- Call : +91 22 67436442

- exports@petrometflange.com

UNI Flange manufacturer in India

- Home /

- UNI Flange

Supply Series 400, 1300, 1400 UNI Flange for ductile iron pipe

What Is UNI Flanges?

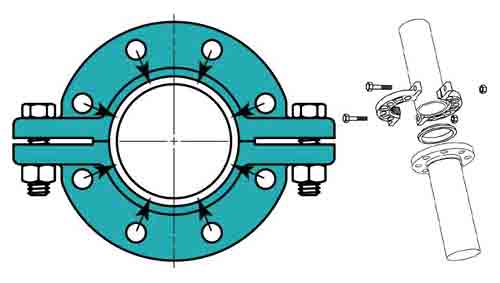

The UNI Flanges helps in eliminating all the issues associated with prefabricated and pre-engineered piping systems. The process of pipe fabrication can be performed on-site without threading, welding, and grooving. They mate with an existing flange and wherein the bolts of the flange are tightened. This leads to the formation of a compression type seal with the mating flange and also the surface of the pipe. The joint basically gets sealed without getting restrained. As the set screws are tightened, they bite into the wall. The UNI Flanges are then locked to the pipe forming a tight connection which restrain thrust. The features of the UNI Flanges are as follows:

- The fabrication is conducted on-site with the help of a plain ended pipe.

- It helps in eliminating the issues associated with bolt holes.

- They permit pipe defection.

- They come with an end restraint which is built-in.

- They can be assembled and disassembled easily, hence maintenance becomes easy.

UNI Flange Installation Instructions

The UNI Flange Installation Instructions are as follows:

- The pipe ends usually need to be cut in a square shape for most of the installation processes. Remove burrs and bevels, if any. Next, the pipe’s plain end should be scraped and cleaned for ensuring a bare metal surface in order to ensure the engagement of the set screw and the gasket seal. It is essential to lubricate the pipe thoroughly, and then the flange can be slid to the pipe easily. Ensure that the cavity of the gasket faces the pipe end. Now, the next step is to slide the lubricated gasket over the end of the pipe. Ensure that the hub faces the joint between the UNI Flange and the pipe.

- The next step is to slide the flange in the forward direction till the gasket is seated evenly in the cavity of the flanges. The UNI Flange should be flushed with the pipe end.

- Now the UNI Flange should be bolted with the conventional flanges. It is essential to ensure that the bolts are alternately tightened on the opposite sides. However, the bolts should never be over-tightened.

- Finally, all the set screws should be advanced to the pipe surface before the torque is applied. The tightening should be done in an alternate manner. A torque wrench can be used so as to verify the proper torque value.

Functions Of UNI Flange

The UNI Flanges helps in eliminating all the issues associated with prefabricated and pre-engineered piping systems. The process of pipe fabrication can be performed on-site without threading, welding, and grooving. All it needs is simple equipment like a plain end pipe, with pipe cutter and a wrench. With UNI flanges, there is no need for off-site fabrications and machine shops. They are widely used for retro-fiiting of piping systems and their renovation.

Where To Use UNI 2282 Pn16 Flanges

Generally, the UNI 2282 Pn16 Flanges are used in industries like natural gas, offshore, shipbuilding, water system, electric power equipment, and many more.

UNI Flange manufacturer in India

Fast & Reliable PN6-PN40 uni2278 and uniflanges manufacturers in India for steel pipe

Table of Content

UNI Flange Specification

| Dimensions | ASME B16.5, ASME B16.47 Series A & B, MSS SP44 |

| Size | 1/2" to 48" |

| JIS | 5K, 16 K 10 K, 20 K, 40 K, 30 K, 63 K |

|---|---|

| Class | 300 LBS, 150 LBS, 900 LBS, 600 LBS, 1500 LBS, 2500 LBS |

| UNI | 6Bar 16Bar 10Bar 25Bar 40Bar |

| Flanges Face Type Provided By Manufacturer | RF (Raised Face), RTJ (Ring Type Joint) |

| EN | 6Bar 25Bar 10Bar 40Bar 16Bar |

| BS | BS4504 , BS4504, BS1560, BS10 |

| Value Added Services | CNC Machining, Customised Flanges |

| Making Methods Provided By Manufacturer | Casting And Forging Rolling And Cutting |

| Outer diameters | 1/2” to 24” |

| Flanges Test | Hydrostatic testing machine/ UI trasonic flaw detector/ X-ray detector/ Direct-reading Spectrograph/ Magnetic particle detector |

| Coating/Surface Treatment By Manufacturer | Antirust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

| Standards Provided By Manufacturer | EN-1092, DIN, API7S-43, API605, B16.48, ISO70051, MSS S44, ANSI/ASME B16.5, B16.47 Series A & B, BS4504, BS 10, API7S-15, JISB2220, BS1560-3.1, ASME/ANSI B16.5/16.36/16.47A/16.47B, EN1092 |

| Flanges Equipment | Pushing Machine/ electric bevelling machine/ Press machine/ Bending machine/ Sand-blasting machine etc |

Leading UNI Flange 1400 Suppliers, stockholders, dealers, wholesalers, distributor, importer, stockists, exporters and Manufacturer in Mumbai.

UNI 2254 PN16 Threaded Flange Dimensions

| Uni 2253 Pn6 Threaded Flanges Dimensions | |||||||||||||

| Flanges | Neck | Raised face (RF) | Screws | Weight in kg (7,85 Kg/dm3) |

|||||||||

| Rated Dia. |

d1 | Thread | D | b | k | h1 | d3 | d4 | f | Number | Thread | d2 | Kilogram |

| 15 | 21,3 | R 1/2 | 80 | 12 | 55 | 20 | 30 | 40 | 2 | 4 | M 10 | 11 | 0,373 |

| 20 | 26,9 | R 3/4 | 90 | 14 | 65 | 24 | 40 | 50 | 2 | 4 | M 10 | 11 | 0,59 |

| 25 | 33,7 | R 1 | 100 | 14 | 75 | 24 | 50 | 60 | 2 | 4 | M 10 | 11 | 0,743 |

| 32 | 42,4 | R 1 1/4 | 120 | 14 | 90 | 26 | 60 | 70 | 2 | 4 | M 12 | 14 | 1,05 |

| 40 | 48,3 | R 1 1/2 | 130 | 14 | 100 | 26 | 70 | 80 | 3 | 4 | M 12 | 14 | 1,2 |

| 50 | 60,3 | R 2 | 140 | 14 | 110 | 28 | 80 | 90 | 3 | 4 | M 12 | 14 | 1,37 |

| 65 | 76,1 | R 2 1/2 | 160 | 14 | 130 | 32 | 100 | 110 | 3 | 4 | M 12 | 14 | 1,92 |

| 80 | 88,9 | R 3 | 190 | 16 | 150 | 34 | 110 | 128 | 3 | 4 | M 16 | 18 | 2,82 |

| 100 | 114,3 | R 4 | 210 | 16 | 170 | 38 | 130 | 148 | 3 | 4 | M 16 | 18 | 3,19 |

| 125 | 139,7 | R 5 | 240 | 18 | 200 | 40 | 160 | 178 | 3 | 8 | M 16 | 18 | 4,47 |

| 150 | 165,1 | R 6 | 265 | 18 | 225 | 44 | 185 | 202 | 3 | 8 | M 16 | 18 | 5,3 |

Supplier of UNI 2282 flange and UNI 1400 Blind, Lap Joint, Weld Neck, Slip On Flange offers Non Destructive Testing with all material

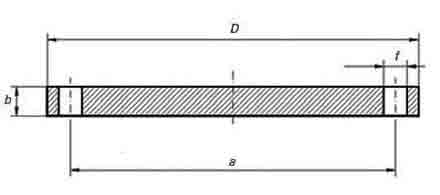

UNI 6092 PN10 Blind Flange Dimensions

| UNI 6092 pn10 Blind Flanges dimensions | |||||||

| Rated Dia. | a | b | D | f | No. of holes | Thread of the screws | Weight in Kilogram |

| 15 | 65 | 14 | 95 | 14 | 4 | M 12 | 0,71 |

| 20 | 75 | 16 | 105 | 14 | 4 | M 12 | 1,01 |

| 25 | 85 | 16 | 115 | 14 | 4 | M 12 | 1,22 |

| 32 | 100 | 16 | 140 | 18 | 4 | M 16 | 1,80 |

| 40 | 110 | 16 | 150 | 18 | 4 | M 16 | 2,09 |

| 50 | 125 | 18 | 165 | 18 | 4 | M 16 | 2,87 |

| 65 | 145 | 18 | 185 | 18 | 4 | M 16 | 3,65 |

| 80 | 160 | 20 | 200 | 18 | 4 | M 16 | 4,61 |

| 100 | 180 | 20 | 220 | 18 | 8 | M 16 | 5,65 |

| 125 | 210 | 22 | 250 | 18 | 8 | M 16 | 8,12 |

| 150 | 240 | 22 | 285 | 22 | 8 | M 20 | 10,5 |

| 175 | 270 | 24 | 315 | 22 | 8 | M 20 | 14,1 |

| 200 | 295 | 24 | 340 | 22 | 8 | M 20 | 16,5 |

| 250 | 350 | 26 | 395 | 22 | 12 | M 20 | 24,1 |

| 300 | 400 | 26 | 445 | 22 | 12 | M 20 | 30,8 |

| 350 | 460 | 26 | 505 | 22 | 16 | M 20 | 39,6 |

| 400 | 515 | 26 | 565 | 25 | 16 | M 22 | 49,6 |

| 450 | 565 | 26 | 615 | 25 | 20 | M 22 | 58,6 |

| 500 | 620 | 28 | 670 | 25 | 20 | M 22 | 75,3 |

UNI Flange Price List

| UNI Flange Price Per Piece in India | PN40 uni2278 Flanges Price in INR | UNI Flanges Price in UAE Dirham | UNI 2254 PN16 Flanges Price in USD |

| 130MM CON FLANGES FORATE UNI PN16,DN 100-4NBR Per Unit | 2880 | UAE Dirham 142.32 | $38.75 |

| FLANGES, UNI- DN100/ 4/ 100_D=98 Per Kg | 3,842 | UAE Dirham 189.85 | $51.69 |

Are you looking for UNI Flange manufacturer in India. Call us to get latest price list of PN40 uni2278 Flange. Compare our price list with other UNI 1400 Blind Flange Suppliers

UNI Flanges Torque Specs

| NPS | Outside Diameter (O.D.) of FlangeS D | Sectional Dimensions of Flanges | Nominal Bolts Sizes | |||||||||||||

| Diameter Of Bolt Circle C | Diameter of Raised Face (RF) g | Outside Diameter (O.D.) of Steel Pipe | T | b | a | R | t | d | Radius r | s | f | No. of Bolt Holes | Diameter of Hole h | |||

| 15 | 115 | 80 | 55 | 21.7 | 45 | 40 | 22 | 20 | 18 | 15.8 | 6 | 3.1 | 1 | 4 | 19 | M16 |

| 20 | 120 | 85 | 60 | 27.2 | 45 | 44 | 27.5 | 20 | 18 | 21.1 | 6 | 3.2 | 1 | 4 | 19 | M16 |

| 25 | 130 | 95 | 70 | 34 | 48 | 52 | 34.4 | 20 | 20 | 26.8 | 6 | 3.8 | 1 | 4 | 19 | M16 |

| 32 | 140 | 105 | 80 | 42.7 | 52 | 62 | 43.1 | 30 | 22 | 35.1 | 6 | 4 | 2 | 4 | 19 | M16 |

| 40 | 160 | 120 | 90 | 48.6 | 54 | 70 | 49.1 | 30 | 22 | 40.7 | 6 | 4.2 | 2 | 4 | 23 | M20 |

| 50 | 165 | 130 | 105 | 60.5 | 57 | 84 | 61 | 30 | 22 | 52.2 | 8 | 4.4 | 2 | 8 | 19 | M16 |

| 65 | 200 | 160 | 130 | 76.3 | 69 | 105 | 76.9 | 30 | 26 | 65.3 | 8 | 5.8 | 2 | 8 | 23 | M20 |

| 80 | 210 | 170 | 140 | 89.1 | 73 | 118 | 89.7 | 30 | 28 | 76.4 | 8 | 6.1 | 2 | 8 | 23 | M20 |

| 90 | 230 | 185 | 150 | 101.6 | 74 | 130 | 102 | 30 | 30 | 89.5 | 8 | 6.4 | 2 | 8 | 25 | M22 |

| 100 | 240 | 195 | 160 | 114.3 | 76 | 142 | 115 | 30 | 32 | 101.5 | 8 | 6.8 | 2 | 8 | 25 | M22 |

| 125 | 275 | 230 | 195 | 139.8 | 86 | 172 | 141 | 50 | 36 | 125.7 | 10 | 7.5 | 2 | 8 | 25 | M22 |

| 150 | 325 | 275 | 235 | 165.2 | 95 | 202 | 166 | 50 | 38 | 150 | 10 | 8.1 | 2 | 12 | 27 | M24 |

| 200 | 370 | 320 | 280 | 216.3 | 102 | 254 | 218 | 50 | 42 | 198.7 | 10 | 9.4 | 2 | 12 | 27 | M24 |

| 250 | 450 | 390 | 345 | 267.4 | 118 | 312 | 269 | 50 | 48 | 247.5 | 12 | 10.6 | 2 | 12 | 33 | M30 3 |

| 300 | 515 | 450 | 405 | 318.5 | 127 | 366 | 320 | 50 | 52 | 296.4 | 15 | 11.8 | 3 | 16 | 33 | M30 3 |

| 350 | 560 | 495 | 450 | 355.6 | 134 | 406 | 357 | 80 | 54 | 331.8 | 15 | 12.7 | 3 | 16 | 33 | M30 3 |

| 400 | 630 | 560 | 510 | 406.4 | 149 | 462 | 408 | 80 | 60 | 379.1 | 20 | 14.6 | 3 | 16 | 39 | M36 3 |

UNI Flange 1400 manufacturer in India suitable for pre-engineered/ prefabricated piping systems

Types of UNI Flange

UNI Flange

uniflanges

UNI 2282 flange

1400 UNI Flange

flange uni 2282

uni flange 1400

PN40 uni2278 Flange

uni flange 1300

UNI 1400 Blind Flange

UNI Flanges Dimensions

| Directions for the designation | d1 | a | b | D | f | Holes | Screws | Weight* Kilogram |

||

|---|---|---|---|---|---|---|---|---|---|---|

| Rated Dia. |

External diameter of the pipe |

Nominal | Tolerance | |||||||

| 15 | 20 | 20,5 | +0,5 | 55 | 10 | 80 | 11 | 4 | M 10 | 0,34 |

| 21,3 | 22 | 0,33 | ||||||||

| 20 | 25 | 25,5 | 65 | 12 | 90 | 11 | 4 | M 10 | 0,51 | |

| 26,9 | 27,5 | 0,50 | ||||||||

| 25 | 30 | 30,5 | 75 | 12 | 100 | 11 | 4 | M 10 | 0,63 | |

| 33,7 | 34 | 0,61 | ||||||||

| 32 | 38 | 38,5 | 90 | 14 | 120 | 14 | 4 | M 12 | 1,09 | |

| 42,4 | 43 | 1,05 | ||||||||

| 40 | 44,5 | 45 | 100 | 14 | 130 | 14 | 4 | M 12 | 1,26 | |

| 48,3 | 49 | 1,23 | ||||||||

| 50 | 57 | 58 | 110 | 14 | 140 | 14 | 4 | M 12 | 1,38 | |

| 60,3 | 61,5 | 1,35 | ||||||||

| 65 | 76,1 | 77 | 130 | 14 | 160 | 14 | 4 | M 12 | 1,68 | |

| 80 | 88,9 | 90 | 150 | 16 | 190 | 18 | 4 | M 16 | 2,63 | |

| 100 | 108 | 109 | +1,0 | 170 | 16 | 210 | 18 | 4*** | M 16 | 3,05 |

| 114,3 | 115,5 | 2,92 | ||||||||

| 125 | 133 | 134,5 | 200 | 18 | 240 | 18 | 8 | M 16 | 4,11 | |

| 139,7 | 141 | 3,90 | ||||||||

| 150 | 159 | 160,5 | 225 | 20 | 265 | 18 | 8 | M 16 | 5,16 | |

| 168,3 | 170 | 4,78 | ||||||||

| 175 | 193,7 | 195,5 | 255 | 22 | 295 | 18 | 8 | M 16 | 6,27 | |

| 200 | 219,1 | 221 | 280 | 22 | 320 | 18 | 8 | M 16 | 6,91 | |

| 250 | 267 | 269 | 335 | 24 | 375 | 18 | 12 | M 16 | 9,53 | |

| 273 | 275 | 9,04 | ||||||||

| 300 | 323,9 | 326 | 395 | 24 | 440 | 22 | 12 | M 20 | 12,1 | |

| 350 | 355,6 | 358 | 445 | 26 | 490 | 22 | 12 | M 20 | 17,0 | |

| 368 | 370,5 | 15,6 | ||||||||

| 400 | 406,4 | 409 | +1,5 | 495 | 28 | 540 | 22 | 16 | M 20 | 20,1 |

| 419 | 422 | 18,3 | ||||||||

| 450 | 457,2 | 460,2 | ±5 | 550 | 28 | 595 | 22 | 16 | M 20 | 25,8 |

| 500 | 508 | 511 | 600 | 30 | 645 | 22 | 20 | M 20 | 30,0 | |

| 600 | 609,6 | 612,6 | 705 | 30 | 755 | 25 | 20 | M 22 | 37,9 | |

| 700 | 711,2 | 714,2 | 810 | 32 | 860 | 25 | 24 | M 22 | 47,9 | |

| 800 | 812,8 | 815,8 | 920 | 34 | 975 | 30 | 24 | M 27 | 62,9 | |

| 900 | 914,4 | 917,4 | 1020 | 36 | 1075 | 30 | 24 | M 27 | 74,6 | |

| 1000 | 1016 | 1019 | 1120 | 36 | 1175 | 30 | 28 | M 27 | 81,9 | |

Dimensions of UNI 2277 PN10 Plate Flange

| Designation Directions | d1 | a | b | D | f | Holes | screws | Weight in Kg | ||

| Rated Dia. |

External dia. of the pipe |

Nominal | Dimensional Tolerance | Kilogram | ||||||

| 15 | 20 | 20,5 | +0,5 | 65 | 12 | 95 | 14 | 4 | M 12 | 0,67 |

| 21,3 | 22 | 0,66 | ||||||||

| 20 | 25 | 25,5 | 75 | 14 | 105 | 14 | 4 | M 12 | 0,83 | |

| 26,9 | 27,5 | 0,82 | ||||||||

| 25 | 30 | 30,5 | 85 | 14 | 115 | 14 | 4 | M 12 | 1,03 | |

| 33,7 | 34 | 1,01 | ||||||||

| 32 | 38 | 38,5 | 100 | 16 | 140 | 18 | 4 | M 16 | 1,66 | |

| 42,4 | 43 | 1,63 | ||||||||

| 40 | 44,5 | 45 | 110 | 16 | 150 | 18 | 4 | M 16 | 1,89 | |

| 48,3 | 49 | 1,85 | ||||||||

| 50 | 57 | 58 | 125 | 18 | 165 | 18 | 4 | M 16 | 2,51 | |

| 60,3 | 61,5 | 2,46 | ||||||||

| 65 | 76,1 | 77 | 145 | 18 | 185 | 18 | 4 | M 16 | 3,00 | |

| 80 | 88,9 | 90 | 160 | 20 | 200 | 18 | 4 | M 16 | 3,61 | |

| 100 | 108 | 109 | +1,0 | 180 | 22 | 220 | 18 | 8 | M 16 | 4,60 |

| 114,3 | 115,5 | 4,40 | ||||||||

| 125 | 133 | 134,5 | 210 | 24 | 250 | 18 | 8 | M 16 | 6,19 | |

| 139,7 | 141 | 5,92 | ||||||||

| 150 | 159 | 160,5 | 240 | 24 | 285 | 22 | 8 | M 20 | 7,63 | |

| 168,3 | 170 | 7,17 | ||||||||

| 175 | 193,7 | 195,5 | 270 | 26 | 315 | 22 | 8 | M 20 | 9,16 | |

| 200 | 219,1 | 221 | 295 | 26 | 340 | 22 | 8 | M 20 | 10,1 | |

| 250 | 267 | 269 | 350 | 28 | 395 | 22 | 12 | M 20 | 13,4 | |

| 273 | 275 | 12,9 | ||||||||

| 300 | 323,9 | 326 | 400 | 28 | 445 | 22 | 12 | M 22 | 14,8 | |

| 350 | 355,6 | 358 | 460 | 30 | 505 | 22 | 16 | M 20 | 22,0 | |

| 368 | 370,5 | 20,4 | ||||||||

| 400 | 406,4 | 409 | +1,5 | 515 | 32 | 565 | 25 | 16 | M 22 | 28,0 |

| 419 | 422 | 25,9 | ||||||||

| 450 | 457,2 | 460,2 | ±5 | 565 | 32 | 615 | 25 | 20 | M 22 | 33,3 |

| 500 | 508 | 511 | 620 | 34 | 670 | 25 | 20 | M 22 | 40,3 | |

| 600 | 609,6 | 612,6 | 725 | 36 | 780 | 30 | 20 | M 27 | 53,0 | |

Check UNI 2223 flange and PN10, PN6, PN16 UNI 1300 Flange dimensions, price list & pressure rating

Features of UNI Flange

- Job Site Fabrication using Plain End Pipe

- Eliminates Bolt Hole Alignment Problems

- Permits Pipe Deflection

- Built-In End Restraints

- Future Maintenance Capabilities

Function Provided by UNI Flanges 1400

There are two funtions of UNI Flange

1) Seal : When UNI Flange is brought to mate against an existing flange and the bolts are tightened, a copression type seal is created against the mating flanges and pipe surface. The joint is now sealed but not restrained.

2) End Restraint : The hardened set screws 'bite into' the wall of the pipe when they are tightened. The Uni-flange then locked on to the pipe to form a rigid connection providing thrust restraint.

Applications Of Uni-flange Adapter Flange

- Refineries

- Nuclear Power

- Power Plants

- Paper & Pulp

- Ship Building

- Oil And Gas Industry

- Marine Applications

- Fossil Fuel Power Plants

Flanges Types

Pipe Fittings Material

Flanges Material

Other Products