickel | Cupro Nickel 70/30 (C71500), Copper Nickel 90/10 (C70600 ), ASTM / ASME SB 62 / 151 / 61 / 152, UNS C71640 |

| Nickel Alloy | ASTM / ASME SB 564 UNS 4400 (MONEL 400 ), UNS 2200 ( NICKEL 200 ), UNS 8825 INCONEL (825), UNS 2201 (NICKEL 201 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 6600 (INCONEL 600 ), UNS 10276 ( HASTELLOY C 276 ) |

| Alloy Steel | F11, F12, F5, F9, F22, F91 |

| Other | Titanium, Aluminium, 254 SMO |

Lap Joint Flange Types

Alloy Steel Loose Flange

Duplex LJ Flange

Super Duplex Lapped Joint Flange

Titanium Vanstone Flange

Mild Steel RFLJ Flange

Nickel Alloy LJFF Flange

Copper Raised Face Lap Joint Flange

Inconel Type A Lap Joint Flange

Hastelloy Lap Joint Backing Flange

Gi Class 600 Lap Joint Flange

ASTM A516 Gr.70 Flat Face Lap Joint Flange

ASTM A182 F316 LJFF Flange

ASTM A182 F304 Large Diameter Lap Joint Flange

ASTM A350 LF2 Lap Joint Flange Material

UNS S31803 Pn16 Lap Joint Flange

A182 F11 Lapped Joint Flange

Stainless Steel 304 Vanstone Flange

316 Stainless Steel RFLJ Flange

Galvanized Lap Joint Flange

Aluminum Lap Joint Flange

ASTM A105 Lap Joint Flange

Copper Nickel Lap Joint Flange

Ductile Iron Lap Joint Flange

Vanstone Flange Stainless Steel

Carbon Steel Lap Joint Flange

Stainless Steel Lap Joint Flange

ASME B16.5 Lap Joint Flange

ANSI 150 Lap Joint Flange

Jis 10k Lap Joint Flange

Lap Joint Flange N06022

Lap Joint Flange Price

| Stainless Steel Lap Joint Flange Price Per Piece in India | Lap Joint Flanges Price in INR | Loose Flanges Price in UAE Dirham | Vanstone Flanges Price in USD |

| F316L 2 LAP JOINT 1500 FLANGES Per Piece | 15,025 | UAE Dirham 741.89 | $201.99 |

| FLANGE: A105N 2 LAP JOINT 300 Per Piece | 2,389 | UAE Dirham 117.96 | $32.12 |

| FLANGES INC.825 2 LAP JOINT 600 Per Piece | 8,707 | UAE Dirham 429.93 | $117.05 |

Supply SS Lap Joint Flanges such as A182 F304 LJFF Flange & ASTM A350 LF2 RFLJ Flange with Safely Pressure Test

How To Make Lap Joint Flanges

A lap-joint flanges is a two-part assembly that consists of a stub end with a lap-joint ring flanges placed over it. After butt welding the stub end to the pipe, the flange ring can be rotated to align with the mating flange. This flanges connection is especially useful for large or difficult-to-adjust flanges.

Stainless Steel Lap Joint Flange Surface Finish

| Normal Pipe Size | (A) | (B) |

|---|---|---|

| 1/2 | 3.0 | 1.5 |

| 3/4 | 3.0 | 1.5 |

| 1 | 3.0 | 1.5 |

| 1-1/4 | 3.0 | 1.5 |

| 1-1/2 | 3.0 | 1.5 |

| 2 | 3.0 | 1.5 |

| 2-1/2 | 3.0 | 1.5 |

| 3 | 4.5 | 1.5 |

| 3-1/2 | 6.0 | 3.0 |

| 4 | 6.0 | 3.0 |

| 5 | 6.0 | 3.0 |

| 6 | 6.0 | 3.0 |

| 8 | 8.0 | 4.5 |

| 10 | 8.0 | 4.5 |

| 12 | 8.0 | 4.5 |

| 14 | 8.0 | 4.5 |

| 16 | 10.0 | 4.5 |

| 18 | 12.0 | 6.0 |

| 20 | 12.0 | 6.0 |

| 22 | 12.0 | 6.0 |

| 24 | 12.0 | 6.0 |

Lap Joint Flanges Limitations

- The most significant limitation of lap joint flanges use is pressure ratings.

- Contaminants can easily collect in the crevices formed between the internal surface of the flanges bore and the external surface of the stub ends.

- At the design temperature specified by ASME B31.3, longitudinal stresses caused by pressure, weight, and thermal expansion may accumulate and exceed the basic allowable stress.

Facing Types of Lap Joint Flange

- Type A: Flat Face (FF)

- Type B: Raised Face (RF)

- Type C: Tongue Face (TF)

- Type D: Grooved Face (GF)

- Type E: Spigo

- Type F: Recess

- Type G: Ring Recess

- Type H: O-Ring Groove

Buy raised/ rtj/ flat face Alloy Steel Lap Joint Flange and ASTM A182 F11 Loose Flange at Unbeatable Prices in Asia

Lap Joint Flange Weight

| Nominal Size | Outside Diameter | Lap Radus | Weight Each |

|---|---|---|---|

| (OD) | (lbs) | ||

| 1 | 4.25 | 0.13 | 2 |

| 11⁄4 | 4.63 | 0.19 | 3 |

| 11⁄2 | 5 | 0.25 | 3 |

| 2 | 6 | 0.31 | 5 |

| 21⁄2 | 7 | 0.31 | 7 |

| 3 | 7.5 | 0.38 | 8 |

| 31⁄2 | 8.5 | 0.38 | 11 |

| 4 | 9 | 0.44 | 13 |

| 5 | 10 | 0.44 | 15 |

| 6 | 11 | 0.5 | 18 |

| 8 | 13.5 | 0.5 | 30 |

| 10 | 16 | 0.5 | 42 |

| 12 | 19 | 0.5 | 64 |

| 14 | 21 | 0.5 | 90 |

| 16 | 23.5 | 0.5 | 98 |

| 18 | 25 | 0.5 | 125 |

| 20 | 27.5 | 0.5 | 160 |

| 24 | 32 | 0.5 | 212 |

| 30** | 38.75 | 0.5 | 305 |

| 36** | 46 | 0.5 | 440 |

150 Lb Lap Joint Flange Dimensions

| Size in Inch | Size in mm | Lapped Radius | Outer Diameter | Lapped Thick. | Lapped ID | Lapped Thick. | Hole Size | No of Bolts | Bolt Size UNC | Machine Bolt Length | PCD | RF Stud Length | ISO Stud Size | Flanges Thick. | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | C | D | G | E | B | ||||||||||

| 1/2 | 15 | 3 | 90 | 16 | 22.9 | 11.2 | 5/8 | 4 | 1/2 | 50 | 60.3 | 55 | M14 | 30 | 0.8 |

| 3/4 | 20 | 3 | 100 | 16 | 28.2 | 12.7 | 5/8 | 4 | 1/2 | 50 | 69.9 | 65 | M14 | 38 | 0.9 |

| 1 | 25 | 3 | 110 | 17 | 34.9 | 14.3 | 5/8 | 4 | 1/2 | 55 | 79.4 | 65 | M14 | 49 | 0.9 |

| 1 1/4 | 32 | 5 | 115 | 21 | 43.7 | 15.9 | 5/8 | 4 | 1/2 | 55 | 88.9 | 70 | M14 | 59 | 1.4 |

| 1 1/2 | 40 | 6 | 125 | 22 | 50 | 17.5 | 5/8 | 4 | 1/2 | 65 | 98.4 | 70 | M14 | 65 | 1.4 |

| 2 | 50 | 8 | 150 | 25 | 62.5 | 19.1 | 3/4 | 4 | 5/8 | 70 | 120.7 | 85 | M16 | 78 | 2.3 |

| 2 1/2 | 65 | 8 | 180 | 29 | 75.4 | 22.3 | 3/4 | 4 | 5/8 | 75 | 139.7 | 90 | M16 | 90 | 3.2 |

| 3 | 80 | 10 | 190 | 30 | 91.4 | 23.9 | 3/4 | 4 | 5/8 | 75 | 152.4 | 90 | M16 | 108 | 3.7 |

| 3 1/2 | 90 | 11 | 215 | 32 | 104.1 | 23.9 | 3/4 | 8 | 5/8 | 75 | 177.8 | 90 | M16 | 122 | 5 |

| 4 | 100 | 11 | 230 | 33 | 116.8 | 23.9 | 3/4 | 8 | 5/8 | 75 | 190.5 | 90 | M16 | 135 | 5.9 |

| 5 | 125 | 11 | 255 | 36 | 144.4 | 23.9 | 7/8 | 8 | 3/4 | 85 | 215.9 | 95 | M20 | 164 | 6.8 |

| 6 | 150 | 13 | 280 | 40 | 171.4 | 25.4 | 7/8 | 8 | 3/4 | 85 | 241.3 | 100 | M20 | 192 | 8.6 |

| 8 | 200 | 13 | 345 | 44 | 222.2 | 28.6 | 7/8 | 8 | 3/4 | 90 | 298.5 | 110 | M20 | 246 | 13.7 |

| 10 | 250 | 13 | 405 | 49 | 277.4 | 30.2 | 1 | 12 | 7/8 | 100 | 362 | 115 | M24 | 305 | 19.5 |

| 12 | 300 | 13 | 485 | 56 | 328.2 | 31.8 | 1 | 12 | 7/8 | 100 | 431.8 | 120 | M24 | 365 | 29 |

| 14 | 350 | 13 | 535 | 79 | 360.2 | 35 | 1 1/8 | 12 | 1 | 115 | 476.3 | 135 | M27 | 400 | 41 |

| 16 | 400 | 13 | 595 | 87 | 411.2 | 36.6 | 1 1/8 | 16 | 1 | 115 | 539.8 | 135 | M27 | 457 | 54 |

| 18 | 450 | 13 | 635 | 97 | 462.3 | 39.7 | 1 1/4 | 16 | 1 1/8 | 125 | 577.9 | 145 | M30 | 505 | 59 |

| 20 | 500 | 13 | 700 | 103 | 514.4 | 42.9 | 1 1/4 | 20 | 1 1/8 | 140 | 635 | 160 | M30 | 559 | 75 |

| 24 | 600 | 13 | 815 | 111 | 616 | 47.9 | 1 3/8 | 20 | 1 1/4 | 150 | 749.3 | 170 | M33 | 663 | 100 |

300# Lap Joint Flanges Dimensions

| Size in Inch | Size in mm | Flanges Thick. | Outer Diameter | Lapped Thick. | PCD | Bolt Size UNC | Lapped Radius | No of Bolts | Hole Size | Machine Bolt Length | RF Stud Length | Lapped ID | Lapped Thick. | ISO Stud Size | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B | A | C | E | D | G | ||||||||||

| 1/2 | 15 | 38 | 95 | 22 | 66.7 | 1/2 | 3 | 4 | 5/8 | 55 | 65 | 22.9 | 14.3 | M14 | 1.2 |

| 3/4 | 20 | 48 | 115 | 25 | 82.6 | 5/8 | 3 | 4 | 3/4 | 65 | 75 | 28.2 | 15.9 | M16 | 1.4 |

| 1 | 25 | 54 | 125 | 27 | 88.9 | 5/8 | 3 | 4 | 3/4 | 65 | 75 | 34.9 | 17.5 | M16 | 1.4 |

| 1 1/4 | 32 | 64 | 135 | 27 | 98.4 | 5/8 | 5 | 4 | 3/4 | 70 | 85 | 43.7 | 19.1 | M16 | 1.8 |

| 1 1/2 | 40 | 70 | 155 | 30 | 114.3 | 3/4 | 6 | 4 | 7/8 | 75 | 90 | 50 | 20.7 | M20 | 2.7 |

| 2 | 50 | 84 | 165 | 33 | 127 | 5/8 | 8 | 8 | 3/4 | 75 | 90 | 62.5 | 22.3 | M16 | 3.2 |

| 2 1/2 | 65 | 100 | 190 | 38 | 149.2 | 3/4 | 8 | 8 | 7/8 | 85 | 100 | 75.4 | 25.4 | M20 | 4.6 |

| 3 | 80 | 117 | 210 | 43 | 168.3 | 3/4 | 10 | 8 | 7/8 | 90 | 110 | 91.4 | 28.6 | M20 | 5.9 |

| 3 1/2 | 90 | 133 | 230 | 44 | 184.2 | 3/4 | 11 | 8 | 7/8 | 95 | 110 | 104.1 | 30.2 | M20 | 7.7 |

| 4 | 100 | 146 | 255 | 48 | 200 | 3/4 | 11 | 8 | 7/8 | 95 | 115 | 116.8 | 31.8 | M20 | 10 |

| 5 | 125 | 178 | 280 | 51 | 235 | 3/4 | 11 | 8 | 7/8 | 110 | 120 | 144.4 | 35 | M20 | 12.7 |

| 6 | 150 | 206 | 320 | 52 | 269.9 | 3/4 | 13 | 12 | 7/8 | 110 | 120 | 171.4 | 36.6 | M20 | 17.7 |

| 8 | 200 | 260 | 380 | 62 | 330.2 | 7/8 | 13 | 12 | 1 | 120 | 140 | 222.2 | 41.3 | M24 | 26 |

| 10 | 250 | 321 | 445 | 95 | 387.4 | 1 | 13 | 16 | 1 1/8 | 140 | 160 | 277.4 | 47.7 | M27 | 36 |

| 12 | 300 | 375 | 520 | 102 | 450.8 | 1 1/8 | 13 | 16 | 1 1/4 | 145 | 170 | 328.2 | 50.8 | M30 | 52 |

| 14 | 350 | 425 | 585 | 111 | 514.4 | 1 1/8 | 13 | 20 | 1 1/4 | 160 | 180 | 360.2 | 54 | M30 | 75 |

| 16 | 400 | 483 | 650 | 121 | 571.5 | 1 1/4 | 13 | 20 | 1 3/8 | 165 | 190 | 411.2 | 57.2 | M33 | 86 |

| 18 | 450 | 533 | 710 | 130 | 628.6 | 1 1/4 | 13 | 24 | 1 3/8 | 170 | 195 | 462.3 | 60.4 | M33 | 113 |

| 20 | 500 | 587 | 775 | 140 | 685.8 | 1 1/4 | 13 | 24 | 1 3/8 | 185 | 205 | 514.4 | 63.5 | M33 | 143 |

| 24 | 600 | 702 | 915 | 153 | 812.8 | 1 1/2 | 13 | 24 | 1 5/8 | 205 | 230 | 616 | 69.9 | M39 | 216 |

Check Duplex Steel Lapped Joint Flange and MS Loose Flange thickness & price in Mumbai

Class 600 Lap Joint Flanges Dimensions

| Size in Inch | Size in mm | ISO Stud Size | Outer Diameter | Hole Size | Lapped Thick. | Lapped ID | Lapped Thick. | PCD | Lapped Radius | No of Bolts | Bolt Size UNC | RF Stud Length | Flanges Thick. | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | C | D | G | E | B | |||||||||

| 1/2 | 15 | M14 | 95 | 5/8 | 22 | 22.9 | 14.3 | 66.7 | 3 | 4 | 1/2 | 75 | 38 | 1.3 |

| 3/4 | 20 | M16 | 115 | 3/4 | 25 | 28.2 | 15.9 | 82.6 | 3 | 4 | 5/8 | 90 | 48 | 1.4 |

| 1 | 25 | M16 | 125 | 3/4 | 27 | 34.9 | 17.5 | 88.9 | 3 | 4 | 5/8 | 90 | 54 | 1.8 |

| 1 1/4 | 32 | M16 | 135 | 3/4 | 29 | 43.7 | 20.7 | 98.4 | 5 | 4 | 5/8 | 95 | 64 | 2.3 |

| 1 1/2 | 40 | M20 | 155 | 7/8 | 32 | 50 | 22.3 | 114.3 | 6 | 4 | 3/4 | 110 | 70 | 3.2 |

| 2 | 50 | M16 | 165 | 3/4 | 37 | 62.5 | 25.4 | 127 | 8 | 8 | 5/8 | 110 | 84 | 4.1 |

| 2 1/2 | 65 | M20 | 190 | 7/8 | 41 | 75.4 | 28.6 | 149.2 | 8 | 8 | 3/4 | 120 | 100 | 5.9 |

| 3 | 80 | M20 | 210 | 7/8 | 46 | 91.4 | 31.8 | 168.3 | 10 | 8 | 3/4 | 125 | 117 | 7.3 |

| 3 1/2 | 90 | M24 | 230 | 1 | 49 | 104.1 | 35 | 184.2 | 11 | 8 | 7/8 | 140 | 133 | 9.6 |

| 4 | 100 | M24 | 275 | 1 | 54 | 116.8 | 38.1 | 215.9 | 11 | 8 | 7/8 | 145 | 152 | 16.8 |

| 5 | 125 | M27 | 330 | 1 1/8 | 60 | 144.4 | 44.5 | 266.7 | 11 | 8 | 1 | 165 | 189 | 29 |

| 6 | 150 | M27 | 355 | 1 1/8 | 67 | 171.4 | 47.7 | 292.1 | 13 | 12 | 1 | 170 | 222 | 36 |

| 8 | 200 | M30 | 420 | 1 1/4 | 76 | 222.2 | 55.6 | 349.2 | 13 | 12 | 1 1/8 | 190 | 273 | 52 |

| 10 | 250 | M33 | 510 | 1 3/8 | 111 | 277.4 | 63.5 | 431.8 | 13 | 16 | 1 1/4 | 215 | 343 | 77 |

| 12 | 300 | M33 | 560 | 1 3/8 | 117 | 328.2 | 66.7 | 489 | 13 | 20 | 1 1/4 | 220 | 400 | 91 |

| 14 | 350 | M36 | 605 | 1 1/2 | 127 | 360.2 | 69.9 | 527 | 13 | 20 | 1 3/8 | 235 | 432 | 105 |

| 16 | 400 | M39 | 685 | 1 5/8 | 140 | 411.2 | 76.2 | 603.2 | 13 | 20 | 1 1/2 | 255 | 495 | 150 |

| 18 | 450 | M42 | 745 | 1 3/4 | 152 | 462.3 | 82.6 | 654 | 13 | 20 | 1 5/8 | 275 | 546 | 182 |

| 20 | 500 | M42 | 815 | 1 3/4 | 165 | 514.4 | 88.9 | 723.9 | 13 | 24 | 1 5/8 | 285 | 610 | 232 |

| 24 | 600 | M48 | 940 | 2 | 184 | 616 | 101.6 | 838.2 | 13 | 24 | 1 7/8 | 330 | 718 | 332 |

Class 900 Lapped Joint Flange Dimensions

| Size in Inch | Size in mm | ISO Stud Size | Lapped Thick. | Outer Diameter | Flanges Thick. | Lapped ID | PCD | Lapped Thick. | Hole Size | No of Bolts | Bolt Size UNC | RF Stud Length | Lapped Radius | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | A | B | D | E | G | |||||||||

| 1/2 | 15 | M20 | 32 | 120 | 38 | 22.9 | 82.6 | 22.3 | 7/8 | 4 | 3/4 | 110 | 3 | 1.8 |

| 3/4 | 20 | M20 | 35 | 130 | 44 | 28.2 | 88.9 | 25.4 | 7/8 | 4 | 3/4 | 115 | 3 | 2.3 |

| 1 | 25 | M24 | 41 | 150 | 52 | 34.9 | 101.6 | 28.6 | 1 | 4 | 7/8 | 125 | 3 | 3.6 |

| 1 1/4 | 32 | M24 | 41 | 160 | 64 | 43.7 | 111.1 | 28.6 | 1 | 4 | 7/8 | 125 | 5 | 4.1 |

| 1 1/2 | 40 | M27 | 44 | 180 | 70 | 50 | 123.8 | 31.8 | 1 1/8 | 4 | 1 | 140 | 6 | 5.5 |

| 2 | 50 | M24 | 57 | 215 | 105 | 62.5 | 165.1 | 38.1 | 1 | 8 | 7/8 | 145 | 8 | 11.5 |

| 2 1/2 | 65 | M27 | 64 | 245 | 124 | 75.4 | 190.5 | 41.3 | 1 1/8 | 8 | 1 | 160 | 8 | 16.5 |

| 3 | 80 | M24 | 54 | 240 | 127 | 91.4 | 190.5 | 38.1 | 1 | 8 | 7/8 | 145 | 10 | 12 |

| 4 | 100 | M30 | 70 | 290 | 159 | 116.8 | 235 | 44.5 | 1 1/4 | 8 | 1 1/8 | 170 | 11 | 24 |

| 5 | 125 | M33 | 79 | 350 | 190 | 144.4 | 279.4 | 50.8 | 1 3/8 | 8 | 1 1/4 | 190 | 11 | 38 |

| 6 | 150 | M30 | 86 | 380 | 235 | 171.4 | 317.5 | 55.6 | 1 1/4 | 12 | 1 1/8 | 190 | 13 | 50 |

| 8 | 200 | M36 | 114 | 470 | 298 | 222.2 | 393.7 | 63.5 | 1 1/2 | 12 | 1 3/8 | 220 | 13 | 78 |

| 10 | 250 | M36 | 127 | 545 | 368 | 277.4 | 469.9 | 69.9 | 1 1/2 | 16 | 1 3/8 | 235 | 13 | 112 |

| 12 | 300 | M36 | 143 | 610 | 419 | 328.2 | 533.4 | 79.4 | 1 1/2 | 20 | 1 3/8 | 255 | 13 | 148 |

| 14 | 350 | M39 | 156 | 640 | 451 | 360.2 | 558.8 | 85.8 | 1 5/8 | 20 | 1 1/2 | 275 | 13 | 182 |

| 16 | 400 | M42 | 165 | 705 | 508 | 411.2 | 616 | 88.9 | 1 3/4 | 20 | 1 5/8 | 285 | 13 | 193 |

| 18 | 450 | M48 | 190 | 785 | 565 | 462.3 | 685.8 | 101.6 | 2 | 20 | 1 7/8 | 325 | 13 | 258 |

| 20 | 500 | M52 | 210 | 855 | 622 | 514.4 | 749.3 | 108 | 2 1/8 | 20 | 2 | 350 | 13 | 317 |

| 24 | 600 | M64 | 267 | 1040 | 749 | 616 | 901.7 | 139.7 | 2 5/8 | 20 | 2 1/2 | 440 | 13 | 608 |

Class 1500 Vanstone Flange Dimensions

| Size in Inch | Size in mm | ISO Stud Size | Outer Diameter | Lapped Thick. | Lapped ID | PCD | Flanges Thick. | Bolt Size UNC | No of Bolts | RF Stud Length | Lapped Thick. | Hole Size | Lapped Radius | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | C | D | E | B | G | |||||||||

| 1/2 | 15 | M20 | 120 | 32 | 22.9 | 82.6 | 38 | 3/4 | 4 | 110 | 22.3 | 7/8 | 3 | 1.8 |

| 3/4 | 20 | M20 | 130 | 35 | 28.2 | 88.9 | 44 | 3/4 | 4 | 115 | 25.4 | 7/8 | 3 | 2.3 |

| 1 | 25 | M24 | 150 | 41 | 34.9 | 101.6 | 52 | 7/8 | 4 | 125 | 28.6 | 1 | 3 | 3.7 |

| 1 1/4 | 32 | M24 | 160 | 41 | 43.7 | 111.1 | 64 | 7/8 | 4 | 125 | 28.6 | 1 | 5 | 4.1 |

| 1 1/2 | 40 | M27 | 180 | 44 | 50 | 123.8 | 70 | 1 | 4 | 140 | 31.8 | 1 1/8 | 6 | 5.5 |

| 2 | 50 | M24 | 215 | 57 | 62.5 | 165.1 | 105 | 7/8 | 8 | 145 | 38.1 | 1 | 8 | 9.8 |

| 2 1/2 | 65 | M27 | 245 | 64 | 75.4 | 190.5 | 124 | 1 | 8 | 160 | 41.3 | 1 1/8 | 8 | 16.4 |

| 3 | 80 | M30 | 265 | 73 | 91.4 | 203.2 | 133 | 1 1/8 | 8 | 180 | 47.7 | 1 1/4 | 10 | 21.8 |

| 4 | 100 | M33 | 310 | 90 | 116.8 | 241.3 | 162 | 1 1/4 | 8 | 195 | 54 | 1 3/8 | 11 | 33 |

| 5 | 125 | M39 | 375 | 105 | 144.4 | 292.1 | 197 | 1 1/2 | 8 | 250 | 73.1 | 1 5/8 | 11 | 59 |

| 6 | 150 | M36 | 395 | 119 | 171.4 | 317.5 | 229 | 1 3/8 | 12 | 260 | 82.6 | 1 1/2 | 13 | 75 |

| 8 | 200 | M42 | 485 | 143 | 222.2 | 393.7 | 292 | 1 5/8 | 12 | 290 | 92.1 | 1 3/4 | 13 | 118 |

| 10 | 250 | M48 | 585 | 178 | 277.4 | 482.6 | 368 | 1 7/8 | 12 | 335 | 108 | 2 | 13 | 198 |

| 12 | 300 | M52 | 675 | 219 | 328.2 | 571.5 | 451 | 2 | 16 | 375 | 123.9 | 2 1/8 | 13 | 264 |

| 14 | 350 | M56 | 750 | 241 | 360.2 | 635 | 495 | 2 1/4 | 16 | 405 | 133.4 | 2 3/8 | 13 | 341 |

| 16 | 400 | M64 | 825 | 260 | 411.2 | 704.8 | 552 | 2 1/2 | 16 | 445 | 146.1 | 2 5/8 | 13 | 454 |

| 18 | 450 | M72 | 915 | 276 | 462.3 | 774.7 | 597 | 2 3/4 | 16 | 495 | 162 | 2 7/8 | 13 | 590 |

| 20 | 500 | M76 | 985 | 292 | 514.4 | 831.8 | 641 | 3 | 16 | 540 | 177.8 | 3 1/8 | 13 | 792 |

| 24 | 600 | M90 | 1170 | 330 | 616 | 990.6 | 762 | 3 1/2 | 16 | 615 | 203.2 | 3 5/8 | 13 | 1248 |

Class 2500 Lap Joint Flanges Dimensions

| Size in Inch | Size in mm | Lapped Radius | ISO Stud Size | Outer Diameter | Lapped Thick. | Flanges Thick. | Lapped ID | Lapped Thick. | PCD | Hole Size | Bolt Size UNC | No of Bolts | RF Stud Length | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | C | B | D | G | E | |||||||||

| 1/2 | 15 | 3 | M20 | 135 | 40 | 43 | 22.9 | 30.2 | 88.9 | 7/8 | 3/4 | 4 | 120 | 3.2 |

| 3/4 | 20 | 3 | M20 | 140 | 43 | 51 | 28.2 | 31.8 | 95.2 | 7/8 | 3/4 | 4 | 125 | 3.7 |

| 1 | 25 | 3 | M24 | 160 | 48 | 57 | 34.9 | 35 | 108 | 1 | 7/8 | 4 | 140 | 5 |

| 1 1/4 | 32 | 5 | M27 | 185 | 52 | 73 | 43.7 | 38.1 | 130.2 | 1 1/8 | 1 | 4 | 150 | 7.5 |

| 1 1/2 | 40 | 6 | M30 | 205 | 60 | 79 | 50 | 44.5 | 146 | 1 1/4 | 1 1/8 | 4 | 170 | 10 |

| 2 | 50 | 8 | M27 | 235 | 70 | 95 | 62.5 | 50.9 | 171.4 | 1 1/8 | 1 | 8 | 180 | 17.5 |

| 2 1/2 | 65 | 8 | M30 | 265 | 79 | 114 | 75.4 | 57.2 | 196.8 | 1 1/4 | 1 1/8 | 8 | 195 | 23 |

| 3 | 80 | 10 | M33 | 305 | 92 | 133 | 91.4 | 66.7 | 228.6 | 1 3/8 | 1 1/4 | 8 | 220 | 37.8 |

| 4 | 100 | 11 | M39 | 355 | 108 | 165 | 116.8 | 76.2 | 273 | 1 5/8 | 1 1/2 | 8 | 255 | 57 |

| 5 | 125 | 11 | M45 | 420 | 130 | 203 | 144.4 | 92.1 | 323.8 | 1 7/8 | 1 3/4 | 8 | 300 | 95 |

| 6 | 150 | 13 | M52 | 485 | 152 | 235 | 171.4 | 108 | 368.3 | 2 1/8 | 2 | 8 | 345 | 148 |

| 8 | 200 | 13 | M52 | 550 | 178 | 305 | 222.2 | 127 | 438.2 | 2 1/8 | 2 | 12 | 380 | 221 |

| 10 | 250 | 13 | M64 | 675 | 229 | 375 | 277.4 | 165.1 | 539.8 | 2 5/8 | 2 1/2 | 12 | 490 | 425 |

| 12 | 300 | 13 | M72 | 760 | 254 | 441 | 328.2 | 184.2 | 619.1 | 2 7/8 | 2 3/4 | 12 | 540 | 500 |

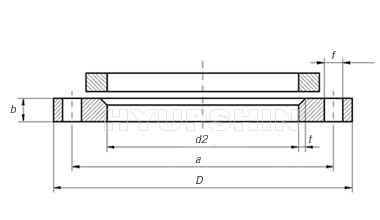

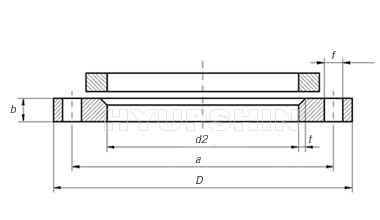

PN10 Lap Joint Flange Dimensions

| Directions for the designation | Lapped flanges | Screws | Weight | |||||||

| Rated Diameter |

External diameter of the pipe |

a | b | D | d2 | f | t | Holes | Flange | |

| 25 | 30 | 85 | 16 | 115 | 33 | 14 | 4 | 4 | M12 | 1,11 |

| 33,7 | 37 | 1,08 | ||||||||

| 32 | 38 | 100 | 16 | 140 | 41 | 18 | 4 | 4 | M 16 | 1,63 |

| 42,4 | 46 | 1,58 | ||||||||

| 40 | 44,5 | 110 | 16 | 150 | 48 | 18 | 4 | 4 | M 16 | 1,85 |

| 48,3 | 52 | 1,81 | ||||||||

| 50 | 57 | 125 | 16 | 165 | 62 | 18 | 4 | 4 | M 16 | 2,16 |

| 60,3 | 64 | 2,14 | ||||||||

| 65 | 76,1 | 145 | 16 | 185 | 80 | 18 | 4 | 4 | M 16 | 2,60 |

| 80 | 88,9 | 160 | 18 | 200 | 94 | 18 | 5 | 8*** | M 16 | 3,14 |

| 100 | 108 | 180 | 18 | 220 | 113 | 18 | 5 | 8 | M 16 | 3,63 |

| 114,3 | 119 | 3,47 | ||||||||

| 125 | 133 | 210 | 18 | 250 | 138 | 18 | 5 | 8 | M 16 | 4,49 |

| 139,7 | 145 | 4,26 | ||||||||

| 150 | 159 | 240 | 18 | 285 | 164 | 22 | 5 | 8 | M 20 | 5,54 |

| 168,3 | 174 | 5,16 | ||||||||

| 175 | 193,7 | 270 | 20 | 315 | 200 | 22 | 5 | 8 | M 20 | 6,76 |

| 200 | 219,1 | 295 | 20 | 340 | 225 | 22 | 5 | 12 | M 20 | 7,22 |

| 250 | 267 | 355 | 24 | 405 | 273 | 25 | 5 | 12 | M 22 | 12,0 |

| 273 | 279 | 11,6 | ||||||||

| 300 | 323,9 | 410 | 28 | 460 | 330 | 25 | 5 | 12 | M 22 | 16,3 |

| 350 | 355,6 | 470 | 32 | 520 | 362 | 25 | 5 | 16 | M 22 | 25,4 |

| 368 | 374 | 23,6 | ||||||||

| 400 | 406,4 | 525 | 36 | 580 | 413 | 30 | 6 | 16 | M 27 | 33,4 |

| 419 | 426 | 31,0 | ||||||||

| 450 | 457,2 | 585 | 40 | 640 | 464 | 30 | 6 | 20 | M 27 | 43,3 |

| 500 | 508 | 650 | 44 | 715 | 515 | 33 | 6 | 20 | M 30 | 60,6 |

PN16 Lap Joint Flange Dimensions

| Directions for the designation | Lapped flanges | Screws | Weight | |||||||

| Rated Diameter |

External diameter of the pipe |

a | b | D | d2 | f | t | Holes | Flange | |

| 25 | 30 | 85 | 16 | 115 | 33 | 14 | 4 | 4 | M12 | 1,11 |

| 33,7 | 37 | 1,08 | ||||||||

| 32 | 38 | 100 | 16 | 140 | 41 | 18 | 4 | 4 | M 16 | 1,63 |

| 42,4 | 46 | 1,58 | ||||||||

| 40 | 44,5 | 110 | 16 | 150 | 48 | 18 | 4 | 4 | M 16 | 1,85 |

| 48,3 | 52 | 1,81 | ||||||||

| 50 | 57 | 125 | 16 | 165 | 62 | 18 | 4 | 4 | M 16 | 2,16 |

| 60,3 | 64 | 2,14 | ||||||||

| 65 | 76,1 | 145 | 16 | 185 | 80 | 18 | 4 | 4 | M 16 | 2,60 |

| 80 | 88,9 | 160 | 18 | 200 | 94 | 18 | 5 | 8*** | M 16 | 3,14 |

| 100 | 108 | 180 | 18 | 220 | 113 | 18 | 5 | 8 | M 16 | 3,63 |

| 114,3 | 119 | 3,47 | ||||||||

| 125 | 133 | 210 | 18 | 250 | 138 | 18 | 5 | 8 | M 16 | 4,49 |

| 139,7 | 145 | 4,26 | ||||||||

| 150 | 159 | 240 | 18 | 285 | 164 | 22 | 5 | 8 | M 20 | 5,54 |

| 168,3 | 174 | 5,16 | ||||||||

| 175 | 193,7 | 270 | 20 | 315 | 200 | 22 | 5 | 8 | M 20 | 6,76 |

| 200 | 219,1 | 295 | 20 | 340 | 225 | 22 | 5 | 12 | M 20 | 7,22 |

| 250 | 267 | 355 | 24 | 405 | 273 | 25 | 5 | 12 | M 22 | 12,0 |

| 273 | 279 | 11,6 | ||||||||

| 300 | 323,9 | 410 | 28 | 460 | 330 | 25 | 5 | 12 | M 22 | 16,3 |

| 350 | 355,6 | 470 | 32 | 520 | 362 | 25 | 5 | 16 | M 22 | 25,4 |

| 368 | 374 | 23,6 | ||||||||

| 400 | 406,4 | 525 | 36 | 580 | 413 | 30 | 6 | 16 | M 27 | 33,4 |

| 419 | 426 | 31,0 | ||||||||

| 450 | 457,2 | 585 | 40 | 640 | 464 | 30 | 6 | 20 | M 27 | 43,3 |

| 500 | 508 | 650 | 44 | 715 | 515 | 33 | 6 | 20 | M 30 | 60,6 |

Stainless Steel Lap Joint Flange Benefits

- Lap Joint flanges can swivel freely around the pipe. This makes it easier to align opposing flange bolt holes.

- Because these flanges are not in contact with the fluid inside the pipe, they are more durable.

- The lap joint flanges in corroding or eroding piping systems can be salvaged for re-use.

- Lap joint flanges have a low pressure-holding capacity. However, it outperforms slip-on flanges.

Carbon Steel Lap Joint Flanges Applications

- Ship Building

- Refineries

- Marine Applications

- Nuclear Power

- Power Plants

- Fossil Fuel Power Plants

- Paper & Pulp

- Industrial Boilers

- Oil & Gas Industry

Stud Bolt length for Lap Joint Flange

| CLass | 150 | 300 | 600 | 900 | 1500 | 2500 |

| DIA A |

30 | 38 | 38 | 38 | 38 | 43 |

| DIA D |

90 | 95 | 95 | 120 | 120 | 135 |

| THK B |

11.2 | 14.3 | 14.3 | 22.3 | 22.3 | 30.2 |

| DIA K |

60.3 | 66.7 | 66.7 | 82.6 | 82.6 | 88.9 |

| H | 16 | 22 | 22 | 32 | 32 | 40 |

| NO. L |

4 | 4 | 4 | 4 | 4 | 4 |

| DIA L |

15.9 | 15.9 | 15.9 | 22.2 | 22.2 | 22.2 |

| Stud Bolts Diameter x Length | ||||||

| DIA ( in) |

1/2 | 1/2 | 1/2 | 3/4 | 3/4 | 3/4 |

| Lenght ( mm) |

55 | 65 | 75 | 110 | 110 | 120 |

Flanges Types

Pipe Fittings Material

Flanges Material

Other Products